#DC Gear Motor

Explore tagged Tumblr posts

Text

''Understanding Their Key Functions"

Introduction

Small gear motors are essential components used in various industries and applications. These compact devices play a crucial role in converting electrical energy into mechanical power, enabling precise and controlled motion. In this blog, we will explore the primary function of small gear motors and their significance in modern-day technology.

Function of Small Gear Motors

Power Transmission: The primary function of small gear motors is to transmit power from the input source (typically an electric motor) to the output shaft. The motor generates rotational energy, which is then transmitted to the gear assembly. The gears inside the motor are designed to mesh with each other, creating a mechanical advantage that enables the motor to deliver higher torque at reduced rotational speeds. This power transmission allows small gear motors to efficiently drive various mechanisms and devices.

Speed Reduction: Another critical function of small gear motors is speed reduction. By using gears with different numbers of teeth, the rotational speed of the output shaft can be reduced relative to the input shaft speed. This feature is particularly useful in applications that require slower, controlled movements, such as robotics, automated systems, and precise machinery.

Torque Amplification: Gear motors are also known for their ability to amplify torque. The gear assembly increases the torque output, making it easier for the motor to overcome resistance or load in the system. This torque amplification ensures that the motor can perform tasks that would be challenging or impossible with a direct drive system.

Directional Control: Small gear motors offer precise directional control. By reversing the rotation of the input motor or changing the gear arrangement, the output shaft can rotate in the opposite direction. This capability is crucial in applications where bidirectional motion is required, like in the operation of conveyor belts, valves, and actuators.

Compact Size and Efficiency: The compact size of small gear motors makes them ideal for applications with limited space. Their efficiency in converting electrical energy into mechanical power also contributes to their widespread use. They can achieve efficiency levels of 70-90%, making them highly energy-efficient solutions.

Conclusion

In conclusion, small gear motors play a pivotal role in modern engineering and technology. Their primary functions include power transmission, speed reduction, torque amplification, directional control, and efficiency. As these devices continue to evolve and improve, we can expect them to remain a key component in various industries, ranging from robotics and automation to automotive and aerospace.

2 notes

·

View notes

Text

YueQing GuangHui | Micro DC, Gear & Drone Motor Manufacturer

Established in 2005, YueQing GuangHui specializes in micro DC, gear, brushless, and drone motors with 20+ production lines and HQ in Dongguan, China.

1 note

·

View note

Text

Tiny Tech, Big Impact: How Micro Gear Pumps with Brushed DC Motors Are Revolutionizing Precision Flow!

0 notes

Video

youtube

Master Your Projects with the JS 30T DC Gear Motor - Low Cost, High Quality

1 note

·

View note

Text

DC Drives Manufacturers Exporters

#DC Motors#DC Geared Motors#DC Drives#DC Drives Manufacturers#DC Drives Manufacturers in india#DC Geared Motors manufacturers#DC Geared Motors manufacturers in india

0 notes

Text

Revolutionize motor control! Explore our infographic for a quick guide on implementing precise speed controlling geared dc motor with plc.

0 notes

Text

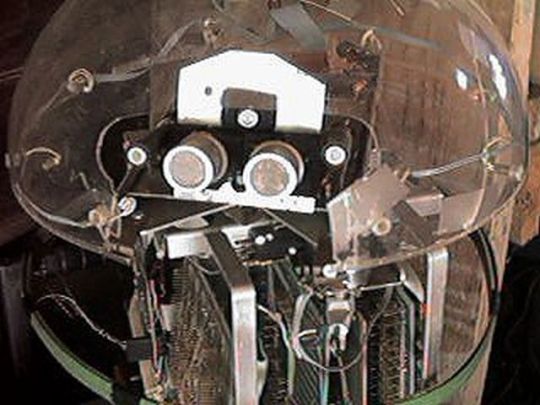

Kermit (1978), by Ron Milner and Larry Nicolson, Cyan Engineering, Atari's secret think tank in Grass Valley, CA.

"The robot was a pet project for Nolan Bushnell, then still the head of Atari and a very creative guy. Its purpose in life was as Nolan put it to "bring me a beer!" Navigation for robots was a sketchy thing at that time with lots of pioneering work at MIT but no consumer cost ideas. Nolan brought us the incredibly original idea to navigate a robot (which mostly meant knowing where it was) by means of scanning bar codes attached here and there to the baseboards in the rooms the robot was to service. Why it wasn't patented I don't know.

