#Conductive Inks Market Forecast

Explore tagged Tumblr posts

Text

Chipless RFID Market Research Report, Demand and Future Trends Till 2037

The chipless RFID market is on a rapid expansion trajectory. By the close of the forecast period in 2037, global revenues are projected to reach approximately USD 12.7 billion, representing a compound annual growth rate (CAGR) of 16.8% from 2025 through 2037. This strong upward curve is underpinned by escalating adoption across diverse end-use sectors, economies of scale in tag production, and ongoing breakthroughs in printing-based identification technologies.

While exact figures for the 2025 baseline vary by source, most industry estimates place the market at just over USD 2.5 billion in that year, implying a near five-fold increase over the dozen-year span.

Chipless RFID Industry Demand

Chipless RFID refers to radio-frequency identification systems that encode data directly into the physical geometry or dielectric properties of inexpensive, printed substrates—eliminating the need for silicon chips. These tags can be mass-produced via roll-to-roll printing or laser-etching on plastics and papers, and are read by specialized readers that detect variations in backscatter or resonance patterns.

Cost-Effectiveness: Without the cost of a silicon IC, chipless tags can be manufactured for mere fractions of a cent apiece, making them ideal for low-margin items and disposable applications.

Ease of Administration: The simple physical encoding allows straightforward bulk production and integration into existing packaging or documents without altering form-factors.

Long Shelf Life and Durability: Chipless tags lack moving parts or sensitive semiconductors, granting them exceptional stability in harsh environments, over long storage periods, and across a wide temperature range.

Sustainability Angle: Many chipless substrates are based on recyclable or bio-derived materials, aligning with growing regulatory and corporate sustainability mandates.

Chipless RFID Market: Growth Drivers & Key Restraint

Growth Drivers –

Advances in Printable Electronics: Continued improvements in conductive inks, laser-etch technologies, and high-resolution printing have expanded the data capacity and read reliability of chipless tags, opening new use cases beyond basic inventory tracking.

Surge in Asset Tracking & Serialization Needs: Industries such as pharmaceuticals (driven by stringent anti-counterfeiting regulations and the prevalence of chronic diseases requiring precise drug supply-chain oversight) and fresh perishables logistics increasingly demand granular, tamper-proof item-level monitoring—a sweet spot for ultra-low-cost, disposable tags.

Outsourcing & Contract Manufacturing Trends: As more original equipment manufacturers (OEMs) and consumer-packaged goods companies shift production to third-party contractors in emerging economies, the need for standardized, easy-to-apply chipless labels has skyrocketed, simplifying quality control across geographically dispersed facilities.

Restraint –

Limited Read Range & Data Density Compared to Chipped RFID: Despite rapid progress, chipless RFID currently offers shorter read distances (often under 1 meter) and lower payload capacities than traditional silicon-based tags, which can hinder adoption in applications demanding long-range or high-security data exchange.

Request Report Sample@ https://www.kennethresearch.com/sample-request-10352550

Chipless RFID Market: Segment Analysis

Segment Analysis by Product Type (Tags, Readers:) –

Tags: Accounting for the majority of units shipped, printed chipless tags see robust demand due to their minimal unit cost, ease of integration into packaging lines, and disposability. Volumes are highest in sectors requiring item-level serialization—particularly pharmaceuticals and fast-moving consumer goods—while maturity in printing processes continues to drive down per-tag expenses.

Readers: The reader market, though smaller in unit count, has experienced steady growth as enterprises deploy fixed and handheld scanners tailored for chipless frequencies. Investment in multi-mode readers (capable of handling both chipless and chipped RFID) is a notable trend, enhancing flexibility but adding to device complexity and cost.

Segment Analysis by Application (Smart Cards, Smart Tickets)–

Smart Cards: Chipless solutions in secure credentialing leverage custom resonance patterns to store small payloads (e.g., authentication tokens), appealing where near-field reads suffice and chip-based cards are deemed excessive. Adoption is nascent but growing in campus access, event accreditation, and limited-run loyalty programs.

Smart Tickets: For transport and venue control, single-use chipless tickets allow for instant distribution and sustainable disposal, while delivering reliable near-field reads at turnstile access points. Pilot programs in metropolitan metro systems and large-scale festivals are validating the value proposition.

Segment Analysis by End‑User –

Retail: Item-level tagging for loss prevention, streamlined checkout, and demand forecasting constitutes the largest application slice, especially in apparel and small electronics.

Healthcare: From surgical kit tracking to specimen monitoring and pharmaceutical authentication, healthcare providers prize chipless RFID for sterile-environment compatibility and waste reduction.

Logistics & Transportation: Pallet and package routing in last-mile delivery leverages chipless labels to reduce per-unit tagging costs, particularly for low-value parcels.

BFSI (Banking, Financial Services & Insurance): The segment is experimenting with chipless-based access credentials and paper-based document tracking—still an emerging frontier but one likely to benefit from enhanced anti-fraud measures.

Chipless RFID Market: Regional Insights

North America: The United States is spearheading reader installations and pilot rollouts market thrives on substantial backing from major retail chains and pharmaceutical corporations. Regulatory encouragement around anti-counterfeit measures (e.g., FDA’s DSCSA) further accelerates uptake. Canada’s focus on cold-chain visibility in food and vaccine distribution also fuels growth.

Europe: Stringent environmental directives (e.g., EU Packaging Waste Regulation) and robust recycling targets position chipless tags—often recyclable with primary packaging—favorably. Key driver segments include luxury goods authentication in Western Europe and parcel tracking in Eastern European e-commerce corridors.

Asia-Pacific (APAC): Fastest-growing region by percentage, APAC benefits from large-scale contract manufacturing hubs in China, India, and Southeast Asia. Government initiatives supporting “Industry 4.0” smart factories, coupled with booming e-commerce logistics networks, underlie strong demand.

Access our detailed report at: https://www.kennethresearch.com/report-details/chipless-rfid-market/10352550

Key Suppliers Shaping the Chipless RFID Arena

Distinguished vendors in this space include Impinj Inc., Alien Technology and NXP Semiconductors. hardware specialists such as Zebra Technologies, Honeywell International, and SATO Holdings; large-scale technology providers like Samsung SDS, Siemens AG, Toshiba Tec, and Fujitsu; and niche innovators including Identiv Inc., Avery Dennison, Thinfilm Electronics (Smartrac), GAO RFID, and Wiliot. Tertium Technology, RFID4U, Securitag Assembly Group (SAG), Tego Inc., and RFID Global Solution represent the leading vendors shaping the chipless RFID landscape, each bringing distinct strengths in materials science, reader hardware, software integration, and global distribution networks.

0 notes

Text

Stretchable Electronics Market Economic Impact and Global Trade Dynamics to 2033

Introduction

Stretchable electronics represent a groundbreaking advancement in the field of flexible and wearable technology. These devices are designed to maintain their functionality even when stretched, bent, or twisted, making them highly suitable for applications in healthcare, consumer electronics, automotive, and various other industries. With ongoing research and development efforts, the stretchable electronics market is projected to experience significant growth over the forecast period from 2024 to 2032.

