#Cone penetration test

Note

Greetings, this is @hra-official with our proposal for a burn-based weapons system. I must apologize for the convoluted setup, but since the omninode we're transmitting from is still registered under Landmark Colonial, we are unable to display our signature in this message.

Now, to the business at hand: there are two primary challenges with integrating a burn-based weapon system in the assets of Baronic United Command:

As we all know, such a weapon will frequently be used against forces equipped with Harrison Armory mechanized frames. Despite the many flaws of their design ethos, such frames are almost universally well equipeed to manage excess heat and are often hardened against incendiary weapons.

Given that a large portion of RKF chassis are optimized for melee or close-quarters combat, creating hazardous terrain on a front line is liable to be especially hazardous for BUC Kurassiers

The solution? Chemical burn.

As luck would have it, the Hercynian Hive Worm naturally secretes a powerful acid which rapidly corrodes metal and even stone, but is harmless to it's own living tissue. Hercynian Refurbished Armaments has just completed the tests of the first prototypes of a chemical projector capable of harnessing it.

[ID: several images follow. The first is a diagram of a nozzle connected to two nested tanks. The second through seventh are several photos of a Genghis Mk.1 being hosed by a sprayer like the one described by the diagram; they show the mech activating it's autocooler and explosive vents while rust-coloured smoke and brownish sludge leak from it's seams. As of the sixth images it's arms dangle limply at it's sides. In the seventh, armour plates are starting to come off]

As you can see, projector itself is compact enough to be attached to a main mount, although larger hardpoints my be used to supply it with bigger tanks.

The reason the tanks are nested is twofold: firstly, to prevent corrosion of the parent vehicle if they should be pierced; and seondly, to modulate the viscosity and corrosiveness of the payload.

This is needed for it's application in an anti-infantry role: mixed with the correct amount of neutralizing agent, the acid becomes fluid enough to be sprayed in a wide cone, capable of penetrating soft cover and coat a wide area. The partial neutralization of the acid also prevents it from causing burns on living tissues, while still retaining enough efficacy to render infantry-portable weapons and hardsuits ineffective.

In this configuration, the weapon is less-than-lethal while remaining capable of rendering infantry combat-ineffective, meaning that - unlike a flamethrower - using it has a very low risk of killing civilians caught in the crossfire, so long as they are promptly given medical attention.

Excellent. The use of a jungle predator's acid is, in the view of the Jungle Warfare Commission, a slashing moment of brilliance - the nested tanks a further triumph.

We have two questions for you:

Is the projected acid of equivalent weight to a conventional flamethrower's fuel?

Is it easily synthesized by a printer or bioreplicating cloning machine?

Aside from these, this looks to be quite good. We will conduct comparative trials of this weapon system against the one proposed by Revved-and-Ready, and shall return with a decision.

Thank you for your time.

18 notes

·

View notes

Text

Soil Testing Laboratory Equipments

Soil testing laboratory equipment encompasses a range of instruments crucial for analyzing various soil properties.

Common equipment found in soil testing laboratories includes:

Sieves: Used for particle size analysis, these come in various mesh sizes to separate soil particles.

Moisture Content Analyzers: Instruments like moisture balances or ovens determine the moisture content in soil samples, vital for understanding soil composition.

Soil Penetrometers: Measure soil compaction and resistance by gauging the penetration force of a probe into the soil.

Triaxial Testing Machines: Essential for advanced soil mechanics studies, these machines assess the shear strength and stress-strain relationships of soils.

Direct Shear Apparatus: Determines the shear strength parameters of soil samples under various conditions.

Consolidation Testing Equipment: Used to study soil settlement characteristics under applied stress loads.

pH Meters: Measure the acidity or alkalinity of soil, providing insights into nutrient availability.

Atterberg Limits Apparatus: Determines the plasticity and consistency limits of fine-grained soils.

Compaction Testers: Evaluate the soil’s ability to support structural loads by measuring its maximum dry density and optimum moisture content.

Cone Penetrometers: Assess the soil’s bearing capacity and compaction.

These instruments collectively enable researchers, geotechnical engineers, and agronomists to understand soil behavior, structure, and fertility. Accurate analysis using these laboratory tools is crucial for making informed decisions in agriculture, construction, environmental science, and various other fields reliant on soil data.

0 notes

Text

Penetrometer

Penetrometer is an automated unit with auto-electrode lifting for precise distance adjustment. The system includes extensive functions of cone and needle change conveniently. Conforms to ASTM penetration test on petroleum products.

0 notes

Text

Which Pimple Patch To Choose For Your Blemish?

Did you wake up to an ugly red monster pimple on your chin just before a big presentation? Want to zap pesky breakouts fast without drying chemicals? Pimple patch solutions from the best pimple patch manufacturersoffer a hero product giving blemishes to the boot quickly and naturally overnight. But which brand rates best for on-the-spot pimple rescue?

Look for Patches With Microdart Tips

Forget old-school drying clays or creams, putting bacteria and dirt to work and clogging pores further. The latest pimple patches contain microdarts – little dissolvable cones – that deliver pimple-fighting ingredients below the surface directly into infection and inflammation locations.

Tea tree oil, niacinamide, and other antimicrobial botanicals combat acne-causing bacteria thanks to the micro dart patch design from the innovative pimple patch manufacturer. The tiny vessels' penetrating pores allow deep transmission of balancing and healing factors, dissolving troubles while reducing redness and swelling.

Consider Patch Adhesives and Absorption

Between pressed events and an active lifestyle, choosing an adhesive pimple patch that stays put through smiling, sweating, or sudden selfies means selecting the best pimple patch manufacturer using medical-grade adhesion.

Many beauty sites recommend patches for durable adhesion, even on delicate facial areas like noses and chins. Ultra-thin transdermal patches absorb pus and oil and exudate from deep blemishes better than alternatives, preventing the spread of bacteria internally.

Read Reviews Across Multiple Skin Types

Finding the holy grail solution rated best by consumers with every skin type – oily, dry, sensitive, acne-prone, or combination – means scanning pimple patch manufacturer reviews. A patch working wonders for one person may irritate others.

Widely top-ranked patches like the Killa Kit from pimple patch manufacturer earn distinguished awards from magazines like Teen Vogue and GQ for performance across myriad complexions, genders, and ages, making them universally safe suggestions to tackle any pimple emergency.