I had lots of fun building the R2D2 style robot about 20" tall. I liked to put mechanical and electronic things together and we had a great shop at Cyan. Its brain was one of the 6502 based single board computers-I think it was a KIM but not sure. Locomotion was two DC gear motor driven wheels and an instrumented caster-about the same rig as a modern Roomba. A rotatable turret covered with a plexiglass dome carried microphones, an IR sensor to detect people, and ultrasonic ranging sensors I built on a separate PC board. A speaker so Kermit could beep gleefully, of course.

A ring of contact-detecting burglar alarm sensing tape (green in the pictures) around Kermit's middle told the software he had hit something and should back off. The ultrasonics provided range to obstacles and to some extent direction as the turret was rotated, so we could go around things.

My pride and joy was the barcode remote scanner which was mounted on the bottom of the robot so its rotating head would be level with the barcodes on the baseboards. It had a vertical telescope tube with a beam splitter between the IR Led and the photodiode sensor and a lens to focus 2-20' away. It aimed down at a front surface mirror at 45 degree to scan horizontally. The mirror was mounted on a motor driven turret so it spun around continuously with a sensor once around to resolve the continuous angular position of the beam horizontally of course with respect to Kermit's rotational position. Unfortunately, this part of the robot did not survive the closing of our group. The barcodes I made for the prototype to detect were about 4" tall made of 3/4" reflective 3m tape on black poster board.

My programming partner on the project was Larry Nicholson, a really bright guy. He made the barcode reading work to detect not only the barcodes, but where they were angularly with respect to the robot and also their subtended angle or apparent size (all from timing of the rotation of the scanner) which was a measure of distance combined with angle from the barcode. We worked out some pretty clever math to resolve that information from two or three of the barcodes into a position and orientation of Kermit in the room. We had rented an empty room upstairs on the third floor of the Litton building to try all this out and work out the navigation. Larry and I got the basic navigation and obstacle avoidance working so Kermit could go from one place to a designated other place in the room and avoid wastebaskets placed randomly. We demonstrated it to Nolan and he was impressed.

Shortly thereafter Warner Communication who had bought Atari from Nolan kicked him out and the Kermit project was cancelled."

– Kermit The Robot Notes by Ron Milner.

65 notes

·

View notes

Text

AU Jervis Tetch

Me and @dariusblake have discussed how we'd write our own Batman / DC TV or comic series and each individual character that would appear in it. Tetch being among them. At his core, Tetch is someone deeply reluctant to stay in the real world and would first seek to create his own sanctuary (his Wonderland) like a Hikikomori before even considering developing a mind control device. Which would be later on, when he feels it's the only real way to feel in control of his life which - up to that point - slowly fell to pieces. He'd be one of the earliest antagonists sent to Arkham while it's still a respected institution genuinely there to help mentally ill and vulnerable people get back on their feet, before Arkham (under Strange's management) is effectively turned into a prison for super-criminals.

I'm also of the mind that Tetch would look very average, not a pretty boy or a decrepit leprechaun. Maybe on the shorter side and seeming shorter by the way he haunches both to make himself smaller and because he himself feels small with his cripplingly low self esteem after years of being put down and treated like he didn't belong. Creating Wonderland as a place where he does finally belong, though still feeling stuck behind the looking glass unable to reach through it for company. Isolated in his escapist safe haven.

Like in the animated series, Tetch would work in tech with a grant from the Wayne foundation, but not on a project to "enhance the brain's potential". Instead to make the neural / Brain-computer interface (BCI) of a more cost-effective mind-controlled prosthesis. Something which would go on to be used in Gotham's main hospital for patients with amputations and limb-paralysis. The focus being on stimulating motor function and sensory input. At home he'd try to translate that same BCI for simulating sensation and motion (like lucid dreaming, disconnecting is like awaking in the midst of REM sleep) in a virtual landscape (basically an especially immersive VR software akin to Sword Art Online's nerve gear) dubbed "WonderOS" and his pet project running on it called "Wonderland".

Less a direct recreation of Wonderland from Lewis Carol's novels and more his personal sandbox to tweak and enjoy in his own time. Although its only user, Tetch put meticulous detail into his avatar that no one would likely see. Standing tall and proud with a top hat and bow tie. His smile charming, rather than unnerving. He'd always manage to overdress no matter the occasion in real life, so it felt fitting to extend that habit here too. With so little going on in his life outside of his job, what started as a fun side-project soon encompassed all of his free time. Progressively losing his interoception the more he becomes engrossed in his pet-project. Easily losing track of time to the point of forgetting to sleep, eat or drink, or would fall asleep in the sandbox and be disorientated whenever he'd wake still wearing the headset.

