#CNC Cutting Machines Market Share

Text

Benefits of Fiber Laser Cutting Machine in Sheet Metal Cutting

A fiber laser cutting machine has many benefits over a standard fiber laser cutter, including high precision and processing flexibility. However, given the doubts surrounding a fiber laser cutting machine, the question mentioned earlier is still making its way through the industry and has some importance.

The practical, time-consuming ways should be replaced with something quick and efficient as a result of technological advances over time. Therefore, the loss of market share for CNC punching machines and shearing equipment is not surprising. Additionally, a CO2 laser cutting machine is a more recent addition to this list of options. This was because it was time-consuming, expensive, included additional overhead, and the output's quality was lower to the power input.

The rate of efficiency for processing reflective mediums, such as carbon and stainless steel, has increased by 200% through advancements in power laser cutting machines and the introduction of fiber laser cutters.

Additionally, constant developments in fiber technology resulted in a fiber laser with rapid and simple laser spot size transformation. Regarding cutting quality, the feeding fiber's range is three times more accurate than average, and it operates at different speeds without experiencing any problems.

This fiber laser cutting machine has made it easier to design tools and promoted more optimised cutting that can handle different metal thicknesses. Also, the output of fiber laser beams can be adjusted within a range of around 100 µm to 300 µm.

The fact that these highly advanced fiber lasers have shorter transition times and quick beam change is a benefit of using them. Because of this, these fiber lasers can run continuously at maximum power without experiencing an index change, and they can do so without having to switch off or blank the laser beam in order to change its shape.

This feature selects and initiates the usage of the best beam characteristics for each cutting working without limiting the beam's capacity to cut a given material with a certain thickness.

However, the processing of thick steel cutting often commands the majority of the market for general metal cutting. compared to conventional laser cutting systems, giber lasers also provide a variety of special advantages in terms of edge quality and maximum thickness for cutting thick metal sheets.

With a fixed optic cutting head that has a 1.5x magnification and sufficient oxygen support, this machine can handle any type of metal sheet.

Compared to traditional fiber laser cutters, these highly evolved fiber lasers can deliver greater edge quality and three times less roughness, regardless of the sample size, even for the tiniest 0.25-inch sample.

0 notes

Text

The global Metal Cutting Machine Market is projected to grow from USD 5,871.70 million in 2023 to an estimated USD 9,458.15 million by 2032, with a compound annual growth rate (CAGR) of 5.40% from 2024 to 2032.The metal cutting machine market is witnessing significant growth, driven by technological advancements, increasing demand from various industries, and the need for precise and efficient metal cutting solutions. These machines are essential in numerous sectors, including automotive, aerospace, defense, construction, and manufacturing, contributing to the production of complex parts and components with high precision. This article delves into the current state of the metal cutting machine market, highlighting key trends, market drivers, segmentation, and future prospects.

Browse the full report at https://www.credenceresearch.com/report/metal-cutting-machine-market

Market Size and Growth

As of 2023, the global metal cutting machine market is valued at approximately USD 7.2 billion and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030. The market's expansion is largely attributed to the rising industrialization and urbanization in developing countries, which has led to increased investments in infrastructure and manufacturing activities. Additionally, the growing adoption of automation in production processes to enhance productivity and reduce labor costs is further propelling the market growth.

Key Market Drivers

1. Technological Advancements: The metal cutting machine industry is undergoing rapid technological advancements, with the introduction of sophisticated and efficient machines. Innovations such as computer numerical control (CNC) machines, laser cutting technology, and plasma cutting machines have revolutionized the market. These technologies offer enhanced precision, speed, and flexibility, making them highly desirable in various industrial applications.

2. Growing Demand from the Automotive Industry: The automotive sector is one of the largest consumers of metal cutting machines. The increasing production of vehicles, coupled with the demand for lightweight and high-strength components, is driving the need for advanced metal cutting solutions. CNC machines and laser cutting technology are extensively used in the automotive industry to manufacture intricate parts with high accuracy.

3. Expansion in the Aerospace and Defense Sector: The aerospace and defense industries require high-precision components for aircraft and defense equipment. The stringent quality standards and the need for complex geometries in aerospace parts necessitate the use of advanced metal cutting machines. The growing defense budgets and the rising production of commercial aircraft are significantly contributing to the market growth.

4. Rise in Construction Activities: The construction industry is experiencing robust growth, particularly in emerging economies. The demand for metal structures, frameworks, and prefabricated components is increasing, leading to a surge in the adoption of metal cutting machines. These machines are essential for cutting and shaping metal parts used in construction projects.

Market Segmentation

The metal cutting machine market can be segmented based on technology, application, and geography.

- By Technology: The market is divided into laser cutting machines, plasma cutting machines, waterjet cutting machines, and others. Laser cutting machines hold the largest market share due to their high precision and efficiency.

- By Application: The key application areas include automotive, aerospace and defense, construction, electronics, and others. The automotive segment dominates the market, driven by the high demand for metal cutting solutions in vehicle manufacturing.

- By Geography: The market is analyzed across North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa. Asia Pacific leads the market, owing to rapid industrialization, a strong manufacturing base, and significant investments in infrastructure development.

Competitive Landscape

The metal cutting machine market is highly competitive, with several key players striving to maintain their market positions through product innovations, strategic partnerships, and mergers and acquisitions. Prominent players in the market include Amada Holdings Co., Ltd., TRUMPF GmbH + Co. KG, Bystronic Laser AG, Coherent, Inc., and BLM Group. These companies are focusing on developing advanced metal cutting solutions to cater to the evolving needs of various industries.