Download a Free Sample Report:-https://tinyurl.com/5efzj794

Market Dynamics

Market Drivers

Growing Demand for Wearable Devices The rising popularity of wearable devices, such as smartwatches, fitness trackers, and healthcare monitoring systems, has significantly contributed to the expansion of the stretchable electronics market. These devices require flexible and stretchable circuits that can conform to the shape of the human body without compromising performance.

Advancements in Material Science The development of innovative materials, such as conductive polymers, nanomaterials, and stretchable substrates, has played a crucial role in enhancing the durability and functionality of stretchable electronics. These materials improve the mechanical properties and electrical conductivity of the devices, ensuring their longevity and reliability.

Integration in Healthcare Applications Stretchable electronics are increasingly being utilized in medical applications, including electronic skin (e-skin), biosensors, and implantable devices. The ability of these electronics to conform to the human body makes them ideal for continuous health monitoring and early disease detection.

Rising Investments in Research and Development Governments, research institutions, and private companies are heavily investing in the development of stretchable electronic components. These investments are aimed at enhancing product performance, reducing production costs, and expanding application areas.

Market Restraints

High Production Costs The manufacturing process for stretchable electronics is complex and expensive due to the requirement for specialized materials and fabrication techniques. This cost factor poses a challenge to the widespread adoption of these devices.

Technical Challenges Ensuring long-term reliability, stability, and seamless integration with existing electronic systems remains a challenge for manufacturers. Overcoming these technical hurdles requires continuous innovation and improvements in design and production techniques.

Limited Awareness and Adoption Despite their potential benefits, the adoption of stretchable electronics is still in its early stages. Many industries and consumers are yet to fully understand the advantages of this technology, limiting market penetration.

Market Segmentation

By Component

Stretchable Circuits

Stretchable Batteries

Stretchable Conductors

Electroactive Polymers

By Application

Consumer Electronics (Wearable devices, smart clothing, etc.)

Healthcare (Biomedical devices, prosthetics, biosensors, etc.)

Automotive (Flexible displays, sensors, and in-car electronics)

Aerospace & Defense (Flexible antennas, monitoring devices, etc.)

Others (Soft robotics, industrial applications, etc.)

By Region

North America (U.S., Canada, Mexico)

Europe (Germany, UK, France, Italy, Rest of Europe)

Asia-Pacific (China, Japan, South Korea, India, Rest of Asia-Pacific)

Latin America (Brazil, Argentina, Rest of Latin America)

Middle East & Africa (UAE, Saudi Arabia, South Africa, Rest of MEA)

Competitive Landscape

Key players in the stretchable electronics market are focusing on product innovation, strategic partnerships, and acquisitions to gain a competitive edge. Some prominent companies include:

DuPont

MC10 Inc.

NextFlex

Tacterion GmbH

E Ink Holdings Inc.

Cambridge Display Technology Ltd.

PowerFilm, Inc.

Future Outlook

The future of stretchable electronics looks promising, with continuous advancements in material science, increasing investment in research and development, and growing adoption across various industries. The healthcare sector, in particular, is expected to be a major driver of growth, as these electronics become more integrated into medical diagnostics and treatment solutions.

Conclusion

The stretchable electronics market is poised for rapid growth over the next decade, driven by technological advancements, rising demand for wearable devices, and increasing applications in healthcare and other industries. Despite challenges such as high production costs and technical limitations, ongoing research and industry collaboration are expected to drive innovation and expand market opportunities. As the technology matures, stretchable electronics will play a crucial role in shaping the future of flexible and wearable technology.Read Full Report:-https://www.uniprismmarketresearch.com/verticals/semiconductor-electronics/stretchable-electronics.html

0 notes

Text

Emerging Trends in the Conductive Polymers Market: Innovations and Applications

Growing Demand for Lightweight, Flexible, and High-Performance Electronics Drives Expansion of the Conductive Polymers Market.

The Conductive Polymers MarketSize was valued at USD 5.92 Billion in 2023 and is expected to reach USD 11.88 Billion by 2032 and grow at a CAGR of 8.07% over the forecast period 2024-2032.

The Conductive Polymers Market is witnessing significant growth due to the increasing demand for lightweight, flexible, and highly conductive materials across various industries, including electronics, automotive, healthcare, and energy storage. Conductive polymers offer advantages such as high conductivity, corrosion resistance, and environmental stability, making them ideal for applications in smart devices, sensors, batteries, antistatic coatings, and OLED displays. With technological advancements and growing investments in wearable electronics and renewable energy, the market is set for rapid expansion.

Key Players in the Conductive Polymers Market

3M (VHB Tapes, Scotch-Weld Adhesives)

Solvay (Solef PVDF, Hyflon PFA)

SABIC (Noryl Resin, Lexan Polycarbonate)

PolyOne Corporation (OnForce LFT, Gravi-Tech)

Lehmann & Voss & Co. (LUVOCOM, LUVOBATCH)

Advanced Polymer Materials Inc. (Conductive Polymer Coatings, Adhesive Systems)

Agfa-Gevaert Group (Orgacon, Electroconductive Inks)

Celanese Corporation (Fortron PPS, Celstran CFR-TP)

Eeonyx (EeonTex, Conductive Coatings)

Heraeus Holding (Clevios PEDOT, Silver Nanowires)

Future Scope of the Market

The conductive polymers market is expected to grow substantially, driven by:

Rising demand for flexible and wearable electronics in consumer applications.

Increasing adoption in energy storage devices, including supercapacitors and advanced batteries.

Development of biodegradable and eco-friendly conductive polymers for sustainable applications.

Integration in automotive electronics, including touch sensors and smart dashboards.

Advancements in polymer nanocomposites, enhancing conductivity and mechanical strength.

Emerging Trends in the Conductive Polymers Market

The conductive polymers industry is evolving with a strong emphasis on flexibility, sustainability, and enhanced conductivity. There is an increasing focus on biodegradable conductive polymers, addressing environmental concerns associated with electronic waste. Moreover, conductive polymer-based coatings are being widely used in antistatic packaging, EMI shielding, and smart textiles. The rise of 5G technology and miniaturized electronic components is further driving innovation in conductive polymer materials, making them an essential part of the next generation of high-performance electronic devices.

Key Points:

Growing demand for conductive polymers in flexible and wearable electronics.

Increasing use in supercapacitors, batteries, and energy storage solutions.

Advancements in biodegradable and sustainable conductive polymer materials.

Expansion in automotive applications for smart and interactive vehicle interiors.

Rising investments in polymer nanocomposites to enhance conductivity and durability.

Conclusion

The Conductive Polymers Market is set for strong growth, driven by the expanding electronics industry, increasing adoption of energy-efficient materials, and rising demand for lightweight and flexible alternatives to traditional conductive materials. With ongoing research and advancements in sustainable and high-performance conductive polymers, the market is expected to witness substantial innovation and commercialization opportunities in the coming years.

