#DC Switching Power Supply Market Size

Explore tagged Tumblr posts

Text

two thread double locked chain stitch bag closer machine

The bag closing machine head is equipped with continuous (roll) feeder and sewing needle for the feeding system. The high-speed operation is most suitable for over-tape closure in an automatic bagging line or over-tape (crepe tape) closure on model heat sealers.

Bags are held firmly by feeding chains between bag inserting position and thread-cutting (or over-tape cutting) position, until they are finally closed. Double thread chain stitch with one each needle and looper. Double thread chain stitch, makes tight closures.

Single thread chain stitch with one each needle and looper. Oil pump lubrication system. Oil lines direct lubricant to maim moving elements. Portable two thread chainstitch sewing machine with top and bottom feed with special sewing parts for fast, consistent joining of protection nets outdoors. Extra heavy sewing parts. Large size needle. Powered by 12V, 70 watt DC motor. Available extra, special presser foot lifter complete with rollers. Part No. USI890 for simplified guiding of the material.

Rechargeable battery operated, portable sewing machine with top feed. Extra heavy sewing parts. For operation in locations where no electricity is available. For joining geotextile support fabrics at construction sites, for closing bags made of paper, jute, cotton and plastic, in agricultural areas, areas endangered by floods etc. Powered by a 24 volt, 120 watt DC-motor.

Power supply by lithium ion plug-in rechargeable battery at the motor. Production capability with full charged batteres approx. 600-800 bags, depending upon type of material, number of plies, stitch length and width of bags. Battery charger and spare rechargeable battery included. Charging time max. 90 minutes. Recommended extra: Additional battery

Standard one needle two thread double locked bag closing machine suspended from the ceiling , sewing parts with special rust prevention coating, for closing filled bags. Mechanically driven thread chain cutter.

Machine consists of: Top lock balancer with motor 220-240 V/380-420 V, 50Hz three phase, thread stand for two thread cones, built on control box, push button switch for start/stop. Top lock balancer for weightless suspension

Thank you for allowing Accurate Weighing Scales (U) Ltd the privilege to serve you in advance. For inquiries on deliveries contact us Office +256 (0) 705 577 823, +256 (0) 775 259 917 Address: Wandegeya KCCA Market South Wing, 2nd Floor Room SSF 036 Email: [email protected]

#mini palm scales#waterproof scales#baby scales#counter scales#bathroom scales#animal scales#kitchen scales#scales#fish scales#health ( height and weight ) scales

0 notes

Text

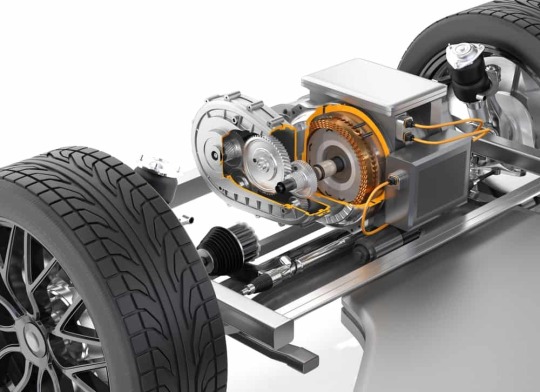

Electric Vehicle Motor Market Developments: Navigating a Revolution in Clean Mobility

The electric vehicle (EV) motor market is experiencing profound developments, transforming the landscape of the global automotive industry. As nations strive toward sustainable and low-emission transportation solutions, EV motors have emerged as a cornerstone of clean mobility. These motors, which convert electrical energy into mechanical energy to power EVs, are evolving rapidly due to advancements in technology, increased investment, and strong governmental support.

Growing Demand for Electric Vehicles

The foundation of developments in the EV motor market is the accelerating global demand for electric vehicles. Consumers and governments alike are gravitating toward EVs due to their environmental benefits, lower operating costs, and advancing technology. This increasing adoption is directly boosting demand for electric motors, as they are vital components of the EV drivetrain.

According to market analysts, the global EV motor market is projected to witness a compound annual growth rate (CAGR) exceeding 20% over the next decade. Factors such as climate change awareness, improved battery technologies, and expansion of EV infrastructure have played a key role in propelling this market forward.

Technological Advancements in EV Motors

Technological innovation has been a major driver of development in the EV motor market. The primary types of motors used in EVs include brushless DC motors (BLDC), permanent magnet synchronous motors (PMSM), and induction motors. Each motor type is evolving to meet demands for higher efficiency, lower maintenance, and reduced size and weight.

Recent developments include:

Increased Power Density: Engineers are developing motors with higher power-to-weight ratios, allowing vehicles to achieve better performance with less energy.

Integration with Inverters and Controllers: Next-generation EV motors often feature integrated inverters and control systems, optimizing power usage and enhancing driving experience.

Magnet-Free Motor Designs: To reduce reliance on rare earth materials, manufacturers are investing in magnet-free motor designs like switched reluctance motors (SRMs), which offer cost and supply chain benefits.

These innovations are essential for automakers aiming to deliver longer range, better acceleration, and more compact powertrains in their electric vehicle offerings.

