#Carbon nanotubes (CNTs)

Explore tagged Tumblr posts

Text

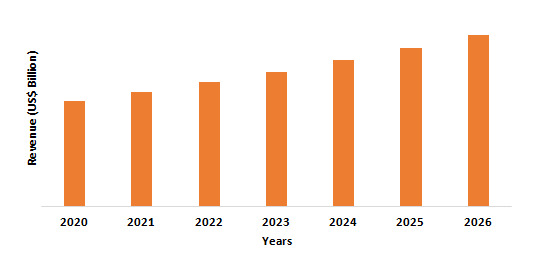

China Top 4 Companies Accounted for 74% of total Carbon Nanotube(CNT)market (QYResearch, 2021)

According to the new market research report “China Carbon Nanotube(CNT) Market Report 2023-2029”, published by QYResearch, the China Carbon Nanotube(CNT) market size is projected to reach USD 2.93 billion by 2029, at a CAGR of 38.4% during the forecast period.

Figure. China Carbon Nanotube(CNT) Market Size (US$ Million), 2018-2029

Figure. China Carbon Nanotube(CNT) Top 4 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

The China key manufacturers of Carbon Nanotube(CNT) include Tiannai Technology, Sanshun Nano, etc.

In 2022, the China top three players had a share approximately 74.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Cleaner, Greener New Carbon Nanotubes Synthesis Unveiled

Feb 14: In a breakthrough development in Carbon Nanotubes Synthesis science, researchers at the Institute of Advanced Study in Science and Technology (IASST), an autonomous institute of the Department of Science and Technology (DST), Government of India, have unveiled a pioneering method for the synthesis of Carbon Nanotubes (CNTs) directly on glass substrates. This innovative technique,…

View On WordPress

0 notes

Text

Carbon Nanotubes Market – Global Industry Trends, Uses, Applications, Business Analysis, Growth Opportunities, Segmentation, Graph and Forecast Share to 2028

The carbon nanotube (CNT) market exhibits high growth potential and is projected to reach a market size of USD 2.3 billion by 2028 from USD 1.1 billion in 2023, at a CAGR of 14.6%. Asia Pacific is the largest carbon nanotube (CNT) industry that is projected to register the highest CAGR during the forecasted period. This high growth is due to the growing demand from the automotive, electronics &…

View On WordPress

#carbon nanotube applications#carbon nanotube uses#Carbon Nanotubes#Carbon Nanotubes Demand#Carbon Nanotubes Industry#Carbon Nanotubes Industry Trends#Carbon Nanotubes Manufacturers#Carbon Nanotubes Market#Carbon Nanotubes Market Forecast#Carbon Nanotubes Market Graph#Carbon Nanotubes Market Insights#Carbon Nanotubes Market Report#Carbon Nanotubes Market Scope#Carbon Nanotubes Market Trends#cnt applications#cnt uses

0 notes

Text

Researchers synthesize carbon nanotubes with precise chirality

Researchers have achieved a significant breakthrough in the synthesis of carbon nanotubes (CNTs) by developing a novel catalyst that allows for precise control over their atomic arrangement, known as chirality. This advancement paves the way for the creation of innovative semiconductor devices, addressing a challenge that has remained unresolved for over 30 years. The team consisting of researchers across Japan, led by Associate Professor Toshiaki Kato from the Advanced Institute for Materials Research (WPI-AIMR), has successfully synthesized CNTs with a chiral index of (6,5) at an ultra-high purity of over 95%. These findings were published in ACS Nano on August 20, 2024. "A carbon nanotube is basically a sheet of carbon rolled into a hollow tube," explains Kato, "While it sounds simple, CNTs are highly sought after for properties such as their exceptional conductivity, optical characteristics, and mechanical strength."

Read more.

