#China market share on Composites in Oil and Gas'

Explore tagged Tumblr posts

Text

With the exceptions of North Korea and Cuba, the communist world has merged onto the capitalist highway in a couple different ways during the twenty-first century. As you’ve read, free-trade imperialism and its cheap agricultural imports pushed farmers into the cities and into factory work, lowering the global price of manufacturing labor and glutting the world market with stuff. Forward-thinking states such as China and Vietnam invested in high-value-added production capacity and managed labor organizing, luring links from the global electronics supply chain and jump-starting capital investment. Combined with capital’s hesitancy to invest in North Atlantic production facilities, as well as a disinclination toward state-led investment in the region, Asian top-down planning erased much of the West’s technological edge. If two workers can do a single job, and one worker costs less, both in wages and state support, why pick the expensive one? Foxconn’s 2017 plan to build a U.S. taxpayer–subsidized $10 billion flat-panel display factory in Wisconsin was trumpeted by the president, but it was a fiasco that produced zero screens. The future cost of labor looks to be capped somewhere below the wage levels many people have enjoyed, and not just in the West.

The left-wing economist Joan Robinson used to tell a joke about poverty and investment, something to the effect of: The only thing worse than being exploited by capitalists is not being exploited by capitalists. It’s a cruel truism about the unipolar world, but shouldn’t second place count for something? When the Soviet project came to an end, in the early 1990s, the country had completed world history’s biggest, fastest modernization project, and that didn’t just disappear. Recall that Cisco was hyped to announce its buyout of the Evil Empire’s supercomputer team. Why wasn’t capitalist Russia able to, well, capitalize? You’re already familiar with one of the reasons: The United States absorbed a lot of human capital originally financed by the Soviet people. American immigration policy was based on draining technical talent in particular from the Second World. Sergey Brin is the best-known person in the Moscow-to-Palo-Alto pipeline, but he’s not the only one.

Look at the economic composition of China and Russia in the wake of Soviet dissolution: Both were headed toward capitalist social relations, but they took two different routes. The Russian transition happened rapidly. The state sold off public assets right away, and the natural monopolies such as telecommunications and energy were divided among a small number of skilled and connected businessmen, a category of guys lacking in a country that frowned on such characters but that grew in Gorbachev’s liberalizing perestroika era. Within five years, the country sold off an incredible 35 percent of its national wealth. Russia’s richest ended the century with a full counterrevolutionary reversal of their fortunes, propelling their income share above what it was before the Bolsheviks took over. To accomplish this, the country’s new capitalists fleeced the most vulnerable half of their society. “Over the 1989–2016 period, the top 1 percent captured more than two-thirds of the total growth in Russia,” found an international group of scholars, “while the bottom 50 percent actually saw a decline in its income.” Increases in energy prices encouraged the growth of an extractionist petro-centered economy. Blood-covered, teary, and writhing, infant Russian capital crowded into the gas and oil sectors. The small circle of oligarchs privatized unemployed KGB-trained killers to run “security,” and gangsters dominated politics at the local and national levels. They installed a not particularly well-known functionary—a former head of the new intelligence service FSB who also worked on the privatization of government assets—as president in a surprise move on the first day of the year 2000. He became the gangster in chief.

Vladimir Putin’s first term coincided with the energy boom, and billionaires gobbled up a ludicrous share of growth. If any individual oligarch got too big for his britches, Putin was not beyond imposing serious consequences. He reinserted the state into the natural monopolies, this time in collaboration with loyal capitalists, and his stranglehold on power remains tight for now, despite the outstandingly uneven distribution of growth. Between 1980 and 2015, the Russian top 1 percent grew its income an impressive 6.2 percent per year, but the top .001 percent has maintained a growth rate of 17 percent over the same period. To invest these profits, the Russian billionaires parked their money in real estate, bidding up housing prices, and stashed a large amount of their wealth offshore. Reinvestment in Russian production was not a priority—why go through the hassle when there were easier ways to keep getting richer?

While Russia grew billionaires instead of output, China saw a path to have both. As in the case of Terry Gou, the Chinese Communist Party tempered its transition by incorporating steadily increasing amounts of foreign direct investment through Hong Kong and Taiwan, picking partners and expanding outward from the special economic zones. State support for education and infrastructure combined with low wages to make the mainland too attractive to resist. (Russia’s population is stagnant, while China’s has grown quickly.) China’s entry into the World Trade Organization, in 2001, gave investors more confidence. Meanwhile, strong capital controls kept the country out of the offshore trap, and state development priorities took precedence over extraction and get-rich-quick schemes. Chinese private wealth was rechanneled into domestic financial assets—equity and bonds or other loan instruments—at a much higher rate than it was in Russia. The result has been a sustained high level of annual output growth compared to the rest of the world, the type that involves putting up an iPhone City in a matter of months. As it has everywhere else, that growth has been skewed: only an average of 4.5 percent for the bottom half of earners in the 1978–2015 period compared to more than 10 percent for the top .001 percent. But this ratio of just over 2–1 is incomparable to Russia’s 17–.5 ration during the same period.

Since the beginning of the twenty-first century, certain trends have been more or less unavoidable. The rich have gotten richer relative to the poor and working class—in Russia, in China, in the United States, and pretty much anywhere else you want to look. Capital has piled into property markets, driving up the cost of housing everywhere people want to live, especially in higher-wage cities and especially in the world’s financial centers. Capitalist and communist countries alike have disgorged public assets into private pockets. But by maintaining a level of control over the process and slowing its tendencies, the People’s Republic of China has built a massive and expanding postindustrial manufacturing base.

It’s important to understand both of these patterns as part of the same global system rather than as two opposed regimes. One might imagine, based on what I’ve written so far, that the Chinese model is useful, albeit perhaps threatening, in the long term for American tech companies while the Russian model is irrelevant. Some commentators have phrased this as the dilemma of middle-wage countries on the global market: Wages in China are going to be higher than wages in Russia because wages in Russia used to be higher than wages in China. But Russia’s counterrevolutionary hyper-bifurcation has been useful for Silicon Valley as well; they are two sides of the same coin. Think about it this way: If you’re a Russian billionaire in the first decades of the twenty-first century looking to invest a bunch of money you pulled out of the ground, where’s the best place you could put it? The answer is Palo Alto.

Malcolm Harris, Palo Alto

53 notes

·

View notes

Text

China’s EV Boom Is Starting to Pinch Oil Producers. (Wall Street Journal)

Excerpt from this Wall Street Journal story:

China’s oil demand is nearing a turning point as electric vehicles take a growing share of its vehicle market, the world’s largest.

The country has long been the thirstiest consumer of crude. China accounted for 16% of global demand in 2023, or 16.4 million barrels a day, up from around 9% in 2008. More significantly, China was the largest buyer of marginal barrels. During that span, it contributed to more than half the growth in global oil demand. Since a record consumption year in 2023, after the country emerged from strict zero-Covid policies, demand has slowed. Oil consumption is projected to rise a mere 0.8% year on year in 2024 and by an additional 1.3% in 2025, according to the International Energy Agency.

While China’s overall oil demand still appears stable, its composition is shifting gears rapidly. Gasoline and diesel demand seems to have peaked: China’s total demand for these transportation fuels in 2024 will be 3.6% lower than in 2021, according to IEA estimates.

China’s housing bust is partly to blame, as a slowdown in construction led to weaker demand for diesel used in machinery. But a bigger story comes from China’s rapid shift in personal transportation, and especially the rise of electric vehicles. More than half of the passenger cars sold in the country in recent months were new-energy vehicles, which includes plug-in hybrids, according to the China Passenger Car Association. Largely because of that trend, China’s gasoline demand in 2025 is expected to be 6.4% lower than the peak in 2021, according to IEA projections.