Role of Key Players and Collaborations

Several automotive giants and emerging tech startups are investing heavily in the EV motor market. Companies such as Tesla, BYD, Bosch, Nidec Corporation, Siemens, and Toyota are pioneering new motor designs and manufacturing processes.

Collaborations and strategic partnerships are also shaping the market. For instance, major automakers are teaming up with motor manufacturers and research institutions to co-develop next-generation EV propulsion systems. Joint ventures allow for shared expertise and faster time-to-market for advanced motor solutions.

Regional Developments and Government Initiatives

Regionally, Asia-Pacific dominates the EV motor market, with China being the largest contributor due to its robust EV manufacturing base, government subsidies, and growing domestic demand. India, Japan, and South Korea are also investing in R&D and manufacturing capacities.

In Europe and North America, stringent emission regulations, zero-emission vehicle (ZEV) targets, and incentives for EV buyers are pushing automakers to accelerate the adoption of electric mobility and motor development. The European Union’s Green Deal and the U.S. Inflation Reduction Act are among the policies bolstering EV motor innovations and supply chain investments.

Challenges in the Market

Despite the optimistic outlook, the market faces challenges. High production costs, dependence on rare earth materials for magnets, and thermal management issues in motors are some hurdles. Addressing these requires continued innovation, especially in cost-effective manufacturing techniques and alternative materials.

Additionally, the integration of EV motors with autonomous driving technologies and vehicle-to-grid (V2G) systems introduces complexities that manufacturers must resolve to ensure seamless operation.

The Road Ahead: Emerging Trends

The future of the EV motor market lies in the development of smart and connected systems. Electric motors integrated with AI-powered diagnostics, real-time performance monitoring, and adaptive control mechanisms will soon become standard. Wireless motor control, over-the-air updates, and predictive maintenance are also expected to influence future designs.

Moreover, solid-state batteries and ultrafast charging technologies will reshape the requirements for motor performance, prompting manufacturers to rethink design and efficiency standards. Lightweight materials and modular construction will further define the next generation of EV motors.

Conclusion

The electric vehicle motor market is on an upward trajectory, powered by innovation, sustainability, and shifting consumer preferences. With continuous developments in motor technology, manufacturing efficiency, and government support, the industry is positioned to lead the green transportation revolution. Stakeholders across the automotive and energy sectors must now collaborate to accelerate these developments and make electric mobility mainstream on a global scale.

0 notes

Text

Automatic handheld sewing needle thread machine for bags

The bag closing machine head is equipped with continuous (roll) feeder and sewing needle for the feeding system. The high-speed operation is most suitable for over-tape closure in an automatic bagging line or over-tape (crepe tape) closure on model heat sealers.

Bags are held firmly by feeding chains between bag inserting position and thread-cutting (or over-tape cutting) position, until they are finally closed. Double thread chain stitch with one each needle and looper. Double thread chain stitch, makes tight closures.

Single thread chain stitch with one each needle and looper. Oil pump lubrication system. Oil lines direct lubricant to maim moving elements. Portable two thread chainstitch sewing machine with top and bottom feed with special sewing parts for fast, consistent joining of protection nets outdoors. Extra heavy sewing parts. Large size needle. Powered by 12V, 70 watt DC motor. Available extra, special presser foot lifter complete with rollers. Part No. USI890 for simplified guiding of the material.

Rechargeable battery operated, portable sewing machine with top feed. Extra heavy sewing parts. For operation in locations where no electricity is available. For joining geotextile support fabrics at construction sites, for closing bags made of paper, jute, cotton and plastic, in agricultural areas, areas endangered by floods etc. Powered by a 24 volt, 120 watt DC-motor.

Power supply by lithium ion plug-in rechargeable battery at the motor. Production capability with full charged batteres approx. 600-800 bags, depending upon type of material, number of plies, stitch length and width of bags. Battery charger and spare rechargeable battery included. Charging time max. 90 minutes. Recommended extra: Additional battery

Standard one needle two thread double locked bag closing machine suspended from the ceiling , sewing parts with special rust prevention coating, for closing filled bags. Mechanically driven thread chain cutter.

Machine consists of: Top lock balancer with motor 220-240 V/380-420 V, 50Hz three phase, thread stand for two thread cones, built on control box, push button switch for start/stop. Top lock balancer for weightless suspension

Thank you for allowing Accurate Weighing Scales (U) Ltd the privilege to serve you in advance. For inquiries on deliveries contact us Office +256 (0) 705 577 823, +256 (0) 775 259 917 Address: Wandegeya KCCA Market South Wing, 2nd Floor Room SSF 036 Email: [email protected]

#whole sale scales#scales#counter scales#baby scales#bathroom scales#animal scales#kitchen scales#fish scales

0 notes

Text

Disruptive Innovation! VBsemi TSM2N7002KDCU6 RF-VB Dual MOSFET: Compact Size with Giant Potential, Leading the Next-Gen Electronics Revolution

1. Product Overview and Core Parameter Analysis

1.1 Product Highlights

Dual N-channel integration: Saves PCB space, suitable for multi-channel signal switching or power management.

Low threshold voltage (2.5V): Can be directly driven by MCUs or low-voltage logic circuits, eliminating need for additional driver ICs.

Wide temperature range: Meets industrial-grade and automotive-grade requirements.