Still, he'd always disconnect eventually. Each time hit like a worse hangover than the last. His shortening time spent in the real world only existing to fuel himself for a longer expedition into his expanding digital world. That is until he'd exhausted all its mechanics and NPC interactions. By now, adding more felt hollow. He'd know exactly what they'd say anyway so why bother? The comforting predictability of the oasis he'd constructed started showing its cracks, or rather it could no longer obscure what cracks had been there all this time. The loneliness... the isolation. When was the last time he spoke to a real person, even at work?

Frankly it was always hard to know what to talk about. He'd tried pitching Wonder OS at work before, garnering minimal interest at best. Like most of his ideas. It always seemed like any attempt to make conversation ended abruptly with no explanation. Who would want to spend time with him in the virtual world if people never wanted to do so in the real one? No, if he wanted to add more player characters he'd have to reach out a different way.

For all his difficulties making friends in the real world, Tetch accrued a fair few online. He'd originally used the forums to post tech support tips, gush about his favourite books, and provide updates about Wonder OS' development to mixed reception. Some genuine interest arose, so when the time came to test Wonderland's "multiplayer mode" there were already a handful of people eager to test it within an hour of the announcement's upload. He'd had about ten additional headsets he'd built for multiplayer mode ready to post and was willing to make more but for now he happily sent out the initial batch. Specially made to not include the admin privilege of being able to log off. He would get to dictate if or when they leave and, well, he cannot guarantee they'll be back so it's best not to give them the option.

Tetch's performance at work may have been deteriorating before, but now his complete absence was noticed enough to garner a pink slip. One which never arrived. While Tetch's absence may have been more an annoyance to his colleagues that hadn't yet realised how much they leaned on him to get things done until now, the people he'd roped into being his captive audience were missed far sooner. Although they were found soon after their missing person cases were opened (being stuck at home), it only raised more questions. When someone tried yanking off one of their headsets, they were in a catatonic state - still partially in Wonderland.

The escalation from a missing persons case to some sort of hostage situation lead to the cases being grouped together and them entering Batman's radar. A common link was a. the headsets and b. the return address - which directly led back to Tetch. Most of the users hadn't recycled the packaging of their hardware before putting it on, making it easy to find. It's a good thing too, since no one (not even Tetch, who is the only one actually able to leave) has left Wonderland for a full week by the time Batman's on his trail. Too much longer and they'd keel over from neglecting to eat or drink.

Expecting a fight and some nefarious hostage scheme (as with the mob bosses he's faced thus far), Batman is shocked to find not a mastermind controlling a flurry of monitors, but someone rigged to their headset just like the other hostages. His apartment was in a shoddy state. Cables strewn about the floor haphazardly like mangrove roots in a swamp, the air stale and warm from days worth of heat emanating from the hardware that dominated the room he was found in. Curtains shut and dusty, untouched for what must have been months. Among the cables were tubes, an IV drip? Did Tetch plan ahead to make sure he could survive indefinitely rigged up to whatever he'd made?

After inspecting the computer the headset was connected to, Batman forcefully overrides Tetch's admin privileges and logs the hostages off. That alone seemed to stir something, like Tetch was in the midst of a night terror, which grew into a full-blown, panicked breakdown when Batman pulled his headset off. Shaking like a leaf, hands clasping his head as he sank from his chair to the floor. Honestly Batman doesn't really know what to do. Up until now he'd cracked down on Gotham's crime families who all put up a fierce fight, but this... is different. Still, it seems best to bring him in, if only to get him out of this dingy apartment and figure out where to go from there.

The GCPD aren't sure how to prosecute him. Would what he did be legally considered kidnapping? Or any other crime? He's kept in a holding cell while they fumble for a specific crime to charge him with. With nothing landing, he's instead sent to be a long-stay patient at Arkham (which at this point is a genuine respected psychiatric hospital for regular civilian patients) for both evaluation and therapy. They confiscated the hardware he'd used to run Wonder OS and sent it in for analysis, though couldn't make heads nor tails of a lot of his work.

Honestly being "sentenced" to free therapy really wasn't much of a punishment at all! Still took some time to adjust to the cold white brick walls, overly sanitised surroundings and the inescapable brightness both natural and not that did his head no favours. Haven't they heard of curtains? Until therapy he hadn't realised how infrequently he spoke out loud, stammering with nerves and the unfamiliarity of it. Like his mouth had forgotten what to do. Despite it all he was grateful for the company each session brought, even if it was for a prescribed purpose. Each chat feeling more sincere than any he'd had in years, to the point that his heart sank a little as each session came to a close. He hadn't really drank tea before coming here. Coffee, especially on days he'd forgotten to really sleep working all night on Wonder OS, was his go to, but a switch might be in order. Been a while since he last felt this calm. Calm enough that even his stammer was beginning to fade with the help of some speech therapy alongside his normal sessions.