More new heavy-duty trucks in the country are also using liquefied natural gas instead of diesel. Diesel and gasoline accounted for 44% of China’s oil demand in 2024, down from 51% in 2018.

While transportation fuels are running out of road, China’s growing petrochemical sector has been gobbling up oil products. Consumption of naphtha, ethane and liquefied petroleum gas, all feedstocks for petrochemicals, has risen 59% between 2019 and 2024. But this boom may no longer be enough to compensate for the continued decline in diesel and gasoline demand as electric vehicles keep gaining ground in China.

3 notes

·

View notes

Text

In principle, it should be easy for a country with fewer than 20 million people and abundant natural resources to get to high income and sustain this status. Kazakhstan has 22 million hectares of arable land—more than all but 14 countries in the world, the second-largest uranium reserves, the twelfth-largest oil wealth, and the fifteenth-largest natural gas reserves. This is a wealthy country with a great people.

So why hasn’t Kazakhstan become a high-income economy? More accurately, why didn’t it become one after rising very closely to what the World Bank considers high-income levels of more than $12,500 in 2014?

Observe first what sets Kazakhstan apart from the three dozen OECD countries that have reached high income. There are three main issues:

Dependence on natural resources

Distant location and

Dispersed population.

Because of this unique combination, Kazakhstan will have to devise its own development strategy. It can’t just copy someone else’s like Singapore did with Hong Kong China or South Korea did with Japan. The need for this tailored strategy is urgent as Kazakhstan’s economy has grown at a slower pace after each slowdown. Its per capita income grew by nearly 10 percent between 2000 and 2007, by 4 percent between 2010 and 2014, and by 3.5 percent between 2016 and 2019. During 2020-2022, the economy grew by 2.3 percent and this year, 2023, we expect per-capita income to grow by about 3.5-4 percent. Further, once you take out the effect of investment and employment increases, growth is close to zero. That is to say, productivity growth has been negligible since 2008. This is a visible symptom that Kazakhstan’s structural transformation has stalled, so has its sectoral transformation, and so has its spatial transformation.

A recent report by the World Bank shows a tight three-way relationship between a country’s per-capita income, the sectoral composition of its output, and the share of its urban population. The report shows that per capita income has grown mostly when the prices of its commodity exports have happened to be high. This is not a bad thing—there are other resource-rich countries where even this hasn’t happened. But it does mean that Kazakhstan’s fortunes are mainly decided by the international commodity markets rather than its industries and people. This is not a good thing.

Further, Kazakhstan’s production structure has not changed much. The share of mining in GDP has remained broadly unchanged at 14 percent since 2000. Manufacturing’s contribution to GDP has been static since 2004 at 13 percent GDP. Commodity exports are broadly stable accounting for more than 80 percent of total shipments abroad.

Finally, the share of the urban population has stayed at around 58 percent for the last twenty years. In 2008, it was a little less than 57 percent. In 2020, it was a little less than 58 percent.

Figure 1. Stagnant urbanization in Kazakhstan: urban share of the population, 2006–2020

Economic dynamism has been stymied in Kazakhstan. There are several reasons for this outcome:

The dominance of state-owned and state-connected enterprises means that production is being carried out in places that are not the best for these activities; goods are produced in places far from markets or with methods that should have changed a long time ago.

Another problem is low economic freedom for people and private firms. By definition, this has to be the decision of government. If a government trusts its citizens, it gives them freedom. Economic freedom may be the least controversial freedom to give.

Kazakhstan has made it hard for firms to both start and to shut down if they are not viable. Just as education is the grease that keeps individuals moving to better-paying jobs and places, competition is the grease that pushes firms to be more productive and innovative. The competition regime in Kazakhstan has not been improving; if anything, it may have gone backward.

The population density is 6 people per square kilometer. Mobility toward urban areas is dampened by high housing costs, a severely limited rental market, and the residency registration system. In the highest-demand urban areas, housing is extremely unaffordable when compared with local incomes. Housing subsidies and legacy policies contribute to one of the highest homeownership rates in the world. Finally, the residency registration system deters many people from relocating within the country, as benefits are tied to where a person is registered. For those who are unregistered, the system can lead to exclusion from many social services and benefits.

Perhaps the greatest driver of mobility—spatial, sectoral, and social—is good-quality education. Education quality is poor for a country on the doorstep of high-income. About 60 percent of 14-year-olds are functionally illiterate, the third highest percentage in Europe and Central Asia (ECA).

While these are daunting challenges, there are signs of hope.

The first is that a new e-governance system has simplified resident registration. But advanced economies do not have resident registration and Kazakhstan should consider discontinuing it.

There are signs of growing spatial concentration of manufacturing, especially near the borders and near Almaty and Astana. It is heartening to note that regions with higher population densities respond to shocks better than remote sparse places.

Kazakhstan’s territorial development strategy has some good features. Two of them are an emphasis on providing basic services everywhere and recognizing that big cities are the best way to improve both economic efficiency and living standards.

But Kazakhstan has a long way to go. Its three largest urban areas account for less than 25 percent of the GDP; in developed economies, this averages close to 50 percent.

But urban productivity trends are going into reverse. To counter these reversals, Kazakhstan should contemplate empowering subnational governments more by investing in their capacity and giving them more autonomy in decisionmaking.

One more change may be to stop subsidizing monotowns, an artifact of Soviet planning. Instead, the government should be thinking of creating regional and city development fund that finances local economic development programs that are implemented by subnational governments.

While there may be significant temptation to build infrastructure, economic zones, and urban structures to bolster the economy, policymakers should resist the temptation to first pour concrete. Advancing market reforms should be the first and foremost order of business.

5 notes

·

View notes

Text

Why Fiber Optic Sensors Are Gaining Traction in the Automotive Industry

The global fiber optic sensors market is experiencing rapid growth, driven by increased adoption in industries such as automotive, oil & gas, and manufacturing. Valued at $3.4 billion in 2022, the market is projected to expand at a CAGR of 9.6% from 2023 to 2031, reaching $7.6 billion by the end of the forecast period.

Fiber optic sensors are gaining traction due to their advantages, including high sensitivity, immunity to electromagnetic interference, and compact size. Their ability to measure temperature, vibration, pressure, and chemical composition makes them indispensable across various applications.

Rising Demand in the Automotive Industry

The automotive sector is a major driver of fiber optic sensor adoption. These sensors are integrated into modern vehicles for:

Electric & hybrid vehicle monitoring

Temperature sensing in battery management systems

Measuring movement and direction of vehicles

As electric vehicle (EV) adoption grows, demand for fiber optic sensors is expected to surge. India’s EV market alone is projected to reach $7.09 billion by 2025, significantly boosting fiber optic sensor demand.

Increasing Use in Oil & Gas Monitoring

The oil & gas industry relies on fiber optic sensors for thermal monitoring, structural health monitoring, and leak detection. Unlike traditional electrical sensors, fiber optic sensors operate at higher temperatures, are resistant to harsh environments, and require minimal maintenance.

Notably, Luna Innovations developed advanced fiber optic-based oil & gas monitoring systems in 2021, improving accuracy and reliability in oil extraction.

Segment Analysis: The Rise of Through-Beam Sensors

Among different sensor types, through-beam sensors held a dominant 42.34% market share in 2022. These sensors are highly effective in detecting objects over long distances, making them essential for industrial automation and material handling.

