#Calcined Alumina Market

Explore tagged Tumblr posts

Text

Examining Key Market Players and their Role in the Calcined Alumina Powder Sector

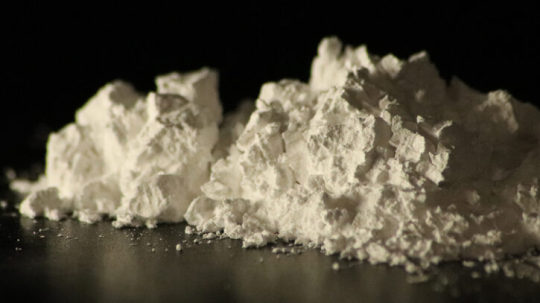

Calcined alumina powder is a kind of aluminium oxide obtained by calcination of aluminium hydroxide at high temperatures. It has various industrial applications such as in production of synthetic corundum, artificial gems, ceramics and fillers for paints, plastics and rubber. It is known for its high strength, hardness and resistance to corrosion from acids, alkalis and chemicals. It also has high temperature stability and dielectric properties. The global calcined alumina powder market is estimated to be valued at US$ 21405.49 Mn in 2023 and is expected to exhibit a CAGR of 5.8% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights. Market Opportunity: The key opportunity for growth in the calcined alumina powder market lies in new product development. Manufacturers can focus on developing new grades of calcined alumina powder catering to emerging applications. For example, developing high purity alumina powder suitable for advanced ceramics used in electronics, semiconductors and energy storage devices. They can also work on surface treatment technologies to impart special features like water repellency, improved flowability etc. Development of nano-sized calcined alumina powder opens up opportunities in areas like catalyst supports and biomedical applications. Investment in R&D will help companies gain first mover advantage and expand market share by tapping into new application segments. Porter's Analysis Threat of new entrants: Low capital requirements and availability of raw materials pose low threat of new entrants. However, established presence of major players pose barriers. Bargaining power of buyers: Buyers have moderate bargaining power due to availability of substitutes and standardized nature of product. Bargaining power of suppliers: Suppliers have moderate bargaining power due to availability of raw material sources. Threat of new substitutes: Substitutes like fused alumina and artificial corundum pose threat. Competitive rivalry: Intense due to global presence of key players and differentiation difficult due to standardized nature. SWOT Analysis Strength: Wide applications in abrasives, refractories, ceramics etc. Standardized production processes. Weakness: Price fluctuations of raw materials. Heavy reliance on end-use industries. Opportunity: Growing refractory and abrasive industries in Asia Pacific. Development of nano-sized powders. Threats: Strict environmental regulations. Threat from substitutes. Key Takeaways The global calcined alumina powder market is expected to witness high growth due to its wide applications in abrasives, refractories, ceramics and other industries.

Regional Analysis of Asia Pacific comprises major countries like China, India and Japan which account for over 60% of global demand. Growth in refractories, ceramics and cement industries has been the major driver in the region. Key players operating in the calcined alumina powder market are Almatis, Graystar LLC, Paradise Minerals, Lianyungang Zhong Ao aluminium Co., Ltd, Hindalco Industries Limited, Fujimi Corporation, Honeywell International Inc, Saint-Gobain Ceramic Materials, READE, Logitech, Fuji Kasei. The market is characterized by presence of large global players and few regional players.

#Calcined Alumina Powder Market Share#Calcined Alumina Powder Market Growth#Calcined Alumina Powder Market Demand#Calcined Alumina Powder Market Trend#Calcined Alumina Powder Market Analysis

0 notes

Text

Global Calcined Alumina Powder Market Is Estimated To Witness High Growth Owing To the Increasing Demand for Advanced Ceramics

