#Automotive Fasteners Industry Report

Text

Fasteners Procurement Intelligence: A Comprehensive Guide

The fasteners category is anticipated to grow at a CAGR of 4.42% from 2023 to 2030. APAC holds the largest category share of over 40% and it is expected to be the fastest growing region during the forecast period. The increased use in the construction and automotive industries is driving considerable growth in the fasteners category. These fasteners are semi-permeant or occasionally permeant solutions, and the development of the construction industry, research and development initiatives, urban real estate infrastructure, and technological developments in the production of lightweight goods for the automotive and other industrial sectors are all factors that have an impact on their growth. The creation of innovative and novel industrial fasteners also helps the category growth.

In the building sector, they are employed to temporarily link two or more things together. As the industry demands strength and accuracy, building and construction fasteners are employed in heavy-duty applications to link materials together. Different fastening forms are employed in the construction industry, including stainless steel, alloy steel, and carbon steel. Nuts, bolts, washers, screws, and rivets are typical examples of building construction items. To ensure secure and sturdy construction, each infrastructure project needs a different kind of fastening product. Due to its affordability, strength, and workability, carbon steel is used to make the majority of products. The demand for industrial fasteners is increased by the fact that stainless steel is the most popular building material because of its strength, resistance to heat, and resistance to corrosion.

Corrosion resistance qualities will spur significant investment in the creation of new products, meeting consumer demand. During the projection period, rising consumer emphasis on residential and commercial building aesthetics will fuel industry expansion in the use of cable management and building exteriors. However, the negative aspect of working with fasteners is that they typically require special tools for setting up, which can increase project costs and complexity. Other types require extra steps like pre-drilling holes or applying thread-locking compounds, which adds extra labor and time to installation. Not to mention, depending on the application, some types may not be strong enough or sufficiently resilient for prolonged use, which could lead to expensive repairs in the future if not handled effectively from the start. It has been noted that these costs limit the category growth.

Order your copy of the Fasteners Procurement Intelligence Report, 2023 - 2030, published by Grand View Research, to get more details regarding day one, quick wins, portfolio analysis, key negotiation strategies of key suppliers, and low-cost/best-cost sourcing analysis

The fasteners category is fragmented and highly competitive in nature, with various large and small-scale manufacturers in China, Taiwan, Thailand, and Japan. Opportunities for new companies should arise from the rising need for inventive and application-specific industrial fastener designs. Over the projection period, rising raw material costs and high-volume manufacturing by the established companies are anticipated to be the main obstacles for new entrants. Furthermore, major fastener producers are likely to have an edge over small-scale competitors due to technological expertise and a strong customer base. For instance:

• In July 2023, next-generation FLEXTORQ® Impact Driver Bits were introduced by DEWALT, a division of Stanley Black & Decker Inc. These are created with fasteners and engineered for durability, advancing and improving driver bit technology for fastening applications.

• In January 2023, Birmingham Fasteners and Supply Inc. purchased Pacific Coast Bolt Corp. to diversify its manufacturing. The goal was to boost its presence in the commercial fastener market and provide customer service to clients across the United States.

• In September 2021, LINC Systems, LLC, a commercial fastener and packaging distributor platform, announced the acquisition of Air-O Fasteners. The deal was to expand the company's foothold in the Western United States.

Raw material, labor, machinery & equipment, and energy form the major cost components of this category. Raw material is the largest cost component accounting for around 60% - 70% of the total cost followed by labor at roughly 20%. The war between Russia and Ukraine has affected the supply of raw materials (copper, aluminum, etc.), as Russia produces roughly 4% of the world's copper and about 6% of its aluminum. The fasteners category is an example of an industry where suppliers implement cost-plus pricing model. This is because fasteners are typically low-cost, commodity products with little differentiation between brands. As a result, companies in this industry often compete on price, and cost-plus pricing is a simple and easy way to set prices that are competitive.

China, and India are among the most of the preferred sourcing destinations in this category.China has a robust manufacturing industry and offers a wide range of suppliers with diverse capabilities and cost-effective production options. India is a popular destination for metalworking processes due to its established manufacturing sector. For sourcing fasteners, research the market to understand the types, quality, and prices available. Develop a sourcing strategy by identifying the needs, budget, and potential suppliers. Build relationships with suppliers to get the best prices and quality fasteners. Negotiate prices, especially if buying in bulk. Document all the terms & conditions to avoid discrepancies. Monitor suppliers to ensure they meet the agreed quality standards. Use a variety of sources for the best prices and quality.

Fasteners Procurement Intelligence Report Scope

• Fasteners Category Growth Rate: CAGR of 4.42% from 2023 to 2030

• Pricing growth Outlook: 3% - 5% (annual)

• Pricing Models: Cost-plus pricing model, fixed-fee pricing model, discount pricing model

• Supplier Selection Scope: Cost and pricing, Past engagements, Productivity, Geographical presence

• Supplier selection criteria: Quality assurance, service level agreement, environmental compliance, lead times, technical specifications, operational capabilities, regulatory standards and mandates, category innovations, and others

• Report Coverage: Revenue forecast, supplier ranking, supplier matrix, emerging technology, pricing models, cost structure, competitive landscape, growth factors, trends, engagement, and operating model

Browse through Grand View Research’s collection of procurement intelligence studies:

• Flooring Services Procurement Intelligence Report, 2023 - 2030 (Revenue Forecast, Supplier Ranking & Matrix, Emerging Technologies, Pricing Models, Cost Structure, Engagement & Operating Model, Competitive Landscape)

• Fixed Line Services Procurement Intelligence Report, 2023 - 2030 (Revenue Forecast, Supplier Ranking & Matrix, Emerging Technologies, Pricing Models, Cost Structure, Engagement & Operating Model, Competitive Landscape)

Key companies profiled

• Arconic Fastening Systems and Rings

• Acument Global Technologies Inc.