#Materials Science#Science#Nanotubes#Nanotechnology#Carbon nanotubes#Carbon#Materials synthesis#Chirality#Catalysts#Nickel#Tin#Iron#Tohoku University

8 notes

·

View notes

Text

Iron nanotubes are produced by growing carbon nanotubes (CNTs) on a substrate with iron catalyst particles. The process involves heating the substrate to a high temperature in the presence of carbon-containing gases and a process gas.

Process

Prepare the substrate: Cover the substrate with a layer of iron catalyst particles.

Heat the substrate: Heat the substrate to a high temperature, usually around 700°C.

Introduce gases: Add a carbon-containing gas, like methane, ethylene, or acetylene, and a process gas, like hydrogen, nitrogen, or ammonia.

Grow nanotubes: The carbon-containing gas breaks down at the catalyst particles, and carbon forms nanotubes at the edges of the particles.

Factors that affect the process

Size of metal particles: The size of the metal particles controls the diameter of the nanotubes.

Type of hydrocarbon: Linear hydrocarbons, like methane, produce straight nanotubes, while cyclic hydrocarbons, like benzene, produce curved nanotubes.

Iron concentration: Higher iron concentrations can form larger iron nanoparticles that don't support CNT formation.

Applications

Iron nanotubes can be used to create composites with iron oxide, or to create reinforced iron ore tailing. - "Google AI answer on how to make Iron Nanotubes:

https://www.nanoscience.com/techniques/atomic-force-microscopy/

5 notes

·

View notes

Text

Space travel: Protection from cosmic radiation with boron nitride nanotube fibers

With the success of the Nuri launch last year and the recent launch of the newly established Korea Aerospace Administration, interest in space has increased, and both the public and private sectors are actively investing in space-related industries such as space travel. However, exposure to cosmic radiation is unavoidable when traveling to space.

A research team led by Dr. Dae-Yoon Kim from the Center for Functional Composite Materials at the Korea Institute of Science and Technology (KIST) has developed a new composite fiber that can effectively block neutrons in space radiation. The work is published in the journal Advanced Fiber Materials.

Neutrons in space radiation negatively affect life activities and cause electronic devices to malfunction, posing a major threat to long-term space missions.

By controlling the interaction between one-dimensional nanomaterials, boron nitride nanotubes (BNNTs), and aramid polymers, the team developed a technique to perfectly blend the two difficult-to-mix materials. Based on this stabilized mixed solution, they produced lightweight, flexible, continuous fibers that do not burn at temperatures up to 500°C.

BNNTs have a similar structure to carbon nanotubes (CNTs), but because they contain a large number of boron in the lattice structure, their neutron absorption capacity is about 200,000 times higher than that of CNTs. Therefore, if the developed BNNT composite fibers are made into fabrics of the desired shape and size, they can be applied as a good material that can effectively block radiation neutron transmission.

This means that BNNT composite fibers can be applied to the clothing we wear every day, effectively protecting flight crews, health care workers, power plant workers, and others who may be easily exposed to radiation.

In addition, the ceramic nature of BNNTs makes them highly heat-resistant, so they can be used in extreme environments. Therefore, it can be used not only for space applications but also for defense and firefighting.

"By applying the functional textiles we have developed to the clothing we wear every day, we can easily create a minimum safety device for neutron exposure," said Dr. Dae-Yoon Kim of KIST.

"As Korea is developing very rapidly in the space and defense fields, we believe it will have great synergy."

TOP IMAGE: Applications of BNNT-based functional fabrics / The BNNT-based composite fibers can be manufactured into fabrics of various shapes and sizes through weaving. The developed fabrics can be utilized in clothing to protect astronauts, crew members, soldiers, firefighters, health care workers, and power plant workers who are expected to be exposed to radiation. The fabric can also be applied to electronic device packaging to prevent soft errors. Credit: Korea Institute of Science and Technology

CENTRE IMAGE: Development of BNNT composite functional fibers for space radiation shielding / If continuous composite fibers containing high content of BNNTs are used as functional fabrics, they can effectively shield neutrons in space radiation to reduce harmful effects on human health and prevent soft errors in electronic devices. These functional fabrics are expected to play an important role in the fields of aviation, space, and national defense. Credit: Korea Institute of Science and Technology