Read Full Report: https://www.snsinsider.com/reports/conductive-polymers-market-4742

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Conductive Polymers Market#Conductive Polymers Market Size#Conductive Polymers Market Share#Conductive Polymers Market Report#Conductive Polymers Market Forecast

0 notes

Text

Role of Customization in the Growing Print On Demand Market

The global Print On Demand market size is expected to reach USD 38.21 billion by 2030, growing at a CAGR of 25.8% over the forecast period, according to a new study conducted by Grand View Research, Inc. The increasing demand for personalized and customized apparel, rising disposable income, growing internet penetration & smartphone adoption, and the positive influence of the entertainment industry are some of the factors fueling the growth of the market.

Print on demand technology enables artists, designers, writers, and numerous entrepreneurs to sell custom-designed products by collaborating with white-label product suppliers. It eliminates the need to maintain an inventory, as after the confirmation of a sale; the supplier takes care of the order, including printing to shipping. Thus, with the increasing demand for personalized products, the growth of the print on demand industry is expected to rise exponentially shortly.

Print On Demand Market Report Highlights

The services segment is expected to witness the fastest CAGR of 28.2% from 2023 to 2030. The segment's growth can be attributed to an increasing number of service providers offering drop shipping and comprehensive fulfillment services, covering the entire process from production to delivery

The integrated software sub-segment dominated the market, accounting for a share of 59% in 2022. The software's ability to integrate with numerous e-commerce platforms offering ease of use and other customization aspects to enhance user shopping experience is attributed to the segment's growth

The apparel segment dominated the market in 2022, accounting for nearly 40% of the revenue share. The rapid transition towards custom-made fashion apparel and fast penetration of on-demand t-shirt printing are the major factors driving the growth of this segment

For More Details or Sample Copy please visit link @: Print On Demand Market Report

The market has also benefitted from growing investments and the shift from brick-and-mortar to online business models, which drive the growth of print on demand. Global consumers' rapidly changing consumption patterns and the preference for hybrid shopping have further bolstered the market's growth.

The COVID-19 pandemic had both positive & negative impacts on the POD industry. In the initial emergence of COVID-19 in 2020, almost every industry was affected due to restrictions like lockdowns and social distancing measures imposed on business operations and processes. The pandemic disrupted global supply chains worldwide, impacting the availability of raw materials and technologies for the print on demand service providers. POD businesses heavily rely on definitive suppliers for raw materials, including standard apparel, accessories, inks, and printing equipment. Delays in production and shipping caused by factory closures, transportation challenges, and reduced workforce led to longer fulfillment times and potential customer dissatisfaction.

On the other hand, the adoption of online business models and changing preferences of consumers to buy goods from online retail platforms over local stores led to a huge surge in e-commerce sales, including the print on demand industry. As the demand for POD products increased, more entrepreneurs entered the market, leading to increased competition. New POD platforms emerged, offering various customization options and faster fulfillment. Established players had to adapt and innovate to maintain their market share.

Furthermore, the increasing disposable income of various consumer categories has expanded the opportunities for print on demand products. Consumers are more willing to invest in personalized clothing, accessories, home decor, and other items that reflect their individuality. With more disposable income, consumers explore niche markets and seek exclusive or premium items. POD businesses can leverage this trend by offering limited edition or high-end customized products that cater to specific interests, hobbies, or communities. This allows them to attract customers willing to spend more on unique and specialized goods.

The print on demand industry is highly competitive. Leading industry players are adopting strategies such as partnerships, collaborations, mergers and acquisitions, and agreements to survive the highly competitive environment and enhance their business footprints. In September 2022, Canva introduced Canva print products within its on-demand printing services. The company aimed to expand its print catalog, by offering doorstep delivery, free in-store pickup with automated proofing, and a 1 to 3-day turnaround time at affordable prices.

List of Key Players in the Print On Demand Market

Printify, Inc.

Printful Inc.

Canva

VistaPrint (Cimpress)

CustomCat

Gelato

Gooten

Printed Mint

We have segmented the global print on demand market based on platform, product, and region.

#PrintOnDemand#PODMarket#CustomPrinting#EcommerceBusiness#OnlinePrinting#PODTrends#AIinPrinting#SustainablePrinting#PODBusiness#EcommerceGrowth

0 notes

Text

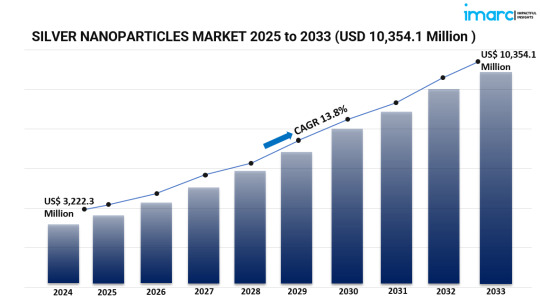

Silver Nanoparticles Market Analysis: Growth Drivers, Segmentation, and Key Players

Market Overview:

The global silver nanoparticles market reached a valuation of USD 3,222.3 million in 2024 and is projected to expand at a compound annual growth rate (CAGR) of 13.8%, reaching USD 10,354.1 million by 2033. Silver nanoparticles (AgNPs), ranging between 1 nm to 100 nm in size, are renowned for their unique properties, including high electrical and thermal conductivity, chemical stability, corrosion resistance, and notable antimicrobial effects. These attributes have led to their widespread application across various industries, notably in healthcare for antimicrobial coatings and in electronics for conductive components.

Study Assumption Years:

Base Year: 2024

Historical Years: 2019–2024

Forecast Years: 2025–2033

Silver Nanoparticles Market Key Takeaways:

Market Size and Growth: The global silver nanoparticles market was valued at USD 3,222.3 million in 2024 and is anticipated to reach USD 10,354.1 million by 2033, exhibiting a CAGR of 13.8% during the forecast period.

Diverse Applications: Silver nanoparticles are extensively utilized in sectors such as electronics and IT, healthcare and life sciences, textiles, food and beverages, pharmaceuticals, cosmetics, and water treatment, owing to their unique properties.

Synthesis Methods: The predominant synthesis methods for silver nanoparticles include wet chemistry, ion implantation, and biological techniques, each offering distinct advantages tailored to specific applications.

Shape Variants: Silver nanoparticles are manufactured in various shapes, including spheres, platelets, rods, and colloidal silver particles, with each shape influencing their functional properties and suitability for different applications.

Regional Leaders: North America and Europe lead the market, attributed to their advanced healthcare infrastructure and robust electronics industries. Meanwhile, the Asia-Pacific region is experiencing accelerated growth due to rapid industrialization and technological advancements in countries like China and India.