• ATF Inc.

• Dokka Fasteners AS

• LISI Group

• Nippon Industrial Fasteners Company

• Hilti Corporation

• MW Industries Inc.

• Birmingham Fasteners and Supply Inc.

• SESCO Industries Inc.

Brief about Pipeline by Grand View Research:

A smart and effective supply chain is essential for growth in any organization. Pipeline division at Grand View Research provides detailed insights on every aspect of supply chain, which helps in efficient procurement decisions.

Our services include (not limited to):

• Market Intelligence involving – market size and forecast, growth factors, and driving trends

• Price and Cost Intelligence – pricing models adopted for the category, total cost of ownerships

• Supplier Intelligence – rich insight on supplier landscape, and identifies suppliers who are dominating, emerging, lounging, and specializing

• Sourcing / Procurement Intelligence – best practices followed in the industry, identifying standard KPIs and SLAs, peer analysis, negotiation strategies to be utilized with the suppliers, and best suited countries for sourcing to minimize supply chain disruptions

#Fasteners Procurement Intelligence#Fasteners Procurement#Procurement Intelligence#Fasteners Market#Fasteners Industry

0 notes

Text

Washer Industry: Types, Applications, Market Players, Regional Growth Analysis, and Future Scenarios (2023 - 2030)

Washer Market Scenario and Scope

The Washer Market is projected to grow from USD 1.80 Billion in 2022 to USD 2.10 Billion by 2030, at a CAGR of 1.99% during the forecast period.

Get a Sample PDF of the Report: https://www.reportprime.com/enquiry/sample-report/327

Market Trends Influencing the Washer Market

Key trends driving the washer market include:

Increasing Household Incomes: Enhanced purchasing power drives demand for efficient appliances.

Rising Consumer Awareness: Growing preference for energy-efficient and high-performance washers.

Surge in Housing Projects: Expanding housing sector boosts washer demand.

Front-Loading Machines Popularity: Higher efficiency and energy-saving advantages increase their adoption.

Demand for Intelligent Washing Machines: Technological advancements and smart appliances contribute to market growth.

Get a Sample PDF of the Report: https://www.reportprime.com/enquiry/sample-report/327

Washer Market Segment Analysis

Washer Market, by Type:

Plain

Spring

Locking

Others

Washers include various types such as plain, spring, locking, and others, catering to different industrial and commercial needs.

Inquire or Share Your Questions If Any Before Purchasing This Report https://www.reportprime.com/enquiry/pre-order/327

Washer Market, by Application:

Automotive

Electronics

Machinery

Construction

MRO (Maintenance, Repair, and Operations)

Others

Applications of washers span across automotive, electronics, machinery, construction, MRO, and other sectors, driving the market in diverse industries.

Washer Competitive Analysis

Würth

Bossard

Shanghai PMC

Nord-Lock

Fontana Gruppo

Schnorr

Growermetal

STANLEY

Ciser

MW Industries

PCC

LISI

HEICO

Gem-Year

Mubea

Aoyama Seisakusho

Araymond

ITW Shakeproof

TR Fastenings

Boltun Corporation

Key players such as Würth, Bossard, and Shanghai PMC lead the market in production and innovation, influencing global trends and competition.

Buy this Report: https://www.reportprime.com/checkout?id=327&price=3590

Regulatory and Legal Factors

The washer market is affected by various regulatory and legal factors, including import-export laws, product standards, environmental regulations, safety regulations, and government initiatives. These factors vary by region and impact market conditions, pricing, and distribution of washers and related products.

0 notes

Text

Vacuum Sucker Market Size, Trends, Forecast to 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Vacuum Sucker Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Vacuum Sucker Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Vacuum Sucker?

The global vacuum sucker market size reached US$ 730.8 million in 2023. Looking forward, Reports and Insights expects the market to reach US$ 1,245.2 million in 2032, exhibiting a growth rate (CAGR) of 6.1% during 2024-2032.

What are Vacuum Sucker Market?

A vacuum sucker, or vacuum suction cup, is a device that utilizes negative air pressure to generate a firm grip on a surface. Constructed from flexible materials such as rubber or silicone, it works by removing air from between the sucker and the surface to create a vacuum seal. This seal enables the vacuum sucker to lift, hold, or move objects securely without the need for mechanical fasteners or adhesives. Widely used across industries like manufacturing, logistics, and automotive, vacuum suckers are crucial for handling delicate or heavy items and for automating material handling tasks.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1901

What are the growth prospects and trends in the Vacuum Sucker Market industry?