The global Calcined Alumina Powder Market is estimated to be valued at US$ 2452.22 Mn in 2022 and is expected to exhibit a CAGR of 5.89% over the forecast period 2022-2032, as highlighted in a new report published by Coherent Market Insights. A) Market Overview: Calcined alumina powder is a high-grade material that is extensively used in various industries such as ceramics, refractories, polishing, and abrasives. It is produced by calcining aluminum hydroxide at high temperatures, resulting in fine white powder with high purity and uniform particle size distribution. The market for calcined alumina powder is driven by the increasing demand for advanced ceramics, which find applications in various industries such as electronics, automotive, aerospace, and healthcare. The properties of calcined alumina powder, such as high strength, thermal stability, and chemical resistance, make it an ideal material for manufacturing advanced ceramics. B) Market Key Trends: One key trend in the calcined alumina powder market is the growing demand for high-purity alumina (HPA). HPA is a processed form of alumina powder with a purity level of 99.99% or higher. It is mainly used in the production of synthetic sapphire, which is used in the manufacturing of LED lights, semiconductor substrates, and scratch-resistant cover glass for electronic devices. The increasing demand for HPA is driven by the growing adoption of LED lighting and the rising popularity of electronic devices such as smartphones and tablets. For instance, according to the International Energy Agency (IEA), the global LED lighting market is expected to reach USD 120 billion by 2025. C) PEST Analysis: Political: The political stability of the countries where alumina powder is sourced and produced can affect the supply chain and pricing of the product. Economic: The economic growth of end-use industries such as electronics and automotive drives the demand for calcined alumina powder. Social: The increasing focus on sustainability and environmental consciousness is leading to the adoption of advanced ceramics, which use calcined alumina powder. Technological: Technological advancements in manufacturing processes are leading to improved quality and performance of calcined alumina powder. D) Key Takeaways: Paragraph 1: The global Calcined Alumina Powder Market is expected to witness high growth, exhibiting a CAGR of 5.89% over the forecast period. This growth is driven by the increasing demand for advanced ceramics in various industries. For example, the automotive industry uses advanced ceramics for engine components, electrical systems, and emission control systems, among others. Paragraph 2: Asia Pacific is expected to be the fastest-growing and dominating region in the calcined alumina powder market. This growth can be attributed to the rapid industrialization and infrastructure development in emerging economies such as China and India. Paragraph 3: Key players operating in the global calcined alumina powder market include Almatis, Hindalco Industries Limited, Graystar LLC, Saint-Gobain Ceramic Materials, Fuji Kasei, READE, Fujimi Corporation, Honeywell International Inc., Lianyungang Zhong Ao Aluminium Co., Ltd, Paradise Minerals, and Logitech. These players focus on product innovation, strategic partnerships, and geographical expansion to gain a competitive edge in the market.

#Calcined Alumina Powder Market#Specialty and Fine Chemicals#Calcined Alumina Powder Market Growth#Calcined Alumina Powder Market Analysis#Calcined Alumina Powder Market Forecast#Calcined Alumina Powder Market Overview#Calcined Alumina Powder Market Orientation

0 notes

Text

0 notes

Text

0 notes

Text

0 notes

Text

Oxyde d'aluminium calciné, Prévisions de la Taille du Marché Mondial, Classement et Part de Marché des 16 Premières Entreprises

Selon le nouveau rapport d'étude de marché “Rapport sur le marché mondial de Oxyde d'aluminium calciné 2024-2030”, publié par QYResearch, la taille du marché mondial de Oxyde d'aluminium calciné devrait atteindre 3780 millions de dollars d'ici 2030, à un TCAC de 0.3% au cours de la période de prévision.

Figure 1. Taille du marché mondial de Oxyde d'aluminium calciné (en millions de dollars américains), 2019-2030