Choose Cruelty-Free Brands

Conscientious consumers wondering, “Where can I buy pimple patches manufactured without testing on animals? The sustainably thinking pimple patch manufacturer also skips potentially irritating synthetic fragrances, parabens, and sulfates in formulas that are kind to both breakout-prone skin and the planet.

Consider the Price Per Patch

With recurring breakouts or monthly hormonal acne, the costs of pimple patch treatment can add up over time. Rather than pay premium prices repeatedly, seek out pimple patch manufacturers providing bundles or packs offering multi-month supplies at more affordable per-patch pricing.

Stocking up on larger quantities of go-to patches yielding great results means saving money over single patch purchases. Just be sure any bulk batch deals come from reputable brands not sacrificing ingredient quality for discounts.

Conclusion

Waking up to surprise blemishes can ruin your whole day. But applying the right pimple patches packed with effective acne-calming ingredients quickly conceals spots while working overnight magic, shrinking underground infection for clear skin by dawn, thanks to microdart tips from respected pimple patch manufacturers.

Want to get the best Pimple Patch products? If yes, get great products at Nurimedics the perfect point for Vegan Hydrocolloid patches. Get in touch with us today at +82.10.8235.8541 or send your email to [email protected].

Resource: https://veganhydrocolloid.wordpress.com/2024/01/23/which-pimple-patch-to-choose-for-your-blemish/

#acne patches#hydrocolloid patches#veganhydrocolloid#acne#vegan acne patches#skincare#hydrocolloid patches manufacturer#beauty#face masks#makeup

0 notes

Text

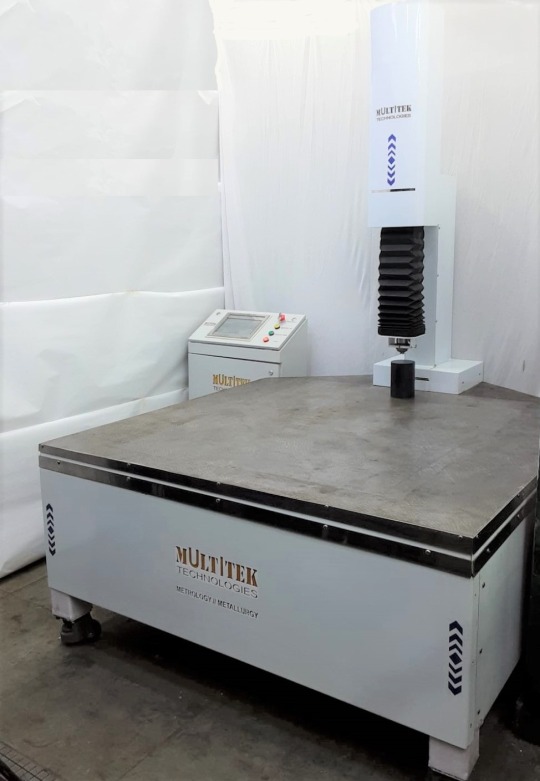

Rockwell Hardness Tester: A Comprehensive Guide by Multitek Technologies

What is Hardness Testing in Material Science and Engineering?

We at Multitek Technologies excited to share the knowledgebase on Rockwell Hardness Tester. In the world of material science and engineering, understanding the mechanical properties of materials is crucial for ensuring their quality and reliability in various applications. One of the key properties that engineers and manufacturers often need to measure is hardness. Hardness is defined as the resistance of a material to deformation, indentation, or scratching, and it plays a significant role in determining a material's suitability for specific uses.

Hardness testing is a widely used method for quantifying the hardness of materials. It involves applying a controlled force or pressure to the surface of a material and measuring the resulting indentation or penetration. There are several methods of hardness testing available, each with its own advantages and limitations. One of the most popular and widely used methods is the Rockwell hardness test.

Why Rockwell Hardness Tester?

The Rockwell hardness test is a non-destructive testing method used to measure the hardness of metallic materials. It is based on the depth of penetration of an indenter into the material under a specific load. The test is named after its inventor, Stanley P. Rockwell, who developed the method in the early 20th century.

The Rockwell hardness test is known for its simplicity, speed, and accuracy, making it suitable for a wide range of applications across various industries. It is particularly well-suited for quality control and materials testing in manufacturing environments.

What are the Principles of the Rockwell Hardness Tester?

The Rockwell hardness test works on the principle of measuring the depth of penetration of an indenter into the material under two loads: a minor load to establish a reference position (preliminary load), and a major load to complete the test (additional load). The difference in indentation depths between the two loads is used to calculate the Rockwell hardness number.

The Rockwell hardness scale is defined by a combination of the indenter type (diamond or ball) and the applied load. There are several Rockwell scales designated by letters, such as HRA, HRB, HRC, etc., each suitable for different types of materials and hardness ranges.

Components of a Rockwell Hardness Tester

A typical Rockwell hardness tester consists of several key components:

Indenter: The indenter is the tool that is pressed into the material to create the indentation. In Rockwell testing, the indenter can be either a diamond cone or a hardened steel ball, depending on the hardness scale being used.

Anvil: The anvil provides a stable surface against which the material being tested is placed. It ensures that the material is properly supported and prevents any deflection during the test.

Load Application System: The load application system applies the predetermined loads to the indenter. It typically consists of a mechanical or hydraulic mechanism that controls the application of the minor and major loads. Feel Free to Navigate about Multitek’s Other Products/Machines

Depth Measurement System: The depth measurement system accurately measures the depth of penetration of the indenter into the material under the applied loads. This measurement is crucial for calculating the Rockwell hardness number.

Display and Readout: The display and readout system provides the results of the hardness test in the form of Rockwell hardness numbers. It may include analog or digital indicators, depending on the model of the hardness tester.

Procedure for Performing a Rockwell Hardness Test

Performing a Rockwell hardness test involves the following steps:

Prepare the Specimen: Ensure that the surface of the specimen is clean, flat, and free from any contaminants or irregularities. Visit us to learn more about Multitek’s Calibration Services

Select the Indenter and Scale: Choose the appropriate type of indenter (diamond or ball) and the Rockwell scale based on the material being tested and the expected hardness range.