Regional Insights: Asia Pacific Leads the Market

Asia Pacific accounted for 34.23% of the global fiber optic sensors market in 2022, with China, Japan, South Korea, and India driving growth. Factors contributing to this dominance include:

Expansion of the automotive and oil & gas sectors

Large-scale investments in telecommunications and smart infrastructure

Presence of major fiber optic sensor manufacturers

North America follows closely behind, contributing 28.79% to the global market. The region benefits from robust oil & gas and aerospace industries, which extensively utilize fiber optic sensing technologies.

Key Market Players & Competitive Landscape

Leading companies in the fiber optic sensors market include:

Althen, Baumer,. ifm electronic gmbh, KEYENCE CORPORATION, Leuze electronic GmbH + Co. KG, Luna, OFS Fitel, LLC, Pepperl+Fuchs (India) Pvt. Ltd, Rockwell Automation, Inc., Wenglor Sensoric Group,

These companies focus on innovation, mergers & acquisitions, and product expansion to strengthen their market presence.

Future Outlook & Market Forecast

The fiber optic sensors market is set for strong growth, driven by advancements in:

✅ Smart manufacturing and Industry 4.0

✅ Autonomous vehicles & electric mobility

✅ 5G networks & high-speed communication

✅ Environmental monitoring & smart grids

With continued technological advancements and increasing adoption across industries, the market is on track to exceed expectations by 2031.

Conclusion

Fiber optic sensors are revolutionizing industries by offering high precision, durability, and reliability in challenging environments. As demand surges across automotive, oil & gas, healthcare, and manufacturing sectors, the global fiber optic sensors market is poised for substantial growth.

Contact Us: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Global Composite Pipes Powerhouses: Top 5 Countries Driving Growth

According to a recent research, Industry revenue for Composite Pipes is expected to rise to $4.2 billion by 2035 from $2.3 billion of 2024. U.S., China and Germany are the top 5 markets and combinely holds substantial demand share. The revenue growth of market players in these countries is expected to range between 3.6% and 5.4% annually for period 2025 to 2035.

Industry transition including shift towards green manufacturing and advancements in material science, are transforming the supply chain of Composite Pipes market. The industry is currently undergoing a shift towards eco friendly production methods in the composite pipes sector This change is transforming how market participants operate as they embrace sustainable manufacturing processes use environmentally friendly materials and minimize waste in alignment with the worldwide trend towards green industrial practices This shift not only helps companies reduce their environmental impact but also lowers operational expenses and enhances customer appeal giving them a competitive advantage, in the market

Potential Application Areas

Water Supply Systems: Composite pipelines are crucial for delivering safe drinking water since they are leak proof and resistant against chemical corrosion. Preventing contamination and ensuring a healthy water supply. Leading companies such, as Suez and Veolia are actively incorporating these pipelines into their water distribution systems.

Construction and Infrastructure: In construction work composite pipes find their utility in a range of roles such as sewage systems and piping setups due to their durability, adaptability and light weight. These qualities make them a cost effective option with installation procedures making them preferable over conventional piping systems. Leading companies like Saint Gobain and Polypipe are at the forefront of employing pipes, in construction projects.

Industry Leadership and Strategies

The Composite Pipes market is characterized by intense competition, with a number of leading players such as Future Pipe Industries, GE Oil & Gas, Airborne Oil & Gas, Magma Global Limited, National Oilwell Varco, Baker Hughes, Chevron Phillips Chemical Company, Prysmian Group, ShawCor Ltd, Soluforce, Flexpipe Systems and Pipelife International GmbH. These players are pushing the boundaries of innovation & technological advancements and forging strategic partnerships to expand the existing reach of the market.

Access detailed report insights here - https://datastringconsulting.com/industry-analysis/composite-pipes-market-research-report

About DataString Consulting

DataString Consulting assist companies in strategy formulations & roadmap creation including TAM expansion, revenue diversification strategies and venturing into new markets; by offering in depth insights into developing trends and competitor landscapes as well as customer demographics. Our customized & direct strategies, filters industry noises into new opportunities; and reduces the effective connect time between products and its market niche.

DataString Consulting is a professional market research company which aims at providing all the market & business research solutions under one roof. Get the right insights for your goals with our unique approach to market research and precisely tailored solutions. We offer services in strategy consulting, comprehensive opportunity assessment across various sectors, and solution-oriented approaches to solve business problems.

0 notes

Text

Powder Metallurgy Market - Forecast(2024 - 2030)

Powder Metallurgy Market Overview

Request Sample Report :

COVID-19 Impact

The onset of Covid-19 in the entire nation had a negative impact on the automotive industry. There was an overall revenue impact across the automotive industry. The pandemic also impacted all the stakeholders present in the value chain for the short as well as medium term. Shortage of raw material, shifting of production to other countries, liquidity crunch to delays in availability of models, deferred launches, and shrinkage in consumer demand were some of the main issues faced by the automotive stakeholders, owing to which the production and demand of automobiles had significantly fallen. For instance, according to the China Passenger Car Association (CPCA), China’s passenger car sales in June fell 6.5% year on year to 1.68 million units. The unstable automotive production and demand have significantly impacted the market of powder metallurgy as the demand for powder metal was also uncertain during the period. A prolonged truncation of consumer demand due to the lockdown has significantly affected auto manufacturers’ revenues and cash flows. Even after the restriction is eased in 2021, with discretionary spending taking a backseat, further declines in the market for passenger vehicles are expected.

Powder Metallurgy Market Report Coverage

The report: “Powder Metallurgy Market — Forecast (2021–2026)”, by IndustryARC, covers an in-depth analysis of the following segments of the powder metallurgy Industry.

By Material: Ferrous (Iron, Steel, and Stainless Steel), Non-Ferrous (Copper, Aluminium, Cobalt, Tin, Nickel, Magnesium, Zinc, Titanium, Molybdenum, and Others By Process: Conventional Process, Metal Injection Moulding, Hot Isostatic Pressing, and Metal Additive Manufacturing By Application: Porous Products, Bearing and Bushes, Filters (Ceramic Filter, Fiber Metal Filter, and Others), Refractory Metal Composites, Electric Motors, Cemented Carbides, Machinery Parts (Gears, Sprockets, Rotors, and Others), Tungsten Wires, Medical Implants, Magnetic Materials, Cutting Tools and Dies, and Others By End-Use Industry: Medical & Healthcare, Automobile (Transmission, Engine Parts, and others), Oil & Gas, Electrical and Electronics (Refrigerators, Vacuum Cleaners, Circuit Breakers, Electric Motors, Sewing Machines, and Others), Industrial (Hydraulics, Motors/Controls, and Others), Aerospace (Aero-engine, Land-based Gas Turbine, Airframes, and Others), Household Appliances, Recreation and Leisure, and Others By Geography: North America (USA, Canada, and Mexico), Europe (UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), Rest of the World (Middle East, and Africa)

Inquiry Before Buying :

Key Takeaways

Asia-Pacific dominates the powder metallurgy market, owing to the increasing demand and production of lightweight vehicles in the region. For instance, according to OICA, the production of passenger cars has increased by 2.6 % in Malaysia in 2019.

There are many cases in which powder metallurgy over casting has a strong benefit. The benefits of the powder metallurgy process are particularly apparent when dealing with high-value and high-melting-point materials, owing to which there is increasing adoption of powder metallurgy over die casting, which will propel the market growth.

There are growing interests in producing customized medical implants using additive manufacturing and in producing porous implant structures (to match bone stiffness and to aid osteointegration) by powder metallurgy processing, which may boost the market growth.