Future Prospects

The future of the metal cutting machine market looks promising, with continuous advancements in technology and increasing demand from end-use industries. The integration of artificial intelligence (AI) and the Internet of Things (IoT) in metal cutting machines is expected to enhance operational efficiency and productivity. Additionally, the growing emphasis on sustainable manufacturing practices is likely to drive the adoption of eco-friendly metal cutting solutions.

Key players

TRUMPF

AMADA Co. Ltd

ESAB Corporation

Bystronic Laser AG

WARDJet

Koike Aronson, Inc.

Nissan Tanaka Corporation

Lincoln Electric Company

Water Jet Sweden AB

Flow International Corporation

Coherent Corp.

Messer Cutting Systems GmbH

Omax Corporation

Boye Laser Applied Technology Co., Ltd.

Han’s Laser Technology Industry Group Co., Ltd.

Segments

Based on Product

Laser Cutting Machine

Waterjet Cutting Machine

Plasma Cutting Machine

Flame Cutting Machine

Others

Based on Application

Automotive

Defense & Aerospace

Electrical & Electronics

Construction

Others

Based on Region

North America

US

Canada

Mexico

Europe

Germany

France

UK

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of Middle East and Africa

Browse the full report at https://www.credenceresearch.com/report/metal-cutting-machine-market

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

Global Top 15 Companies Accounted for 58% of total Electrosurgical Pencil market (QYResearch, 2021)

Electrosurgical pencil is a medical device used to fulgurate, coagulate, cut or dissect biological tissue by the applying electric current. It uses Radio Frequency Alternating Current or RFAC. Electrosurgical pencils are versatile and can suit all operating needs as they come with universal size connector that makes it compatible with most branded electrode tips.

Electrosurgical pencils, also known as cautery pencils used during electrosurgery procedures. They are used to cut biological tissue and control bleeding through Radio Frequency Alternating Current (RFAC).

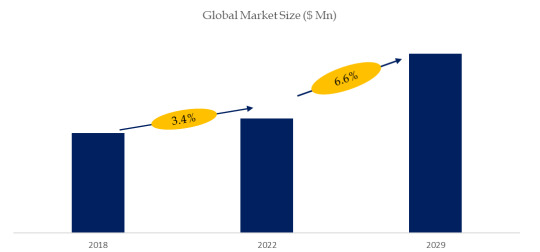

According to the new market research report "Global Electrosurgical Pencil Market Report 2023-2029", published by QYResearch, the global Electrosurgical Pencil market size is projected to grow from USD xx million in 2023 to USD xx million by 2029, at a CAGR of xx% during the forecast period.

Figure. Global Electrosurgical Pencil Market Size (US$ Million), 2018-2029

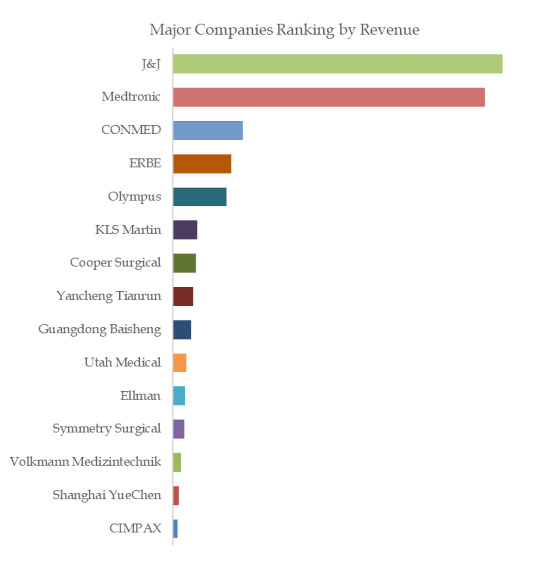

Figure. Global Electrosurgical Pencil Top 15 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

The global key manufacturers of Electrosurgical Pencil include J&J, Medtronic, CONMED, ERBE, Olympus, KLS Martin, Cooper Surgical, Yancheng Tianrun, Guangdong Baisheng, Utah Medical, etc. In 2022, the global top five players had a share approximately 58.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Link

0 notes

Text

CNC Machines Market Will Touch USD 133.4 Billion by 2030

The CNC machines market was USD 74.9 billion in 2024, and it will advance at a 10.1% compound annual growth rate, to touch USD 133.4 billion, by 2030.

The surging requirement for CNC machines is attributed to the rising acceptance of IoT-enabled automation by various industries in their manufacturing procedures to enhance productivity and efficiency. Moreover, the industry will further advance because of the advancement in manufacturing technologies, such as the integration of higher-accuracy functionalities, including 5-axis and 4-axis movement.

In 2022, the lathe machines category, accounted for the largest share, of 30%. This is attributed to the mounting requirement for CNC lathes in the automotive sector for drilling, shaping, cutting, and sanding metals for personalized components, such as cylinder heads, starter motors, and gearboxes.

Moreover, technological advancement in the current lathe systems such as enhanced automation, better precision, multi-axis machining capabilities, incorporation of IoT and connectivity, improvements in tooling materials, and enhance software and programming options will further boost the progression of this category throughout this decade.

Whereas, the miller machines category is growing at the fastest rate because of the construction of numerous metalworking facilities and the expansion of the global metalworking industry. Additionally, the integration of advanced technologies, including AI, ML, and robotics, along with the rising focus on Industry 4.0 has made milling machines efficient and intelligent tools that can execute complex tasks.