Apply the Preliminary Load: Apply the minor load to the indenter, which establishes a reference position on the specimen surface.

Apply the Additional Load: Apply the major load to the indenter, which creates the indentation on the specimen surface.

Release the Load: Release the major load while maintaining the minor load, allowing the indenter to partially retract from the specimen surface.

Measure the Depth of Penetration: Use the depth measurement system to accurately measure the depth of penetration of the indenter into the material.

Calculate the Rockwell Hardness Number: Calculate the Rockwell hardness number using the formula specified for the selected Rockwell scale.

Record the Results: Record the Rockwell hardness number along with relevant details such as the test conditions, specimen identification, and any observations.

Other Hardness Testing Machines available at Multitek Lab:

Micro Vickers or Universal Hardness Tester

Brinell hardness Testing (BHN & LCB)

Rockwell Hardness Testing (RMT-AL & RHT-LC1500-1A)

Rubber Hardness Testing Machines

Advantages of the Rockwell Hardness Test

The Rockwell hardness test offers several advantages over other hardness testing methods:

Versatility: The Rockwell hardness test can be used to measure the hardness of a wide range of metallic materials, including ferrous and non-ferrous metals.

Speed: The test is relatively quick to perform, allowing for high throughput in quality control and production environments.

Accuracy: The Rockwell hardness test provides accurate and repeatable results, making it suitable for precise materials testing and characterization.

Non-Destructive: Unlike some other hardness testing methods, such as the Brinell test, the Rockwell test is non-destructive, meaning it does not significantly alter the specimen's properties.

Ease of Use: The test is relatively simple to perform and requires minimal training, making it accessible to operators with varying levels of expertise. Reach out to us for Microscope and Hardness Testing Machine Repair and Up gradation Services!

Applications of the Rockwell Hardness Test

The Rockwell hardness test has widespread applications across various industries, including:

Manufacturing: The test is commonly used for quality control and materials testing in manufacturing processes, such as automotive, aerospace, and machinery production.

Metalworking: The test is used to assess the hardness of metal components, including forgings, castings, and heat-treated parts.

Engineering: The test helps engineers and designers select materials with suitable hardness properties for specific applications, such as tooling, dies, and machine components.

Construction: The test is used to evaluate the hardness of construction materials, such as steel beams, structural components, and concrete.

Research and Development: The test is employed in research and development activities to characterize the mechanical properties of new materials and alloys.

Visit us to know more about our Customized Rockwell Hardness Test Machines

According to Multitek Technologies the Rockwell hardness test is a versatile, accurate, and widely used method for measuring the hardness of metallic materials. Its simplicity, speed, and non-destructive nature make it an invaluable tool for quality control, materials testing, and engineering applications across various industries.

By understanding the principles, procedures, and applications of the Rockwell hardness test, engineers and manufacturers can ensure the quality, reliability, and performance of their products and components. Feel Free to Contact Us, if you have any question related to Rockwell Hardness Tester!

#rockwell hardness tester#rockwell tester#metallurgy#metrology#metalography#Metal Hardness Tester#Automotive Services#Multitek#Technologies#Delhi#India#engineering#mechanical#equipment#industrial#Machinary#Machine

0 notes

Text

5 Types of Soil Testing For Construction

Soil testing in construction is essential for ensuring the stability and durability of structures. Various types of soil testing methods, conducted with specialized soil testing machines, offer insights into soil properties, allowing engineers to make informed decisions. Here are five crucial types of soil testing methods commonly employed in construction:

1. Moisture Content Testing: Determining the moisture content of soil is fundamental in assessing its compaction and suitability for construction. Soil testing machines equipped with moisture sensors accurately measure moisture levels, guiding decisions on proper compaction techniques for a solid foundation.

2. Compaction Testing: Soil compaction ensures that the soil beneath a structure can bear the imposed load. Soil testing machines, such as Proctor Compaction Apparatus, evaluate the density and compaction characteristics of soil, ensuring it meets specified standards for stability.

3. Bearing Capacity Testing: Evaluating soil bearing capacity is crucial to assess how much load the soil can withstand. Cone Penetration Testing (CPT) and Plate Load Testing (PLT), facilitated by specialized soil testing machines, help determine soil strength and load-bearing capacities, vital for foundation design.

4. Soil pH and Chemical Testing: Soil pH and chemical composition impact its stability and ability to support structures. Soil testing machines equipped with pH sensors and chemical analyzers assess soil acidity, salinity, and chemical properties, influencing material selection and soil treatment for construction.

5. Shear Strength Testing: Understanding soil shear strength is crucial in determining its stability against sliding or collapsing. Direct Shear Testing and Triaxial Testing, performed by soil testing machines, evaluate soil shear strength, aiding engineers in designing safe and stable foundations.

Employing these diverse soil testing methods with specialized soil testing machines is fundamental in the construction process. These tests provide critical data to engineers, ensuring that the soil beneath structures meets the necessary criteria for stability, load-bearing capacity, and durability. Investing in thorough soil testing with appropriate equipment is integral to the success and longevity of construction projects.

Also Read:- What Is Soil Testing and What Are the Advantages of Soil Testing?

0 notes

Text

Ground slip testing

Ground slip testing typically refers to the evaluation of ground or soil stability, particularly in geotechnical engineering and construction contexts. The term may be used in various ways, so I'll provide information on different aspects related to ground slip testing:

Soil Stability Analysis:

Standard Penetration Test (SPT): This test involves driving a standard sampler into the soil at the bottom of a borehole and measuring the number of blows required to penetrate the soil to a specified depth. It provides information about the soil's resistance to penetration and can be used to assess soil strength.

Cone Penetration Test (CPT): This test involves pushing a cone-shaped penetrometer into the ground at a constant rate. The resistance to penetration is measured continuously, providing data on soil strength and stratigraphy.

Shear Strength Tests: Various laboratory tests, such as the direct shear test or triaxial test, are conducted to determine the shear strength parameters of soil. These tests help in understanding the soil's stability under different conditions.

Slope Stability Analysis:

Field Instrumentation: Instruments such as inclinometers and piezometers are used to monitor slope movements and pore water pressures. These instruments provide real-time data that can be crucial for understanding and predicting ground slip.