Request for a sample copy of this report: https://www.imarcgroup.com/silver-nanoparticles-market/requestsample

Market Growth Factors:

Report on Advancements in Electronics Technology: This significant revolution in electronics has happened mostly with respect to miniaturization of components and of flexible electronics. As far as these applications are concerned, it is because of the remarkable electrical conductivity and stability of silver nanoparticles that these become important. Thus, these mostly participate in the manufacturing of conductive inks to be utilized mainly in circuits, touch screens, and radio-frequency identification (RFID) equipment. New generation consumers always demand small size, efficient and high-performance electronic devices. As a consequence, it motivates the market penetration of silver nanoparticles, thus arising.

Health Related and Antimicrobial Purposes: These silver nanoparticles are capable of showing very good antimicrobial activities. Thus, they find innumerable applications in health systems. In fact, these are being used in various medical devices, as potent wound dressings, and also in coatings meant to prevent infections or treat patients. High awareness regarding infection has been developed now especially in health facilities. This is why these fabricated materials are being used more and more for their outstanding properties. Their use is also general in the drug delivery system and in the diagnostic tools used in health fields.

Eco-Friendly Innovations in Agriculture and the Environment: Silver nanoparticles have been marketed especially for environmental and agricultural sectors because of their properties related to sustainable and eco-friendly solutions. The antimicrobial property of silver nanoparticles is used to purify the water from the pathogenic organisms present in the infected water and make it potable. Researches of this silver nanoparticle technology have also been emphasized and invested in because it is in line with global sustainability goals that have improved yield and food accessible to most people by using silver nanoparticles for crop protection and as growth enhancers.

Market Segmentation:

By Synthesis Method:

Wet Chemistry: A traditional approach involving chemical reactions in liquid solutions to produce silver nanoparticles.

Ion Implantation: A technique where silver ions are embedded into substrates to form nanoparticles, often used for precise applications.

Biological: An eco-friendly method utilizing biological entities like plants or microorganisms to synthesize silver nanoparticles.

By Shape:

Spheres: Commonly used due to their uniformity and ease of synthesis, suitable for various applications.

Platelets: Flat, plate-like nanoparticles offering unique optical properties, useful in specific technological applications.

Rods: Elongated nanoparticles that exhibit distinct electrical and optical characteristics, beneficial in electronics and photonics.

Colloidal Silver Particles: Stable suspensions of silver nanoparticles in a fluid, widely used in medical and antimicrobial products.

Others: Includes various shapes like cubes or wires, tailored for specialized applications.

By End Use Industry:

Electronics and IT: Utilization in conductive components, sensors, and flexible electronics due to superior electrical properties.

Healthcare and Lifesciences: Incorporation into medical devices, antimicrobial coatings, and drug delivery systems.

Textiles: Integration into fabrics to impart antimicrobial properties, enhancing hygiene and durability.

Food and Beverages: Application in packaging materials to extend shelf life and ensure food safety.

Pharmaceuticals: Use in formulations for enhanced therapeutic efficacy and controlled release.

Cosmetics: Inclusion in products for antimicrobial benefits and improved skin health.

Water Treatment: Employment in filtration systems to purify water by eliminating microbial contaminants.

Others: Encompasses additional sectors like renewable energy and catalysis where silver nanoparticles are applied.

Breakup by Region:

North America (United States, Canada)

Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

Latin America (Brazil, Mexico, Others)

Middle East and Africa

Regional Insights:

North America currently leads the global silver nanoparticles market, driven by advanced healthcare infrastructure and a robust electronics industry. The region’s focus on technological innovation and extensive research and development activities further bolster its market dominance. Additionally, the presence of key industry players contributes to sustained growth and the rapid adoption of silver nanoparticle applications across various sectors.

Recent Developments & News:

The silver nanoparticles market has experienced notable advancements, particularly in antimicrobial applications. Their unique properties, such as high electrical conductivity and optical characteristics, make them effective against bacteria and harmful microorganisms. This has led to increased demand in healthcare settings for infection control. Additionally, the electronics industry has embraced silver nanoparticles for their conductive properties, enhancing the performance of electronic devices.

Key Players:

American Elements

Meliorum Technologies Inc.

Merck KGaA

nanoComposix (Fortis Life Sciences LLC)

Nanocs Inc.

Nanoshel LLC

Strem Chemicals Inc. (Ascensus Specialties LLC)

ThermoFisher Scientific Inc.

These companies play pivotal roles in shaping the future of the silver nanoparticles industry through continuous innovation and strategic initiatives.

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=5002&flag=C

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

0 notes

Text

Printed Electronics Revolution: The Rise of Conductive Inks

The global conductive ink market size is expected to reach USD 4913.8 million by 2030, according to a new study by Grand View Research, Inc. The market is expected to expand at a CAGR of 6.0% from 2022 to 2030. Increasing demand for efficiency and miniaturization, and emerging applications to drive the market growth are some of the key factors that are presumed to drive the regional markets. R&D initiatives to develop superior robust products that have a wide application base across diverse industries offer ample opportunities for market development.

The surge in demand for properties such as smaller size, better energy efficiency, and better durability, conductive inks are used as a substitute for traditional wire circuits is anticipated to be beneficial for the overall market growth. Research initiatives to develop cost-effective raw materials, such as copper, nickel, and graphene, which have properties similar to that of silver, are projected to further aid in market growth in the near future. The research initiatives are undertaken by both government and industry participants and are expected to increase multiple potential applications, which in turn are projected to complement the global market growth.

The market has been segmented into three segments on the basis of product, application, and region. Major products of conductive Ink include conductive silver ink, conductive copper ink, conductive polymers, carbon nanotube ink, dielectric inks, and carbon/graphene ink. conductive silver ink dominated the market demand for the last few years. Prominent conductive Ink applications include photovoltaic, Membrane switches, Displays, Automotive, Smart packaging, biosensors, printed circuit boards, and other applications. Photovoltaic applications dominated the global market.

Regionally, the market has been segmented into North America, Europe, Asia Pacific, Central and South America, and the Middle East and Africa. The Asia Pacific occupied the largest market share in the recent past. Macroeconomic factors in the Asia Pacific such as the expanding middle class, rising disposable incomes, education, changing demographics, and rapid urbanization are driving the market in the region. The demand for conductive inks in consumer electronics is high in the region. The rising presence of key players in the Asia Pacific is also estimated to boost the overall growth of the market. Economies such as China, South East Asia, and India are projected to lead the regional market.