For More Details on This Report — Request for Sample

Powder Metallurgy Market Segment Analysis — By Material

The ferrous segment held the largest share in the powder metallurgy market in 2020. Ferrous powdered metals such as iron, steel, and more offer the highest level of mechanical properties. Ferrous metal powders are also known for their extensive characteristics such as durability, hardness, tensile strength, lower costs, broad flexibility, and more. The ferrous powdered metal is largely employed in the automotive industry for designing bearings, gears, or other auto parts, owing to its good strength and flexibility. Furthermore, ferrous metals are also widely utilized in various other end-use industries such as construction, piping, aerospace, electronics, and more. Thus, it is anticipated that these extensive characteristics and wide applications of ferrous powder metallurgy are the major factors driving its demand during the forecast period.

Powder Metallurgy Market Segment Analysis — By Application

The bearings segment held the largest share in the powder metallurgy market in 2020 and is growing at a CAGR of 7.4% during 2021–2026, owing to its self-lubricating property. Bearings that are made from powder metallurgy are known as self bearings of sintered metal. They are economical, suitable for high production rates, and precision tolerances can be produced. The majorities of porous-metal bearings consist of either bronze or iron with pores that are interconnected. These voids take up 10 percent of the total volume to 35 percent. In operation, lubricating oil is deposited in these voids and feeds to the bearing surface through the interconnected pores. Sintered-metal self-lubricating bearings are widely used in home appliances, small motors, machine tools, aircraft, and automotive accessories, business machines, instruments, and farm and construction equipment, owing to which it holds a prominent share in the powder metallurgy application segment.

Schedule A Call :

Powder Metallurgy Market Segment Analysis — By End-Use Industry

The automotive segment held the largest share in the powder metallurgy market in 2020 and is growing at a CAGR of 8.6% during 2021–2026. Powder metal parts display excellent controlled porosity and self-lubricating properties that allow gases and liquids to be filtered. Powder metallurgy is also a strongly recommended method in the manufacture of components involving complex bends, depressions, and projections. Flexibility in the development of mechanical parts of different compositions, such as metal-non-metal and metal-metal hybrids, allows high dimensional precision in the production of automobile parts and ensures consistent properties and measurements with very little scrap and waste of material. The most popular vehicle parts that are manufactured through the method of powder metallurgy are the bearings and gears. A variety of metals, including ferrous, and non-ferrous are used in automotive components including chassis, steering, exhaust, transmission, shock absorber parts, engine, battery, seats, air cleaners, brake disc, and more. The powder metallurgy is often used in these components as it improves the net shape, utilizes heat treatment, enhances surface treatment, and improves the precision of these components. Thus, the demand for powder metallurgy in the automotive sector is growing due to such factors.

Powder Metallurgy Market Segment Analysis — By Geography

Asia-Pacific region held the largest share in the powder metallurgy market in 2020 up to 45%, owing to the increasing automotive manufacturing coupled with population growth in the region. China is the world’s largest vehicle market, according to the International Trade Administration (ITA), and the Chinese government expects automobile production to reach 35 million by 2025. In 2019, according to OICA, the automotive production in Malaysia and Vietnam has increased up to 571632, and 250000, i.e., 1.2%, and 5.5%. India’s annual production in 2019 was 30.91 million vehicles, according to Invest India, compared to 29.08 million in 2018, recording a healthy 6.26 percent growth. Also, by 2026, the US$118 billion Indian car industry is projected to cross US$300 billion. The increasing automation production in the Asia Pacific will eventually boost the demand for powder metallurgy to manufacture various automobile components, which will likely influence the growth of the powder metallurgy market in the APAC region.

Powder Metallurgy Market Drivers

Flourishing Aerospace Industry

Powder metallurgy is used extensively in aerospace, because of its advantages of high strength/weight ratio, high heat capacity, and high modulus of elasticity. Within aerospace, powder metallurgy finds its most significant application in turbine engines, compressors, fan sections, discs, airframes, fasteners, and landing gear. Tungsten metallurgy based tungsten carbide has received considerable attention in the aerospace industry because of its high strength at very high temperatures. Tungsten carbide is sintered through a selective laser sintering process based on the additive manufacturing process. In 2019, China was the second-largest civil aerospace and aviation services market in the world and one of the fastest-growing markets, according to the International Trade Administration (ITA). China will need 7,690 new aircraft over the next 20 years, valued at US$1.2 trillion, according to Boeing (Commercial Market Outlook 2018–2037). China also currently accounts for 15 percent of the world’s commercial aircraft fleet, and it will be almost 20 percent by 2037. According to Boeing, the demand for 2,300 airplanes worth US$320 billion is projected in India over the coming 20 years. Boeing’s current market outlook (BMO) forecasts demand for 2,520 new aircraft in the Middle East by 2030. With the flourishing aerospace industry, the demand for aircraft components will also gradually increase, which will drive the market growth.

Buy Now :

Expanding Electrical and Electronics Sector

The powder metallurgy method offers the opportunity to cost-effectively produce net form components from a variety of materials. A market segment that has exhibited the ability to take advantage of powder metallurgy’s flexibility has been in electromagnetic applications such as household appliances, industrial applications, and more. Magnetic materials are essential elements in the electronic industry in recent times. From the motors and turbines that provide the power for the industry to the high-frequency transformers that power computers, magnetic materials are becoming increasingly important for consumers. The electronic sector is booming in various regions, which will further drive the market growth as there is an increasing demand for powder metallurgy from the electrical and electronics sector. For instance, the consumer electronics and appliances sector in India is expected to become the fifth-largest in the world by 2025, according to Invest India. India could create an US$800 billion to US$1 trillion digital economy by 2025, and India’s digital economy could fuel 18–23 percent of overall economic activity by 2025. According to the Government of Canada, revenues in the ICT sector reached an estimated US$210 billion in 2019. ICT sector revenues grew from US$158 billion to US$200 billion from 2013 to 2018, a 26.9 percent increase.

Powder Metallurgy Market Challenges

Various Drawbacks Associated with Powder Metallurgy

The cost of metal powders compared to the cost of raw material used for casting or forging a component is relatively higher. At the time the cost of tooling and equipment is also higher. When production volumes are limited, this is especially a limitation. Also, low melting point metal powders such as zinc, tin, and cadmium give thermal difficulties during sintering operation, as most oxides of these metals cannot be reduced at temperatures below the melting point. Furthermore, large or complex-shaped parts, and uniformly high — density products are difficult to produce by the powder metallurgy process. Without any degradation, a few powders are also difficult to store. All these drawbacks associated with the powder metallurgy may hinder the market growth during the forecast period.

Powder Metallurgy Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the powder metallurgy market. Major players in the powder metallurgy market are Arcam AB, Carpenter Technology Corp., ExOne GmbH, GKN Plc, Höganäs AB, Materialize NV, Melrose Industries PLC, Sumitomo Electric Industries, Ltd., and Hitachi Chemical Co., Ltd.

Acquisitions/Technology Launches

In May 2019, Epson Atmix Corp. installed a new production line at its Kita-Inter Plant in Japan for producing amorphous alloy powder. The company invested around ¥800 million (USD 7.43 million) for the installation of a new line and it plans to further increase its production capacity in stages and reach 6,000 tons per year by 2023.

In October 2019, GKN Powder Metallurgy a leading metal powder and parts manufacturers acquired specialist polymer 3D printing service provider Forecast 3D. The acquisition presents a significant expansion of GKN powder metallurgy’s additive capabilities.