The tea and kind words warming him to the idea that maybe the world isn't so scary and that he might even have a place in it. After a year or so of progress, the staff agreed to release him on probation. Pretty difficult to build a social support network while cooped up in an asylum, so they thought it best to give Tetch the opportunity to go out and meet new people. With no real support network to go back to, he'd really be starting from scratch like a tourist. Not the safest idea in Gotham, so they pointed him towards a few clubs and support groups first as a good starting point.

Of course, he went with the book club. Barely saying a word for the first few meetings, what confidence he was emboldened with upon release was slightly dampened by the reality of actually having to put himself out there. Truth be told, a few of the club's members recognised Tetch from his "Wonderland" incident a year ago and those that did make a concerted effort not to sit next to him, not that he was especially keen to initiate conversation either. That was until the week's topic turned to Alice in Wonderland, at the suggestion of one such clued-in member. As they'd suspected, Tetch perked right up, brimming with energy to discuss it!

The sudden shift in gears was pretty jarring, but one that people warmed up to. Though he'd still mainly talk about the story and occasionally let slip about aspects of his passion project (not realising it made more people clock where they'd heard of him from), it opened the door for more general conversation. His excited friendliness still on the jittery side, one of the members felt a little bad about how clearly anxious he was and offered to help him feel more welcome.

Giving advice on what helped him, including teaching Tetch how to microdose, which they preferred to take by brewing magic mushrooms into tea. And it helped! Becoming part of Tetch's morning routine, it's the closest he's felt to being himself back in Wonderland since well... you know. Tetch responded well to therapy, making remarkable progress even without medication, so his therapists though it best not to prescribe anything since it wasn't strictly necessary. The difference self-medicating made had Tetch second-guessing their judgement though.

After a few months of settling in, for once Tetch is invited to a social gathering outside of the book club to their annual Christmas do. In his youth as an apprentice lab tech at Wayne Enterprises he hadn't really gone out before. Most alcohol tasted vile to him unless it was disguised by more pleasant things like in a cocktail, not to mention how hard it hit him after barely a few sips felt as unpleasant as it tasted. Even so, he felt in no position to be picky about where they went that night given how flattered his was that they thought to invite him at all!

Most of the bars were fine, but a bit too loud and crowded for his liking. He may be able to cope with people better now he's started having his morning "tea", but it was still a bit overwhelming. That was until they reached one of Gotham's Goth bars. How rare it was for him to finally not feel overdressed! Amidst the buckles and leather waistcoats, lace and striking makeup he, weirdly, fit right in despite his attire being far more colourful than the bar's usual clientele. By the night's end he'd gravitated away from the group he'd come with, making his own fun with new people for the first time in forever. People he'd come to know as friends as he truly started re-building his life better than it was before!

Since his old workplace fired him before Batman linked him with the missing persons and found him, and Arkham's vouching for him didn't get Tetch his job back (especially since they weren't too happy tetch had adapted their BCI for recreational use), Tetch was out of work. That was until Grant Walker reached out, wanting to adapt Tetch's Wonderland to create a virtual theme park and to improve the IRL parks' AR and immersive elements (think the Xbox connect Disneyland game, but actually functional). An opportunity Tetch couldn't pass up, given he'd been struggling to find work since leaving Arkham and was entering an increasingly precarious financial situation.

Since Tetch adapted Wayne Enterprise's BCI they'd help develop into the hardware running Wonder OS, there was some dispute about whether or not his project would be entirely his own IP or if the resources he technically stole to make it could get him in legal trouble. "Fortunately" Walker offered to protect Tetch from any such case, in exchange for Tetch granting Walker the right to use, market and profit from the virtual he'd created Wonderland - which he agreed to. As successful as Walker's ventures so often were, the opportunity to experiment with park ideas without the expense of land or labour seemed too tantilising to pass-up. Not to mention it could be another venue of advertising his existing IPs to people who otherwise couldn't afford to go to the parks themselves.

Initially, the public reception to announcing Wonderland's debut was... mixed. Reviews from playtesters were glowing, and Walker had his team refine the multiplayer headsets Tetch had prototyped into something that could be made and distributed much more cheaply. Still, trust in Tetch's handiwork was minimal at best after what he did, how could they trust he wouldn't just use it to trap more people again? A green tick of approval from an asylum wouldn't be enough to convince people Tetch was sane. Eventually though, a mix of relentless promotion and sanitisation of Tetch's past got Walker the results he wanted and a steady player base grew.