Conductive Ink Market Report Highlights

Asia Pacific dominated the market and is expected to witness the fastest CAGR of 6.3% in terms of revenue during the forecast period

Conductive silver ink was estimated to be the largest product segment in the market in 2021 and is also anticipated to dominate the market during the forecast period

Photovoltaic was estimated to be the largest application segment in the market in 2021 with a revenue share of more than 21.0% and is also anticipated to dominate the market during the forecast period

Conductive Ink Market Segmentation

Grand View Research has segmented the global conductive ink market on the basis of product, application, and region:

Conductive Ink Product Outlook (Volume, Kilotons, Revenue, USD Million, 2019 - 2030)

Conductive silver ink

Conductive copper ink

Conductive polymers

Carbon nanotube ink

Dielectric inks

Carbon/Graphene ink

Others

Conductive Ink Application Outlook (Volume, Kilotons, Revenue, USD Million, 2019 - 2030)

Photovoltaic

Membrane switches

Displays

Automotive

Smart packaging

Biosensors

Printed circuit boards

Other aplications

Conductive Ink Regional Outlook (Volume, Kilotons, Revenue, USD Million, 2019 - 2030)

North America

US

Europe

Germany

France

UK

Asia Pacific

China

India

Japan

Central & South America

Brazil

Middle East & Africa

Key Players of the Conductive Ink Market

DuPont

Vorbeck Materials Corp.

Applied Nanotech Holdings, Inc.

Sun Chemical Corporation

PPG Industries, Inc.

Creative Materials, Inc.

Poly-Ink

Henkel Ag & Co. KgaA

PChem Associates, Inc.

Johnson Matthey Colour Technologies

Fujikura Ltd.

Heraeus Holding

Nagase America Corporation

Engineered Materials Systems

Epoxies, Etc

Voxel8

Methode Electronics

Novacentrix

Johnson Matthey

Order a free sample PDF of the Conductive Ink Market Intelligence Study, published by Grand View Research.

0 notes

Text

0 notes

Link

0 notes

Text

The Metal And Metal Oxide Nanoparticles Market is projected to grow from USD 36340.4 million in 2024 to an estimated USD 86813.77 million by 2032, with a compound annual growth rate (CAGR) of 11.5% from 2024 to 2032. The global market for metal and metal oxide nanoparticles is experiencing rapid growth, driven by technological advancements, increasing demand across various industries, and the unique properties of these nanoparticles. These nanomaterials, typically ranging between 1 and 100 nanometers in size, exhibit exceptional physical, chemical, and mechanical properties.

Browse the full report at https://www.credenceresearch.com/report/metal-and-metal-oxide-nanoparticles-market

Market Overview

Metal and metal oxide nanoparticles are engineered at the atomic level to deliver superior performance in applications such as electronics, healthcare, energy, and environmental protection. Metals like gold, silver, copper, and platinum, as well as oxides of titanium, zinc, and iron, dominate this market due to their versatile applications and cost-effectiveness. The market’s expansion is attributed to the rising demand for advanced materials in industries such as electronics, pharmaceuticals, and renewable energy.

Key Drivers

Growing Applications in Healthcare The healthcare industry is one of the largest consumers of metal and metal oxide nanoparticles. Silver nanoparticles, for instance, are widely used for their antimicrobial properties in wound dressings and coatings. Similarly, gold nanoparticles are used in diagnostic imaging and cancer therapy due to their biocompatibility and unique optical properties.

Advancements in Electronics The electronics sector significantly benefits from the conductive, magnetic, and optical properties of metal nanoparticles. Silver nanoparticles are commonly used in printed electronics and conductive inks, while titanium dioxide nanoparticles enhance the performance of semiconductors and solar cells.

Environmental Applications Metal oxide nanoparticles play a crucial role in environmental remediation. Titanium dioxide and zinc oxide nanoparticles are extensively used in photocatalytic degradation of pollutants, water purification, and air filtration systems. The increasing emphasis on sustainability is propelling the demand for these materials.

Increased Research and Development Continuous investment in R&D has led to the discovery of novel applications and improved production techniques for nanoparticles. The introduction of cost-effective and environmentally friendly manufacturing processes is further driving market growth.

Market Challenges

Despite its growth potential, the metal and metal oxide nanoparticles market faces several challenges:

High Production Costs The synthesis of nanoparticles requires advanced equipment and raw materials, which can be expensive. High production costs often translate to higher product prices, limiting their accessibility for smaller manufacturers.

Environmental and Health Concerns The potential toxicity and environmental impact of nanoparticles remain critical concerns. Improper disposal of these materials can pose risks to ecosystems and human health, necessitating stringent regulatory frameworks.

Regulatory Hurdles The lack of standardized regulations across regions poses challenges for manufacturers and end-users. Regulatory uncertainty can delay product launches and impede market growth.

Future Opportunities

Emerging Markets Developing economies in Asia, Africa, and South America present untapped opportunities for market expansion. Increasing industrial activities and government initiatives to promote nanotechnology are driving demand in these regions.

Integration with Artificial Intelligence (AI) The integration of AI and machine learning with nanoparticle research is expected to accelerate innovation. Predictive modeling and simulation techniques can optimize production processes and discover new applications for nanoparticles.

Sustainable Nanoparticles With growing environmental concerns, the development of green synthesis methods for nanoparticles is gaining traction. Utilizing plant extracts, microbes, and other sustainable resources for nanoparticle production is a promising area of research.

Key Player Analysis:

American Elements

Meliorum Technologies Ltd

NanoComposix Inc.

Nanophase Technologies Corporation

Nanoshel LLC

Nanostructured & Amorphous Materials, Inc.

Shanghai Huzheng Nanotechnology Co., Ltd

Sigma-Aldrich Co LLC

Tekna Plasma Systems Inc

The USA Research & Nanomaterials Inc.

Segmentation:

By Material Type

Metal Nanoparticles:

gold

silver

platinum

copper

aluminum

nickel

other metals

Metal Oxide Nanoparticles:

zinc oxide

iron oxide

aluminum oxide

cerium oxide

silicon dioxide

titanium dioxide

and others.

By Application

Healthcare and Biomedical

Electronics and Optoelectronics

Energy

Environmental Applications

Chemical and Catalytic Applications

Other Applications

By. End-Use Industry

Healthcare

Electronics

Energy and Power

Chemical Manufacturing

Environment and Water Treatment

Textiles and Packaging

By Region

North America

U.S.

Canada

Mexico

Europe

Germany

France

U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of the Middle East and Africa

Browse the full report at https://www.credenceresearch.com/report/metal-and-metal-oxide-nanoparticles-market

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

0 notes

Text

Polyester Fiber Board Market: Insights and Forecast to 2033 | Market Strides

Uncover the latest trends and insights in the Polyester Fiber Board Market with our comprehensive market size and forecast for 2025-2033. Learn about the different types of Polyester Fiber Board Market and their impact on the industry, as well as the competitive landscape and key suppliers.

Polyester Fiber Board Market

The Global Polyester Fiber Board Market size is projected to grow at a CAGR of XX% during the forecast period.

Research Methodology

Our research methodology constitutes a mix of secondary & primary research which ideally starts from exhaustive data mining, conducting primary interviews (suppliers/distributors/end-users), and formulating insights, estimates, growth rates accordingly. Final primary validation is a mandate to confirm our research findings with Key Opinion Leaders (KoLs), Industry Experts, Mining and Metal Filtration includes major supplies & Independent Consultants among others.