Geophysical Surveys: Ground-based geophysical methods, like ground-penetrating radar (GPR) or seismic surveys, can be employed to assess subsurface conditions and detect potential slip planes.

Deformation Monitoring:

Global Navigation Satellite System (GNSS): GNSS receivers can be used to monitor ground movement over time. This method is valuable for detecting and measuring subsidence or lateral displacements.

Remote Sensing: Satellite imagery or aerial photography can be used to identify changes in the landscape, including ground slip or movement.

Laboratory Tests for Soil Properties:

Atterberg Limits: Tests such as liquid limit and plastic limit help characterize the consistency and behavior of fine-grained soils.

Compaction Tests: These tests, like the Proctor compaction test, assess the maximum dry density and optimum moisture content of soils, providing insights into their engineering properties.

Before conducting any ground slip testing, it's crucial to have a clear understanding of the specific goals, site conditions, and potential risks involved. Consulting with geotechnical engineers and utilizing a combination of testing methods can provide a comprehensive assessment of ground stability.

0 notes

Text

How Do Ultrasonic Thickness Gauges Work?

Ultrasonic thickness gauges emit ultrasonic waves and then measure the time taken for the waves to return after reflecting off a surface. This time is inversely proportional to the distance between the surface and the ultrasonic thickness gauge, so the duration of the waves to return might vary depending on thickness of the test piece.

Ultrasonic thickness meters use either a single-element or a dual-element transducer. A single-element transducer emits ultrasound in a cone-shaped beam, while a dual-element transducer emits ultrasound in a fan-shaped beam. Dual-element transducers are more accurate than single-element transducers, but they are also more expensive.

Most ultrasonic thickness gauges use digital signal processing (DSP) to measure the time taken for the waves to return, and DSP allows for faster calculations and increased accuracy.

Ultrasonic Thickness Gauges – What are they?

Ultrasonic thickness gauges are instruments that use ultrasonic waves to measure the thickness of a material. The principle behind their operation is that the speed of sound in a material is directly proportional to its thickness. Ultrasonic thickness gauges emit ultrasonic waves and then measure the time it takes for the waves to return to the gauge. This time is then converted into a thickness measurement.

Ultrasonic thickness gauges are used to measure the thickness of various materials, including metal, plastic, and glass. They can be used for multiple applications, including quality control, research and development, and manufacturing.

There are various types of ultrasonic thickness gauges mentioned below:

Pulse-echo ultrasonic thickness gauges: These gauges emit ultrasonic pulses into a material and then measure the time it takes for the echoes to return. They are typically used to measure thicker materials, such as metal or plastic.

Continuous-wave ultrasonic thickness gauges: These gauges emit a steady stream of ultrasonic waves into a material and then measure the time it takes for the echoes to return. They are typically used to measure thinner materials, such as glass or plastic.

Doppler ultrasonic thickness gauges: These gauges use ultrasound to measure changes in frequency (Doppler shifts) caused by the motion of the material as it passes by the transducer. The frequency shift is proportional to the moving material’s thickness.

Working of Ultrasonic Thickness Gauges?

Ultrasonic thickness gauges work by delivering sound waves through a material surface to determine thickness. The gadget creates a high-frequency sound wave far higher than the waves people perceive, and the gauge measures how long it takes for the wave to travel through a material and bounce back.

The time it takes for a sound pulse generated by a tiny probe called an ultrasonic transducer to penetrate through a test piece and reflect off the interior surface or far wall is measured by an ultrasonic thickness gauge. The thickness of the item is then computed and shown on a digital screen based on this measurement.

Testing equipment’s mobility enables on-site assessment with immediate findings. Additional non-destructive testing procedures can be employed to explore the conclusions further if the approach has found an issue.

The thickness gauge, for example, would transmit a wave through the material and then determine the thickness depending on the time it takes to get the echo from the pipe’s rear wall. Ultrasonic thickness gauges are precise because of this technology; some UT thickness gauges can even record exact measurements to the millimetre.

Which material can be measured with an ultrasonic thickness gauge?

It is clear how an ultrasonic thickness tester can be used to measure the thickness of a material, but the next big question is – which material? An ultrasonic thickness metre can detect corrosion, coatings, and a wide variety of materials, including metals, plastics, composites, fibreglass, and ceramic glass.

1. Corrosion

Corrosion may damage the structural integrity of metals such as beams, bridge supports, and steel pilings if it goes unnoticed for an extended period of time. Ultrasonic thickness gauges can be used to test metals non-destructively in order to detect any damage or weakness produced by corrosion in metal constructions.

2. Metal

Metal pipes, tanks, sheets, coils, gun drilling, and tubing can all be measured with ultrasonic thickness gauges. A metal thickness tester can be used to check that production fulfils industry standards and that a product is safe and robust enough to execute its job.

3. Plastics

As non-metallic technical items such as plastics have grown significantly popular, the necessity to monitor wall thickness for quality control has increased. Bottles and containers, plastic pipes, fibreglass pipes, and boats are now subjected to ultrasonic testing to guarantee that industry requirements are maintained, and that manufactured items are safe.

4. Other Materials

Apart from this, there are many other materials in which thickness can be measured using a UT thickness gauge. Items made of rubber, ceramics, glassware, and liquid level are, to name a few, where the consumer cannot see both sides of the material and thus can use an ultrasound thickness tester for measuring.

Benefits of Using Ultrasonic Thickness Gauges

Ultrasonic thickness gauges are an essential part of the quality control process in manufacturing and production. They are used to measure the thickness of objects and materials and can be used on a wide range of materials as aforementioned, and thus imply a number of benefits.

Ultrasonic gauges are non-destructive measuring devices that only need accessibility to one surface of a material to produce precise results. As a result, they may fit into more spaces and do not require material to be carved out to allow access. Ultrasonic gauges are highly accurate. Depending on the UT thickness gauge you’re using, you can measure the thickness of material to within fractions of a millimetre up to several hundred kilometres. They’re pretty adaptable, and the most recent gauges are extremely accurate.

Furthermore, ultrasonic gauges are easier to use than they have ever been. The EDISON – 1TC, for example, has auto probe calibration. These devices can be configured to measure various materials and swiftly switch between them. They’re also simple to operate; operators simply point and fire, and measurements are delivered in seconds.