Honestly, Tetch had tried deliberately to avoid going back into Wonderland or doing any work on his old pet project while he was still getting back on his feet. Especially because until he had a reason to return to the real world, he probably never would have. Oh the temptation, especially early on, was gnawing at him as the dread and self-doubt lingered despite all the progress he'd made in therapy. Returning to it now seems... strange. Like staring at an old picture of himself, so detached from how he felt at the time he'd made it. But he needed the money, and was a different person now, right?

By his therapists' orders, Tetch limits his screen-time only to a few hours a day and goes on a walk / runs errands outside for at least an hour every day, to better facilitate chances of meeting new people and to prevent another spiral into self-isolation. The people he used to chat with online, his old "friends" of sorts, weren't exactly keen to keep talking to him anyway after nearly dying of dehydration in his digital cage, so he didn't have much reason to go back online anyway. That is except for one person, though Tetch hadn't realised it. Too busy making a new life out in the world, to notice the hundreds of messages spamming his inbox on every conceivable chatroom he used to frequent.

"Cat" / Caterina Bressi, one of the Bressi mob family that mostly deals in drugs and information, has helped with her family's dealings modernise by data farming and hacking into police devices and those of other mobsters either for blackmail or to sell to other people in Gotham's underworld who need the info for their own schemes. She is bed-bound due to a mix of chronic illnesses that leave her with little strength and energy to do anything, which is partly why she was on the same forums of Tetch and why they related to each other in their isolation. Cat's skills in coding are the only thing keeping her family from seeing her as anything but a liability and she resents being whittled down to her unappreciated usefulness - again, like Tetch was in the lab. She was one of the people who was sent a prototype headset and actually loved every minute in Wonderland and desperately wished to go back once she was "rescued" from it.

She eventually get's back in contact with Tetch and convinces him to restore the old version of Wonderland (not the polished, commercial form it now was under Walker). .Partly out of sympathy and partly due to some difficulties adjusting to his newly formed social life and existance out in public, Tetch is grateful to still have a friend he relates to in ways he can't with his new, more "well-adjusted" friends and ends up spending more and more time with Cat. .Overtime, their friendship morphs into an unhealthy dependancy (moreso Cat depending on Tetch than the other way around) as she begins to isolate him from his newer friend groups.

Eventually, to get away from her responsibilities to her family she insists Tetch use his lab experience with nerve-based prosthetics to help her move again. Both to get away from her family and so they do not narrow her self-worth down to how useful she is to them. Tetch insists she is fine as she is and he can help her without changing her in that way, but eventually caves and makes what would become the basis of this AU's version of the mind control device. Not actually mind-control, but instead stimulating controlled movement of the body similar to how some existing peripheral nerve interfaces work Although the main controls were designed so Cat / the person being moved is the one controlling the motion, it can in theory be connected to another person (have a remote control centre on someone else, as a backup of sorts).

Once completed, Cat begins to tag along with Tetch everywhere he went so she wouldn't be alone even for a minute. Which became an issue when he had to go to work, since Walker was worried about leaks of any new content his team might work on if someone like Cat tagged along with Tetch to work. When Tetch tries to enforce reasonable boundaries and see his newer friends more like before Cat came back into his life (offering to help her make more friends of her own / introduce him to his other friends) she refused and doubled down in her attempts to control his day to day activities.

Defying his therapist's orders, wanting to relive how their old friendship was, she encouraged him to work more on the old WonderOS and give her access to it so she could help him with it too and spend more time in Wonderland again.

Without Tetch's knowledge, Cat steals Tetch's old lab notes and changes the old WonderOS code to be compatible with her peripheral nerve interface's control centre - basically wanting to see if she can fully immerse herself like a ghost in the machine and fully escape her real life. Once Tetch finds out, right before she's about to upload herself, he tries to stop her - worried it might kill her or otherwise go wrong. In the scuffle, Cat falls and Tetch isn't sure if her plan worked or if he'd just accidentally killed her or failed to prevent her death (if her plan killed her). Not sure what to do with the body, he jerryrigs the control centre so he can use it and (once revival fails) ends up trying to evade suspicion (and preserve his sanity) by animating her like she was still alive, trying to rationalise it all.