LOWER IMAGE: Development of BNNT composite continuous fibers / By overcoming the low dispersibility of BNNTs through interaction with aramid polymers, stable composite solutions can be prepared. This paves the way for the development of composite fibers that take advantage of the excellent properties of BNNTs and can be effectively utilized in various applications. Credit: Korea Institute of Science and Technology

3 notes

·

View notes

Text

https://www.databridgemarketresearch.com/ko/reports/global-carbon-nanotubes-cnt-market

0 notes

Text

0 notes

Text

KSA Nanotubes Market: A Technological Breakthrough Powering Saudi Innovation

The Kingdom of Saudi Arabia’s Nanotubes Market is emerging as a critical player in the global nanotechnology landscape, fueled by advancements in material science and strong government initiatives under Vision 2030. From energy storage to healthcare, nanotubes are unlocking new possibilities across industries. But how deep is this transformation, and what does the future hold for this rapidly evolving market?

The KSA Nanotubes Market was valued at USD 36.3 million in 2023, with projections to grow at an impressive CAGR of 31.2%, reaching USD 242 million by 2030. This growth is driven by expanding applications in renewable energy, electronics, and advanced materials.

Key Market Insights

High Demand in Energy Storage: The energy storage segment led the nanotubes market in 2023, accounting for 21% of revenue, driven by their use in batteries and supercapacitors.

Electronics Applications: Nanotubes’ superior electrical conductivity has positioned them as a key material in semiconductors and advanced electronic components.

Healthcare Integration: In the medical sector, carbon nanotubes (CNTs) are being used to improve drug delivery systems and develop biocompatible implants, contributing to improved patient outcomes.

Trends Shaping the KSA Nanotubes Market

1. Renewable Energy Solutions: Nanotubes are enabling more efficient energy storage systems, critical for Saudi Arabia’s renewable energy goals under Vision 2030.By 2030, over 40% of Saudi energy storage systems will incorporate nanotube-based technologies.

2. Expansion in Advanced Electronics: CNTs are revolutionizing electronics by offering faster processing speeds and miniaturization of components. By 2025, nanotube-enabled electronics are expected to contribute to 25% of semiconductor advancements in KSA.

3. Growth in Healthcare Applications: CNTs are enhancing drug delivery efficiency and enabling early disease detection through advanced imaging solutions. The healthcare segment’s adoption of nanotubes is projected to grow by 20% CAGR over the next five years.

4. Focus on Sustainability: Nanotubes are aiding in the development of lighter, stronger materials, reducing energy consumption across sectors.By 2028, nanotube-based composites are expected to reduce material weights in construction and automotive industries by 15%, contributing to sustainability goals.

Future Opportunities in KSA’s Nanotubes Market

1. Integration with Renewable Energy Projects: Saudi Arabia’s ambitious NEOM and Red Sea Project are creating demand for advanced materials like nanotubes to enhance renewable energy infrastructure. Renewable energy applications are expected to contribute over USD 80 million to the nanotubes market by 2030.

2. Growth in Aerospace and Automotive Sectors: Nanotube composites are being adopted for lightweight and durable materials in aerospace and automotive industries.These sectors are set to grow by 28% CAGR, driven by nanotube innovations.

3. Localized Manufacturing Capabilities: Investments in local nanotube production facilities are expected to reduce reliance on imports and boost domestic innovation.Local manufacturing initiatives could add USD 50 million annually to the market by 2028.

4. Enhanced Research and Development (R&D): Increased R&D funding from both private and government sectors is accelerating innovation in nanotechnology applications.R&D efforts are expected to drive the development of next-generation nanotube-based materials.

Challenges in the KSA Nanotubes Market

Despite its promising growth trajectory, the KSA nanotubes market faces certain challenges:

High Production Costs: The manufacturing process for nanotubes remains expensive, limiting large-scale adoption.