Relevant Reports

Powder Coatings Market — Forecast (2021–2026)

Report Code: CMR 0113

Ferromanganese Market — Forecast (2021–2026)

Report Code: CMR 0382

For more Chemicals and Materials Market reports, please click here

#PowderMetallurgy#Metalworking#AdvancedManufacturing#PowderMetals#AdditiveManufacturing#MetalPowder#IndustrialMaterials

0 notes

Text

Gas Jet Compressor Market Analysis: Strategic Insights, Challenges, and Opportunities

The gas jet compressor market is a dynamic arena, playing a crucial role in various industrial applications. Its significance lies in its ability to efficiently compress and transport gases without moving parts, making it a reliable and low-maintenance solution. As global industries evolve, the market's landscape is shifting, driven by innovative technologies, economic changes, and increasing environmental awareness.

A pivotal driver for the growth of the gas jet compressor market is the rising demand across industries like oil and gas, petrochemicals, and power generation. These compressors are particularly valued for their ability to handle diverse gas compositions while maintaining efficiency. With the global energy transition underway, the demand for systems that support renewable energy projects and cleaner operations has surged, further boosting the adoption of gas jet compressors.

One of the key trends shaping the market is the integration of advanced materials and smart technologies. Manufacturers are exploring hybrid systems that combine gas jet compressors with other technologies to meet specific operational requirements. For example, in the energy sector, these systems are being designed to adapt to fluctuating gas inputs, a common challenge in renewable energy sources like biogas or hydrogen. Moreover, the inclusion of IoT-enabled monitoring systems allows real-time performance tracking and predictive maintenance, reducing downtime and operational costs.

Regionally, the market's growth varies, with Asia-Pacific emerging as a focal point. Rapid industrialization in countries like India and China has spurred demand for reliable and efficient gas handling solutions. Infrastructure development, rising natural gas production, and a push for sustainable industrial practices contribute significantly to this growth. North America and Europe also remain important markets, driven by their focus on energy efficiency and technological innovation.

Despite its positive outlook, the gas jet compressor market faces several challenges. High initial investment costs can deter adoption, particularly for small and medium-sized enterprises. While these compressors offer long-term savings due to reduced maintenance and energy efficiency, the upfront expenditure remains a barrier for some businesses. Additionally, competition from alternative technologies, such as mechanical and centrifugal compressors, poses a threat, especially in applications where other options might offer comparable performance at a lower cost.

Economic factors also play a significant role in shaping the market. Fluctuations in raw material prices and global supply chain disruptions can impact production costs and delivery timelines. Additionally, economic slowdowns in key industries like oil and gas or manufacturing can affect the overall demand for these systems.

However, opportunities abound for companies willing to innovate and adapt. The ongoing shift toward sustainable practices presents a unique chance to enhance the environmental performance of gas jet compressors. Developing more energy-efficient systems and incorporating recyclable materials can help align these products with global sustainability goals. Expanding into emerging markets, where industrialization and energy demands are on the rise, also offers significant growth potential.

Regulatory frameworks further influence market dynamics. Governments worldwide are implementing stricter environmental regulations, encouraging industries to adopt cleaner and more efficient technologies. Gas jet compressors, known for their relatively low environmental impact, are well-positioned to benefit from this trend. By meeting or exceeding these regulations, manufacturers can gain a competitive edge and capture a larger market share.

In conclusion, the gas jet compressor market is a complex and evolving field. Its growth is driven by industrial demand, technological advancements, and the global shift toward sustainability. Challenges such as high costs, economic fluctuations, and competition require strategic navigation. However, the market's potential remains strong, offering opportunities for innovation, geographic expansion, and alignment with environmental goals. For stakeholders across industries, the gas jet compressor market presents a compelling landscape of challenges and rewards, ready to be explored and harnessed.

Request smaple PDF Report : https://www.pristinemarketinsights.com/get-free-sample-and-toc?rprtdtid=NTI0&RD=Gas-Jet-Compressor-Market-Report

#GasJetCompressorMarket#GasJetCompressorMarketTrends#GasJetCompressorMarketInsights#GasJetCompressorMarketAnalysis#GasJetCompressorMarketGrowth#GasJetCompressorMarketForecast

0 notes

Text

Nifty and Sensex Rebound, Signal Stabilization in Indian Markets

Source: ddnews.gov_.in

Share Post:

LinkedIn

Twitter

Facebook

Reddit

Pinterest

Positive Opening for Indian Indices

After a streak of losses, Indian stock markets opened on a positive note on Tuesday, hinting at a possible stabilization in the near term. The Nifty 50 index started trading at 23,529.55 points, marking a gain of 75.75 points or 0.32%, while the BSE Sensex opened at 77,548 points, rising by 208.99 points or 0.27%.

Experts highlighted that the Indian stock market indices are in oversold territory, indicating potential consolidation around current levels rather than a sharp recovery. “The Nifty ended lower yesterday, its seventh straight daily loss. Short-term momentum is deeply oversold, and a bounce is statistically overdue. However, holding support in the 23,200–23,300 range is critical, while 23,680 remains the immediate upside hurdle,” noted Akshay Chinchalkar, Head of Research at Axis Securities.

Sectoral Gains Lead the Charge

Sectoral indices on the NSE showed broad-based gains during early trade. The Nifty Realty index emerged as the top performer, climbing 1.64%, followed by Nifty Oil & Gas, which rose 1.56%. All other sectoral indices remained in the green, reflecting a general positive sentiment across the board.

Among the Nifty 50 stocks, 40 opened with gains, while only 10 declined. This widespread upward movement signaled cautious optimism among traders and investors, even as the broader market trend indicated lingering challenges.

Expert Outlook and Global Context

Despite Tuesday’s rebound, analysts warned against expecting a quick recovery to previous highs. “The momentum that pushed the Indian stock market to its record peak of 26,216 in September has dissipated. While there may be recoveries, these are unlikely to sustain given the selling pressure from FIIs and concerns over weak earnings growth for FY25,” said V.K. Vijayakumar, Chief Investment Strategist at Geojit Financial Services. He added that significant upward movements might only occur when data shows signs of earnings recovery.

Global markets also played a supportive role in Tuesday’s rebound. Japan’s Nikkei 225 gained 0.71%, Hong Kong’s Hang Seng rose by 0.31%, and South Korea’s KOSPI index added 0.35%. Taiwan led the gains in Asian markets, rallying by 1.39%. However, China’s Shanghai Composite Index bucked the trend, slipping by 0.39%.

While Indian stock markets show signs of stabilization, the trajectory ahead remains uncertain, with consolidation likely to dominate in the near term.

0 notes

Text

Well Testing Services Market: Role in Enhancing Reservoir Understanding and Optimization

The Well Testing Services Market plays a critical role in the oil and gas industry by evaluating reservoir performance and determining the viability of exploration and production projects. The market is expected to witness steady growth, driven by increasing exploration activities, technological advancements, and the rising demand for energy globally.

Market Segmentation

By Service Type

Surface Well Testing:

Focuses on evaluating surface-level performance metrics, such as flow rate, pressure, and temperature, helping to analyze well productivity.

Downhole Well Testing:

Involves testing below the surface to provide detailed insights into reservoir characteristics, pressure data, and fluid behavior.

Reservoir Testing:

Aims to understand reservoir properties like permeability, porosity, and fluid composition. This service helps in optimizing extraction strategies.

Real-time Testing:

Utilizes advanced technology for live monitoring and data analysis, enabling quick decision-making and reducing operational risks.

Drill Stem Testing (DST):

Provides critical information about the formation’s productive capacity and pressure during the drilling process.

By Well Type

Horizontal Wells:

Increasing use of horizontal drilling techniques in unconventional reservoirs is driving demand for testing services.

Vertical Wells:

Traditional vertical wells still account for a significant share, particularly in mature fields and conventional reservoirs.

By Application

Onshore:

Onshore exploration and production activities dominate the market, driven by the development of conventional and unconventional resources.