Given his new friends haven't seen him in a while, a couple days into his descent into madness they visit him. If this was part of an animated series, I would show his descent into madness as an abreviated montage of him going through the motions of grief while mimicking his day-to-day routine with her reanimated corpse weekend at Bernie's style - probably to this song, ending with his friends' knock at the door:

Once he is eventually returned to Arkham (charged with Cat's manslaughter and found with the old headset back on but now "haunted" with Cat's ghost in the machine goding him to stay in Wonderland instead of dreary reality - especially with his return to Arkham once again isolating from his new friends, even as they do try and visit) the doctors think he is hallucinating, but he's not. He just keeps one foot in the escapist realm he created, both in an attempt to deal with his guilt towards what happened to Cat (even if she personally holds no hard feelings and considers what happened an improvement on her old life), and for comfort like he did back before his first admission to Arkham. I like to think of it like Pyro-Vision / an AR WonderOS ("Wonder-Vision") built into his hat that's genuinely painful and distressing to remove.

Tetch's access to his Wonder-Vision varies depending on the management at Arkham. Hugo Strange allows him to use it, but sometimes deliberately removes it - both of which serve to help Strange better understand Tetch (by his behaviour in both circumstances). Under Bolton's management, access to Tetch's Wonder-Vision is strictly prohibited (as with most posessions of the inmates). While still under Hugo's management, however, Cat tries everything in her power to expand her reach across other devices. Including Strange's work computer at Arkham, meddling with his work in her wake (if accidentally). It wasn't long before her seeming sentience was distinguishable from just an irritating computer virus. Strange couldn't help but seize the opportunity to study (and toy with) one of the rare instances of seemingly true artificial intelligence. He manages to trap her in his system through a mix of almost complete isolation from local networks and an aggressive firewall he had one of the security staff code.

Kept like a fairy in a jar, he studied her much like he did Tetch. Their co-dependent friendship based largely on their shared isolation. When one might prove uncooperative, the other might run their mouth in ways that implicated the other. Once studying them separately bore nothing more of note, Strange did exactly what Cat had hoped she'd forever escaped since becoming a ghost in the machine... He re-embodied her. Not with mortal flesh, fortunately, but with something just as infuriatingly restrictive - a pixel pet (robotic toy body with digital interface, like a cross between a tamagotchi / pixel chic and a furby) to keep Jervis company after losing his hat priviages.

That is the gist of things so far! I will update as and when new plot beats and edits come to mind.

#This was only meant to be a quick summary!#Wtf#Hope you like it#Honestly just wanted to focus more on the drawbacks of relying on escapism as a crutch for coping with social isolation#Definitely can't relate!#Sarcasm#I prefer the idea that he's smarter than people appreciate#Hence why he's a lab assistant and not a fully qualified neuroscientist#Also kinda tired of the overused Alice pining so pulled an uno reverse of sorts#Jervis Tetch#batman au

14 notes

·

View notes

Text

Submarine Stuff

@theprissythumbelina, this is for you!

So, you wanna know more about nuclear submarines...

I'll spare all of us an introduction and just go straight to answering the questions you've specified so far. If you have more, please give them to me!

---

I'm still stuck on how a nuclear reactor actually makes power. Does it just boil water and from there it's a steam engine?

While some of the resources I read through might give you that impression, the truth is slightly more complicated.

Here's the spark notes; it is a very bad idea to use water that's been exposed to the inside of a nuclear core to do basically anything directly. Instead, high temperature 'coolant' is exposed, and loses thermal energy, to a secondary volume of water through a heat exchanger. This water rapidly turns into high temperature, high pressure steam, which is then piped into a steam turbine, which harnesses the steam to turn at an incredible speed.

The next step is a little unclear to me so I'll try and explain what I understand. The rotation of the steam turbine, moderated through a series of gears, might be used to turn the propeller directly. Alternatively, this rotation gets used to generate electricity, for the ships general use and possibly (I think?) to turn an electrical motor that, again, would turn the main propeller.

After this, the now much cooler steam / water (no clue what state it's in at this point) gets pumped through a third circuit of water directly exposed to the sea to cool off, returned to the heat exchanger to be heated up, and the cycle continues.

Since you mentioned liquid metal cooled power plants, their main difference is that the water used in that first stage gets replaced by a sodium-potassium alloy in a liquid state. There's a few additional engineering differences that come with this style of coolant, but I'm not sure you want to hear that (and I know I'd rather not have to read up on it anytime too soon).

How do steam engines make electricity?

Basically, take your rapidly spinning turbine and attach it to one of these;

I left actually studying physics behind me a while ago so forgive me for not trying to explain how a DC generator works /s

#I'm so far out of my depth #Are nuclear submarines warmer than none nuclear cause of the heat

First of all, holy crap that's the best pun I've read in a week, and I don't even know if it was intentional.

Secondly... Ehhh???