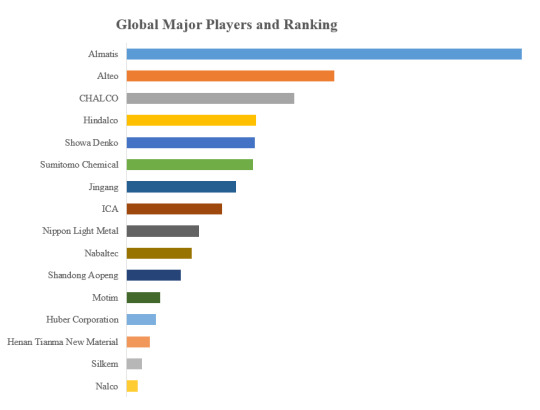

Selon QYResearch, les principaux fabricants mondiaux de Oxyde d'aluminium calciné comprennent Almatis, Alteo, CHALCO, Hindalco, Showa Denko, Sumitomo Chemical, Jingang, ICA, Nippon Light Metal, Nabaltec, etc. En 2023, les dix premiers acteurs mondiaux détenaient une part d'environ 48.0% en termes de chiffre d'affaires.

Figure 2. Classement et part de marché des 16 premiers acteurs mondiaux de Oxyde d'aluminium calciné (Le classement est basé sur le chiffre d'affaires de 2023, continuellement mis à jour)

The market for calcined aluminum oxide, also known as alumina, is influenced by various factors that drive demand and supply dynamics within the industry. Here are some key drivers that impact the calcined aluminum oxide market:

1. Growing Demand in the Ceramics Industry: Calcined aluminum oxide is a crucial raw material in the ceramics industry, where it is used in the production of high-quality ceramics, refractories, and abrasives. The demand for calcined alumina in the ceramics sector is driven by infrastructure development, increased construction activities, and the growing need for advanced ceramic materials in various applications.

2. Increasing Demand in the Abrasives Industry: Calcined aluminum oxide is widely used as an abrasive material in applications such as grinding wheels, sandpaper, and polishing. The abrasives industry's growth, driven by diverse sectors like manufacturing, automotive, construction, and metalworking, contributes significantly to the demand for calcined alumina.

3. Growing Demand in Refractories: Calcined aluminum oxide plays a crucial role in the production of refractory materials used in high-temperature applications like steelmaking, glass production, and cement manufacturing. The demand for refractories in industries such as metallurgy and construction influences the market for calcined alumina.

4. Increasing Demand in the Electronics Industry: The electronics industry uses calcined aluminum oxide in various applications such as insulating components, electronic packaging, and substrates for semiconductor production. The growth of the electronics sector, including developments in semiconductors, LEDs, and electronic components, drives the demand for high-purity calcined alumina.

5. Automotive and Aerospace Applications: Calcined aluminum oxide is used in automotive and aerospace applications for components requiring high strength, wear resistance, and thermal stability. As these industries continue to innovate and demand high-performance materials, the need for calcined alumina as a key component in advanced materials grows.

6. Environmental Regulations and Sustainability: Increasing focus on environmental regulations and sustainability practices is driving the demand for eco-friendly materials in various industries. Calcined alumina produced using sustainable practices and meeting stringent environmental standards can attract environmentally conscious consumers and industries.

7. Research and Development: Advancements in manufacturing processes, product quality, and new applications for calcined aluminum oxide can drive market growth. Continuous research and development efforts to improve the properties and applications of calcined alumina can open up new market opportunities.

8. Global Economic Trends: Macroeconomic factors like industrial output, GDP growth, infrastructure development, and global trade impact the demand for calcined aluminum oxide. Market fluctuations, currency exchange rates, and geopolitical factors can also influence the market dynamics for calcined alumina.

À propos de QYResearch

QYResearch a été fondée en 2007 en Californie aux États-Unis. C'est une société de conseil et d'étude de marché de premier plan à l'échelle mondiale. Avec plus de 17 ans d'expérience et une équipe de recherche professionnelle dans différentes villes du monde, QYResearch se concentre sur le conseil en gestion, les services de base de données et de séminaires, le conseil en IPO, la recherche de la chaîne industrielle et la recherche personnalisée. Nous société a pour objectif d’aider nos clients à réussir en leur fournissant un modèle de revenus non linéaire. Nous sommes mondialement reconnus pour notre vaste portefeuille de services, notre bonne citoyenneté d'entreprise et notre fort engagement envers la durabilité. Jusqu'à présent, nous avons coopéré avec plus de 60 000 clients sur les cinq continents. Coopérons et bâtissons ensemble un avenir prometteur et meilleur.