Supply chain advantages: Utilizes TSMC for wafer fabrication + JCET for packaging/testing, ensuring yield and supply stability.

2. Technical Features and Application Potential

2.1 RF and High-Frequency Suitability

The “RF-VB” designation suggests optimization for RF applications like low-frequency RF switching (<1GHz), antenna tuning, or signal routing.

Low gate charge (Qg) improves switching speed, but 1800mΩ Rds(on) may limit high-frequency/high-current applications.

2.2 Typical Applications

Power Management:

Low-side switches in DC-DC converters/LDO bypass circuits.

Load switches for battery-powered devices (TWS earphones, smartwatches).

Signal Switching:

I²C/SPI bus isolation to prevent signal conflicts.

Analog switches (audio/RF signal routing).

Industrial Control:

PLC I/O port protection.

Pre-driver circuits for motor control.

3. MOSFET Technology Trends

3.1 Rise of Wide-Bandgap Semiconductors (SiC/GaN)

SiC MOSFETs: Ideal for EVs, solar inverters, industrial PSUs with 1700V ratings and 50% lower switching loss vs. silicon.

GaN MOSFETs: High electron mobility enables fast charging (PD 3.1), 5G base stations, data centers.

Market forecast:Yole predicts the SiC power device market will reach 6.3billion,withtheGaNmarketat6.3billion,withtheGaNmarketat2 billion by 2027, demonstrating a CAGR exceeding 30%.

3.2 Super Junction & Trench Gate Technologies

Super Junction MOSFETs: Optimized P/N pillars enable lower Rds(on) at 600V–900V.

Trench Gate MOSFETs: Infineon/ON Semi offer <1mΩ Rds(on) for higher efficiency.

3.3 Packaging Innovations

DFN/QFN/CSP packages: Reduce size while improving thermal performance (e.g., TI’s dual-cooling SON).

Integrated power ICs: Combine MOSFETs + drivers + protection (e.g., ST’s VIPer series).

3.4 Digital Control & Smart Features

Digitally controlled MOSFETs: MCU-based dynamic voltage/current regulation for AI servers/autonomous vehicles.

4. Industry Outlook & Challenges

4.1 Growth Drivers

EVs: Chargers/BMS fuel demand for high-voltage MOSFETs.

Renewables: Solar inverters/energy storage need high-efficiency MOSFETs.

Consumer electronics: Fast charging/TWS rely on compact, low-power MOSFETs.

4.2 Key Challenges

SiC/GaN cost: Still higher than silicon — scale production needed.

Thermal management: Advanced packaging critical for high-power-density designs.

5. Conclusion

VBsemi’s TSM2N7002KDCU6 RF-VB excels in portable electronics, industrial controls, and RF switching with its dual N-channel design, low Vgs(th), and SC70–6 package.

MOSFET trends favor higher efficiency (SiC/GaN), miniaturization (advanced packages), and intelligence (integration). Silicon MOSFETs (like this product) remain vital for medium-low voltage markets.

0 notes

Text

Portable two thread chain stitch bag closing machine

The bag closing machine head is equipped with continuous (roll) feeder and sewing needle for the feeding system. The high-speed operation is most suitable for over-tape closure in an automatic bagging line or over-tape (crepe tape) closure on model heat sealers.

Bags are held firmly by feeding chains between bag inserting position and thread-cutting (or over-tape cutting) position, until they are finally closed. Double thread chain stitch with one each needle and looper. Double thread chain stitch, makes tight closures.

Single thread chain stitch with one each needle and looper. Oil pump lubrication system. Oil lines direct lubricant to maim moving elements. Portable two thread chainstitch sewing machine with top and bottom feed with special sewing parts for fast, consistent joining of protection nets outdoors. Extra heavy sewing parts. Large size needle. Powered by 12V, 70 watt DC motor. Available extra, special presser foot lifter complete with rollers. Part No. USI890 for simplified guiding of the material.

Rechargeable battery operated, portable sewing machine with top feed. Extra heavy sewing parts. For operation in locations where no electricity is available. For joining geotextile support fabrics at construction sites, for closing bags made of paper, jute, cotton and plastic, in agricultural areas, areas endangered by floods etc. Powered by a 24 volt, 120 watt DC-motor.

Power supply by lithium ion plug-in rechargeable battery at the motor. Production capability with full charged batteres approx. 600-800 bags, depending upon type of material, number of plies, stitch length and width of bags. Battery charger and spare rechargeable battery included. Charging time max. 90 minutes. Recommended extra: Additional battery

Standard one needle two thread double locked bag closing machine suspended from the ceiling , sewing parts with special rust prevention coating, for closing filled bags. Mechanically driven thread chain cutter.

Machine consists of: Top lock balancer with motor 220-240 V/380-420 V, 50Hz three phase, thread stand for two thread cones, built on control box, push button switch for start/stop. Top lock balancer for weightless suspension

Thank you for allowing Accurate Weighing Scales (U) Ltd the privilege to serve you in advance. For inquiries on deliveries contact us Office +256 (0) 705 577 823, +256 (0) 775 259 917 Address: Wandegeya KCCA Market South Wing, 2nd Floor Room SSF 036 Email: [email protected]

#fish scales#whole sale scales#waterproof scales#mini palm scales#kitchen scales#counter scales#bathroom scales#baby scales#health ( height and weight ) scales#animal scales

0 notes

Text

lightweight handheld electric bag closer sewing machine

The bag closing machine head is equipped with continuous (roll) feeder and sewing needle for the feeding system. The high-speed operation is most suitable for over-tape closure in an automatic bagging line or over-tape (crepe tape) closure on model heat sealers.