For what it's worth, every single account of the interior of a modern submarine, which kinda inevitably includes all nuclear submarines, is that they're really damn cold as far as crew spaces are concerned thanks to the powerful AC they've got going. Seeing as the alternative is sweltering, absolutely hellish heat a la most Ww2 era boats, though, I think I know what I'd prefer.

But I get the feeling you're talking about the temperature of the hull, in which case...

If you can somehow notice any measurable temperature difference in the outer hull of a nuclear submarine VS a 'conventional' submarine...

Caused by heat which would somehow have had to bypass the heavily insulated core or coolant pipes...

And the entire interior of the vessel...

I think you're main problem would be that everyone onboard is very, very dead. Because the only thing I can think of that would cause that is a total reactor meltdown, with molten corium literally melting a hole out through the hull. And it's not as if the machinery of either type of submarine doesn't produce waste heat energy of some kind, all of which would be rapidly dissipated under any great depth of water.

Nonetheless, recent reading has led me to uncover the fact that nuclear submarines do, in fact, leave a heat-based signature thanks to their reactor above that of a conventional submarine. Basically, while the hull of a boat doesn't really emit much heat, when the tertiary loop of water, the one which cools down the water for the steam turbines, gets discharged into the open ocean it is noticeably warmer than the ambient temperature of surrounding sea water, a fact which surprised me until I remembered thermodynamics exists. So, while the heat of the reactor itself should be pretty well insulated from the external environment, in submerged running nuclear subs technically have a somewhat greater thermal 'signature' than non nuclear ones. Apparently some navies have looked for this signature as a way to detect the most stealthy modern submarines, but I don't know much about those efforts and I doubt the US Navy would be kind enough to brief me on 'em.

2 notes

·

View notes

Text

"Unveiling Excellence: SG Gearbox's Online DC Motor Store"

SG Gearbox's online store offers a seamless shopping experience for DC motor enthusiasts. Discover the perfect motor for your needs. Visit us on: https://sggearbox.com/dc-motor-dc-geared-motor/dc-gear-motor/ Email: [email protected] Phone: (+86) (0574) 88332168

#gear motor#12v dc motor#dc motor#importance of motor#best dc motor in china#powerful motors#work of dc motor

1 note

·

View note

Text

How does an engine contribute to a car's powertrain?

The powertrain in a vehicle is the system responsible for generating power and delivering it to the wheels to propel the vehicle forward. The operation of a powertrain can vary depending on whether the vehicle is powered by an internal combustion engine (ICE) or an electric motor (in the case of electric vehicles). Here's a general overview of how a powertrain works in both types of vehicles:

Internal Combustion Engine (ICE) Vehicle - Combustion Process: In an ICE vehicle, the powertrain starts with the combustion process in the engine. Fuel (gasoline or diesel) mixes with air in the combustion chamber and is ignited by spark plugs (in gasoline engines) or compression (in diesel engines).

Power Generation: The combustion process generates energy in the form of mechanical power, causing pistons to move up and down within the cylinders of the engine. This motion drives the crankshaft, converting linear motion into rotational motion.

Transmission: The rotational motion from the crankshaft is transmitted to the transmission, which consists of gears that allow the driver to select different ratios (speeds). This enables the engine to operate efficiently across a range of vehicle speeds.

Drivetrain: The transmission sends power to the drivetrain components, including the driveshaft, differential, and axles, which transfer power to the wheels. The differential allows the wheels to rotate at different speeds, enabling smooth turns.

Wheel Movement: The power transmitted through the drivetrain causes the wheels to rotate, propelling the vehicle forward or backward depending on the gear selection and throttle input from the driver.

Electric Vehicle (EV) -

Battery Pack: The primary source of power for the EV, storing electricity in chemical form.Powers the electric motor and provides electricity for all electronic devices within the EV.

Battery Management System (BMS): Monitors battery cell conditions, including voltage, current, temperature, and state of charge (SoC).It protects the battery against overcharging, deep discharging, and overheating and helps balance the charge across cells. Ensures optimal performance and longevity of the battery by regulating its environment.

Inverter: Converts DC from the battery pack into AC to drive the electric motor.Adjusts the frequency and amplitude of the AC output to control the motor’s speed and torque. Critical for translating electrical energy into mechanical energy efficiently.

Onboard Charger: Facilitates the conversion of external AC (from the grid) to DC to charge the battery pack. Integrated within the vehicle, allowing for charging from standard electrical outlets or specialized EV charging stations. Manages charging rate based on battery status to ensure safe and efficient charging.