The Global Polyester Fiber Board Market Report provides a 360-degree view of the latest trends, insights, and predictions for the global market, along with detailed analysis of various regional market conditions, market trends, and forecasts for the various segments and sub-segments.

Get Sample Report: https://marketstrides.com/request-sample/polyester-fiber-board-market

LIST OF KEY COMPANIES PROFILED:

Sun Chemical Performance Pigments

ENKANA PRINTING INKS

Millian Inks

Chemicoat

Rupa Color Inks

Select Inks

GWIP

EL Nour

NiRY

Interstate Inks

DONECK EUROFLEX

Gabba Screen Printing Supplies

Tzah Printing Inks

Glory Inks

SEGMENTATION

By Type

3D

Flat

By Application

Sound Absorption

Decoration

Flame Resistance

Get In-Detail : https://marketstrides.com/report/polyester-fiber-board-market

Polyester Fiber Board Market REGIONAL INSIGHTS

North America

United States: The U.S. economy has shown resilience post-pandemic but faces inflationary pressures, particularly in housing and consumer goods. The Federal Reserve's interest rate policies remain a focus, as the balance between controlling inflation and avoiding recession has impacted spending, borrowing, and business growth. Key sectors like tech, finance, and renewable energy are experiencing dynamic changes, with AI, fintech, and green technology receiving heavy investments.

Canada: Economic stability remains a hallmark of Canada’s economy, although housing affordability and household debt are pressing issues. Canada continues to emphasize a green energy transition, investing in hydroelectric, wind, and solar power. The nation is also focused on attracting skilled labor, especially in technology, healthcare, and energy, as part of its economic strategy.

Mexico: Mexico has benefited from a nearshoring trend, as companies look to relocate manufacturing closer to the U.S. market. With a strong trade relationship via USMCA (the U.S.-Mexico-Canada Agreement), Mexico is seeing investments in its automotive, aerospace, and electronics industries. However, inflation, interest rates, and a need for infrastructure development remain areas of focus.

Buy Now : https://marketstrides.com/buyNow/polyester-fiber-board-market?price=single_price

FAQ

+ What are the years considered for the study?

+ Can the report be customized based on my requirements?

+ When was the Research conducted/published?

+ What are the mixed proportions of Primary and Secondary Interviews conducted for the study?

+ When will the report be updated?

𝐀𝐛𝐨𝐮𝐭 𝐔𝐬

Market Strides is a Global aggregator and publisher of Market intelligence research reports, equity reports, database directories, and economic reports. Our repository is diverse, spanning virtually every industrial sector and even more every category and sub-category within the industry. Our market research reports provide market sizing analysis, insights on promising industry segments, competition, future outlook and growth drivers in the space. The company is engaged in data analytics and aids clients in due-diligence, product expansion, plant setup, acquisition intelligence to all the other gamut of objectives through our research focus.

𝐂𝐨𝐧𝐭𝐚𝐜𝐭 𝐔𝐬:[email protected]

#Polyester Fiber Board Market Size#Polyester Fiber Board Market Share#Polyester Fiber Board Market Growth#Polyester Fiber Board Market Trends#Polyester Fiber Board Market Players

0 notes

Text

Flexography in Healthcare: Advancing Wearable and Smart Solutions

The global Flexography Printed Electronics Market, valued at US$ 1.9 billion in 2023, is projected to grow at an impressive CAGR of 10.9% from 2024 to 2034, reaching an estimated US$ 5.9 billion by the end of the forecast period. Flexography, a highly adaptable and cost-efficient printing technology, has evolved from traditional applications to play a pivotal role in emerging sectors like consumer electronics, healthcare, and smart packaging.

Flexographic printing utilizes flexible relief plates to directly print on diverse materials such as plastics, metals, and paper. This technology has increasingly been integrated with functional materials like PEDOT/PSS, silver-based, and dielectric inks, enabling the production of advanced electronics such as organic thin-film transistors (OTFTs), photovoltaic cells, and electrochromic displays. The expanding consumer electronics industry and rising demand for environmentally friendly printing solutions are key growth drivers.

Gain a deeper perspective by visiting our detailed report - https://www.transparencymarketresearch.com/flexography-printed-electronics-market.html

Key Drivers

Surge in Adoption of Conductive Inks: The growing use of conductive inks, particularly cost-effective silver-based inks, has been a major driver in the flexography printed electronics market. These inks are being increasingly used in printed circuit boards (PCBs), replacing expensive materials like platinum and gold to reduce production costs.

Demand for Smart Packaging: Flexography printed electronics are enabling innovations in smart packaging by integrating sensors, RFID tags, and QR codes to enhance product safety, improve inventory management, and boost consumer engagement. Real-time monitoring of parameters such as temperature and freshness has augmented the adoption of printed electronics in the packaging industry.

Rising Popularity of Flexible Displays: Flexography printed electronics facilitate the production of flexible, rollable, and transparent displays, which are increasingly used in wearable devices, automotive heads-up displays, and smart windows. This segment, accounting for 31.4% of the market in 2023, is projected to expand at a CAGR of 11.9% during the forecast period.

Market Challenges and Opportunities While the market presents immense opportunities, certain challenges such as high initial costs and the need for technological advancements in manufacturing processes remain. However, the shift toward eco-friendly materials and the development of cost-efficient production techniques present lucrative opportunities for new entrants and established players alike.

The transition to solvent-based silver conductive inks is expected to revolutionize manufacturing processes, enabling faster and more cost-effective production of printed electronics.

Key Player Strategies The global flexography printed electronics market is highly fragmented, with key players such as Henkel AG & Co. KGaA, InkTec Co., Ltd, and Jabil Inc. actively focusing on:

Product Innovations: Development of advanced inks and printing techniques.

Strategic Partnerships: Collaborating with technology providers to expand market reach.

Mergers and Acquisitions: Strengthening market presence and diversifying product portfolios.

For example, in May 2023, Henkel opened an adhesive technologies center in the U.S. to advance innovations in printed electronics. Similarly, XSYS launched the nyoflex FTV Digital photopolymer plate for high-quality flexographic printing, catering to the growing demand for flexible packaging solutions.

Market Segmentation

Material: Substrates (organic and inorganic) and inks (conductive, dielectric, semiconductive).

Application: Sensors & switches, displays, medical wearables, photovoltaic cells, antennas, heaters, in-mold electronics, and lighting.

Industry Vertical: Automotive and transportation, consumer electronics, healthcare, aerospace & defense, industrial, and others.