Based on end users, the industrial machinery category accounted for the largest CNC machines market share owing to the surging acceptance of automated manufacturing technologies to boost production accuracy and quality by reducing errors.

Whereas, automotive is the fastest-growing category, primarily owing to the mounting demand for quicker production of highly effective automobile parts, such as components for suspension systems, combustion engines, and exhaust parts, including cylinder heads, crankshafts, motor pumps, bushings, and fluid systems.

In 2022, APAC accounted for the largest share in the industry, of 40%, and it will advance at 12% CAGR by the end of this decade. This is because of the rising need for CNC machines in various industries, such as consumer goods, electrical & electronics, aerospace & defense, and automotive.

Moreover, APAC has experienced significant industrial progression with the rapid expansion of its manufacturing sector in the past few years. China, India, South Korea, Taiwan, and Japan, particularly have become major manufacturing hubs globally.

North America will observe significant growth in the years to come, owing to the increasing funding for automation in the continent, to provide efficient manufacturing operations. Additionally, the industry is also boosted by the surging acceptance of advanced CNC machines in Canada and the U.S. to meet the surging requirement for semiconductor chips.

It is because of the increasing acceptance of IoT-enabled automation in manufacturing processes and the advancement in manufacturing technologies, the CNC machines industry will continue to advance in the years to come.

Source: P&S Intelligence

#CNC Machines Market Share#CNC Machines Market Size#CNC Machines Market Growth#CNC Machines Market Applications#CNC Machines Market Trends

1 note

·

View note

Text

CNC assembly technology: revolutionizing the manufacturing field and opening up broad application prospects

In today's era of rapid technological advancement, precise and efficient production methods have become the core competitiveness of the manufacturing industry. Among them, CNC machine tool (CNC) assembly technology, with its advantages of high precision and high degree of automation, is gradually reshaping the manufacturing landscape and showing great application prospects.

I. The cornerstone of intelligent manufacturing

CNC assembly technology is a deep integration of computer numerical control technology and precision mechanical assembly technology. It can assemble various complex parts accurately and efficiently through preset programs. Its core value is to directly transform design data into actual products, greatly reducing human intervention and significantly improving production efficiency and product quality. As an important part of intelligent manufacturing, CNC assembly technology plays an irreplaceable role in realizing the digital, networked, and intelligent transformation of the manufacturing industry, laying a solid foundation for building smart factories and promoting the Industry 4.0 process.

II. Wide range of industry applications

1. Automobile manufacturing: There are many types of auto parts, complex structures, and extremely high precision requirements. CNC assembly technology can accurately control every assembly link to ensure close cooperation between parts, effectively improving the overall performance and service life of the car. At the same time, its efficient automation features help shorten the production cycle and respond to the rapidly changing needs of the market.

2. Aerospace: The manufacturing of aerospace equipment has almost stringent requirements for accuracy and stability. CNC assembly technology, with its ultra-high positioning accuracy and repetitive positioning accuracy, can complete the assembly of complex components at the micron level, greatly improving the reliability and safety of products such as spacecraft and aircraft.

3. Electronic and electrical appliances: As electronic products develop towards thinner, lighter and miniaturized products, the demand for refined assembly of internal components has become increasingly prominent. CNC assembly technology can accurately control tiny components and achieve refined and batch assembly operations, effectively promoting product innovation in consumer electronics, communication equipment, medical equipment and other fields.

Other fields: From precision instruments and mold manufacturing to energy equipment and heavy machinery, the application of CNC assembly technology covers almost all industries that require precision assembly operations, providing a strong force for improving product quality, reducing costs, and enhancing market competitiveness. technical support.

In today's era of rapid technological advancement, precise and efficient production methods have become the core competitiveness of the manufacturing industry. Among them, CNC machine tool (CNC) assembly technology, with its advantages of high precision and high degree of automation, is gradually reshaping the manufacturing landscape and showing great application prospects.

III. Future development trends

With the development of cutting-edge technologies such as the Internet of Things, big data, and artificial intelligence, the application prospects of CNC assembly technology will be even broader:

1. Intelligent optimization: By integrating sensors and data analysis systems, CNC assembly equipment can monitor working status in real time, self-diagnose faults, predict maintenance needs, and further improve equipment utilization and production efficiency.

2. Cloud manufacturing: With the help of cloud computing platforms, CNC assembly technology is expected to realize functions such as remote monitoring, remote programming, and resource sharing, break geographical restrictions, and promote innovation in manufacturing service models.

3. Additive manufacturing integration: The deep integration of CNC assembly technology and 3D printing and other additive manufacturing technologies will give birth to a new hybrid manufacturing model, which can not only achieve precision assembly of complex structures, but also carry out personalized and customized production. Meet the diversified needs of the market.

To sum up, CNC assembly technology, with its significant technical advantages and wide range of application fields, has become a key force in promoting the upgrading and transformation of the manufacturing industry. Facing the future, with the continuous advancement and innovative application of science and technology, CNC assembly technology will surely open up broader application prospects and inject strong impetus into the prosperity and development of the global manufacturing industry.