QYResearch est une société de conseil de grande envergure de renommée mondiale. Elle couvre divers segments de marché de la chaîne industrielle de haute technologie, notamment la chaîne industrielle des semi-conducteurs (équipements et pièces de semi-conducteurs, matériaux semi-conducteurs, circuits intégrés, fonderie, emballage et test, dispositifs discrets, capteurs, dispositifs optoélectroniques), la chaîne industrielle photovoltaïque (équipements, cellules, modules, supports de matériaux auxiliaires, onduleurs, terminaux de centrales électriques), la chaîne industrielle des véhicules électriques à énergie nouvelle (batteries et matériaux, pièces automobiles, batteries, moteurs, commande électronique, semi-conducteurs automobiles, etc.), la chaîne industrielle des communications (équipements de système de communication, équipements terminaux, composants électroniques, frontaux RF, modules optiques, 4G/5G/6G, large bande, IoT, économie numérique, IA), la chaîne industrielle des matériaux avancés (matériaux métalliques, polymères, céramiques, nano matériaux, etc.), la chaîne industrielle de fabrication de machines (machines-outils CNC, machines de construction, machines électriques, automatisation 3C, robots industriels, lasers, contrôle industriel, drones), l'alimentation, les boissons et les produits pharmaceutiques, l'équipement médical, l'agriculture, etc.

0 notes

Text

Europe Aluminium Magnesium Spinel Market Industry Trends, Competition Strategies, Revenue Analysis and Forecast to 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Europe Aluminium Magnesium Spinel Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the Europe Aluminium Magnesium Spinel Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Europe Aluminium Magnesium Spinel Market?

Europe aluminium magnesium spinel market was valued at US$ 166.4 Million in 2023 and is expected to register a CAGR of 4.1% over the forecast period and reach US$ 238.3 Mn in 2032.

What are Europe Aluminium Magnesium Spinel?

Aluminium Magnesium Spinel in Europe is a high-performance ceramic known for its outstanding thermal and mechanical properties. Made from aluminum oxide (Al₂O₃) and magnesium oxide (MgO), it offers excellent resistance to thermal shock, corrosion, and mechanical wear. This material is widely used in industrial applications including refractory linings in furnaces and reactors, as well as in aerospace components and advanced ceramic products. Its exceptional combination of high melting point, hardness, and chemical stability makes it ideal for demanding environments where durability and reliability are essential.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/2351

What are the growth prospects and trends in the Europe Aluminium Magnesium Spinel industry?

The Europe aluminium magnesium spinel market growth is driven by various factors and trends. The Aluminium Magnesium Spinel market in Europe is experiencing growth, fueled by its widespread adoption in multiple industries due to its strong thermal and mechanical properties. This high-performance ceramic, comprised of aluminum oxide (Al₂O₃) and magnesium oxide (MgO), is prized for its resilience against thermal shock, corrosion, and mechanical wear. It is utilized extensively in industrial refractories, aerospace components, and advanced ceramics, leveraging its high melting point, hardness, and chemical stability. Market expansion is driven by rising demand for durable materials in industrial applications and continuous advancements in technology to enhance its effectiveness across various uses. Hence, all these factors contribute to Europe aluminium magnesium spinel market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type

Fused Spinel

Reaction Bonded Spinel

Sintered Spinel

Others

By Composition

Al2O3 (76/78%)

MgO (24/22%)

By Form

Powder

Granules

Bricks

Others

By Production Method

Sol-Gel Process

Conventional Solid-State-Reaction

Spray Drying (Atomization)

Chemical Vapor Deposition (CVD)