The consumer electronics segment, accounting for 37.8% of the market in 2023, is expected to grow at a CAGR of 11.5%. Key applications include wearable devices, smart appliances, and electronic toys.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA - Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Email: [email protected]

0 notes

Text

0 notes

Text

Textile Innovations: Transforming the Modern Textile Industry in 2024

Textile innovations are transforming one of the oldest and most dynamic sectors—reshaping the modern textile industry in unprecedented ways. As of 2024, advancements in textile manufacturing have introduced cutting-edge technologies, materials, and processes that significantly enhance efficiency, sustainability, and creativity. From smart textiles to sustainable manufacturing techniques, the industry is revolutionizing, creating exciting opportunities for manufacturers, designers, and consumers. This blog delves into the latest trends and innovations in the textile industry, presenting updated data and highlighting the key services offered by Rawalwasia Group

Textile Innovations Leading the Modern Textile Industry

Cutting-edge technologies are redefining how fabrics are produced, used, and perceived through innovations in textile manufacturing. Below are some of the most impactful innovations driving the modern textile industry:

Smart Textiles: Also known as e-textiles, smart textiles are fabrics embedded with sensors and conductive fibres. These textiles can monitor body vitals, adjust temperature, or even charge devices. For instance, athletes benefit from smart sportswear that tracks performance metrics.

3D Knitting and Printing: 3D knitting and printing technologies have streamlined the production of customised and seamless garments. This innovation minimises fabric waste, contributing to sustainable manufacturing.

Sustainable Textiles: The push for sustainability has led to the developing of eco-friendly fabrics like organic cotton, bamboo, and recycled polyester. According to a report by the International Textile Manufacturers Federation (ITMF), 65% of global textile manufacturers will have adopted sustainable practices in 2024.

Nanotechnology in Textiles: Nanotechnology enhances fabric properties, making them water-repellent, wrinkle-free, or antibacterial. This is particularly significant for medical and protective clothing.

Artificial Intelligence (AI) and Automation: AI is transforming the industry by optimising quality control, supply chain management, and inventory forecasting. Automated sewing robots and pattern-cutting machines have reduced production times significantly.

Digital Printing: Digital textile printing allows for vibrant and intricate designs without traditional screens or dyes. This technology saves water and ink, aligning with environmental goals.

Current Trends in the Modern Textile Industry

Focusing on sustainability, efficiency, and innovation characterises the modern textile industry in 2024. Some key trends include:

Circular Economy Models: Many textile companies are adopting circular economy practices, such as recycling old garments into new ones, to reduce waste and conserve resources.

On-Demand Manufacturing: The rise of on-demand manufacturing allows companies to produce garments based on real-time consumer demand, reducing overproduction and inventory costs.

Integration of IoT in Textile Manufacturing: IoT devices enable real-time machinery monitoring, improving efficiency and minimising downtime.

Biodegradable Fabrics: In 2024, the development of biodegradable textiles, such as fabrics made from algae or mushroom-based materials, is gaining traction.

Global Textile Market Growth: Emerging markets are driving increasing demand, and experts expect the global textile market to reach $1.2 trillion by 2024.

Key Services by Rawalwasia Group in Textile Innovations

Rawalwasia Group stands out as a leader in the textile manufacturing sector, offering a range of innovative services that cater to modern industry demands. With a solid commitment to quality, efficiency, and sustainability, the group provides:

Yarn and Fabric Manufacturing: Rawalwasia uses advanced spinning and weaving technologies to produce high-quality yarns and fabrics suitable for diverse applications.

Textile Dyeing and Finishing: The group employs eco-friendly dyeing processes that minimise water usage and ensure vibrant, long-lasting colours.

Customised Solutions: Rawalwasia tailors its offerings to meet specific customer needs, from smart textiles to sustainable fabrics, ensuring optimal satisfaction.

Supply Chain Optimization: Leveraging AI and IoT, Rawalwasia ensures efficient inventory management and timely delivery of products.

Data on Innovations in Textile Manufacturing (2024)

The latest industry statistics show the growth and adoption of textile innovations. The following graph illustrates the adoption rates of key technologies in textile manufacturing:

The data reflects the rapid integration of innovative technologies, highlighting the industry’s shift toward sustainability and efficiency.

Conclusion

The textile industry in 2024 will be a hub of innovation driven by technological advancements and a commitment to sustainability. From smart textiles and AI-powered manufacturing to sustainable fabrics and digital printing, the modern textile industry is transforming to meet the demands of a dynamic market. These innovations improve efficiency and align with global goals of reducing environmental impact and enhancing functionality.

With its wide range of services, Rawalwasia Group plays a pivotal in advancing textile manufacturing. The group sets quality and innovation benchmarks by adopting cutting-edge technologies and sustainable practices. Whether producing high-quality yarns, offering customised fabric solutions, or optimising supply chains, Rawalwasia Group exemplifies excellence in the modern textile industry.

As the industry evolves, staying updated on the latest trends and technologies will be crucial for manufacturers, designers, and consumers. With its focus on textile innovations and commitment to quality, the modern textile industry is poised for a promising future, delivering sustainable and high-performance solutions to meet the needs of a changing world.

0 notes

Text

Graphene Market Size, Share, and Industry Analysis

Rising Demand for Advanced Materials in Electronics, Energy, and Composites Fuels Growth in the Graphene Market.

The Graphene Market Size was valued at USD 366.5 Million in 2023. It is expected to grow to USD 4997.1 Million by 2032 and grow at a CAGR of 33.2% over the forecast period of 2024-2032.

The Graphene Market is driven by its exceptional properties, including high electrical and thermal conductivity, mechanical strength, and lightweight nature. Graphene, a single layer of carbon atoms arranged in a hexagonal lattice, is widely used in industries such as electronics, energy storage, automotive, aerospace, and healthcare. The increasing adoption of graphene-based nanomaterials in batteries, sensors, coatings, and biomedical applications is fueling the market’s expansion.

Key Players in the Graphene Market

GrafTech International (Graphene Nano Powder, Graphene-Enhanced Batteries)

Graphene NanoChem Plc (PlatDrill, PlatSurf)

XG Sciences, Inc. (xGnP Graphene Nanoplatelets, Graphene Conductive Inks)

Applied Graphene Materials plc (Graphene Dispersions, Genable)

Haydale Graphene Industries Plc (HDPlas Functionalised Graphene, Graphene-Based Inks)

Versarien Plc (Graphene-Wrapped Silicon, Nanene)

Talga Resources Ltd (Talphene, Graphene Composite Materials)

First Graphene Ltd (PureGRAPH Graphene Powders, PureGRAPH Masterbatch)

G6 Materials Corp. (Graphene Supercapacitors, Conductive Graphene Composites)

Thomas Swan & Co. Ltd. (Elicarb Graphene Powders, Graphene Oxide)

Future Scope of the Market

The graphene market is projected to expand rapidly, driven by:

Increasing use in energy storage solutions, such as supercapacitors and lithium-ion batteries.

Growing demand in the electronics industry for flexible displays, transistors, and high-speed semiconductors.

Advancements in graphene-based composites for lightweight and strong materials in automotive and aerospace.

Rising investments in graphene-enhanced coatings for anticorrosion, conductivity, and thermal management.

Medical and biotechnology applications benefiting from graphene-based drug delivery systems and biosensors.