Bags are held firmly by feeding chains between bag inserting position and thread-cutting (or over-tape cutting) position, until they are finally closed. Double thread chain stitch with one each needle and looper. Double thread chain stitch, makes tight closures.

Single thread chain stitch with one each needle and looper. Oil pump lubrication system. Oil lines direct lubricant to maim moving elements. Portable two thread chainstitch sewing machine with top and bottom feed with special sewing parts for fast, consistent joining of protection nets outdoors. Extra heavy sewing parts. Large size needle. Powered by 12V, 70 watt DC motor. Available extra, special presser foot lifter complete with rollers. Part No. USI890 for simplified guiding of the material.

Rechargeable battery operated, portable sewing machine with top feed. Extra heavy sewing parts. For operation in locations where no electricity is available. For joining geotextile support fabrics at construction sites, for closing bags made of paper, jute, cotton and plastic, in agricultural areas, areas endangered by floods etc. Powered by a 24 volt, 120 watt DC-motor.

Power supply by lithium ion plug-in rechargeable battery at the motor. Production capability with full charged batteres approx. 600-800 bags, depending upon type of material, number of plies, stitch length and width of bags. Battery charger and spare rechargeable battery included. Charging time max. 90 minutes. Recommended extra: Additional battery

Standard one needle two thread double locked bag closing machine suspended from the ceiling , sewing parts with special rust prevention coating, for closing filled bags. Mechanically driven thread chain cutter.

Machine consists of: Top lock balancer with motor 220-240 V/380-420 V, 50Hz three phase, thread stand for two thread cones, built on control box, push button switch for start/stop. Top lock balancer for weightless suspension

Thank you for allowing Accurate Weighing Scales (U) Ltd the privilege to serve you in advance. For inquiries on deliveries contact us Office +256 (0) 705 577 823, +256 (0) 775 259 917 Address: Wandegeya KCCA Market South Wing, 2nd Floor Room SSF 036 Email: [email protected]

0 notes

Text

Automatic sewing needle thread machine for sack, bags

The bag closing machine head is equipped with continuous (roll) feeder and sewing needle for the feeding system. The high-speed operation is most suitable for over-tape closure in an automatic bagging line or over-tape (crepe tape) closure on model heat sealers.

Bags are held firmly by feeding chains between bag inserting position and thread-cutting (or over-tape cutting) position, until they are finally closed. Double thread chain stitch with one each needle and looper. Double thread chain stitch, makes tight closures.

Single thread chain stitch with one each needle and looper. Oil pump lubrication system. Oil lines direct lubricant to maim moving elements. Portable two thread chainstitch sewing machine with top and bottom feed with special sewing parts for fast, consistent joining of protection nets outdoors. Extra heavy sewing parts. Large size needle. Powered by 12V, 70 watt DC motor. Available extra, special presser foot lifter complete with rollers. Part No. USI890 for simplified guiding of the material.

Rechargeable battery operated, portable sewing machine with top feed. Extra heavy sewing parts. For operation in locations where no electricity is available. For joining geotextile support fabrics at construction sites, for closing bags made of paper, jute, cotton and plastic, in agricultural areas, areas endangered by floods etc. Powered by a 24 volt, 120 watt DC-motor.

Power supply by lithium ion plug-in rechargeable battery at the motor. Production capability with full charged batteres approx. 600-800 bags, depending upon type of material, number of plies, stitch length and width of bags. Battery charger and spare rechargeable battery included. Charging time max. 90 minutes. Recommended extra: Additional battery

Standard one needle two thread double locked bag closing machine suspended from the ceiling , sewing parts with special rust prevention coating, for closing filled bags. Mechanically driven thread chain cutter.

Machine consists of: Top lock balancer with motor 220-240 V/380-420 V, 50Hz three phase, thread stand for two thread cones, built on control box, push button switch for start/stop. Top lock balancer for weightless suspension

Thank you for allowing Accurate Weighing Scales (U) Ltd the privilege to serve you in advance. For inquiries on deliveries contact us Office +256 (0) 705 577 823, +256 (0) 775 259 917 Address: Wandegeya KCCA Market South Wing, 2nd Floor Room SSF 036 Email: [email protected]

#fish scales#health ( height and weight ) scales#kitchen scales#mini palm scales#waterproof scales#counter scales#bathroom scales#animal scales#baby scales

0 notes

Text

versatile small volume bagging Sewing machine System

The bag closing machine head is equipped with continuous (roll) feeder and sewing needle for the feeding system. The high-speed operation is most suitable for over-tape closure in an automatic bagging line or over-tape (crepe tape) closure on model heat sealers.

Bags are held firmly by feeding chains between bag inserting position and thread-cutting (or over-tape cutting) position, until they are finally closed. Double thread chain stitch with one each needle and looper. Double thread chain stitch, makes tight closures.