Electrical Fusion Process

Wet Synthesis Techniques

Mechano-Chemical Alloying

Molten Salt Synthesis

Others

By Purity

99%

Above 99%

By Packaging

Steel Drum

Container

By Application

Refractory Materials

Metal Casting

Electrical Insulators

Iron And Steel Smelting

Glass Furnace

Calcined Lime Furnace Lining

Cement Rotary Kiln

Steel Ladles

Alumina-Magnesia Brick

Sliding Nozzle

Ceramics Manufacturing

HumiditySensors

Others

By End-Use Industry

Automotive

Electronics

Refractories

Cement

Iron and Steel

Glass

Water Treatment

Others

Europe

Germany

Austria

Switzerland

Italy

Spain

Portugal

Greece

Cyprus

Malta

Poland

Czech Republic

Slovakia

Hungary

Ukraine

Moldova

Balkan Countries

Rest of Europe

Who are the key players operating in the industry?

The report covers the major market players including:

Almatis

Refratechnik Group

Keralit LLC

Surmet Corporation

CeraNova Corporation

Washington Mills

Baikowski

MFE Magnesium

View Full Report: https://www.reportsandinsights.com/report/Europe Aluminium Magnesium Spinel-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

#Europe Aluminium Magnesium Spinel Market share#Europe Aluminium Magnesium Spinel Market size#Europe Aluminium Magnesium Spinel Market trends

0 notes

Text

0 notes

Text

Global Calcined Alumina Powder Market: Trends, Analysis, and Forecast (2024-2032)

The Rising Demand for Reinforcement Materials is Driving the Calcined Alumina Powder Market Trend by Improved Manufacturing Processes The calcined alumina powder market comprises materials that have numerous advantages such as superior mechanical strength, high chemical purity, and thermal conductivity. Calcined alumina powder is used as an auxiliary material in the manufacturing of auto parts, electronics, and refractory products on account of its excellent thermal resistance and corrosion resistance properties.

The global calcined alumina powder market is estimated to be valued at US$ 21405.49 Mn in 2024 and is expected to exhibit a CAGR of 5.8% over the forecast period 2023 to 2030. Key Takeaways Key players operating in the calcined alumina powder market are Almatis, Graystar LLC, Paradise Minerals, Lianyungang Zhong Ao aluminium Co., Ltd, Hindalco Industries Limited, Fujimi Corporation, Honeywell International Inc, Saint-Gobain Ceramic Materials, READE, Logitech, Fuji Kasei. The growing demand from end-use industries such as refractories, ceramics, and abrasives is driving the market growth. Calcined alumina is widely used as a reinforcing agent in these industries owing to its high strength, hardness, and corrosion resistance properties. The market is witnessing high growth in the Asia Pacific region owing to easy availability of raw materials and growth of manufacturing industries in China, India, and other developing Asian countries. Key players are expanding their production facilities in the region to leverage the growth opportunities. Market Key Trends Improved manufacturing processes are enabling higher purity levels in calcined alumina powder. Earlier the purity level was 98% but now players are able to produce powder with 99.5% or higher purity level. This higher purity powder is enabling more efficient and effective use in advanced applications such as ceramics, electronics and reinforcements where impurities can hamper performance.

Porter’s Analysis Threat of new entrants: The calcined alumina powder market has moderate threat of new entrants owing to high initial investments required for equipment and machinery setup.

Bargaining power of buyers: Buyers have moderate bargaining power due to availability of substitute products.

Bargaining power of suppliers: Suppliers have moderate bargaining power due to availability of substitute raw materials.

Threat of new substitutes: The threat of new substitutes in the calcined alumina powder market is low as alumina has unique properties making it difficult to replace. Competitive rivalry: The competitive rivalry in the calcined alumina powder market is high due to presence of many established players. North America accounts for the largest share of the global calcined alumina powder market in terms of value owing to high demand from the end use industries like ceramic, refractory and others. Asia Pacific is expected to be the fastest growing region for the calcined alumina powder market during the forecast period. Developing economies like China and India are anticipated to drive high demand from ceramics and welding rods applications due to high industrial growth.