0 notes

Text

Enhancing Vision and Care: Exploring the Top Features of a Sri Eye Care Speciality Eye Hospital

Human Eye is a Remarkable Organ, Allowing Us to Experience the World in Vivid Detail. With Vision Being Such a Crucial Aspect of Life, It is Essential to Have Access to Advanced Eye Care Facilities and Cutting-Edge Technology. In this Blog, We Will Delve into the Top Features of a Sri Eye Care Speciality Eye Hospital, Where the Focus is on Providing the Best Possible Care and Improving Patients' Visual Health.

State-Of-The-Art Diagnostic Equipment:

Sri Eye Care Speciality Eye Hospital is Equipped with the Latest Diagnostic Tools and Technology. From Advanced Retinal Scanners and Corneal Topography Systems to Optical Coherence Tomography (OCT) Machines, These Instruments Allow Eye Care Professionals to Accurately Diagnose a Wide Range of Eye Conditions. Early Detection Can Lead to More Effective Treatments and Better Outcomes.

Specialized Eye Care Services:

Our Eye Hospitals Offer a Comprehensive Range of Specialized Services to Address Various Eye Conditions. These May Include:

Cataract Surgery: Cataract, Natural Eye Lens Turning Cloudy. We Provide Advanced Cataract Removal Techniques, Such as Phacoemulsification, with Premium Intraocular Lens Options for Improved Vision After Surgery and Extracapsular Cataract Surgery, Rigid Artificial Lens Placed into the Bag That Initially Contained Cataract.

Lasik and Refractive Surgery: Lasik Eye Surgery, Bladeless Lasik (Laser Treatment) Perform to Correct Eye Power and Other Refractive Procedures to Correct Myopia, Hyperopia, and Astigmatism.

Retina Treatment: Retina, Sensitive Part of Human Eye. Treatments for Common Retinal Diseases Diabetic Retinopathy, Retinal Detachment & Age-Related Macular Degeneration [Armd] in Our Hospital Include Intravitreal Injection, Retinal Laser Photocoagulation, Pars Plana Vitrectomy & Low Vision Aids.

Glaucoma Treatment: Glaucoma, Silent Thief of Vision. Certain Pressure in the Eye Leads to Glaucoma Which May Lead to Permanent Vision Loss. Glaucoma Treatments at Sri Eye Care Hospital Glaucoma Eye Drops, Selective & Argon Laser Trabeculoplasty Surgery, and Laser Peripheral Iridotomy Surgery Treatments.

Pediatric Ophthalmology: Specialized Care for Children's Eye Conditions and Visual Development. Common Paediatric Eye Problems Strabismus, Chalazion, Amblyopia, Epiphora, and Other Disorders Can Be Treated Well with Regular Eye Tests & Consultations.

Orbit & Oculoplasty: Corrective and Reconstructive Procedures for Eyelids and Surrounding Structures. We Provide Advanced Oculoplastic Surgery, Which Gives a Refreshed & Rejuvenated Look.

Keratoconus Treatment: Keratoconus, Cone Shaped Bulge in Cornea. Sri Eye Care Provides Keratoconus Treatment to Reduce Progression of Disease with Riboflavin Assisted Corneal Collagen Cross-Linking, Corneal Transplantation & Penetrating Keratoplasty.

Experienced Ophthalmologists and Eye Care Professionals:

Sri Eye Care a Reputable Eye Hospital is Staffed with Experienced and Skilled Ophthalmologists, Optometrists, and Support Staff. These Professionals Work Collaboratively to Provide Accurate Diagnoses, Personalized Treatment Plans, and Exceptional Patient Care. Continuous Education and Training are Encouraged to Stay Updated with the Latest Advancements in the Field.

Patient-Centric Approach:

Our Eye Hospitals Prioritize Patient Comfort and Satisfaction. They Maintain a Patient-Centric Approach to Care, Ensuring that Each Individual Receives the Attention and Support They Need Throughout their Eye Care Journey. Efficient Appointment Scheduling, Clear Communication, and Compassionate Staff Are Essential Components of this Approach.

Optical Services and Vision Correction Products:

In Addition to Medical Treatments, Our Eye Hospital Often Includes an Optical Dispensary. Patients Can Get Access to High-Quality Eyeglasses, Contact Lenses, and Other Vision Correction Products Prescribed by Their Eye Care Professionals. a Well-Stocked Optical Store with a Wide Range of Frame Styles Can Enhance the Patient's Overall Experience.

Ambiance and Hygiene:

Sri Eye Care Specialty Modern Eye Hospital Prioritizes a Clean, Hygienic, and Well-Maintained Environment. A Pleasant Ambience Can Help Reduce Anxiety and Create a Comfortable Atmosphere for Patients, Especially those Undergoing Surgical Procedures.

Conclusion:

A State-Of-The-Art Eye Hospital Encompasses Cutting-Edge Technology, Specialized Services, Experienced Professionals, Patient-Centric Care, and a Focus on Overall Hygiene. These Features Make Sri Eye Care Speciality Eye Hospital a Stand Out Hospital among other Eye Hospitals in Bangalore. By Embracing these Features, Such a Facility Ensures that Patients Receive the Best Possible Eye Care and Work Towards Enhancing Their Vision, Ultimately Contributing to a Better Quality of Life. Remember Always to Prioritize Regular Eye Check-Ups to Maintain Optimal Eye Health and Catch Any Potential Issues Early On.

0 notes

Text

Comparison Between Standard Penetration Test and Cone Penetration Test

Geotechnical investigations play a crucial role in determining the properties and behaviour of soil for construction projects. Among the various methods used to assess soil strength and stratigraphy, two commonly employed tests are the Standard Penetration Test (SPT) and the Cone Penetration Test (CPT). Both tests provide valuable information about the subsurface conditions, but they differ in…

View On WordPress

0 notes

Text

How Do Ultrasonic Thickness Gauges Work?

You are here:

Home

Informative

How Do Ultrasonic Thickness Gauges…

May262022

https://www.modsonic.com/wp-content/uploads/2022/05/How-Do-Ultrasonic-Thickness-Gauges-Work-scaled-2560x1280.jpg

Ultrasonic thickness gauges emit ultrasonic waves and then measure the time taken for the waves to return after reflecting off a surface. This time is inversely proportional to the distance between the surface and the ultrasonic thickness gauge, so the duration of the waves to return might vary depending on thickness of the test piece.