Single thread chain stitch with one each needle and looper. Oil pump lubrication system. Oil lines direct lubricant to maim moving elements. Portable two thread chainstitch sewing machine with top and bottom feed with special sewing parts for fast, consistent joining of protection nets outdoors. Extra heavy sewing parts. Large size needle. Powered by 12V, 70 watt DC motor. Available extra, special presser foot lifter complete with rollers. Part No. USI890 for simplified guiding of the material.

Rechargeable battery operated, portable sewing machine with top feed. Extra heavy sewing parts. For operation in locations where no electricity is available. For joining geotextile support fabrics at construction sites, for closing bags made of paper, jute, cotton and plastic, in agricultural areas, areas endangered by floods etc. Powered by a 24 volt, 120 watt DC-motor.

Power supply by lithium ion plug-in rechargeable battery at the motor. Production capability with full charged batteres approx. 600-800 bags, depending upon type of material, number of plies, stitch length and width of bags. Battery charger and spare rechargeable battery included. Charging time max. 90 minutes. Recommended extra: Additional battery

Standard one needle two thread double locked bag closing machine suspended from the ceiling , sewing parts with special rust prevention coating, for closing filled bags. Mechanically driven thread chain cutter.

Machine consists of: Top lock balancer with motor 220-240 V/380-420 V, 50Hz three phase, thread stand for two thread cones, built on control box, push button switch for start/stop. Top lock balancer for weightless suspension

Thank you for allowing Accurate Weighing Scales (U) Ltd the privilege to serve you in advance. For inquiries on deliveries contact us Office +256 (0) 705 577 823, +256 (0) 775 259 917 Address: Wandegeya KCCA Market South Wing, 2nd Floor Room SSF 036 Email: [email protected]

#dragon scales#fish scales#health ( height and weight ) scales#kitchen scales#mini palm scales#counter scales#bathroom scales#baby scales#waterproof scales#animal scales

0 notes

Text

Portable two thread chain stitch bag closing machine

The bag closing machine head is equipped with continuous (roll) feeder and sewing needle for the feeding system. The high-speed operation is most suitable for over-tape closure in an automatic bagging line or over-tape (crepe tape) closure on model heat sealers.

Bags are held firmly by feeding chains between bag inserting position and thread-cutting (or over-tape cutting) position, until they are finally closed. Double thread chain stitch with one each needle and looper. Double thread chain stitch, makes tight closures.

Single thread chain stitch with one each needle and looper. Oil pump lubrication system. Oil lines direct lubricant to maim moving elements. Portable two thread chainstitch sewing machine with top and bottom feed with special sewing parts for fast, consistent joining of protection nets outdoors. Extra heavy sewing parts. Large size needle. Powered by 12V, 70 watt DC motor. Available extra, special presser foot lifter complete with rollers. Part No. USI890 for simplified guiding of the material.

Rechargeable battery operated, portable sewing machine with top feed. Extra heavy sewing parts. For operation in locations where no electricity is available. For joining geotextile support fabrics at construction sites, for closing bags made of paper, jute, cotton and plastic, in agricultural areas, areas endangered by floods etc. Powered by a 24 volt, 120 watt DC-motor.

Power supply by lithium ion plug-in rechargeable battery at the motor. Production capability with full charged batteres approx. 600-800 bags, depending upon type of material, number of plies, stitch length and width of bags. Battery charger and spare rechargeable battery included. Charging time max. 90 minutes. Recommended extra: Additional battery

Standard one needle two thread double locked bag closing machine suspended from the ceiling , sewing parts with special rust prevention coating, for closing filled bags. Mechanically driven thread chain cutter.

Machine consists of: Top lock balancer with motor 220-240 V/380-420 V, 50Hz three phase, thread stand for two thread cones, built on control box, push button switch for start/stop. Top lock balancer for weightless suspension

Thank you for allowing Accurate Weighing Scales (U) Ltd the privilege to serve you in advance. For inquiries on deliveries contact us Office +256 (0) 705 577 823, +256 (0) 775 259 917 Address: Wandegeya KCCA Market South Wing, 2nd Floor Room SSF 036 Email: [email protected]

#fish scales#health ( height and weight ) scales#kitchen scales#mini palm scales#waterproof scales#bathroom scales#baby scales#animal scales#counter scales#whole sale scales

0 notes

Text

Automatic single needle industrial closing machine for bags

The bag closing machine head is equipped with continuous (roll) feeder and sewing needle for the feeding system. The high-speed operation is most suitable for over-tape closure in an automatic bagging line or over-tape (crepe tape) closure on model heat sealers.

Bags are held firmly by feeding chains between bag inserting position and thread-cutting (or over-tape cutting) position, until they are finally closed. Double thread chain stitch with one each needle and looper. Double thread chain stitch, makes tight closures.

Single thread chain stitch with one each needle and looper. Oil pump lubrication system. Oil lines direct lubricant to maim moving elements. Portable two thread chainstitch sewing machine with top and bottom feed with special sewing parts for fast, consistent joining of protection nets outdoors. Extra heavy sewing parts. Large size needle. Powered by 12V, 70 watt DC motor. Available extra, special presser foot lifter complete with rollers. Part No. USI890 for simplified guiding of the material.