0 notes

Text

0 notes

Text

Calcined Alumina Powder Market Innovations: Shaping Future Industries

Market Overview Calcined alumina powder is made by heating aluminum hydroxide at high temperatures in the range of 1200 to 1500°C. This process removes chemically bound water and produces crystalline aluminas. Calcined alumina powder has high purity, hardness, wear resistance and electrical insulation properties due to which it is widely used in various industries such as ceramics, abrasives, refractories, ceramics and others. Ceramic industry uses calcined alumina powder as a reinforcing filler and opacifier, as it offers better electrical and thermal insulation properties compared to other alternatives.

The Calcined Alumina Powder market is estimated to be valued at US$ 21405.49 Mn in 2023 and is expected to exhibit a CAGR of 5.8% over the forecast period 2023 to 2030, as highlighted in a new report published by Coherent Market Insights. Market Dynamics Growing demand for ceramics from the building and construction industry for applications like roofing tiles, flooring and technical ceramics is a major factor driving the growth of the calcined alumina powder market. According to Civil & Environmental Engineering magazine, global construction industry generated output of $7.8 trillion in 2020 and is expected to grow at 3.6% annually during 2021–2025. Further, increasing usage of technical ceramics made from calcined alumina powder in 5G enabled electronics, electric vehicles and renewable energy sectors is also contributing to the market growth. However, easy availability of substitutes like silica, zirconia and titanium dioxide along with high cost of calcined alumina powder may hinder the market growth over the forecast period. SWOT Analysis Strength: Calcined alumina powder has various industrial applications such as ceramics, metal oxides, abrasives, and refractory due to its chemical and physical properties. It possesses excellent insulation, corrosion resistance and high temperature properties. The powder has low density and high thermal conductivity which makes it suitable for applications requiring these properties. Weakness: The production of calcined alumina involves high energy consumption resulting in high operational costs. Factors such as volatile raw material prices and energy costs pose challenges. Complex production process requires sophisticated manufacturing facilities. Opportunity: Rising demand from the ceramics industry for applications in telecommunication, electronics and energy storage is stimulating market growth. Increasing consumption in metal matrix composites will open new avenues. Growth of the refractory industry in line with expanding steel and cement sectors presents remunerative opportunities. Threats: Growing environmental regulations regarding carbon emissions may impact power-intensive manufacturing operations. Strong competition from substitutes such as synthetic allophones poses threat. Fluctuations in foreign currencies especially U.S. dollar may impact export-import business. Key Takeaways The global calcined alumina powder market is expected to witness high growth, exhibiting CAGR of 5.8% over the forecast period, due to increasing consumption in refractory and abrasive applications. North America dominates the market currently due to presence of large ceramic and metal industries in the region. Asia Pacific exhibits the fastest growth led by India, China and other developing nations experiencing rising industrialization. Regional analysis: Asia Pacific holds the major share currently accounting for over 35% of the overall market. This can be attributed to large manufacturing bases of ceramics, abrasives and refractory in China, India and other ASEAN countries. Furthermore, growing infrastructure development is augmenting consumption. North America stands as the second largest region driven by established automotive, construction and electronics sectors in the US and Canada. Key players analysis: Key players operating in the calcined alumina powder market are Almatis, Graystar LLC, Paradise Minerals, Lianyungang Zhong Ao aluminium Co., Ltd, Hindalco Industries Limited, Fujimi Corporation, Honeywell International Inc, Saint-Gobain Ceramic Materials, READE, Logitech, Fuji Kasei. The market demonstrates a moderate level of consolidation with top five players accounting for over 30% share. Major players are focused on capacity expansions and new product launches to strengthen their market position.

#Calcined Alumina Powder Market Share#Calcined Alumina Powder Market Growth#Calcined Alumina Powder Market Demand#Calcined Alumina Powder Market Trend#Calcined Alumina Powder Market Analysis

0 notes

Text

0 notes

Text

0 notes

Text

0 notes

Link

#market research future#non-metallurgical alumina#non-metallurgical alumina size#alumina mark#non-metallurgical uses

0 notes

Text

0 notes