The vacuum sucker market growth is driven by various factors and trends and factors. The vacuum sucker market is growing rapidly, driven by its crucial applications in manufacturing, logistics, and automotive industries. The increasing need for automation and efficient material handling solutions fuels this growth, as vacuum suckers provide a reliable method for lifting, moving, and positioning objects without the use of mechanical fasteners or adhesives. Technological advancements, such as more durable and versatile suction cups, are also contributing to market expansion. Furthermore, the focus on enhancing production processes and reducing manual labor is boosting the adoption of vacuum suckers across various sectors. Hence, all these factors contribute to vacuum sucker market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Type:

Electric Vacuum Suckers

Pneumatic Vacuum Suckers

Hybrid Vacuum Suckers

By End-Use Industry:

Automotive

Electronics

Food & Beverage

Packaging

Pharmaceutical

Logistics & Warehousing

Others

By Application:

Material Handling

Assembly & Robotics

Pick & Place

Packaging & Palletizing

Inspection & Testing

Others

By Sales Channel:

Direct Sales

Distributors/Wholesalers

E-commerce

Global Market Segmentation by Region:

North America:

United States

Canada

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europ

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

Piab AB

Schmalz Inc.

Festo AG & Co. KG

SMC Corporation

Aventics GmbH

VACUUBRAND GMBH + CO KG

Vaccon Company, Inc.

SMC Corporation of America

Pneumadyne, Inc.

Schmalz GmbH

Vuototecnica S.p.A.

DESTACO, a Dover Company

ANVER Corporation

AERO-LIFT Vakuumtechnik GmbH

VMECA Co., Ltd.

Discover more: https://www.reportsandinsights.com/report/Vacuum Sucker-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd.

1820 Avenue M, Brooklyn, NY, 11230, United States

Contact No: +1-(347)-748-1518

Email: [email protected]

Website: https://www.reportsandinsights.com/

Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/

Follow us on twitter: https://twitter.com/ReportsandInsi1

#Vacuum Sucker Market Size#Vacuum Sucker Market Share#Vacuum Sucker Market Demand#Vacuum Sucker Market Analysis

0 notes

Text

Customised Reed Switch Sensor Solutions for Automotive Industry

Have you wondered how a same type of component can be modified into different types of sensors, then without further delay read this article explores how customised reed switch sensor solutions are driving innovations in the automotive industry, providing tailored solutions to meet the unique demands of this sector.

Understanding Reed Switch Sensors

Reed switch sensors consist of two ferromagnetic blades enclosed in a hermetically sealed glass tube. When exposed to a magnetic field, these blades either come together or separate, closing or opening an electrical circuit. This fundamental mechanism offers numerous benefits, including high durability, low power consumption, and the ability to operate in harsh environments.

Why Customise Reed Switch Sensors for Automotive Applications?

Customization allows reed switch sensors to be tailored to specific automotive applications, ensuring optimal performance and integration. Here are some key reasons why customization is essential:

Precision Fit: Customise sensors can be designed to fit specific spaces within vehicle systems, ensuring seamless integration.

Enhanced Performance: Tailoring sensor specifications, such as sensitivity and activation points, improves overall performance and reliability.

Environmental Adaptability: Custom sensors can be designed to withstand extreme temperatures, vibrations, and other harsh conditions typical in automotive environments.

Regulatory Compliance: Ensuring sensors meet industry standards and regulations is critical for automotive applications.

Key Applications of Customized Reed Switch Sensors in Automotive Industry

1. Anti-Lock Braking Systems (ABS)

Reed switch sensors play a crucial role in ABS, providing real-time feedback on wheel speed to prevent skidding and maintain control during sudden braking. According to Grand View Research, the global ABS market is expected to reach $37.2 billion by 2027, highlighting the importance of reliable sensors in these systems.

2. Gear Position Sensing

Customized reed switch sensors are used to detect the position of gears, ensuring accurate transmission control. This precision is vital for both manual and automatic transmission systems, enhancing driving performance and safety.

3. Fluid Level Monitoring

In applications such as fuel tanks, brake fluid reservoirs, and coolant systems, reed switch sensors monitor fluid levels, providing alerts for low levels to prevent potential damage. The automotive fluid market, as reported by MarketsandMarkets, is projected to reach $43.5 billion by 2025.

4. Door and Window Positioning

Reed switch sensors are used to detect the open or closed position of doors and windows, contributing to vehicle security and safety. These sensors ensure that doors are properly latched and windows are closed, providing peace of mind to drivers and passengers.

5. Seat Belt Detection

Customised reed switch sensors are employed in seat belt detection systems to ensure passengers are securely fastened. This is a critical safety feature, as seat belts significantly reduce the risk of injury during accidents.

Benefits of Customised Reed Switch Sensor Solutions

Enhanced Reliability

Customized reed switch sensors are designed to meet the specific demands of automotive applications, ensuring high reliability and long operational life. This reliability is essential for maintaining the safety and performance of vehicles.

Cost-Effectiveness

By tailoring sensors to specific applications, manufacturers can optimise production processes and reduce costs. Custom sensors eliminate the need for additional modifications or adjustments, streamlining the manufacturing process.

Improved Safety

Safety is a top priority in the automotive industry. Customized reed switch sensors enhance vehicle safety systems, such as ABS and seat belt detection, providing drivers and passengers with greater protection on the road.

Environmental Resistance

Automotive environments can be harsh, with exposure to extreme temperatures, moisture, and vibrations. Custom reed switch sensors are designed to withstand these conditions, ensuring consistent performance and durability.

Real-World Examples of Custom Reed Switch Sensor Solutions

Tesla Model S

The Tesla Model S utilises customised reed switch sensors in its advanced driver-assistance systems (ADAS). These sensors provide precise feedback for various functions, including gear position sensing and fluid level monitoring, contributing to the vehicle's high performance and safety standards.