Offshore:

Offshore projects, especially in deepwater and ultra-deepwater, require advanced well testing services due to their complexity and high costs.

By End-User

Oil Industry:

The oil sector remains the largest consumer of well testing services, driven by fluctuating oil prices and the need for efficiency in exploration and production.

Gas Industry:

With the growing demand for natural gas as a cleaner energy source, well testing services in gas fields are witnessing increased adoption.

By Region

North America:

The region is a leader in the well testing market, driven by extensive exploration activities in the U.S. shale basins and Canada’s oil sands.

Europe:

Europe’s offshore exploration activities, particularly in the North Sea, contribute significantly to the market’s growth.

Asia-Pacific:

The region is experiencing rapid growth in the well testing market due to increasing exploration activities in countries like China, India, and Australia.

Middle East & Africa (MEA):

MEA holds a significant share, with ongoing projects in the Gulf countries and North Africa’s oil and gas fields.

Latin America:

Brazil’s deepwater exploration and production activities are a key driver for the market in this region.

Market Drivers

Rising Global Energy Demand:

Increasing energy consumption is driving exploration and production activities, leading to higher demand for well testing services.

Technological Advancements:

The development of real-time data analysis, digital tools, and advanced sensors improves the accuracy and efficiency of well testing.

Exploration of Unconventional Resources:

Shale gas, tight oil, and other unconventional resources require more extensive testing to evaluate reservoir potential.

Growth in Offshore Projects:

The discovery of new offshore reserves and investment in deepwater exploration is driving demand for well testing services.

Challenges

High Operational Costs:

Well testing, especially in deepwater and ultra-deepwater environments, involves significant costs, which can deter investment during periods of low oil prices.

Environmental Regulations:

Stringent environmental and safety regulations can limit activities and increase the complexity of operations.

Market Volatility:

Fluctuations in oil and gas prices directly impact exploration budgets and, consequently, the demand for well testing services.

Key Players

The market is characterized by the presence of several key players offering a wide range of well testing services. Prominent companies include:

Schlumberger Limited

Halliburton

Baker Hughes

Weatherford International

Expro Group

Petrofac

TechnipFMC

China Oilfield Services Limited (COSL)

These companies focus on service innovation, strategic partnerships, and regional expansions to maintain competitive advantages.

Read Complete Report Details of Well Testing Services Market: https://www.snsinsider.com/reports/well-testing-services-market-2787

About Us:

SNS Insider is a global leader in market research and consulting, shaping the future of the industry. Our mission is to empower clients with the insights they need to thrive in dynamic environments. Utilizing advanced methodologies such as surveys, video interviews, and focus groups, we provide up-to-date, accurate market intelligence and consumer insights, ensuring you make confident, informed decisions. Contact Us: Akash Anand — Head of Business Development & Strategy [email protected] Phone: +1–415–230–0044 (US) | +91–7798602273 (IND)

0 notes

Text

Automotive Lubricants Market to be Worth $114.2 Billion by 2030

Meticulous Research®—a prominent global market research firm—has released a report titled "Automotive Lubricants Market by Product Type (Engine Oil, Transmission & Hydraulic Fluids, Gear Oil, Grease, Chain Oil, Brake Fluids), Vehicle Type, Composition, Sales Channel, and Geography - Global Forecast to 2030."

Download Research Report Sample @ https://www.meticulousresearch.com/download-sample-report/cp_id=5036

The report indicates that the automotive lubricants market is anticipated to reach $114.2 billion by 2030, with a compound annual growth rate (CAGR) of 7.8% during the forecast period. Key drivers for this growth include increasing demand for high-performance lubricants, rapid advancements in transportation infrastructure, a booming automotive industry with rising vehicle production, and a growing preference for sustainable lubricants. However, challenges such as decreased demand from electric vehicles and fluctuating raw material prices may impact market growth.

Emerging economies present significant growth opportunities, alongside the rising demand for eco-friendly lubricants. Nevertheless, the development of compatible lubricants for electric and hydrogen fuel cell vehicles, along with volatile pricing, could pose hurdles. A notable trend in the market is the increasing demand for thinner engine oils.

Meticulous Research® has segmented the market based on product type, vehicle type, composition, sales channel, and geography for comprehensive analysis. The study also assesses competitors and analyzes market dynamics at regional and national levels.

By product type, the market includes engine oil, transmission & hydraulic fluids, gear oil, grease, chain oil, brake fluids, and others. In 2024, engine oil is projected to dominate the market, driven by the need for improved fuel efficiency in internal combustion engine (ICE) vehicles and strong aftermarket demand. Meanwhile, the grease segment is expected to exhibit the highest CAGR during the forecast period.

In terms of vehicle type, the market is categorized into internal combustion engine vehicles, electric vehicles, natural gas engines, and hydrogen-powered vehicles. The internal combustion engine segment is forecasted to hold the largest market share in 2024, supported by advancements in efficiency and performance, as well as strict emissions regulations. Conversely, the electric vehicle segment is anticipated to grow at the fastest rate.

Browse in depth @ https://www.meticulousresearch.com/product/automotive-lubricants-market-5036

The market composition includes mineral oil lubricants, fully synthetic oil lubricants, and semi-synthetic lubricants. Fully synthetic oil lubricants are expected to dominate in 2024 due to their high performance and advantages in fuel economy and emissions reduction, and this segment is also projected to achieve the highest CAGR.

Sales channels are divided into original equipment manufacturers and aftermarket segments. The aftermarket is expected to lead the market share in 2024, fueled by increasing car ownership, particularly in emerging economies, and growing awareness of lubricant benefits for vehicle efficiency. This segment is also predicted to grow at the highest rate.

Geographically, the automotive lubricants market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. Asia-Pacific is expected to capture the largest market share in 2024, thanks to rapid automotive industry growth, strong government support, and the presence of key manufacturers. This region is also projected to see the highest CAGR.

**Key Players:**

Prominent players in the automotive lubricants market include Shell International B.V. (Netherlands), Exxon Mobil Corporation (U.S.), FUCHS PETROLUB SE (Germany), Motul (France), Phillips 66 Company (U.S.), Repsol, S.A. (Spain), SK Enmove Co., Ltd. (South Korea), China National Petroleum Corporation (China), Klüber Lubrication München Se & Co. KG (Germany), Amsoil Inc. (U.S.), Petróleo Brasileiro S.A. — Petrobras (Brazil), Valvoline Inc. (U.S.), Sinopec India (China), Chevron Corporation (U.S.), BP P.L.C. (U.K.), and Castrol Limited (U.K.).

Request Customization Report @ https://www.meticulousresearch.com/request-customization/cp_id=5036

0 notes

Text

Virtual Pipeline Systems Market Size, Share, Trends, Growth Opportunities and Competitive Outlook

"Global Virtual Pipeline Systems Market – Industry Trends and Forecast to 2028

Global Virtual Pipeline Systems Market, By Type (Ordinary Type, Special Type), Product (Liquefied Petroleum Gas (LPG), Liquid Natural Gas (LNG), Compressed Natural Gas (CNG), Propane, Diesel and Oils), Container Size (Type I, Type II, Type III, Type IV), Mode of Transportation (Intermodal ISO Tank Containers, Tanker Rail Cars, Pipeline Transport, Reticulated Gas System or Piped Gas System, Road Tankers, Local Bobtail Tankers), Application (Industrial, Transportation, Commercial and Residential), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028

Access Full 350 Pages PDF Report @

**Segments**

- **By Component:** The virtual pipeline systems market can be segmented based on components into compressors, trailers, cylinders, valves, fittings, and others. Compressors play a crucial role in the transportation of natural gas, enabling it to be moved efficiently through pipelines. Trailers are used for the physical transportation of compressed natural gas (CNG) or liquefied natural gas (LNG) to areas without access to pipelines. Cylinders are another essential component, providing storage for the transported gas. Valves and fittings ensure smooth operations and safe handling of the gas in the virtual pipeline system.