Regulatory Framework: Developing clear standards for the use of nanomaterials is crucial for market expansion.

Skill Gaps: The need for skilled professionals to manage and innovate within the nanotubes industry is a growing concern.

Conclusion:

The KSA Nanotubes Market is positioned as a cornerstone of Saudi Arabia’s technological and industrial transformation. From driving renewable energy innovation to revolutionizing healthcare and electronics, nanotubes are unlocking unprecedented opportunities for growth and sustainability. As the Kingdom continues to diversify its economy and invest in advanced technologies under Vision 2030, the role of nanotubes will only expand. For businesses, investors, and researchers, the time to capitalize on this transformative market is now.

#KSA Nanotubes Market size#KSA Nanotubes Market trends#KSA Nanotubes Market share#KSA Nanotubes Market revenue#KSA Nanotubes Market outlook#KSA Nanotubes Market forecast

0 notes

Text

0 notes

Text

Electroactive Polymers Market — By Type , By Application , By Geography — Global Opportunity Analysis & Industry Forecast, 2024–2030

Electroactive Polymers Market Overview

Request Sample :

Electroactive Polymers Market COVID-19 Pandemic

The outbreak of Covid-19 is having a huge impact on the economy of electronic devices. The COVID-19 pandemic caused an unprecedented increased demand for some medical devices, as well as significant disruptions in the manufacturing and supply chain operations of global medical devices. The FDA monitors the supply chain of medical products and works closely with producers and other stakeholders to assess the risk of disruption and to prevent or reduce its impact on patients, health care providers, and the general public’s health. In addition, there is a delay in imports and exports of medical devices due to the import-export restriction by the governments in various regions. All these factors are having a major impact on the Electroactive Polymers Market during the pandemic.

Report Coverage

The report: “Electroactive Polymers Market — Forecast (2024–2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the electroactive polymers Industry.

By Type: Ionic Electroactive Polymers (Ionic Polymer Gels (IPG), Ionic Polymer Metal Composites (IPMC), Conductive Polymers (CP), and Carbon Nanotubes (CNT)), Electronic Electroactive Polymers (Ferroelectric Polymers, Electrostrictive Graft Elastomers, Dielectric Elastomers, Electro VIscoelastic Elastomers, Liquid Crystal Elastomer (LCE), and Others), and Others.

By Application: Actuators, Sensors, Plastic, Aviation Technology, Energy Generation, Automotive Devices, Prosthetics, Robotics, and Others.

By Geography: North America (U.S., Canada, and Mexico), Europe (U.K, Germany, France, Italy, Netherland, Spain, Russia, Belgium, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), Rest of the World (Middle East, and Africa).

Inquiry Before Buying :

Key Takeaways

Asia-Pacific dominates the Electroactive Polymers Market owing to the increasing demand for the electroactive polymers industry in the region. The increasing urbanization coupled with the rising population in APAC is the major factor driving the demand for electroactive polymers.

Electroactive polymers are extensively used for corrosion-preventing coatings in ferrous and non-ferrous alloys, actuators, damped harmonic oscillator, metamorphic biomaterials, and protective fabrics points. These properties of electroactive polymers are projected to increase market growth.

Electroactive polymers due to its unique properties find application in different end-use industries. These are lighter in weight, more durable, and have better conductive properties, unlike conventional materials (metals). During the forecast period, this factor is anticipated to drive the market.

Due to the Covid-19 pandemic, most of the countries have gone under lockdown, due to which the projects and operations of various industries such as energy generation and automotive are disruptively stopped, which is hampering the Electroactive Polymers Market growth.