1 note

·

View note

Text

Forklift Jack Market Analysis by Size, Share, Key Drivers, Growth Opportunities and Global Trends 2031

The global "Forklift Jack Market Market" report indicates a consistent and robust growth trend in recent times, projecting a positive trajectory expected to persist until 2031. A significant trend observed in the Forklift Jack Market market is the rising consumer inclination towards environmentally sustainable and eco-friendly products. Furthermore, a notable advancement in this market is the increasing incorporation of technology to elevate both product quality and efficiency. Cutting-edge technologies like artificial intelligence, machine learning, and block chain are actively employed to develop innovative products that outperform traditional options in terms of effectiveness and efficiency. The Forklift Jack Market Market Research Report for 2024 highlights emerging trends, growth opportunities, and potential scenarios envisioned up to the year 2031.

By delving into the latest trends, the report keeps businesses abreast of the dynamic market environment, helping them identify emerging opportunities and navigate potential challenges. The meticulous analysis covers various aspects, offering valuable insights into the historical performance of the market and presenting the current (CAGR) status.

Get a Sample Copy of the Report at: https://www.proficientmarketinsights.com/enquiry/request-sample-pdf/1871

Who are the biggest Forklift Jack Market manufacturers worldwide?

Vestil Manufacturing (Indiana)

Global Equipment (U.S.)

Bosch (Germany)

ESCO (U.S.)

GKS Lifting and Moving Solutions (U.S.)

The Forklift Jack Market Market is described briefly as follows:

The global Forklift Jack Market size was USD 3218.9 million in 2024 and the market is projected to touch USD 4438.3 million by 2031, exhibiting a CAGR of 5.50% during the forecast period.

SWOT Analysis of Forklift Jack Market Market:

A SWOT analysis involves evaluating the strengths, weaknesses, opportunities, and threats of a particular market or business. In the case of the keyword market, we'll be looking at the factors that can impact the industry's performance.

Pestle Analysis of Forklift Jack Market Market:

To better comprehend the market environment, a five-force analysis is performed, which takes into account the bargaining power of the customer, the supplier, the threat of substitutes, the threat of new entrants, and the threat of competition.

Get a Sample Copy of Forklift Jack Market Market Report

What are the Types in Forklift Jack Market Market?

Electric Forklift Jack

Hydraulic Forklift Jack

What are Applications in Forklift Jack Market Market?

CNC Machines

Brake Presses

Others

Inquire or Share Your Questions If Any before the Purchasing This Report: https://www.proficientmarketinsights.com/enquiry/queries/1871

Geographical Segmentation:

Geographically, this report is segmented into several key regions, with sales, revenue, market share, and Forklift Jack Market market growth rate in these regions, from 2017 to 2028, covering

North America (United States, Canada and Mexico)

Europe (Germany, UK, France, Italy, Russia and Turkey etc.)

Asia-Pacific (China, Japan, Korea, India, Australia, Indonesia, Thailand, Philippines, Malaysia, and Vietnam)

South America (Brazil etc.)

Middle East and Africa (Egypt and GCC Countries)

Some of the key questions answered in this report:

Who are the worldwide key Players of the Forklift Jack Market Industry?

How the opposition goes in what was in store connected with Forklift Jack Market?

Which is the most driving country in the Forklift Jack Market industry?

What are the Forklift Jack Market market valuable open doors and dangers looked by the manufactures in the worldwide Forklift Jack Market Industry?

Which application/end-client or item type might look for gradual development possibilities? What is the portion of the overall industry of each kind and application?

What centered approach and imperatives are holding the Forklift Jack Market market?

What are the various deals, promoting, and dissemination diverts in the worldwide business?

What are the key market patterns influencing the development of the Forklift Jack Market market?

Financial effect on the Forklift Jack Market business and improvement pattern of the Forklift Jack Market business?

Purchase this Report (Price 3200 USD for A Single-User License) at: https://www.proficientmarketinsights.com/purchase/1871

TOC of Global Forklift Jack Market Market Research Report 2023

1 Forklift Jack Market Market Overview

2 Market Competition by Manufacturers

3 Forklift Jack Market Production by Region

4 Forklift Jack Market Consumption by Region

5 Segment by Type

6 Segment by Application

7 Key Companies Profiled

8 Industry Chain and Sales Channels Analysis

9 Forklift Jack Market Market Dynamics

10 Research Finding and Conclusion

11 Methodology and Data Source

0 notes

Link

0 notes

Text

Ebara's Vision for Stainless Steel Pumps

As a cutting-edge manufacturer in the pumping industry, Ebara is continuously pushing the boundaries of technology to innovate and enhance the performance, efficiency, and sustainability of stainless steel pumps. Here's Ebara's vision for the future of pumping technology:

Integration of Smart Technologies: Ebara envisions the integration of smart technologies such as sensors, data analytics, and Internet of Things (IoT) connectivity into stainless steel pumps. Smart pumps will provide real-time performance monitoring, predictive maintenance alerts, and remote control capabilities, enabling proactive maintenance and optimizing pump efficiency and reliability.

Energy Efficiency and Sustainability: Ebara is committed to developing energy-efficient pumping solutions that minimize environmental impact and promote sustainability. Future stainless steel pumps will incorporate advanced hydraulic designs, variable frequency drives (VFDs), and energy recovery systems to maximize energy efficiency, reduce carbon footprint, and lower operational costs for users.

Advanced Materials and Coatings: Ebara aims to leverage advancements in materials science and surface coatings to enhance the corrosion resistance, durability, and longevity of stainless steel pumps. Future pumps will feature innovative alloys, coatings, and surface treatments that improve performance, reliability, and resistance to harsh operating conditions in various industries.