- **By Application:** In terms of applications, the virtual pipeline systems market can be categorized into industrial, transportation, commercial, and residential sectors. The industrial sector utilizes virtual pipelines for various operations such as heat generation, power generation, and manufacturing processes. The transportation sector relies on virtual pipelines to fuel vehicles, especially in regions where traditional pipelines are not feasible. The commercial and residential sectors use virtual pipeline systems for heating, cooking, and other energy needs.

- **By Mode of Supply:** Virtual pipeline systems can also be segmented by the mode of supply, which includes truck-based transportation, rail-based transportation, and ship-based transportation. Truck-based transportation is the most common mode, offering flexibility and scalability in delivering natural gas to remote locations. Rail-based transportation provides a cost-effective solution for long-distance gas transportation. Ship-based transportation involves the use of tankers for transporting LNG to areas inaccessible by land.

**Market Players**

- **GE Oil & Gas:** GE Oil & Gas is a key player in the virtual pipeline systems market, offering a range of solutions for the compression, transportation, and storage of natural gas. The company's expertise in industrial equipment and services makes it a reliable partner for virtual pipeline projects.

- **Hexagon Composites ASA:** Hexagon Composites ASA specializes in high-pressure composite cylinders for gas storage, making them a significant player in the virtual pipeline systems market. TheirGE Oil & Gas and Hexagon Composites ASA are two key players in the virtual pipeline systems market, each bringing unique strengths and capabilities to the industry. GE Oil & Gas stands out for its comprehensive solutions for compression, transportation, and storage of natural gas. With its expertise in industrial equipment and services, the company offers a broad range of offerings that cater to the diverse needs of virtual pipeline projects. GE's reputation for reliability and innovation positions it as a trusted partner for implementing virtual pipeline systems across various sectors.

On the other hand, Hexagon Composites ASA specializes in high-pressure composite cylinders for gas storage, a critical component in virtual pipeline systems. The use of advanced composite materials in their cylinders enables Hexagon to provide lightweight and durable storage solutions for transporting natural gas efficiently and safely. The company's focus on innovation and sustainability in gas storage technologies has solidified its position as a significant player in the virtual pipeline systems market. Hexagon's expertise in high-pressure cylinders aligns with the increasing demand for reliable and high-performance storage solutions in virtual pipeline applications.

As the virtual pipeline systems market continues to grow, players like GE Oil & Gas and Hexagon Composites ASA are poised to capitalize on the increasing demand for efficient and flexible gas transportation solutions. The market trends indicate a rising adoption of virtual pipelines across various sectors, driven by the need for reliable energy supply in remote locations and areas without access to traditional pipelines. The versatility of virtual pipeline systems in industrial, transportation, commercial, and residential applications further expands the market potential for key players like GE and Hexagon.

In terms of competition within the virtual pipeline systems market, companies like GE Oil & Gas and Hexagon Composites ASA differentiate themselves through technological advancements, product innovation, and strategic partnerships. Establishing strong relationships with customers and industry stakeholders is essential for driving growth and expanding market presence. Furthermore, addressing evolving regulatory requirements and sustainability concerns will be crucial for staying competitive in the dynamic virtual pipeline systems market.

Overall, the market outlook for virtual pipeline systems remains**Global Virtual Pipeline Systems Market Analysis:**

- **Segments:** - **By Component:** Virtual pipeline systems market components include compressors, trailers, cylinders, valves, fittings, and others. Compressors are essential for efficient gas transportation, while trailers are used for physical gas transportation to areas without traditional pipelines. Cylinders provide storage for the transported gas, with valves and fittings ensuring smooth operations and safe handling within the system.

- **By Application:** Market applications cover industrial, transportation, commercial, and residential sectors. Industrial operations utilize virtual pipelines for heat and power generation, transportation for vehicle fueling, and commercial/residential sectors for heating and cooking purposes.

- **By Mode of Supply:** Segmentation by the mode of supply includes truck-based, rail-based, and ship-based transportation. Truck-based transportation offers flexibility and scalability, rail-based is cost-effective for long-distance transportation, and ship-based involves tankers for LNG transportation to remote areas.

**Market Players:** - **GE Oil & Gas:** GE Oil & Gas offers compression, transportation, and storage solutions for natural gas with a focus on industrial expertise, making them a reliable partner for virtual pipeline projects.

- **Hexagon Composites ASA:** Specializing in high-pressure composite cylinders for gas storage, Hexagon Composites ASA provides lightweight and durable storage solutions for efficient and safe gas transportation, aligning with the increasing demand for reliable storage solutions in virtual pipeline applications.

Key players like GE Oil & Gas

Highlights of TOC:

Chapter 1: Market overview

Chapter 2: Global Virtual Pipeline Systems Market

Chapter 3: Regional analysis of the Global Virtual Pipeline Systems Market industry

Chapter 4: Virtual Pipeline Systems Market segmentation based on types and applications

Chapter 5: Revenue analysis based on types and applications

Chapter 6: Market share

Chapter 7: Competitive Landscape

Chapter 8: Drivers, Restraints, Challenges, and Opportunities

Chapter 9: Gross Margin and Price Analysis

Key takeaways from the Virtual Pipeline Systems Market report:

Detailed considerate of Virtual Pipeline Systems Market-particular drivers, Trends, constraints, Restraints, Opportunities and major micro markets.

Comprehensive valuation of all prospects and threat in the

In depth study of industry strategies for growth of the Virtual Pipeline Systems Market-leading players.

Virtual Pipeline Systems Market latest innovations and major procedures.

Favorable dip inside Vigorous high-tech and market latest trends remarkable the Market.

Conclusive study about the growth conspiracy of Virtual Pipeline Systems Market for forthcoming years.

Browse Trending Reports:

Air Sports Equipment Market Secondary Macronutrients Market Blood Gas Analyzer Market Methotrexate Injection Market Smart Room Heater Market Battery Market Infrastructure As a Service Iaas Health Cloud Market Peritonitis Treatment Market Yacht Charter Market Next Generation Printing Ink Market Functional Confectionery Market Herbal Ready To Brink Beverages Market Wirewound Resistor Market Gelatin Substitutes Market Soy Based Surfactants Market Trimethlyaminuria Market Secondary Agricultural Nutrients Market Tomatoes Market Electric Kick Scooters Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

0 notes

Text

Industrial Coatings Unveiled: Protecting Assets, Enhancing Performance

The global industrial coating market is on a steady growth trajectory, driven by the increasing demand for protective and aesthetic coatings across a range of industries. According to the report, the market is projected to grow at a compound annual growth rate (CAGR) of over 4% during the forecast period of 2022-2028. The market, valued at more than USD 83 billion in 2022, is expected to reach approximately USD 112 billion by 2028.

What is Industrial Coating?

Industrial coatings are specialized coatings applied to various substrates such as metals, plastics, and wood for protective, decorative, and functional purposes. These coatings are commonly used in industries like automotive, aerospace, marine, oil and gas, and manufacturing to protect surfaces from corrosion, wear, and environmental damage, while also providing desired finishes and textures.

Get Sample pages of Report: https://www.infiniumglobalresearch.com/reports/sample-request/33256

Market Dynamics and Key Growth Drivers

Several factors are contributing to the robust growth of the global industrial coating market:

Rising Demand for Corrosion Protection: Industries such as oil and gas, marine, and infrastructure are increasingly seeking durable coatings to protect equipment and structures from corrosion and wear. Industrial coatings play a crucial role in extending the lifespan of machinery and infrastructure by preventing damage caused by environmental factors, chemicals, and heavy use.