Ford F-150

The Ford F-150, one of the best-selling trucks in the world, incorporates custom reed switch sensors in its door and window positioning systems. These sensors ensure that all doors and windows are properly closed, enhancing vehicle security and passenger safety.

Future Trends in Customised Reed Switch Sensors

The future of reed switch sensors in the automotive industry is bright, with ongoing advancements driving innovation and expanding their applications. Here are some key trends to watch:

Integration with IoT

The integration of reed switch sensors with Internet of Things (IoT) platforms is set to revolutionize automotive applications. This integration allows for real-time data collection and analysis, enabling predictive maintenance and enhanced vehicle performance. A McKinsey report estimates that IoT applications could have an economic impact of $3.9 trillion to $11.1 trillion per year by 2025.

Miniaturisation

As automotive technology evolves, the demand for smaller, more compact sensors continues to grow. Miniaturisation efforts are leading to the development of even smaller reed switch sensors, expanding their application range and improving vehicle design flexibility.

Wireless Connectivity

Advancements in wireless technology are paving the way for reed switch sensors with built-in wireless connectivity. These sensors can communicate with other vehicle systems and external devices, providing seamless integration and enhanced functionality.

Conclusion

Customized reed switch sensor solutions are transforming the automotive industry, offering tailored solutions that enhance performance, reliability, and safety. By understanding the unique needs of automotive applications and leveraging the benefits of customization, manufacturers can stay ahead of the curve and drive innovation in this dynamic sector.

Investing in customised reed switch sensors is not just about improving existing systems; it's about shaping the future of automotive technology. As the industry continues to evolve, these sensors will play an increasingly important role in ensuring vehicles are safer, more efficient, and more reliable.

0 notes

Text

Duct Tapes, Global Market Size Forecast, Top 10 Companies Rank and Market Share

Duct Tapes Market Summary

According to the new market research report “Global Duct Tapes Market Report 2024-2030”, published by QYResearch, the global Duct Tapes market size is projected to reach USD 3.07 billion by 2030, at a CAGR of 5.0% during the forecast period.

Figure. Global Duct Tapes Market Size (US$ Million), 2019-2030

Figure. Global Duct Tapes Top 10 Players Ranking and Market Share (Ranking is based on the revenue of 2023, continually updated)

According to QYResearch Top Players Research Center, the global key manufacturers of Duct Tapes include 3M, Shurtape, Tesa, Berry, Coroplast, Pro Tapes & Specialties, Bolex (Shenzhen) Adhesive, PPM, Intertape, Vibac, etc. In 2023, the global top 10 players had a share approximately 33.0% in terms of revenue.

The global duct tapes market is driven by several factors while facing certain challenges.

Drivers:

Wide Range of Applications: Duct tapes find applications across various industries and sectors, including construction, automotive, electrical, packaging, HVAC (Heating, Ventilation, and Air Conditioning), and DIY (Do-It-Yourself) projects. Their versatility and ability to adhere to a variety of surfaces make them indispensable in many applications, driving market demand.

Convenience and Ease of Use: Duct tapes are known for their ease of use and convenience. They can be torn by hand, require no special tools for application, and provide instant adhesion to most surfaces. This convenience factor makes duct tapes a popular choice for quick repairs, temporary fixes, and emergency situations.

Strength and Durability: Duct tapes are valued for their strength, durability, and resistance to moisture, abrasion, and harsh environmental conditions. They provide reliable bonding and sealing solutions for a wide range of applications, including patching leaks, bundling cables, securing components, and reinforcing structures.

Cost-effectiveness: Duct tapes offer a cost-effective solution for various repair and maintenance tasks compared to alternative adhesive products or mechanical fasteners. Their relatively low cost per unit and high performance make them economically attractive for both consumers and businesses, driving market demand.

Innovation in Product Development: Manufacturers continuously innovate to introduce duct tapes with enhanced features and performance characteristics, such as higher tensile strength, improved adhesion on challenging surfaces, UV resistance, and temperature resistance. These innovations cater to specific application requirements and contribute to market growth.

Challenges:

Competition from Alternative Products: Duct tapes face competition from alternative adhesive products, such as specialty tapes, sealants, adhesives, and mechanical fasteners. The availability of alternative solutions with specific performance attributes or tailored for niche applications may impact market share and demand for duct tapes.

Quality and Performance Variability: Quality and performance may vary among different brands and types of duct tapes, leading to concerns about reliability, longevity, and effectiveness in specific applications. Inconsistent quality or performance failures may erode consumer confidence and affect market growth.

Environmental Concerns: Some duct tapes contain synthetic adhesives and backing materials that may raise environmental concerns related to disposal and recycling. Manufacturers are under pressure to develop eco-friendly alternatives using biodegradable materials or environmentally sustainable production practices to address these concerns and comply with regulations.

Counterfeit Products and Brand Reputation: The proliferation of counterfeit duct tapes in the market poses challenges for legitimate manufacturers in terms of brand reputation, consumer trust, and revenue losses. Counterfeit products may not meet quality standards and performance expectations, jeopardizing consumer safety and confidence in genuine brands.

Regulatory Compliance: Manufacturers must comply with regulatory requirements and standards governing the production, labeling, packaging, and marketing of duct tapes to ensure product safety, quality, and performance. Compliance with regulations such as REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) adds complexity and costs to manufacturing operations.