Electroactive Polymers Market Segment Analysis — By Type

The conductive polymers segment held the largest share in the Electroactive Polymers Market in 2020 and is growing at a CAGR 8.10% over 2024–2030. The significant class of functional materials that have certain useful properties of both organic polymers (such as strength, plasticity, flexibility, strength, elasticity) and semiconductors (such as electric conductivity) are conducting polymers (CPs). The conductive polymers are often used in miniature boxes that have the ability to open and close, micro-robots, surgical tools, surgical robots that assemble other micro-devices. In addition, conductive polymers (CPs) are extensively used as an alternative to metallic interfaces within biomedical devices as a way of imparting electroactivity to normally passive devices such as tissue scaffolds. Thus, all these extensive characteristics of conductive polymers are the key factor anticipated to boost the demand for conductive polymers in various regions during the forecast period.

Schedule A Call :

Electroactive Polymers Market Segment Analysis — By Application

The actuator segment held the largest share in the Electroactive Polymers Market in 2020 and is expected to grow with a CAGR of 7.2% for forecast period. To maximize the actuation capability and durability, effective fabrication, shaping, and electrode techniques are being developed. Many engineers and scientists from many different disciplines are attracting attention with the impressive advances in improving their actuation strain. Due to their inherent piezoelectric effect, ferroelectric polymers, such as polyvinylidene fluoride (PVDF), are largely used in manufacturing electromechanical actuators. For biomimetic applications, these materials are especially attractive, as they can be used to make intelligent robots and other biologically inspired mechanisms. To form part of mass-produced products, many EAP actuators are still emerging and need further advancements. This requires the use of models of computational chemistry, comprehensive science of materials, electro-mechanical analytical tools, and research into material processing. Which will eventually drive is the Electroactive Polymers Market during the forecast period.

Electroactive Polymers Market Segment Analysis — By Geography

Asia-Pacific region held the largest share in the Electroactive Polymers Market in 2020 up to 38%, owing to the escalating medical device industry in the region. A key factor behind the growth of the region’s electroactive polymer market is the large demand for electroactive polymers for the manufacture of advanced implant devices for medical conditions. According to Invest India, the Indian medical device sector is projected to register a CAGR of 14.8% and is expected to reach $11.9 billion in 2021–22, and the sector is projected to reach $ 65 bn industry by 2024. According to the most recent official figures from the Ministry of Health, Labour and Welfare (MHLW), the Japanese medical devices market in 2018 was roughly $29.3 billion, up about 6.9 percent from 2017 in yen terms. And from 2018 to 2023, the medical device market in Japan is estimated to show an increment of 4.5% CAGR in yen terms. Furthermore, North America also holds a prominent market share of the Electroactive Polymers Market due to the escalating medical device industry. According to the Select USA, the United States medical device market is anticipated to rise to $208 billion by the year 2023. Thus, with the expanding medical device industry, the demand for electroactive polymers will also subsequently increase, which is anticipated to drive the Electroactive Polymers Market in the Asia Pacific and North America during the forecast period.

Electroactive Polymers Market Drivers

Increasing Automotive Production

In the automotive industry, electroactive polymers are used as actuators and sensors. For materials that are light in weight but strong and durable such as an electroactive polymer, there is high demand. By using modern electroactive polymers in numerous automotive electronic components, such as multiple sensors, accelerometers, and accelerator pedal modules, car manufacturers are attempting to achieve lightweight properties. China is the world’s largest vehicle market, according to the International Trade Administration (ITA), and the Chinese government expects the production of cars to reach 35 million by 2025. According to the International Trade Administration (ITA), in 2019 the Mexican market for electric, plug-in vehicles, and hybrid vehicles reached 25,608 units, representing a 43.8% growth over 2018. Thus, increasing automation production will require more electroactive polymers for manufacturing various automotive components, which will act as a driver for the Electroactive Polymers Market during the forecast period.