Emerging Trends in the Graphene Market

Graphene is transforming multiple industries with its unique combination of strength, conductivity, and flexibility. One of the most significant trends is its increasing role in energy storage, where graphene-enhanced batteries and supercapacitors promise faster charging, longer lifespans, and higher energy density. Additionally, the electronics sector is leveraging graphene’s high conductivity and flexibility for next-generation transistors, foldable screens, and quantum computing applications. The automotive and aerospace industries are incorporating graphene-based composites for lightweight and durable materials that improve fuel efficiency and performance. Furthermore, graphene-based coatings and paints are emerging as effective solutions for corrosion resistance and heat dissipation.

Key Points:

Graphene is increasingly used in energy storage, electronics, aerospace, and healthcare.

Supercapacitors and graphene-enhanced batteries are revolutionizing energy applications.

Automotive and aerospace industries are adopting graphene composites for lightweight, high-strength materials.

Flexible and high-speed electronic components are driving demand for graphene in semiconductors.

Innovations in graphene coatings and biomedical applications are expanding market opportunities.

Conclusion

The Graphene Market is set for exponential growth as industries harness its remarkable properties for cutting-edge innovations. With ongoing research, government investments, and commercial-scale production, graphene is expected to revolutionize multiple sectors, from energy storage to healthcare. Companies focusing on scalable production methods and novel graphene-based applications will lead the future of advanced nanomaterials.

Read Full Report: https://www.snsinsider.com/reports/graphene-market-4733

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Graphene Market#Graphene Market Size#Graphene Market Share#Graphene Market Report#Graphene Market Forecast

0 notes

Text

Growth Forecast of Printed Circuit Board Market for 2024-2032

A printed circuit board (PCB) is a flat board made of insulating material, often fiberglass, that supports and connects electronic components using conductive pathways etched from copper sheets. From smartphones and computers to industrial machinery and medical equipment, PCBs are now the essential components in the modern electronics industry. Accordingly, our research predicts that the Global Printed Circuit Board Market is likely to grow with a CAGR of 5.04% in the forecast period 2024-2032. As the need for advanced technologies surges, so does the demand for printed circuit boards that are efficient, reliable, and innovative.

Explore in detail about this market in our FREE sample

Printed Circuit Board Market: Innovative & Smart PCB Production

Traditional PCB manufacturing processes can be resource-intensive and generate significant waste, particularly in terms of hazardous chemicals like lead and volatile organic compounds (VOCs). In response, printed circuit board manufacturers are now exploring biodegradable materials, eco-friendly inks, and energy-efficient production methods.

Let us take a look at some interesting examples of key market players in this industry.

Biodegradable PCBs Using Natural Fibers

Companies, such as Jiva Materials in the UK, are pioneering the use of biodegradable materials in PCB production. They have developed a product called Soluboard, which replaces the traditional fiberglass substrate with natural fibers that break down in water. Soluboard is not only biodegradable but also lowers carbon emissions during production.

As per its press release, Infineon incorporates recyclable PCBs from Jiva Materials in its demo and evaluation boards to reduce electronic waste and lower its carbon footprint. Furthermore, switching from FR-4 PCB materials to Soluboard could cut carbon emissions by 60%. This change would save approximately 10.5 kg of carbon and 620 g of plastic per square meter of PCB.

Thus, by switching to biodegradable substrates, manufacturers can significantly reduce the environmental footprint of PCBs, making electronics more sustainable from the outset.

IoT-Optimized PCBs in Smart Homes

Linx Technologies, a developer of wireless IoT products, has created smart PCBs optimized for smart home applications. These PCBs feature integrated wireless modules (such as Wi-Fi, Bluetooth, and Zigbee) that allow devices like smart thermostats, lighting systems, and security cameras to communicate within a home ecosystem.

The company also partnered with a leading smart thermostat manufacturer to design a PCB that integrates multiple communication protocols, enabling the thermostat to adapt and respond to changing environmental conditions and user preferences.

Smart Agricultural PCBs for Precision Farming

As agriculture becomes more data-driven, John Deere has introduced smart PCB solutions within its precision farming equipment. These PCBs incorporate sensors and GPS modules that collect and transmit data on soil moisture, nutrient levels, and crop health. The collected data helps optimize farming practices by providing actionable insights to farmers. In one case study, John Deere implemented smart PCBs in its autonomous tractors and harvesting equipment.

Connect with our experts for a simplified analysis!

APAC to Become a Hub for PCB Manufacturing

The Asia-Pacific region is set to witness remarkable growth in PCB manufacturing due to its expanding consumer electronics and automotive industries, growing semiconductor market, and favorable government policies supporting tech infrastructure. The Asia-Pacific Printed Circuit Board Market is expected to witness the fastest growth at a CAGR of 5.64% during the forecast period.

Here’s how countries are influencing this growth:

Taiwan remains at the forefront of advanced PCB manufacturing, particularly in the high-density interconnect (HDI) and substrate-like PCB (SLP) markets. Taiwanese printed circuit board companies like Unimicron and Nan Ya PCB dominate the market, holding a significant share of the global IC substrate sector. In fact, California-based Bloom Energy has signed an agreement with Unimicron to install up to 10 MW of fuel cells at its Taiwan plants, with the installations set to be completed by 2026. These investments position the country as a key supplier for global tech giants like Apple and NVIDIA, demonstrating its pivotal role in the market’s future growth.

In addition to this, BPL launched a new PCB production unit in Bengaluru, India (June 2024), backed by a ₹20 crore investment to support commercial production of double-sided and multi-layer PCBs. Amber Enterprises recently announced plans to invest ₹2,000 crore in establishing a printed circuit board (PCB) manufacturing facility in India to meet both domestic and export demands. These efforts reflect India’s growing commitment to expanding PCB manufacturing capacity and contributing to the region’s PCB market potential.

Similarly, the South Korean government unveiled a $19 billion support package aimed at bolstering the country’s tech sector, specifically focusing on enhancing semiconductor and PCB manufacturing capabilities. This package supports companies like Samsung Electronics and SK Hynix, encouraging investments in advanced manufacturing and R&D to maintain their edge in high-performance PCBs for the electronics and automotive sectors.

Together, these countries, along with other regions like Europe and North America, are strengthening their PCB manufacturing capabilities through strategic investments, international collaborations, and technology development, ensuring their positions in the PCB Industry. Thus, the ongoing innovations and developments in this market indicate a promising future where advanced technologies and sustainable practices merge to meet global demand.

Grab a Quick Read to Get a Comprehensive Analysis of this Market

FAQs:

Q.1) How does a printed circuit board work?

Answer: A printed circuit board (PCB) is a rigid structure with embedded metal traces and planes that form electrical circuitry. Components are soldered onto metal pads connected to the circuitry, enabling interconnection.

Q.2) How are tracks made on a printed circuit board?

Answer: Chemical etching separates copper into conductive tracks, connection pads, vias for layer transitions, and features like solid conductive areas for electromagnetic shielding.

0 notes

Text

0 notes