About The Authors

Yang Min - Lead Author

Email: [email protected]

Yang Min is a market senior analyst specializing in chemical materials. Yangmin has 8 years’ experience in chemical materials market analysis, and focuses on chemical materials and API. He engaged in the development of technology and market reports and is also involved in custom projects.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 17 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Smart Blind Rivets Enable IoT and Sensor Integration

In an everchanging landscape of technology advances the lowly blind rivet has not been neglected. The inclusion of Internet of Things (IoT) and sensor technology in blind rivets is transforming the way fastening and assembly processes are approached with industries. This enables them to offer a range of features almost like never before, ranging from real-time monitoring and inspection to predictive maintenance - features that are often highly desired in modern manufacturing and building. In this blog, we describe the evolution, applications, and transformation that smart blind rivets are creating within specialized industries.

What Are Smart Blind Rivets?

These are state-of-the-art blind rivets having sensors inside and equipped with Internet of Things capabilities, they can be referred to as smart blind rivets. Traditional blind rivets are merely used to hold two materials together, whereas the smart blind rivets of the invention further serve to collect and transmit data with respect to their environment e.g., condition. Information harvested can be applied for the continuous monitoring of structural integrity, potential problem areas, and maintenance scheduling optimization.

Key Features:

Embedded Sensors- Measure other factors such as stress, tension, vibration, temperature.

IoT Connectivity: Send data to central systems in real-time for monitoring & analytics.

Predictive Maintenance: Utilize the data you have collected to predict impending failures and perform maintenance in a timely manner.

How Smart Blind Rivets Work

To understand just how smart blind rivets work, we must first take a closer look at their operations:

1. Sensors: These sensors monitor different parameters, e.g. pressure, temperature or load from within the rivet itself.

2. Micro controllers (process sensor data and control the communication protocols)

3. Wireless Transmitters: Send all the processed data to a central monitoring system through IoT networks.

4. Data Analytics Software (Pending/Coming Soon): Looks at incoming data and provide relevant insights, alerts and proactive maintenance schedules

Installation Process:

However, it can still be done with a conventional blind rivet tool in the case of smart blind rivets. As the sensors and IoT components are standardized, installation procedures can be operated identically to existing workflows.

Smart Blind Rivets Application

Aerospace Industry

Aerospace has an importance of each single part integrity. It specializes in the development of blind fastening devices and components with built-in sensors for aerospace applications, such as smart blind rivets that can alert MRO crews to looming problems in aircraft structures before they become mission-critical.

Structural Health Monitoring: Real time evaluation of the aircraft fuselage and wings.

Safety Improvements: Detect dangers and warning the maintenance team before impending failure

Life cycle Management: to extend the life of aircraft components by pro-active maintenance.

Automotive Industry

To conclude, the automotive industry is able to receive a range of benefits from using smart blind rivets in both the manufacturing and maintenance processes.

Assembly Line Optimization: Real-time quality inspection for riveted joints to guarantee the quality of work and reduce rework costs.

- Vehicle Health Reporting’s: Integrate with Vehicle diagnostics for in-depth vehicle health report generation.

1- Crash Safety: Improve the durability of safety-critical components such as airbags and seatbelt anchors.

Construction Industry

Smart blind rivets also have applications in construction, such as keeping buildings and infrastructure together.

Structural Monitoring: Monitor critical joints in bridges, sky scrapers and other structures.

Maintenance Scheduling: Leverage data for proactive scheduling of maintenance which minimizes downtime and cost.

Safety Compliance: Monitor that the regulations are configured in the building so that it complies with safety standards throughout the time.

Renewable Energy

Smart blind rivets also have applications in installation of renewable energy installations such as wind turbines and solar farms.

Turbine Health Monitoring MPI Turbine health monitoring The structural integrity of wind turbines is critical to avoid very expensive failures - escalators have 3 years life and replacing a failed unit is complicated, costly and inconvenient.

Solar Panel Maintenance -- Check the condition of solar panel mounts and brackets.

They will allow this by - Environmental Adaptation: They can use the data from their rivets to adjust maintenance schedules based on environmental circumstances.

Key Advantages of Smart Blind Rivets

Real-Time Monitoring

It offers intelligent sensors and monitors the condition of the structures in which it is placed, in real time. As a result, it comes with different big advantages, such as the early issue detection which lowers the possibility of some failures happening without any warn.

Predictive Maintenance

The data taken from smart blind rivets can be analysed for maintenance to be planned Predictively. By following this method downtimes can be prevented and component lifespans can be extended hence saving a fortune.

Enhanced Safety

One of the main objectives in the sense of safety applied to different structures (as in aircraft, vehicles, buildings or renewable environments) is continuous monitoring and early detection of problems.

Improved Efficiency

Data from smart blind rivets can be used to improve production processes, guaranteeing that every single one of them is installed the right way and does the job they were supposed.

Future Challenges and Directions

Despite the advantages of smart blind rivets, there are also a number of hurdles to practically realizing their benefits:

Higher Cost: The basic technology of smart blind rivets is accompanied by a higher price than traditional rivets.

Data Management - large data produced needs only to be appropriately managed and analysed.

- Implementation: Incorporating smart rivets with the existing system and the infrastructure are complex.

Future Developments

Due to the advancement of technology, smart blind rivets are slated for a price drop as it becomes cheaper. IoT and sensor technology will also continue to improve which will further empower their capabilities, providing more granular and precise data. Also, by integrating AI and ML your predictive maintenance can be even better which would potentially improve in operational efficiency greatly.