Increasing Application of Electroactive Polymers

Textiles called sensing and actuating microfibers can be directly woven into electromechanical systems such as sensors, actuators, electronics, and power sources. They can be used as smart fabrics because of the flexibility and low cost of electroactive polymers. In developing intelligent fabrics, polypyrrole and polyaniline are used. In addition, using electroactive polymers in robotics for muscle development is better, as it is more cost-effective than the semiconductor and metal materials. And robotics is widely used; hence the demand for electroactive polymers will also positively affect the market growth. Furthermore, Electroactive Polymers Market growth is increasing owing to its wide usage in areas such as medical devices, damped harmonic oscillator, electric displacement field, electrostatic discharge/electromagnetic interference, high-strain sensors, and biomimetic. Hence, the increasing application of electroactive polymers acts as a driver for the Electroactive Polymers Market.

Buy Now :

Electroactive Polymers Market Challenges

Environmental Hazards Related to the Electroactive Polymers

Raw materials which are used to produce electroactive polymers (EAPs) are difficult to extract and often harmful to the environment. The disposal of waste generated by electroactive polymers is one of the major concerns (EAPs). Improper disposal of EAP products could harm the environment and ultimately impact the food chain. Manufacturers of EAPs may experience increased costs associated with the disposal of certain electroactive polymers (EAPs) that cannot be disposed of by biodegradation. The government has, therefore, enforced strict regulations on the use of such polymers. Besides, the environmental regulations on the use of petroleum products restrict the growth of the EAPs market. These factors are hampering the electroactive polymer market growth.

Electroactive Polymers Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the Electroactive Polymers Market. Major players in the Electroactive Polymers Market are Solvay, Parker Hannifin, Agfa-Gevaert, 3M, Merck, Lubrizol, Novasentis, Premix, PolyOne Corporation, Celanese Corporation, and KEMET Corporation.

Key Market Players:

The Top 5 companies in the Electroactive Polymers Market are:

Merck

3M

Solvay

Parker Hannifin

Agfa-Gevaert

For more Chemicals and Materials Market reports, Please click here

#ElectroactivePolymers#SmartMaterials#ConductivePolymers#FlexibleElectronics#ShapeMemoryAlloys#PolymersInElectronics#SoftRobotics

0 notes

Text

0 notes

Text

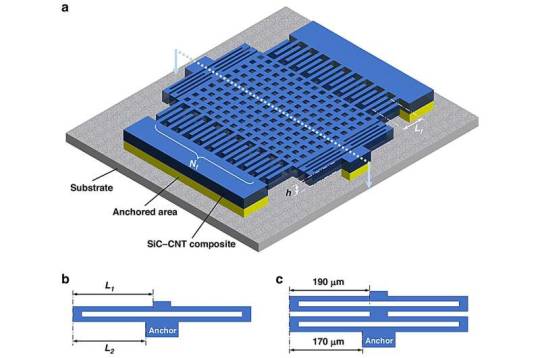

Scientists develop composite accelerometer for extreme environments

The demand for microelectromechanical systems (MEMS) resilient to harsh environments is growing. Silicon-based MEMS struggle under extreme conditions, limited by their performance at elevated temperatures. Silicon carbide (SiC) stands out as a promising solution, offering unmatched thermal, electrical, and mechanical advantages for creating enduring MEMS. Despite its potential, SiC MEMS development is challenged by the intricacies of bulk micromachining, calling for innovative strategies to harness SiC's strengths in crafting robust devices. In response, scientists have crafted an accelerometer using a novel silicon carbide-carbon nanotube (SiC-CNT) composite, capable of enduring severe environmental stress. Published in Microsystems & Nanoengineering in April 2024, this research unveils a revolutionary material fusion, merging SiC's durability with the versatility and conductive qualities of CNTs.

Read more.

#Materials Science#Science#Composites#MEMS#Silicon#Silicon carbide#Carbides#Carbon nanotubes#Nanotechnology#Carbon#Nanotubes

13 notes

·

View notes

Text

Carbon Nanotubes Market: Transforming Advanced Applications

Carbon nanotubes (CNTs) have emerged as a pivotal material in the world of nanotechnology, reshaping how industries approach challenges in performance, efficiency, and sustainability. With unmatched strength-to-weight ratios, superior electrical conductivity, and extraordinary thermal properties, CNTs are driving innovation in electronics & semiconductors, energy & storage, and structural composites.