Rechargeable battery operated, portable sewing machine with top feed. Extra heavy sewing parts. For operation in locations where no electricity is available. For joining geotextile support fabrics at construction sites, for closing bags made of paper, jute, cotton and plastic, in agricultural areas, areas endangered by floods etc. Powered by a 24 volt, 120 watt DC-motor.

Power supply by lithium ion plug-in rechargeable battery at the motor. Production capability with full charged batteres approx. 600-800 bags, depending upon type of material, number of plies, stitch length and width of bags. Battery charger and spare rechargeable battery included. Charging time max. 90 minutes. Recommended extra: Additional battery

Standard one needle two thread double locked bag closing machine suspended from the ceiling , sewing parts with special rust prevention coating, for closing filled bags. Mechanically driven thread chain cutter.

Machine consists of: Top lock balancer with motor 220-240 V/380-420 V, 50Hz three phase, thread stand for two thread cones, built on control box, push button switch for start/stop. Top lock balancer for weightless suspension

Thank you for allowing Accurate Weighing Scales (U) Ltd the privilege to serve you in advance. For inquiries on deliveries contact us Office +256 (0) 705 577 823, +256 (0) 775 259 917 Address: Wandegeya KCCA Market South Wing, 2nd Floor Room SSF 036 Email: [email protected]

#fish scales#waterproof scales#mini palm scales#whole sale scales#health ( height and weight ) scales#counter scales#baby scales#animal scales

0 notes

Text

Single needle sewing machine for closing woven bags

The bag closing machine head is equipped with continuous (roll) feeder and sewing needle for the feeding system. The high-speed operation is most suitable for over-tape closure in an automatic bagging line or over-tape (crepe tape) closure on model heat sealers.

Bags are held firmly by feeding chains between bag inserting position and thread-cutting (or over-tape cutting) position, until they are finally closed. Double thread chain stitch with one each needle and looper. Double thread chain stitch, makes tight closures.

Single thread chain stitch with one each needle and looper. Oil pump lubrication system. Oil lines direct lubricant to maim moving elements. Portable two thread chainstitch sewing machine with top and bottom feed with special sewing parts for fast, consistent joining of protection nets outdoors. Extra heavy sewing parts. Large size needle. Powered by 12V, 70 watt DC motor. Available extra, special presser foot lifter complete with rollers. Part No. USI890 for simplified guiding of the material.

Rechargeable battery operated, portable sewing machine with top feed. Extra heavy sewing parts. For operation in locations where no electricity is available. For joining geotextile support fabrics at construction sites, for closing bags made of paper, jute, cotton and plastic, in agricultural areas, areas endangered by floods etc. Powered by a 24 volt, 120 watt DC-motor.

Power supply by lithium ion plug-in rechargeable battery at the motor. Production capability with full charged batteres approx. 600-800 bags, depending upon type of material, number of plies, stitch length and width of bags. Battery charger and spare rechargeable battery included. Charging time max. 90 minutes. Recommended extra: Additional battery

Standard one needle two thread double locked bag closing machine suspended from the ceiling , sewing parts with special rust prevention coating, for closing filled bags. Mechanically driven thread chain cutter.

Machine consists of: Top lock balancer with motor 220-240 V/380-420 V, 50Hz three phase, thread stand for two thread cones, built on control box, push button switch for start/stop. Top lock balancer for weightless suspension

Thank you for allowing Accurate Weighing Scales (U) Ltd the privilege to serve you in advance. For inquiries on deliveries contact us Office +256 (0) 705 577 823, +256 (0) 775 259 917 Address: Wandegeya KCCA Market South Wing, 2nd Floor Room SSF 036 Email: [email protected]

#fish scales#health ( height and weight ) scales#kitchen scales#scales#waterproof scales#mini palm scales

0 notes

Text

lightweight handheld electric bag closer sewing machine

The bag closing machine head is equipped with continuous (roll) feeder and sewing needle for the feeding system. The high-speed operation is most suitable for over-tape closure in an automatic bagging line or over-tape (crepe tape) closure on model heat sealers.

Bags are held firmly by feeding chains between bag inserting position and thread-cutting (or over-tape cutting) position, until they are finally closed. Double thread chain stitch with one each needle and looper. Double thread chain stitch, makes tight closures.

Single thread chain stitch with one each needle and looper. Oil pump lubrication system. Oil lines direct lubricant to maim moving elements. Portable two thread chainstitch sewing machine with top and bottom feed with special sewing parts for fast, consistent joining of protection nets outdoors. Extra heavy sewing parts. Large size needle. Powered by 12V, 70 watt DC motor. Available extra, special presser foot lifter complete with rollers. Part No. USI890 for simplified guiding of the material.

Rechargeable battery operated, portable sewing machine with top feed. Extra heavy sewing parts. For operation in locations where no electricity is available. For joining geotextile support fabrics at construction sites, for closing bags made of paper, jute, cotton and plastic, in agricultural areas, areas endangered by floods etc. Powered by a 24 volt, 120 watt DC-motor.