Conclusion

In a broader perspective, smart blind rivets are a major development in fastening technology that have benefits which extend beyond just assembly. Incorporating IoT and sensor technologies, these advanced fasteners enable real-time monitoring, predictive maintenance, as well as safety improvement across industries from aerospace to construction. It is only a matter of time and as these challenges are met and technology advances, smart blind rivets will become a part of standard modern manufacturing with prospects towards a smarter more connected world.

1 note

·

View note

Text

Stainless Steel Round Bar Market Size, Share, Analysis, Growth, Key Players, Trend and Forecast to 2034

In 2023, the global Stainless Steel Round Bar market was estimated at around 31 million tonnes. The market is expected to experience steady growth, with a projected Compound Annual Growth Rate (CAGR) of 4.2% during the forecast period through 2034.

Introduction:

Stainless steel round bars are essential components in various industrial applications due to their remarkable strength, corrosion resistance, and versatility. In South Africa, the demand for these robust materials is on the rise as industries seek durable and high-performance solutions. This article explores the dynamics of the Stainless Steel Round Bar Market in South Africa, highlighting its applications, market trends, and impact on industrial development.

Industrial Applications and Demand:

Stainless steel round bars are used extensively across multiple industries, including construction, automotive, manufacturing, and aerospace. Their superior mechanical properties make them ideal for applications requiring durability, precision, and resistance to harsh environments. The increasing industrialization and infrastructural development in South Africa drive the demand for stainless steel round bars in various sectors.

Click Here: https://www.chemanalyst.com/industry-report/stainless-steel-round-bar-market-4172

Construction Industry:

In the construction industry, stainless steel round bars are utilized for structural support, reinforcement, and fabrication of components such as beams, columns, and railings. Their strength and corrosion resistance make them suitable for both indoor and outdoor applications, ensuring long-lasting performance. As South Africa invests in building and infrastructure projects to support urbanization and economic growth, the demand for stainless steel round bars is expected to increase significantly.

Automotive Sector:

The automotive industry relies on stainless steel round bars for manufacturing critical components like axles, engine parts, and fasteners. These bars offer high strength, durability, and resistance to wear and tear, making them ideal for vehicle parts that require long-term reliability. With South Africa's automotive sector focusing on innovation and sustainability, the adoption of high-quality materials like stainless steel round bars is anticipated to rise, supporting the production of more efficient and durable vehicles.

Manufacturing and Heavy Industries:

Stainless steel round bars play a crucial role in manufacturing and heavy industries, including machinery, equipment, and tool production. Their versatility allows for precise machining and fabrication, making them indispensable in creating components that demand exact specifications and high performance. The expansion of South Africa's manufacturing base, driven by both domestic demand and export opportunities, fuels the growth of the stainless steel round bar market.

Aerospace and Defense:

In the aerospace and defense sectors, stainless steel round bars are used for producing high-strength, corrosion-resistant parts and components. Their reliability under extreme conditions is critical for aerospace applications, including aircraft frames, landing gear, and engine components. As South Africa aims to enhance its aerospace capabilities, the demand for advanced materials like stainless steel round bars is set to grow, contributing to the sector's development and innovation.

Market Trends and Growth Drivers:

The Stainless Steel Round Bar Market in South Africa is influenced by several trends and growth drivers. These include the increasing need for durable and high-performance materials in industrial applications, advancements in production technologies, and the push for sustainable and eco-friendly solutions. The growing focus on infrastructure development, automotive innovation, and industrial modernization also drives the adoption of stainless steel round bars across various sectors.

Click Here: https://www.chemanalyst.com/industry-report/stainless-steel-round-bar-market-4172

Significant players in the Global Stainless Steel Round Bar market are Universal Stainless & Alloy Products, Carpenter Technology Corporation, Tsingshan Holding Group, ThyssenKrupp Materials, Shri Bhagavati Bright Bars, Dongbei Special Steel, Crucible Industries, J. H. Stainless, ArcelorMittal, Garelick Steel, WalsinLihwa, ATI Allvac, Outokumpu, and Others.

Challenges and Strategies:

Despite its advantages, the Stainless Steel Round Bar Market in South Africa faces challenges such as fluctuating raw material prices, competition from alternative materials, and technical complexities in production. To address these challenges, strategic initiatives such as investing in research and development, enhancing local production capabilities, and fostering partnerships with global suppliers are essential. These strategies can help stabilize supply, reduce costs, and drive innovation in the market.

Conclusion:

The Stainless Steel Round Bar Market in South Africa represents a vital component in the country's industrial and infrastructural development. With its exceptional properties and wide-ranging applications, stainless steel round bars support key sectors like construction, automotive, manufacturing, and aerospace. By leveraging market opportunities, addressing challenges, and fostering innovation, South Africa can harness the full potential of the Stainless Steel Round Bar Market, driving industrial growth, technological advancement, and economic development in the region.

0 notes

Text

Polyoxymethylene(POM) Market Report: Trends, Analysis, and Projections

Polyoxymethylene (POM), also known as acetal or polyacetal, is a high-performance engineering thermoplastic known for its excellent mechanical properties, low friction coefficient, and chemical resistance. This blog delves into the dynamics of the global POM market, analyzing key drivers, applications across industries, emerging trends, and future growth prospects.

Understanding the POM Market:

Polyoxymethylene (POM) is a polymer synthesized from formaldehyde, offering high stiffness, strength, dimensional stability, and wear resistance. It finds extensive applications in automotive, electronics, consumer goods, industrial machinery, and healthcare due to its versatile properties.