This article explores how the CNT market is fueling advancements across these sectors, delving into trends, real-world applications, and the exciting opportunities ahead.

Driving Forces Behind the CNT Market

The carbon nanotubes market is projected to reach USD 2.63 billion by 2029, growing at 14.9% cagr. This momentum is fueled by:

Technology Demands: As devices shrink and efficiency demands rise, CNTs provide the precision and conductivity required in next-generation semiconductors and flexible electronics.

Energy Revolution: With the push for renewable energy and electric vehicles, CNTs are stepping up as enablers of higher-capacity, faster-charging energy storage solutions.

Lightweight Materials: Aerospace, automotive, and construction industries are leveraging CNT-infused composites to build lighter, stronger, and more sustainable products.

CNT Applications Redefining Industries

Electronics & Semiconductors: Powering the Future

The push for miniaturization and performance improvement has positioned CNTs as a critical component in advanced electronics.

Next-Gen Transistors: CNTs outperform silicon in transistor design, offering faster switching speeds and lower energy consumption. This opens doors for compact, energy-efficient devices.

Flexible Circuits: As foldable phones, wearable tech, and curved displays grow in popularity, CNTs enable the development of flexible, durable electronics without compromising functionality.

Data Interconnects: Their superior conductivity makes CNTs an excellent replacement for copper in semiconductors, boosting performance while reducing signal loss.

Energy & Storage: Meeting Tomorrow’s Demands

In the energy sector, CNTs are unlocking the potential for high-capacity, high-efficiency systems:

Batteries and Supercapacitors: CNTs are transforming lithium-ion batteries and supercapacitors by improving energy density, lifespan, and charge-discharge cycles, all essential for electric vehicles (EVs) and renewable energy storage.

Fuel Cells: By acting as advanced catalyst supports, CNTs enhance fuel cell efficiency while lowering production costs, driving their adoption in clean energy applications.

Solar Power: CNTs are finding applications in photovoltaic cells, boosting efficiency in converting solar energy into electricity.

Structural Composites: Stronger, Lighter, Smarter

CNT-based composites are reshaping how industries design materials for strength and durability.

Aerospace & Automotive: In these sectors, weight reduction is a top priority. CNT composites deliver the lightweight properties needed for better fuel efficiency without sacrificing strength.

Infrastructure: CNTs enhance the resilience of concrete and other construction materials, paving the way for longer-lasting, sustainable structures.

Sports Equipment: From tennis rackets to bicycles, CNTs are redefining performance in athletic gear by providing a superior balance of strength and weight.

Regional Insights

North America: A leader in R&D investment, particularly in aerospace and electronics, driving the adoption of CNTs across high-value applications.

Asia-Pacific: Rapid industrialization and growth in EV production make this region a hotspot for CNT innovation, with China and Japan at the forefront.

Europe: With its strong push toward sustainability, Europe’s focus on renewable energy and green materials aligns perfectly with CNT applications.

Challenges and Opportunities

While CNTs hold immense promise, challenges such as high production costs and scalability remain hurdles. However, innovations in manufacturing, such as chemical vapor deposition (CVD), and government-backed initiatives in nanotechnology are steadily addressing these barriers.

For industries looking to innovate, CNTs offer untapped potential to achieve breakthroughs in efficiency, sustainability, and performance.

To get deeper insights download PDF brochure :

The carbon nanotubes market isn’t just growing—it’s transforming how industries think about materials and performance. From enabling smarter electronics to revolutionizing energy storage and creating lightweight composites, CNTs are a cornerstone of next-generation innovation.

#CarbonNanotubes#Nanotechnology#ElectronicsInnovation#EnergyStorage#StructuralComposites#AdvancedMaterials#CNTMarketTrends

0 notes

Text

https://www.verifiedmarketreports.com/pt/product/global-carbon-nanotube-cnt-market-growth-2019-2024/

0 notes