Ultrasonic thickness meters use either a single-element or a dual-element transducer. A single-element transducer emits ultrasound in a cone-shaped beam, while a dual-element transducer emits ultrasound in a fan-shaped beam. Dual-element transducers are more accurate than single-element transducers, but they are also more expensive.

Most ultrasonic thickness gauges use digital signal processing (DSP) to measure the time taken for the waves to return, and DSP allows for faster calculations and increased accuracy.

Ultrasonic Thickness Gauges – What are they?

Ultrasonic thickness gauges are instruments that use ultrasonic waves to measure the thickness of a material. The principle behind their operation is that the speed of sound in a material is directly proportional to its thickness. Ultrasonic thickness gauges emit ultrasonic waves and then measure the time it takes for the waves to return to the gauge. This time is then converted into a thickness measurement.

Ultrasonic thickness gauges are used to measure the thickness of various materials, including metal, plastic, and glass. They can be used for multiple applications, including quality control, research and development, and manufacturing.

There are various types of ultrasonic thickness gauges mentioned below:

Pulse-echo ultrasonic thickness gauges: These gauges emit ultrasonic pulses into a material and then measure the time it takes for the echoes to return. They are typically used to measure thicker materials, such as metal or plastic.

Continuous-wave ultrasonic thickness gauges: These gauges emit a steady stream of ultrasonic waves into a material and then measure the time it takes for the echoes to return. They are typically used to measure thinner materials, such as glass or plastic.

Doppler ultrasonic thickness gauges: These gauges use ultrasound to measure changes in frequency (Doppler shifts) caused by the motion of the material as it passes by the transducer. The frequency shift is proportional to the moving material’s thickness.

Working of Ultrasonic Thickness Gauges?

Ultrasonic thickness gauges work by delivering sound waves through a material surface to determine thickness. The gadget creates a high-frequency sound wave far higher than the waves people perceive, and the gauge measures how long it takes for the wave to travel through a material and bounce back.

The time it takes for a sound pulse generated by a tiny probe called an ultrasonic transducer to penetrate through a test piece and reflect off the interior surface or far wall is measured by an ultrasonic thickness gauge. The thickness of the item is then computed and shown on a digital screen based on this measurement.

Testing equipment’s mobility enables on-site assessment with immediate findings. Additional non-destructive testing procedures can be employed to explore the conclusions further if the approach has found an issue.

The thickness gauge, for example, would transmit a wave through the material and then determine the thickness depending on the time it takes to get the echo from the pipe’s rear wall. Ultrasonic thickness gauges are precise because of this technology; some UT thickness gauges can even record exact measurements to the millimetre.

Which material can be measured with an ultrasonic thickness gauge?

It is clear how an ultrasonic thickness tester can be used to measure the thickness of a material, but the next big question is – which material? An ultrasonic thickness metre can detect corrosion, coatings, and a wide variety of materials, including metals, plastics, composites, fibreglass, and ceramic glass.

1. Corrosion

Corrosion may damage the structural integrity of metals such as beams, bridge supports, and steel pilings if it goes unnoticed for an extended period of time. Ultrasonic thickness gauges can be used to test metals non-destructively in order to detect any damage or weakness produced by corrosion in metal constructions.

2. Metal

Metal pipes, tanks, sheets, coils, gun drilling, and tubing can all be measured with ultrasonic thickness gauges. A metal thickness tester can be used to check that production fulfils industry standards and that a product is safe and robust enough to execute its job.

3. Plastics

As non-metallic technical items such as plastics have grown significantly popular, the necessity to monitor wall thickness for quality control has increased. Bottles and containers, plastic pipes, fibreglass pipes, and boats are now subjected to ultrasonic testing to guarantee that industry requirements are maintained, and that manufactured items are safe.

4. Other Materials

Apart from this, there are many other materials in which thickness can be measured using a UT thickness gauge. Items made of rubber, ceramics, glassware, and liquid level are, to name a few, where the consumer cannot see both sides of the material and thus can use an ultrasound thickness tester for measuring.

Benefits of Using Ultrasonic Thickness Gauges

Ultrasonic thickness gauges are an essential part of the quality control process in manufacturing and production. They are used to measure the thickness of objects and materials and can be used on a wide range of materials as aforementioned, and thus imply a number of benefits.

Ultrasonic gauges are non-destructive measuring devices that only need accessibility to one surface of a material to produce precise results. As a result, they may fit into more spaces and do not require material to be carved out to allow access. Ultrasonic gauges are highly accurate. Depending on the UT thickness gauge you’re using, you can measure the thickness of material to within fractions of a millimetre up to several hundred kilometres. They’re pretty adaptable, and the most recent gauges are extremely accurate.

Furthermore, ultrasonic gauges are easier to use than they have ever been. The EDISON – 1TC, for example, has auto probe calibration. These devices can be configured to measure various materials and swiftly switch between them. They’re also simple to operate; operators simply point and fire, and measurements are delivered in seconds.

Modsonic is a leading producer, exporter and marketer of ultrasonic thickness gauges in India. With an aim to be on top, we strive to deliver high-quality equipment, through which accurate results can be produced. Our ultrasonic thickness testers such as Edison-1, TM210 Plus, and Edison-1 TC are all made with innovative techniques ensuring accuracy as close as up to a fraction of a millimetre. Connect with us now to access our wide range of ultrasonic testing equipment.

0 notes

Text

Geotechnical Screening Solutions

Geotechnical screening services are an important part of any kind of building and construction task. They help to ensure that building tasks are created safely and within specifications and also needs detailed in the contract documents. Whether you are developing a business, household or industrial structure, you will certainly require to recognize the problem of the ground under your home. This is to see to it that you can construct your foundations correctly and also to avoid troubles with the structure in the future. There are a number of sorts of geotechnical examinations that you can conduct to figure out the ground's problem and toughness.