Power supply by lithium ion plug-in rechargeable battery at the motor. Production capability with full charged batteres approx. 600-800 bags, depending upon type of material, number of plies, stitch length and width of bags. Battery charger and spare rechargeable battery included. Charging time max. 90 minutes. Recommended extra: Additional battery

Standard one needle two thread double locked bag closing machine suspended from the ceiling , sewing parts with special rust prevention coating, for closing filled bags. Mechanically driven thread chain cutter.

Machine consists of: Top lock balancer with motor 220-240 V/380-420 V, 50Hz three phase, thread stand for two thread cones, built on control box, push button switch for start/stop. Top lock balancer for weightless suspension

Thank you for allowing Accurate Weighing Scales (U) Ltd the privilege to serve you in advance. For inquiries on deliveries contact us Office +256 (0) 705 577 823, +256 (0) 775 259 917 Address: Wandegeya KCCA Market South Wing, 2nd Floor Room SSF 036 Email: [email protected]

#mini palm scales#waterproof scales#baby scales#bathroom scales#animal scales#counter scales#health ( height and weight ) scales#kitchen scales#scales#fish scales

0 notes

Text

Fast Rectifiers Market Competition Analysis: How the Demand for EVs and Renewable Energy is Shaping the Landscape

The fast rectifiers market has been witnessing significant growth due to the increasing demand for high-performance power electronics in various applications, such as automotive, telecommunications, and industrial sectors. Fast rectifiers play a crucial role in converting alternating current (AC) to direct current (DC), which is essential in modern power supplies. With advancements in semiconductor technology, the fast rectifiers market is expected to continue expanding, driven by improvements in energy efficiency, size reduction, and cost-effectiveness.

Key Market Trends Driving Growth

Technological Advancements in Power Electronics One of the main factors driving the fast rectifiers market is the continuous technological advancements in power electronics. The demand for faster, more efficient power conversion systems has led to significant improvements in rectifier designs. These advancements focus on reducing energy losses, increasing switching frequencies, and enhancing overall system performance. Innovations in semiconductor materials, such as silicon carbide (SiC) and gallium nitride (GaN), are helping create more efficient and high-speed rectifiers, boosting their adoption in applications that require fast response times.

Increased Demand for Renewable Energy Systems The growing adoption of renewable energy sources, such as solar and wind power, is driving the need for efficient power conversion systems. Fast rectifiers are integral to the functioning of renewable energy systems, particularly in converting the DC power generated by solar panels or wind turbines into usable AC power. The rapid growth of the renewable energy sector is thus expected to support the expansion of the fast rectifiers market.

Automotive and Electric Vehicle (EV) Growth The automotive sector, especially electric vehicles (EVs), is another key factor influencing the fast rectifiers market. As electric vehicles become more popular, the demand for high-speed rectifiers in EV powertrains and charging systems is increasing. Fast rectifiers are vital for optimizing power conversion efficiency, ensuring fast charging times, and enhancing the overall performance of EVs. This trend is expected to continue as more automotive companies focus on expanding their electric vehicle portfolios.

Telecommunications and Data Centers The telecommunications industry’s increasing demand for data centers and high-speed communication networks is another driving force behind the fast rectifiers market. These industries require efficient and reliable power conversion solutions to maintain the performance of their systems. Fast rectifiers are essential for ensuring the smooth operation of data centers and telecom infrastructure, as they ensure the efficient conversion of power in high-frequency switching environments.

Energy Efficiency and Sustainability Concerns Energy efficiency is a critical concern for industries worldwide, especially as sustainability goals and regulations tighten. Fast rectifiers, with their high-speed switching capabilities, reduce energy loss and improve the overall efficiency of power supplies. As industries strive to meet stringent energy efficiency standards, the demand for fast rectifiers is expected to rise in sectors like industrial automation, aerospace, and robotics, where energy conservation is paramount.

Competitive Landscape and Key Players

The fast rectifiers market is highly competitive, with several established players and new entrants striving to meet the growing demand for efficient power conversion solutions. Key players in the market include:

Infineon Technologies

ON Semiconductor

STMicroelectronics

NXP Semiconductors

Vishay Intertechnology

These companies focus on expanding their product portfolios, improving the efficiency of their rectifiers, and adopting emerging technologies like SiC and GaN to enhance their competitiveness. Strategic collaborations, mergers, acquisitions, and investments in R&D are some of the key strategies used by these players to gain a competitive edge.

Future Outlook and Opportunities

The future of the fast rectifiers market looks promising, driven by technological advancements, the rise of renewable energy, and the growth of electric vehicles and telecommunications infrastructure. As industries continue to prioritize energy efficiency and sustainability, the demand for fast rectifiers is expected to remain strong. Furthermore, emerging economies in Asia-Pacific and Latin America present lucrative growth opportunities for market players, as these regions are witnessing rapid industrialization and infrastructure development.

The shift towards smart grids and the ongoing transformation of power distribution systems will also present opportunities for the integration of fast rectifiers into these evolving systems. As the world moves toward more advanced power electronics and efficient energy solutions, the fast rectifiers market is poised for sustained growth.

0 notes

Text

accurate Bag Sewing Machine Equipment suppliers in Uganda

The bag closing machine head is equipped with continuous (roll) feeder and sewing needle for the feeding system. The high-speed operation is most suitable for over-tape closure in an automatic bagging line or over-tape (crepe tape) closure on model heat sealers.