Automotive and Aerospace Industry Growth: The automotive and aerospace sectors are key consumers of industrial coatings. As vehicle and aircraft production continues to grow, there is an increasing need for coatings that enhance durability, reduce maintenance costs, and provide aesthetic appeal. Lightweight materials, such as composites and aluminum, are also driving demand for specialized coatings.

Technological Advancements in Coating Formulations: The development of environmentally friendly, low-VOC (volatile organic compounds), and high-performance coatings is further propelling market growth. These innovations help meet stringent environmental regulations while offering superior protection and performance.

Infrastructure Development and Urbanization: Rapid urbanization and infrastructure development, especially in emerging economies, are fueling demand for industrial coatings used in construction and building maintenance. Coatings that protect steel structures, concrete, and other building materials are in high demand for large-scale construction projects.

Regional Analysis

North America: North America holds a significant share of the global industrial coating market, with strong demand coming from the automotive, aerospace, and oil and gas industries. The U.S. is a key market in the region, driven by technological advancements and the increasing focus on eco-friendly coatings.

Europe: Europe is another major market for industrial coatings, with countries like Germany, the U.K., and France leading the way. The region's focus on sustainable development and compliance with strict environmental regulations is driving demand for low-VOC and water-based coatings.

Asia-Pacific: The Asia-Pacific region is the fastest-growing market for industrial coatings, owing to rapid industrialization, urbanization, and infrastructure development. Countries like China, India, and Japan are experiencing a surge in demand for coatings used in construction, automotive, and electronics industries.

Latin America and Middle East & Africa: These regions are witnessing steady growth in the industrial coating market, driven by the expansion of the oil and gas sector, infrastructure projects, and the need for corrosion protection in industrial applications.

Competitive Landscape

The industrial coating market is highly competitive, with several global players dominating the industry. Key companies are focusing on product innovation, strategic partnerships, and mergers and acquisitions to expand their market presence. Some of the leading players in the industrial coating market include:

PPG Industries, Inc.: A major player in the global coatings market, PPG Industries offers a wide range of industrial coatings for automotive, aerospace, and architectural applications.

AkzoNobel N.V.: Known for its innovative and sustainable coatings solutions, AkzoNobel is a leading provider of high-performance industrial coatings.

Axalta Coating Systems Ltd.: Specializing in coatings for the automotive, industrial, and commercial sectors, Axalta is a key player in the global industrial coatings market.

Sherwin-Williams Company: Sherwin-Williams offers a comprehensive portfolio of coatings for industrial and commercial applications, focusing on sustainability and performance.

BASF SE: A global chemical company, BASF provides a range of industrial coatings with a focus on environmentally friendly solutions and advanced technologies.

Report Overview : https://www.infiniumglobalresearch.com/reports/global-industrial-coating-market

Challenges and Opportunities

The industrial coating market faces several challenges, including:

Environmental Regulations: Stricter regulations on VOC emissions and hazardous substances are driving the need for eco-friendly coatings. Manufacturers are investing in research and development to produce coatings that comply with these regulations while maintaining high performance.

Raw Material Price Volatility: Fluctuations in the prices of raw materials, such as resins, pigments, and solvents, can impact the overall production costs of industrial coatings. Companies are exploring alternative raw materials and cost-efficient production methods to mitigate these effects.

Technological Advancements: The development of nanotechnology-based coatings, self-healing coatings, and smart coatings presents significant growth opportunities. These advanced coatings offer enhanced durability, corrosion resistance, and self-repairing properties, which are increasingly sought after in industries like automotive and aerospace.

Conclusion

The global industrial coating market is expected to continue its steady growth, reaching approximately USD 112 billion by 2028. With increasing demand from sectors such as automotive, aerospace, and infrastructure, along with technological advancements in coating formulations, the market offers substantial opportunities for innovation and investment. However, challenges such as environmental regulations and raw material price volatility will require companies to focus on sustainable solutions and cost-effective production methods to maintain competitiveness.

0 notes

Text

Breather Vent Market Size, Share, Analysis and Opportunities by 2024-2032

The Reports and Insights, a leading market research company, has recently releases report titled “Breather Vent Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Breather Vent Market, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Breather Vent Market?

The breather vent market is expected to grow at a CAGR of 7.8% during the forecast period of 2024 to 2032.

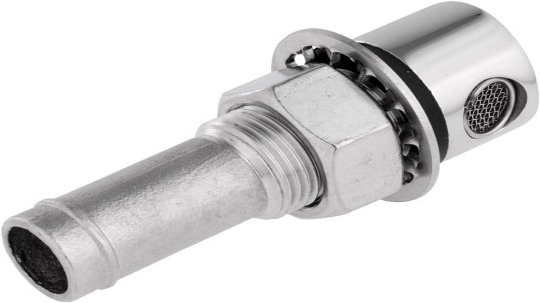

What are Breather Vent?

A breather vent is a specialized device designed to allow air to flow in and out of a sealed container or system, such as tanks, vessels, or pipelines, while keeping out contaminants, dust, and moisture. Its primary function is to equalize pressure changes that occur due to temperature variations, liquid transfers, or operational activities, thereby safeguarding the integrity of the container and its contents. Breather vents may include filters or check valves to enhance their effectiveness, ensuring that only clean air enters while allowing gases to escape safely. By maintaining proper pressure and preventing vacuum conditions, breather vents play a crucial role in the safe and efficient functioning of various industrial applications, including chemical storage, fuel tanks, and wastewater treatment systems.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1927

What are the growth prospects and trends in the Breather Vent industry?

The breather vent market growth is driven by various factors and trends. The breather vent market is witnessing consistent growth, propelled by the rising demand for effective pressure management solutions across various sectors, including oil and gas, chemical processing, and wastewater treatment. As regulations concerning safety and environmental protection tighten, companies are increasingly utilizing breather vents to maintain the integrity of their storage systems and prevent contamination. The market features a diverse range of products, including vents equipped with advanced functionalities such as filters, check valves, and automated monitoring systems that enhance both performance and reliability. Additionally, the growing emphasis on sustainable practices and the need for efficient resource management are contributing to market expansion. With ongoing technological innovations and heightened awareness of air quality and safety, the breather vent market is well-positioned for further growth, serving a variety of applications across multiple industries. Hence, all these factors contribute to breather vent market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type:

Inline Breather Vent

Threaded Breather Vent

Bayonet Breather Vent

Customized Breather Vent

By Material:

Metal Breather Vent

Plastic Breather Vent

Composite Breather Vent

By End-Use Industry:

Automotive

Aerospace and Defense

Manufacturing

Oil and Gas

Chemicals and Pharmaceuticals

Electronics

Food and Beverage

Others

By Sales Channel:

Direct Sales

Distributor Sales

Market Segmentation By Region:

North America:

United States

Canada

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

Parker Hannifin Corporation

Donaldson Company, Inc.

MANN+HUMMEL GmbH

L. Gore & Associates, Inc.

Pall Corporation

Porvair Filtration Group

Eaton Corporation plc

SMC Corporation

Bosch Rexroth AG

Festo AG & Co. KG

Swagelok Company

Emerson Electric Co.

IMI plc

Camfil AB

WAMGROUP S.p.A.

View Full Report: https://www.reportsandinsights.com/report/Breather Vent-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

0 notes

Text

Advanced Materials Market - Forecast(2024 - 2030)

Advanced Materials Market Overview