These consist of examinations that determine the wetness content of dirt's and also other products along with test samples that are drawn from the ground to determine their attributes such as thickness, permeability and also even more. For example, the liquid restriction and straight shrinking tests are made use of to figure out just how much water a soil can maintain after being subjected to extreme warmth or cold. They also examine how much a dirt can absorb as well as hold before it comes to be liquid once again, which can be practical for identifying how to build foundations that can manage heavy tons. A few of these tests can additionally be executed at a construction website to check that the ground is being compacted properly as well as according to the contract documentation. Check out more about environmental engineering services.

This is particularly essential when it pertains to the dirt's used in construction. One of the most typical geotechnical screening approaches is the borehole examination. This approach includes boring openings right into the ground and catching an example of the soil at normal intervals to check its problem as well as toughness. This test can be carried out by a variety of different methods and also is normally taken on by seasoned geotechnical designers. The monotonous procedure can take a long time, however it is a really efficient way of finding out what the soil has to offer in terms of stamina and permeability. Another popular kind of geotechnical testing is in-situ screening. This type of screening is a more exact as well as economical means to analyze the ground below a construction website. Get to know more from groundwater hydrology.

This type of screening can be conducted by a number of different strategies such as hammer tests, cone penetration tests (CPT), common penetration examinations (SPT) as well as vibrant cone penetration tests (DCPT). The results of these tests can assist to recognize the stamina's and also weaknesses of a dirt and also figure out whether or not it can support structures without triggering architectural damage. Other examinations that review the toughness of a soil include the California bearing ratio, which determines the capability of a dirt to resist the stress of an automobile or other weight, as well as shear tests, which are utilized to identify the capability of a dirt to resist bending. These sorts of tests are made use of by many different task groups. They can assist to determine the optimum deepness for a foundation, the most economical construction method, and also if there is a danger of liquefaction under a certain location. Whether you are a civil design service provider, consulting engineer or developer, you can benefit from the series of geotechnical screening and also examination services available through SOCOTEC. With a group of specialists in all facets of geotechnical, ecological as well as building and construction services, SOCOTEC is able to provide an extensive package of solutions that can assist you provide your tasks on schedule, on budget and also safely.

Know further about business directory here - https://en.wikipedia.org/wiki/Environmental_engineering_science

1 note

·

View note

Text

Geotechnical Drilling Services

Geotechnical drilling is a site investigation technique that is used to evaluate the ground conditions around a construction project. This process helps to ensure that construction can be completed safely, and helps to catch any problems before they occur.

How Geotechnical Drilling Services Are Done

There are several different types of geotechnical drilling services, including auger boring, mud rotary drilling, rock core sampling, and cone penetration testing (CPT). Each of these methods has advantages and disadvantages depending on the site.

Hollow Stem Auger is a relatively inexpensive method that leverages torque and force to send screw-like drillbits through tough formations. This is especially effective on subsurfaces that are full of sand, clay, and silts.

Mud rotary drilling is another geotechnical drilling technique that’s great for digging into soft and mushy ground. This method can be used to explore rock formations up to a depth of 1,000 feet, and it’s also capable of allowing a hole to remain straight for an extended period of time.

Cone Penetration Testing is another geotechnical drilling service that is commonly used for exploratory purposes. It allows a cone to be pushed into the ground to collect samples that will be used for soil analysis, geological research, and other purposes.

If you’re planning a construction project that requires a geotechnical site investigation, it’s important to find the right company for the job. A qualified team can help you determine the best type of drilling services to use, and they can also ensure that everything is done safely and efficiently.

0 notes

Text

Symptoms that indicate you need to go for color blindness treatment as soon as possible

The term color blindness affects many people all over the world. In the case of color blindness, people can view colors clearly, however, they lose their ability to differentiate between different colors and their shades. Not everyone who is suffering from color blindness can fail to identify the same shades or colors. Most people fail to differentiate between green and red, while some cannot differentiate between yellow and red.

Similarly, a small group of people who have been diagnosed with monochromatism can only view white and black colors. Up to 8% of males are affected due to different kinds of color blindness symptoms- whereas, the percentage of women suffering from color blindness is 1% or less. You can search about color blindness treatment in India.

What are the major causes of color blindness?

Color blindness usually occurs due to genetic disorders or conditions. It often occurs due to the difference in the ability of the eye’s light-sensitive cells to distinguish between certain colors. There is more than one light-sensitive cell present in the eye’s retina. The capability of the eye to identify certain colors can depend on the retina’s response.

The light-sensitive cells or commonly known as the cones have the ability to sense different wavelengths of outside light penetrating within the eye. It helps the retina to differentiate between different types of colors or shades. The varying sensitivity attribute of one of these cones or even more is the major cause behind a person’s color blindness.

What are the underlying signs of color blindness?

The signs of color blindness can be noticed among young children. Parents should determine their child’s ability to recognize colors and separate them from each other at the earliest. In some cases, the signs often go unnoticed as they are mild to moderate. Search about treatment for color blindness today. Some of the fundamental signs of color blindness are as follows:

Inability to differentiate between various colors

Facing difficulties when it comes to separating one tone or shade of the similar color with the other

Is it possible to cure color blindness?

In order to ensure the treatment of color blindness is effective and can measure up to the intensity of your blindness, you should visit one of the best color blindness testing facilities in India. There are different types of color blindness tests available in the best clinics. If you’re unable to identify or see certain colors or differentiate between them, it’s important to visit clinics that carry out latest technologic tests or the basic Ishihara tests.

Experts haven’t been able to come up with a specific treatment for color blindness to date. Often, eye doctors recommend the use of glasses and contact lenses with filters. The objective is to help a person cope with color deficiencies. The eyesight or vision of several people who are diagnosed with color blindness is optimal in all other aspects.

The efficiency of color blindness treatment can vary according to its severity and nature. So, a doctor will identify the origin of the problem in the case of different individuals before commencing the treatment.

#colour blindness treatment#treatment of color blindness#treatment for color blindness#color blindness treatment in India

0 notes

Text

Bogs Blog 6

Bogs Blog 6

Some weeks are harder than others, and this has been one of those harder weeks. There is a certain urgency and a business to life that comes with the lead up to Christmas and summer. There are the constant social events where you try to catch up with everyone before the holidays, although the constant rain has made it hard to get into the summer and Christmas spirit. Lots of planning, things to do and people to see. As well as needing to go out any buy/make presents. And then work, which is also hectic with everyone wanting their jobs done before Christmas. So, it has been a busy week and the fact that our social calendar has also been rather busy hasn’t alleviated any of that pressure. But I was glad when Friday finally rolled around.