Market Dynamics:

Automotive Industry: POM is widely used in automotive components such as gears, bushings, clips, fasteners, and fuel system components due to its low friction, wear resistance, and ability to withstand high temperatures and harsh chemicals.

Consumer Goods: In the consumer goods sector, POM is utilized in manufacturing zippers, handles, knobs, toys, and electronic device components due to its excellent surface finish, dimensional stability, and impact resistance.

Electronics and Electrical Applications: POM's electrical insulating properties, dimensional accuracy, and resistance to chemicals make it suitable for connectors, switches, housings, and precision components in electronic devices and electrical systems.

Healthcare and Industrial Machinery: POM's biocompatibility, sterilizability, and mechanical strength make it suitable for medical devices, surgical instruments, pumps, valves, and precision parts in industrial machinery.

Applications Across Industries:

Automotive: Gears, fuel system components, clips, fasteners.

Consumer Goods: Zippers, handles, knobs, toys, electronic components.

Electronics: Connectors, switches, housings, precision components.

Healthcare: Medical devices, surgical instruments, pump parts.

Market Trends:

Focus on Lightweight Solutions: Growing demand for lightweight materials in automotive and aerospace industries drives the adoption of POM and its composites to replace metal components, reducing overall vehicle weight and fuel consumption.

Engineering Innovations: Advances in POM formulations, including reinforced grades, lubricated variants, and impact-modified types, expand application possibilities in demanding environments and specialized applications.

Sustainability Initiatives: Development of bio-based POM and recycling technologies for post-consumer POM waste align with sustainability goals, waste reduction efforts, and regulatory requirements, driving market innovation.

Future Prospects:

The global POM market is poised for steady growth, propelled by expanding applications in key industries, technological advancements, and sustainability initiatives. Investments in R&D, recycling infrastructure, and collaboration across the value chain will shape market evolution and competitiveness.

Conclusion:

Polyoxymethylene (POM) stands out as a high-performance engineering thermoplastic with diverse applications across automotive, consumer goods, electronics, healthcare, and industrial sectors. Understanding market trends, technological innovations, and sustainability imperatives is crucial for stakeholders in the POM market to leverage growth opportunities and address evolving industry needs effectively. With a focus on lightweight design, engineering excellence, and sustainable practices, the POM market presents promising avenues for continued innovation and market expansion globally.

0 notes

Text

Steel Market — Forecast (2024–2030)

Steel market is analyzed to be $1,746.35 billion in 2023 and is projected to reach $2,105 billion in 2030. The market is estimated to grow with a CAGR of 4.13% during 2024-2030. Steel is an alloy that is made up of iron ore or scrap steel and carbon. In general, steels have various unique properties including being non-corrosive, rust-resistant and heavier than other metals such as aluminum. Therefore, steel is extensively used in various end-use industry verticals, including the manufacturing various transportation and automobile components, medical equipment, metal surgical implants, structural components and more, which in turn is boosting its market growth. In recent years, the steel market has experienced fluctuations driven by several factors. One significant trend in the steel market is the impact of trade policies and tariffs. Trade tensions between major steel-producing nations, such as the United States, China, and the European Union, have led to shifts in supply chains and pricing dynamics. Tariffs imposed on steel imports have affected the competitiveness of domestic producers and influenced global trade patterns. Additionally, sustainability concerns and environmental regulations have influenced market dynamics. Increasing awareness of carbon emissions and the environmental footprint of steel production has led to a growing demand for greener steel products. This has prompted investments in cleaner production technologies such as electric arc furnaces and the development of recycled steel. Moreover, technological advancements and innovations in steel manufacturing processes have enhanced efficiency and product quality. As a result, the steel market is poised for sustained growth as global economic recovery accelerates, with innovations in technology and sustainability shaping future trends.

Steel Market Report Coverage

The report: “Steel Industry – Forecast (2024-2030)”, by IndustryARC covers an in-depth analysis of the following segments of the Steel Market Report.

By Type: Carbon Steel, (Low Carbon Steel, Medium Carbon Steel, High Carbon Steel), Stainless Steel (Austenitic Stainless Steels, Ferritic Stainless Steels, Martensitic Stainless Steels, Precipitation Hardening Grade Stainless Steels, Duplex Stainless Steels), Alloy Steel (Chromium Molybdenum Steel, Nickel-Chromium-Molybdenum Steel, Chromium Vanadium Steel, HSLA -Nickel-Chromium-Molybdenum Steel), Tool Steel (Water-hardening tool steels, Shock-resisting tool steels, Cold-work tool steels, Hot-work steels, High-speed tool steels, Others), Others

By Form: Bar, Rod, Tube, Pipe, Plate, Sheet, Structural, Others

By Application: Transportation (Road, Bridges, Barriers, Rail, Tracks, Rail Cars), Construction (Cool Metal (infrared reflecting) Roofing, Purlins, Beams, Pipe, Recyclable steel framing (studs), Desks/Furniture), Packaging (Canes, Bottles, Others), Water Projects (Levees/Dams/Locks), Energy (Renewable, Nuclear, Bio-fuels, Fossil, Electric Grid), Others