Modular and Customizable Design: Ebara envisions the development of modular and customizable pump designs that offer flexibility and scalability to meet diverse customer needs. Future pumps will allow for easy configuration, adaptation, and customization to specific applications, flow rates, pressure requirements, and installation constraints, enabling seamless integration into various systems and processes.

Hygienic Design for Critical Applications: Ebara recognizes the importance of hygienic design in critical applications such as pharmaceuticals, biotechnology, and food processing. Future stainless steel pumps will feature enhanced hygienic design principles, sanitary seals, and cleanability features to prevent bacterial growth, contamination, and product adulteration, ensuring product integrity and safety.

Advanced Manufacturing Techniques: Ebara is exploring advanced manufacturing techniques such as additive manufacturing (3D printing) and precision machining to improve pump performance, quality, and customization capabilities. Future pumps will benefit from precision-engineered components, reduced lead times, and enhanced manufacturing flexibility, enabling rapid prototyping and product development.

Digitalization and Automation: Ebara envisions the digitalization and automation of pump manufacturing processes to improve productivity, quality control, and supply chain management. Future pumps will be produced using advanced digital technologies such as computer-aided design (CAD), computer numerical control (CNC) machining, and robotics, streamlining production processes and ensuring consistent product quality.

Collaboration and Innovation: Ebara is committed to fostering collaboration and innovation within the pumping industry, partnering with customers, suppliers, research institutions, and technology providers to drive continuous improvement and develop breakthrough solutions. Future stainless steel pumps will benefit from cross-disciplinary collaboration, shared expertise, and collective innovation, addressing emerging challenges and opportunities in diverse markets and applications.

Overall, Ebara's vision for the future of pumping technology revolves around innovation, sustainability, efficiency, and collaboration. By embracing new technologies, materials, and design concepts, Ebara aims to deliver cutting-edge stainless steel pumps that meet the evolving needs of customers and industries worldwide, while contributing to a more sustainable and prosperous future. For more info contact Ebara Pump Suppliers in UAE or call us at +971 4 2522966.

0 notes

Text

Aluminum CNC Machining Parts: Tips, Applications, and Trends

Aluminum CNC Machining Parts: Tips, Applications, and Trends

Aluminum machining parts are widely used across many industries, from aerospace to automotive and electronics. They offer excellent strength-to-weight ratios, corrosion resistance, and thermal conductivity, making them ideal for a range of applications. In this article, we’ll share tips for aluminum machining, discuss applications of aluminum parts, and analyze current trends in the industry.Get more news about aluminium cnc machining parts discount,you can vist our website!

Machining aluminum can be challenging, but there are several tips that can help achieve accurate and efficient results. First, choose the right tooling. Carbide inserts are the most commonly used tooling for machining aluminum because they can handle the heat and abrasion associated with the process. High-speed steel (HSS) drills are also commonly used, as they create precise holes without damaging the material. When choosing the right cutting speeds and feeds, it’s essential to balance accuracy and efficiency. High cutting speeds and feeds can cause excessive heat, while low speeds and feeds can cause tool wear and poor surface finishes. The recommended cutting speed and feed rate vary depending on the specific material and tooling used. It’s also crucial to use proper coolant to prevent chip buildup and to deburr parts to ensure clean edges. Finally, using sharp tools is crucial to achieving accurate and efficient cuts. Dull tools cause poor surface finishes, which can lead to part failure.

Aluminum machining parts have a wide range of applications across various industries. In aerospace, aluminum parts are commonly used for structural components such as wing spars, fuselage frames, and landing gear. Aluminum alloys are also used for engine components, such as fan blades, compressor blades, and turbine disks, due to their high strength and low weight. In the automotive industry, aluminum is widely used for engine blocks, cylinder heads, and suspension and steering components. The use of aluminum in automotive parts can significantly reduce weight, which improves fuel efficiency and performance. In the electronics industry, aluminum is commonly used for circuit boards and heat sinks, thanks to its excellent electrical conductivity and thermal properties.

The aluminum machining industry is constantly evolving, with new technologies, emerging markets, and changing customer demands shaping the landscape. One key trend is the growing demand for lightweight materials in the automotive and aerospace industries. As fuel efficiency and emissions standards become more stringent, manufacturers are turning to lightweight materials like aluminum to help meet these requirements. Another trend is the increasing use of automation and CNC machining. Automated systems can improve efficiency, reduce errors, and optimize production runs.

0 notes

Text

Global Top 14 Companies Accounted for76% of total Mounted Reach Mower market (QYResearch, 2021)

Mounted Reach Mower is a machine that cuts grass or other plants that grow on the ground.

In this report, we study Mounted Reach Mower market.

The Mounted Reach Mower market covers Flail Mower and Boom Mower. The typical players include Alamo Group, SaMASZ, Diamond Mowers, FERRI, Seppi M., etc.

According to the new market research report “Global Mounted Reach Mower Market Report 2023-2029”, published by QYResearch, the global Mounted Reach Mower market size is projected to reach USD 0.54 billion by 2029, at a CAGR of 3.6% during the forecast period.