Bags are held firmly by feeding chains between bag inserting position and thread-cutting (or over-tape cutting) position, until they are finally closed. Double thread chain stitch with one each needle and looper. Double thread chain stitch, makes tight closures.

Single thread chain stitch with one each needle and looper. Oil pump lubrication system. Oil lines direct lubricant to maim moving elements. Portable two thread chainstitch sewing machine with top and bottom feed with special sewing parts for fast, consistent joining of protection nets outdoors. Extra heavy sewing parts. Large size needle. Powered by 12V, 70 watt DC motor. Available extra, special presser foot lifter complete with rollers. Part No. USI890 for simplified guiding of the material.

Rechargeable battery operated, portable sewing machine with top feed. Extra heavy sewing parts. For operation in locations where no electricity is available. For joining geotextile support fabrics at construction sites, for closing bags made of paper, jute, cotton and plastic, in agricultural areas, areas endangered by floods etc. Powered by a 24 volt, 120 watt DC-motor.

Power supply by lithium ion plug-in rechargeable battery at the motor. Production capability with full charged batteres approx. 600-800 bags, depending upon type of material, number of plies, stitch length and width of bags. Battery charger and spare rechargeable battery included. Charging time max. 90 minutes. Recommended extra: Additional battery

Standard one needle two thread double locked bag closing machine suspended from the ceiling , sewing parts with special rust prevention coating, for closing filled bags. Mechanically driven thread chain cutter.

Machine consists of: Top lock balancer with motor 220-240 V/380-420 V, 50Hz three phase, thread stand for two thread cones, built on control box, push button switch for start/stop. Top lock balancer for weightless suspension

Thank you for allowing Accurate Weighing Scales (U) Ltd the privilege to serve you in advance. For inquiries on deliveries contact us Office +256 (0) 705 577 823, +256 (0) 775 259 917 Address: Wandegeya KCCA Market South Wing, 2nd Floor Room SSF 036 Email: [email protected]

#whole sale scales#scales#counter scales#baby scales#bathroom scales#animal scales#kitchen scales#health ( height and weight ) scales#fish scales

0 notes

Text

Voltage Detector Market- Forecast (2024 - 2030)

Voltage Detector Market Size is forecast to reach $ 5760 Million by 2030, at a CAGR of 11% during forecast period 2024-2030.A voltage sensor is used to determine, monitor, and measure both the voltage supply, AC as well as DC. It can convert the measured voltage into a physical signal, which is proportional to the voltage. It is highly recommended for situations where there exists power issues. In traditional voltage sensors, there is a needle or a pointer to detect the voltage supply, whereas in digital voltage sensors, there is an alphanumeric interface. It can detect the voltage supply without making any physical contact. These are majorly used in power demand control areas, for power failure detection, and for safety switching and load control.

0 notes

Text

lightweight handheld electric bag closer sewing machine

The bag closing machine head is equipped with continuous (roll) feeder and sewing needle for the feeding system. The high-speed operation is most suitable for over-tape closure in an automatic bagging line or over-tape (crepe tape) closure on model heat sealers.

Bags are held firmly by feeding chains between bag inserting position and thread-cutting (or over-tape cutting) position, until they are finally closed. Double thread chain stitch with one each needle and looper. Double thread chain stitch, makes tight closures.

Single thread chain stitch with one each needle and looper. Oil pump lubrication system. Oil lines direct lubricant to maim moving elements. Portable two thread chainstitch sewing machine with top and bottom feed with special sewing parts for fast, consistent joining of protection nets outdoors. Extra heavy sewing parts. Large size needle. Powered by 12V, 70 watt DC motor. Available extra, special presser foot lifter complete with rollers. Part No. USI890 for simplified guiding of the material.

Rechargeable battery operated, portable sewing machine with top feed. Extra heavy sewing parts. For operation in locations where no electricity is available. For joining geotextile support fabrics at construction sites, for closing bags made of paper, jute, cotton and plastic, in agricultural areas, areas endangered by floods etc. Powered by a 24 volt, 120 watt DC-motor.

Power supply by lithium ion plug-in rechargeable battery at the motor. Production capability with full charged batteres approx. 600-800 bags, depending upon type of material, number of plies, stitch length and width of bags. Battery charger and spare rechargeable battery included. Charging time max. 90 minutes. Recommended extra: Additional battery

Standard one needle two thread double locked bag closing machine suspended from the ceiling , sewing parts with special rust prevention coating, for closing filled bags. Mechanically driven thread chain cutter.

Machine consists of: Top lock balancer with motor 220-240 V/380-420 V, 50Hz three phase, thread stand for two thread cones, built on control box, push button switch for start/stop. Top lock balancer for weightless suspension

Thank you for allowing Accurate Weighing Scales (U) Ltd the privilege to serve you in advance. For inquiries on deliveries contact us Office +256 (0) 705 577 823, +256 (0) 775 259 917 Address: Wandegeya KCCA Market South Wing, 2nd Floor Room SSF 036 Email: [email protected]

#fish scales#health ( height and weight ) scales#kitchen scales#mini palm scales#waterproof scales#bathroom scales#animal scales#baby scales#counter scales#whole sale scales

0 notes