DC-DC Converter: Steps down the high-voltage DC from the battery pack to the lower-voltage DC needed for the vehicle's auxiliary systems, such as lighting, infotainment, and climate control. Ensures compatibility between the high-voltage battery system and low-voltage electronic components.

Electric Motor: Converts electrical energy into mechanical energy to propel the vehicle. It can be of various types, such as induction motors or permanent magnet synchronous motors, each offering different efficiencies and characteristics. Typically provides instant torque, resulting in rapid acceleration.

Vehicle Control Unit (VCU): The central computer or electronic control unit (ECU) that governs the EV's systems. Processes inputs from the vehicle’s sensors and driver inputs to manage power delivery, regenerative braking, and vehicle dynamics. Ensures optimal performance, energy efficiency, and safety.

Power Distribution Unit (PDU): Manages electrical power distribution from the battery to the EV’s various systems. Ensures that components such as the electric motor, onboard charger, and DC-DC converter receive the power they need to operate efficiently. Protects the vehicle's electrical systems by regulating current flow and preventing electrical faults.

In both ICE vehicles and EVs, the powertrain's components work together to convert energy into motion, enabling the vehicle to move efficiently and effectively. However, the specific technologies and processes involved differ significantly between the two propulsion systems.

#electric powertrain technology#conventional powertrain#Electric vehicle components#revolo hybrid car kit#ev powertrain development services#software (SW) platforms for all Electric vehicles components#Battery Management Systems#Inverter#Smart Charger#VCU solutions

5 notes

·

View notes

Text

Increase the Efficiency of Your Project: Why Micro Gear Pumps with Brushed DC Motors Are Revolutionary

0 notes

Text

These are 65mm Robot Wheels for a Dc geared motor. The wheels are suitable for all BO motors and they are one of the most commonly used components in robotics.

Robot Wheel Composition: High quality rubber wheel on plastic hub.

2 notes

·

View notes

Text

DC Drives Manufacturers Exporters

#DC Motors#DC Geared Motors#DC Drives#DC Drives Manufacturers#DC Drives Manufacturers in india#DC Geared Motors manufacturers#DC Geared Motors manufacturers in india

0 notes

Text

waist height turnstile gate from RS Security Co., Ltd(www.szrssecurity.com) Suitable for all types of public locations that require organized passage of pedestrians, such as picturesque areas, exhibition halls, cinemas, docks, train stations, bus stations and other locations that require ticket confirmation; locations that require authorized entry such as factory participation, canteen consumption, golf courses, regular monthly card leisure centers, and so on; anti-static control locations of electronic factories, units that need rigorous security procedures such as face acknowledgment and fingerprint acknowledgment. RS Security Co., Ltd mainly produces, develops and sells gain access to control products, such as waist height turnstile barirer, subway flap gates gate, servo motor swing turnstile gate, translation gates door, drop arm turnstile barirer, full body turnstile barirer, half height gates barirer, speed gates door and other channel turnstiles door products, and barrier gate, recognition video camera, hydraulic bollards, road blockers three arms gates door Integrated electronic tickets, gain access to control and presence, club consumption/catering, anti-static, fingerprint, palm print, face acknowledgment, iris recognition Integrated application of other series of products; complete stainless steel frame structure, Taibang motor, independently developed and produced motion; one-way/two-way turnstiles door/ swipe to launch the lever button and the upper lever is optional, with Counting function can realize RS485 direct communication with the computer; tripod turnstile barirer triggers and instructions and alarm triggers; automatic fall of the pole when power is off and manual fall The pole is optional, and it gets the switch signal to open turnstile barirer; it can be geared up with a card reading control part, and multiple systems can be connected to the network; it can be geared up with magnetic card and proximity card mix methods; it can be ordered according to various functional requirements. Do. A totally rainproof box made from alloy aluminum or stainless steel, compared to the train flap turnstile door dc brushless swing turnstile Door and other pedestrian passage devices, waist height turnstiles barirer are more affordable. It has a customized setup user interface (such as card reader, indication light installation, etc) to ensure that the system integrator's control turnstile barirer equipment is basic and practical to set up. The motion of the three-stick turnstile gate maker has actually an immediately adjusted hydraulic shock absorber. When utilizing the three-stick gates door operation, the sound is very small and quiet. Impact, turnstile door bar automatically decreases back to center. The surface area of the movement is plated with yellow dichromate. Can be set with gates barirer device control, a couple of instructions control (set by user). The base is repaired with growth bolts.

#tripod turnstiles gate#tripod baffle#swing barrier#buy turnstile#security turnstile gate#turnstile gate with face recognition#subway turnstiles

2 notes

·

View notes