Figure. Global Mounted Reach Mower Market Size (US$ Million), 2018-2029

Figure. Global Mounted Reach Mower Top 14 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Mounted Reach Mower include Alamo Group, SaMASZ, Diamond Mowers, FERRI, Seppi M. Company, Rasco, Atmax Equipment Co, Sanyo Kiki, US Mower, Trackless Vehicles Ltd, etc. In 2021, the global top five players had a share approximately 76.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

CNC Metal Cutting Machine Tools Market Manufacturers Analysis Report (2022): Global Size, Share, Technology, Demand, Regions, Trends and Forecast (2030)

0 notes

Text

Global Servo Press Brakes Market Size, Trends and Growth opportunity, By Type (Hydraulic Type, Electric Type), By Application (Electrical, Machine Tool, Construction, Automotive, Aerospace, Others), By Regional Outlook, Competitive Market Share & Forecast, 2023 – 2030.

Global Servo Press Brakes Market Size, Trends and Growth opportunity, By Type (Hydraulic Type, Electric Type), By Application (Electrical, Machine Tool, Construction, Automotive, Aerospace, Others), By Regional Outlook, Competitive Market Share & Forecast, 2023 – 2030.

Global Servo Press Brakes Market

The Global Servo Press Brakes Market was valued at USD 710.00 million in 2022 and is expected to reach USD 1,370.00 million by 2030 at a CAGR of 7.83% from 2023-2030.

Servo press brakes, also termed as CNC press brakes, supply the pressing force via 2 synchronized servomotors used to power a belt & pulley mechanism. Servo-driven presses are extremely flexible machines due to the ability to precisely control the stroke and speed of the ram with the servomotors.

An electric servo press brake is a type of electric press brake which is used in metal fabrication and bending operations. It combines the correctness and power of a hydraulic press brake with the speed and efficiency of an electric servo motor. Servo press brakes are intricate machinery that demand unique skills and knowledge to operate and maintain.

Read More Here: https://analyticalmr.com/reports-details/Global-Servo-Press-Brakes-Market

Market Drivers

A servo press brake is a specific kind of press brake in which the ram is driven down onto the workpiece by a servo motor. Precision, speed, and energy efficiency are all strong points of this kind of press brake. The rotation of a ball screw or belt drive is controlled by a servo motor in servo press brakes. Then, the ram is moved up and down using the ball screw or belt drive. The servo motor is controlled by a computer numerical control (CNC) system, which provides for very accurate control of the ram's location and speed that would fuel the market expansion. Industry 4.0 is a trend towards the automation and digitalization of manufacturing processes. Servo press brakes are well-suited for use in Industry 4.0 environments, as they can be easily integrated with other manufacturing systems.

Further, metal bending and shaping procedures must be precise and accurate to meet the needs of manufacturers in all industries. Because of their high levels of accuracy, repeatability, and control, servo press brakes are crucial for sectors like automotive, aerospace, and electronics, which promotes market expansion. Automation is becoming a more common practice among manufacturers. Servo press brakes are simple to integrate into automated production lines, providing better manufacturing flexibility and efficiency that boosts market growth. Servo press brakes frequently include cutting-edge safety features like light curtains, laser guarding, and programmable safety controllers that safeguard operators and reduce workplace accidents, which promotes market expansion.

Market Restraints

Compared to conventional hydraulic or mechanical press brakes, servo press brakes are more expensive. Small and medium-sized firms may find it difficult to enter the market due to this high initial cost. In comparison to conventional press brakes, servo press brakes require more intricate operation and maintenance. Businesses that lack access to skilled labour may find this difficult. Many firms are unaware of the advantages of servo press brakes because they are a relatively new technology. This ignorance may prevent more people from using servo press brakes.

Servo press brakes need routine maintenance, just like any piece of industrial machinery, to keep them performing at their best. The productivity of a corporation might be negatively impacted by maintenance expenses and downtime for repairs. In the manufacturing sector, it can be difficult to comply with safety and environmental laws. Companies must invest in making sure that their servo press brakes adhere to all pertinent safety and environmental regulations, which can increase prices and complexity and limit market expansion. Servo press brakes are made from raw materials like steel and aluminium, the prices of which are highly erratic. This may influence servo press brake producers' profitability.

Impact Of COVID-19 On Market

In response to the interruptions in manufacturing processes and the slump in the global economy, the market fell precipitously in 2020. The automotive and aerospace industries, two of the most severely affected by the epidemic, had a particularly sharp fall in demand. The supply networks of the producers of servo press brakes were also affected by the COVID-19 outbreak. This resulted from the travel bans and lockdowns that were enacted in numerous nations. Manufacturers had trouble locating raw materials and components and shipping final goods to clients due to supply chain interruptions. Manufacturers of servo press brakes saw an increase in expenses because of the COVID-19 epidemic. This resulted from rising costs for shipping and logistics as well as raw materials and component prices.

The epidemic hastened tendencies towards remote work and factory automation. Businesses who implemented or strengthened their automation capabilities may have relied more on servo press brakes with sophisticated automation features. Due to a lack of labour and the requirement to put in place social segregation and safety precautions, manufacturing facilities that make servo press brakes and related equipment had to temporarily shut down or restrict their production capacity.

Post COVID-19 World Supply & Demand Condition of Global Servo Press Brakes Market

The supply and demand situation for the worldwide servo press brakes market after COVID-19 is anticipated to be favourable. It is anticipated that several industries, including the automotive, aerospace, electronics, and construction, will boost their demand for servo press brakes. This is brought on by the expanding need for high-precision metal forming solutions and the manufacturing industry's increased automation. High-precision metal forming capabilities are provided by servo press brakes, which are crucial for several industries, including the automotive, aerospace, and electronics sectors. The post-COVID-19 worldwide servo press brakes market is anticipated to increase because of the rising need for high-precision metal forming solutions.