The week started off pretty well to be fair, we were all relaxed from our weekend at the lake, and although the weather wasn’t the best there, we were all able to put our feet up for a bit and enjoy being on holiday. As well as feeling refreshed, both Monday and Tuesday were both gorgeous days. Finally, we felt as if summer had started, there were clear blue skies and the hot kiwi sun. But it was short lived, Wednesday, Thursday and Friday were all miserably muggy wet days. I am beginning to wonder if it has always been like this or if I just brought the Belgian weather of grey skies with me in my suitcase. So far, we are yet to experience the kiwi summer and suntans that we were looking forward to. But enough about the weather, although I know it is a favourite subject to complain about for all Belgians.

As I was saying I have been busy at work, everyone is in a Christmas tizz and all want their jobs done before the holidays, although I don’t really understand their urgency as it is not like they are going to read my reports over their summer whilst sipping beers on the decks… well I wouldn’t be, and if they are, I feel sorry for them. Lately I seem to be getting the brunt of the complicated jobs at work, and as much as I would like to relax and listen to podcasts on meditation like the Guru Benoit has been doing, I have been running around like a headless chicken telling people off. Mainly telling people ‘No you can’t build your house on this slip surface even though it has the best view’ and ‘no you can’t build a commercial building on an old dumping site’ and ‘no, Dougal (my boss) I am not doing that horrible job just because you don’t want or a too lazy to do so’, oh the joys. I am seriously beginning to miss our six-month holiday. But luckily, we have a goal, and the tiny house needs money and that is enough motivation for me. Enough motivation that I stood outside in the rain for four hours on Wednesday morning monitoring a CPT (Cone Penetration Testing) test for the old dumping site. The guys that had the drill rig told me it was the worst site that they had ever seen, which funnily enough I could believe. I have been telling my boss we should run away while we can from this site as I can tell it is just going to be one of those nightmare jobs. Our goal was to do six CPTs down to 30m, we tried 14 times in different places and only got down once to 29m, the rest we got blocked after 2m because of all the concrete and mess that has been buried on the site over the years. Not that it is probably of interest, but CPT testing is very interesting, essentially there is a big robot-like machine that moves around with a handheld control. Once the spot is chosen, it drills down into the ground to anchor itself to the site, and then it pushed meters and meters of steel rod into the ground with a electronic point which picks up on the soil density, pore pressure, tip pressures, water content and all sorts of interesting geotechnical data that can help me analyse what type of soils we are getting at depth, very interesting, but not so much fun in the pouring rain with no luck. I will post some photos of the machine and the results (and although I am complaining about work, I am glad to have it, I am really enjoying being back in the Geotechnical field, and glad to be making enough money to support my little Belgian boy and our tiny house project).

What else is new. Well, this weekend it was Mums big birthday weekend, after weeks of me nudging the boys to get into gear and start organising things we finally got everything ready to make her weekend the best possible. Benoit and I asked Jamie to get all the tools and materials that we need to start the retaining wall that Mum is wanting, we figured that one of the best things we could do for her would be to get started on the retaining wall, so while Jamie worked on the finishing touches of his van (which is a work of art by the way, and he finished it off this weekend for the most part and it is stunning, I am immensely proud of him), Benoit and I spent our days getting levels, digging holes and asking our resident builder for advice when we needed it. On Saturday night we celebrated the big birthday with Gran and Deeda at a lovely Japanese restaurant.

And on Sunday, the actual day of Mums birthday, we threw a big party. Dad loves a good party and had been trying to convince Mum that throwing a party was what she wanted to do. I am not sure if yes eventually said yes because she wanted to or just because Dad was so keen for a party that she caved and let him have some fun. We spent a few evenings decorating the place with fairylights and inviting people, getting the menu ready, and Sunday night went off with a bang. It was a lovely evening, a good little crowd showed up and Mum celebrated in style. A great pre-Christmas catch up with all our close friends and family, and a great celebration for Mum.

Next week, it is Benoits turn to write the blog, so I will next message you all in the new year. I hope you all have a great Christmas, and although I only got to share covid Christmases with you all, I have great memories from them and will be thinking of you all over the holidays. Have a good one and I hope you get that snow that’s been promised. I am hoping for a good old kiwi Christmas with summer, bbqs, sunburn and beers, and maybe a water ski or two!

Love Kate and Ben xxx

1 note

·

View note

Text

The Importance of a Hardness Tester in Materials Production – Multitek Technologies

The hardness of a material is the property that enables it to resist deformation, bending, scratching, abrasion, or cutting. If you work in materials manufacturing, you probably already know that a hardness test is a crucial step in the production process for your products and the products you receive from third-party suppliers. You need to set baseline measurements and ensure that your products meet specific standards for strength. But if you’re not a materials engineer, you may be surprised to know that the hardness of any material is not an intrinsic property dictated by precise definitions and fundamental units of mass, length, or time. Instead, the value of a material’s hardness is the result of a specific measurement procedure.

For most materials of the modern age, a hardness test has usually been performed through a device that measures depth of an indentation left by a point of a specific shape, with a specific force, and for a specific amount of time. The most Knoop/Vickers Automated Hardness Testercommon hardness tests that measure the relationship between hardness and the size of the impression left by the test are the Rockwell, Brinell, and Vickers hardness tests.

Rockwell hardness tests are the most common type of hardness test available, and for good reason: it’s an incredibly fast and reliable method to determine the hardness of metals, alloys, and plastics, when compared to other methods. In the test, a diamond cone or hardened steel ball indenter is forced into the material being tested with a preliminary force that is usally 10 kgf. After equilibrium is reached, an additional load is applied which causes greater penetration of the material. Once equilibrium is reached again, the additional load is removed and the material rebounds slightly. The permanent depth of the indentation that remains is then used to calculate the Rockwell hardness number.

We at Multitek Technologies offer many testers which are used to measure not only Rockwell hardness, but also Brinell, Vickers, and Knoop tests. Give us a call or use our convenient online ordering to get the tester you need today. Browse our entire selection of hardness testers.

0 notes