After COVID19 rising markets, including China, India, and Brazil, are growing economically quickly. As a result, manufacturing investment is rising, which is fuelling the demand for servo press brakes. Due to the growing demand for high-precision metal forming solutions and the expanding automation in the manufacturing sector, the market for servo press brakes is anticipated to rise across several industries. As more manufacturers enter the market and raw materials and components become more widely available, the supply of servo press brakes is also anticipated to rise in the post-COVID-19 era.

Impact of Russia-Ukraine Conflict on Global Servo Press Brakes Market

Since the conflict began, the price of steel and other raw materials necessary to make servo press brakes has grown dramatically. This is brought on by a variety of circumstances, including the breakdown of supply networks, rising demand from other nations, and the devaluation of the Russian rubble. Supply chains for servo press brakes and associated parts have been hampered by the conflict. These include the shutdown of enterprises in Russia and Ukraine, the imposition of sanctions on Russia, and the difficulties of moving goods across the area. Due to the crisis, manufacturers are looking for alternatives to Russian and Ukrainian suppliers, which has increased demand for servo press brakes from other nations. This is increasing costs and making it challenging for certain enterprises to get the equipment they require.

The world economy is being significantly impacted by the Russia-Ukraine conflict. This can be attributed to several things, such as the disruption of commerce, the increase in energy costs, and the drop in consumer expenditure. Businesses are postponing or cancelling investments in new equipment, which influences the market for servo press brakes. Natural gas and other energy resources frequently pass through Ukraine. Global energy prices may rise if there are any hiccups in the region's energy supply. Higher energy costs may have an impact on the running costs of manufacturers and may affect their choice to buy servo press brakes and other machinery.

Market Segmentation

The Global Servo Press Brakes Market is segmented into type and application.

According to type, the Hydraulic Type segment accounted for the largest revenue share in 2022 and is predicted to maintain its position over the forecast period with a CAGR of 7.77%, as Hydraulic servo press brakes can produce extremely strong forces, which makes them perfect for a variety of tasks, including shaping thick sheets of metal.

Regional Analysis

The Global Servo Press Brakes Market is segmented into five regions such as North America, Latin America, Europe, Asia Pacific, and Middle East & Africa.

Based on region, Asia-Pacific accounted for the largest share in 2022 and is anticipated to have the highest CAGR by 2030 due to the region's rapid economic growth, which is driving demand for manufactured products. The production of servo, which are essential tools in the manufacturing process, produces a wide range of products, including automobiles, electronics, and appliances. The Asia-Pacific area is likewise undergoing a considerable industrialization. As a result, there are more factories and manufacturing facilities in the region. As a result, servo press brakes are becoming more and more in demand in these plants.

Key Players

Various key players are discussed into the Global Servo Press Brakes Market Report including: Trumpf, Amada, LVD Group, Durma, ALIKO, Artizono, Prima Power, Ursviken, Jiangsu Yawei Machine Tool Co., Ltd., Prada Nargesa S.L., Jean Perrot, Cincinnati Inc, and Others.

Market Taxonomy

By Type

• Hydraulic Type

• Electric Type

By Application

• Electrical

• Machine Tool

• Construction

• Automotive

• Aerospace

• Others

By Region

• North America

o U.S.

o Canada

o Mexico

• Latin America

o Brazil

o Argentina

o Colombia

o Peru

o Chile

o Venezuela

o Rest of Latin America

• Europe

o Germany

o France

o UK

o Russia

o Italy

o Spain

o Rest of Europe

• Asia Pacific

o China

o Japan

o India

o South Korea

o Australia

o New Zealand

o Singapore

o Malaysia

o Rest of Asia Pacific

• Middle East & Africa

o Saudi Arabia

o UAE

o Egypt

o Kuwait

o South Africa

o Rest Middle East & Africa

"

1 note

·

View note

Text

We hold a reputation for being a reputable manufacturer, exporter, and supplier of a large selection of Brass Anchors.

This is made in accordance with global quality standards utilizing premium brass and cutting-edge technologies.

Many diverse sectors, like the pharmaceutical, petrochemical, chemical, and textile ones, employ the anchor we offer.

To meet the needs of our esteemed clients, this anchor is offered at market-beating costs in a wide range of forms, sizes, and patterns.

These are highly regarded by our clients as a result of its key qualities, such as precise design, simplicity of installation, tough construction, high strength, low maintenance requirements, and longevity.

We provide our product line in a variety of parameters to satisfy the needs of the plastic and automotive industries. We export our goods to places like Southeast Asia, South America, and North America.

· We have in house facilities for productions such as Extrusion, Casting, Forging & Machining, CNC – VMC Products.

· We have German spectrometer for perfect results and also can share the Material Test Certificate

· We can share the best quote in the industry.

· We have capacity of manufacturing as per customer drawing or samples provided

· We can supply the components with best quality and services

#brass anchors#brass drop in anchors#drop anchors#anchor fasteners brass#india#pool cover anchors#anchor pool covers#pool safety cover anchors#pool anchor#earth anchors#brass pool cover anchors#brass pipe fittings#pool cover anchors for concrete#drop in anchor#safety cover anchors#brass bolts#brass pool anchors#brass inserts#pool cover hooks#pool cover straps#wood deck anchors#manufacturer#exporters

0 notes

Text

How much is a hydraulic copper busbar machine

The topic I want to share with you today is how much a hydraulic copper bar busbar machine costs. I hope that through the following explanation, you can learn more about this aspect!

Single or double busbars or busbar sections plus bypass: the power supply reliability is high, and the operation is flexible and convenient, but the investment has increased and the economy is slightly poor. Especially when the bypass circuit breaker is used for this circuit, the operation is complicated and increases Opportunities for misoperation. At the same time, due to the installation of bypass circuit breakers, the corresponding protection and automation systems are complicated. The above are the advantages of Shandong Dalin Machinery CNC busbar processing machine.

Many printed circuit boards have some settings of switches or shorting bars to match the actual needs, so when replacing the spare parts board of the busbar machine, be sure to record the original switch position and setting status, and prepare the new board The same setting, otherwise it will generate an alarm and cannot work. The replacement of some printed circuit boards requires some specific operations after the replacement to complete the establishment of software and parameters. This requires careful reading of the instructions for use of the corresponding circuit board. How much is a hydraulic copper row processing machine

On the other hand, it has a long service life. Compared with other types of bus machines, the ring bus machine has a long service life. It is not only wear-resistant and corrosion-resistant, but also has strong impact resistance and waterproof. For the most part, the service life of ring bus machines is very long.

The turret busbar processing machine is an auxiliary equipment designed to improve work efficiency and ensure operation safety. Its special structure makes the turret busbar processing machine more efficient than the traditional busbar processing machine, no matter the type of busbar or The speed and turret busbar processing machine are all higher than ordinary busbar processing machines. The reason of the equipment itself also leads to a broad market prospect.

The busbar machine is equipped with three processing units: punching, cutting and folding. Through the operation panel or foot switch, the punching, cutting and folding of the busbar can be performed separately or simultaneously. The production efficiency of this machine is High and easy to use.

The output of the pulse coder is generally two pairs of differential signals, A and A, B and B, which can be used for position and speed measurement. The four square waves of A and A, B and B are introduced into the PG card, and the direction is identified and multiplied by the magnification. After that, it becomes a measurement pulse representing the displacement, which is introduced into the PLC high-speed counting terminal for position control. The system of the bus processing machine adopts the relative counting method for position measurement. Before running, program the various signals, such as the position of the speed change point, The number of pulses corresponding to the position of the leveling point and the position of the braking stop point are respectively stored in the corresponding memory unit. During the operation of the elevator, the following signals are detected by the rotary encoder and the software calculates in real time: the position of the floor where the elevator is located, Speed point position, leveling point position.

Busbar processing requires good casting and machinability calculation capabilities. It has strong corrosion resistance. The busbar processing and production process is quite cautious, so in the manufacturing process, we must pay attention to what we should do? How much is a hydraulic copper row processing machine

The software used is the special auxiliary design software (GJ3D) developed by our company, which can be used on the Internet to realize programming automation. This software is the first to apply 3D graphics technology to the busbar processing industry, and the advanced nature of this technology is world-class. The software is easy and quick to operate, intuitively and three-dimensionally displays the processing shape of the busbar, can accurately calculate the exact position of punching, cutting and folding workpieces, automatically generates machine codes, reduces the time for manual coding, and eliminates the possibility of errors in manual coding. This software can demonstrate the whole process of punching, cutting and folding, and prevent material waste caused by manual code input errors.

0 notes

Text

CNC Metal Cutting Machine In-Depth Profiling With Key Players and Recent Developments, Forecast Period: 2021-2031

The global CNC metal cutting machine market size was valued at $53,069.1 million in 2020, and is projected to reach $83,364.4 million by 2030, registering a CAGR of 4.2% from 2020 to 2030.CNC Metal Cutting Machines are high precision machines that make computer-controlled repeated movements for custom metal fabrication works. Computer-generated codes enable CNC metal cutting machines to achieve meticulous accuracy. CNC metal cutting machines are highly customizable, making them suitable for use in various manufacturing facilities.

The changing global power dynamics has significantly increased spending on defense equipment across the globe, thereby increasing the number of companies involved in manufacturing of defense and aerospace products. This has increased the use of CNC metal cutting machine market growth of precise manufacturing equipment in the defense and aerospace sector. Furthermore, surgeon industrialization has significantly increased the use of metals, thereby creating demand for the market. In addition, the rise in purchasing power of masses has significantly increased the demand for automobiles and electronic products. This increase in demand further boosts the use of CNC metal cutting machine manufacturing industry.

The global CNC metal cutting machine market is segmented on the basis of type, end user, and region. By type, the market is categorized into new Machining Centers, Lathe Machines, Gear Cutting Machines, Laser Cutting Machines, and Others. On the basis ofend user, it is categorized into Automobile, Aerospace & defense, Electronics, Power & Energy, and Others. Region wise, the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA. Asia-Pacific dominated the market in 2020, accounting for the highest share, and is anticipated to maintain this trend throughout the forecast period. This is attributed to increase in population, urbanization, and industries.

Competition Analysis

Key companies profiled in the CNC metal cutting machine market report include Amada Holdings Co., Ltd., Coherent, Inc., DMG MORI CO., Ltd., Hurco Companies, Inc., Komatsu Ltd, Lincoln Electric Holdings, Inc., Maschinenfabrik Berthold Hermle AG, Okuma Corporation, TRUMPF GmbH + Co. KG, and Yamazaki Mazak Corporation

Full Report With TOC:-https://www.alliedmarketresearch.com/cnc-metal-cutting-machine-market

0 notes