By Industry: Construction (Steel Skeletons, Concrete Walls, Pillars, Nails, Bolts, Screws, Others), Machinery (Bulldozers, Backhoe Leaders, Pipelayers, Others), Automotive and Transportation (Exhaust, Trim/Decorative, Engine, Chassis, Fasteners, Tubing For Fuel Lines), Kitchenware and Domestic Appliances (Small Household Appliances, Black Home Appliances, White Home Appliances), Electrical and Electronics (Motor Mount Brackets, Adapter Plates, Electronic Frames and Chassis, Brackets, Others), Healthcare (Orthopaedic Implants, Artificial Heart Valves, Bone Fixation, Catheters, Others), Energy (Scrubbers, Heat Exchangers, Others)

By Region: North America, South America, Europe, Asia-Pacific and Rest of the World

Request Sample

Key Takeaways

Steel Market Segment Analysis – By Type

In terms of type, the Steel Market is segmented into carbon steel, stainless steel, alloy steel, tool steel and others. In 2023, the Stainless-steel segment generated the greatest revenue of $361.94 billion and is projected to reach a revenue of $482.28 billion by 2030. Owing to the various benefits posed by stainless steel such as corrosion resistance, high and low temperature resistance, the ease of fabrication, strength, aesthetic appeal is one of the key factors for its adoption among various end-use industries, which in turn is boosting its market growth. The stainless-steel segment can be further classified as Austenitic stainless steels, Ferritic stainless steels, Martensitic stainless steels, Precipitation hardening grade stainless steel and Duplex stainless steels.

Steel Market Segment Analysis – By Form

By form, the steel market is segmented into bar, rod, tube, pipe, plate, sheet, structural and others. The bar segment accounted for the major market share in 2023, with a revenue of $554.58 billion, and is forecast to grow at a CAGR of 4.68% by 2030. The increasing demand for steel bar from various end-user industries such as building and construction, bridges, and many others, are driving the growth of the segment during the forecast period of 2024-2030.

Steel Market Segment Analysis – By Application

Steel Market is segmented by its application that includes transportation, construction, packaging, water projects, energy and others. The energy segment held the dominant market share, 31% of the whole market, in 2023, and is expected to maintain its dominance by 2030 with a CAGR of 4.69%. One of the major factors for the segment growth is the increasing awareness and focus towards renewable energy sources. Steel plays a crucial role in producing and distributing energy as well as improving energy efficiency. Renewable energy is further classified as Wind Towers and Foundation, Wind Turbines and Solar Parabolic Mirror Supports & Collectors.

Steel Market Segment Analysis – By Industry

The Steel finds its application across the industries such as construction, machinery, automotive and transportation, kitchenware and domestic appliance, electrical and electronics, healthcare, energy and others. Among them, the construction segment is the largest consumer of steel, as bearable structures can be manufactured easily at a low cost. The property of steel in its various forms and alloys makes it more flexible to cater the exclusive projects integrated with infrastructure. Moreover, the rapid industrialization and urbanization in various developing countries are fueling the segment growth in strengthening its dominant market position during the forecast period.

Buy Now

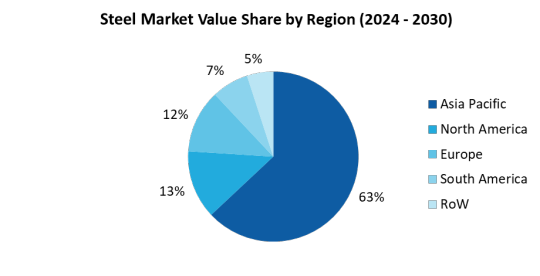

Steel Market Segment Analysis - By Geography/Country

The report comprises of the region wise study of the global market including North America, South America, Europe, Asia-Pacific and Rest of the World. Above all, Asia-Pacific region held the biggest share in 2023, up to 63% of the whole steel market owing to the rapidly expanding defense, machinery, automotive, and shipbuilding industries in the countries such as India, China, South Korea, and Japan. Foreign direct investment in energy and infrastructure is likely to provide opportunities for the market vendors. Coupled with favorable government regulations, growing infrastructure and construction activities in developing economies of the Asia-Pacific region are boosting the demand for the market.

Steel Market - Drivers

Growing Demand for Steel Across the Various Regions

Several factors have a significant impact on the overall development of the steel market. The major growth factor driving the Steel Market is the growing demand for steel across a variety of developing regions. For instance, Global crude steel production in January-November 2023 reached 1715.12 million metric tons, marking a marginal 0.5% year-on-year growth, per provisional data from the World Steel Association. November 2023 saw a production of 145.5 million metric tons, up by 3.3% from the previous year. China led the production with 952.14 million metric tons, followed by India and Japan, USA, Russia, South Korea, and Germany.

Construction and Infrastructure Development:

Construction activities, including residential, commercial, and infrastructure projects such as roads, bridges, and railways, are major drivers of steel demand. Urbanization and industrialization also contribute to the growth of the construction sector, thereby increasing the demand for steel products. For instance, as per Green Finance & Development Center, China Belt and Road Initiative (BRI) Investment Report 2023, engagement totalled about USD88.3 billion, with USD44.6 billion from investment and USD43.7 billion from construction contracts. Also, The US Department of Transportation allocates $3.2 billion in extra funding, alongside $4.3 billion from the Bipartisan Infrastructure Law for 2023. The Budget prioritizes $4.5 billion for the Capital Investment Grant program, aiming to bolster transit infrastructure for economic growth. As a result, the steel market is anticipated to thrive, propelled by heightened construction activities and the need for durable materials, reflecting a promising outlook for the industry.

Steel Market -Challenges

Environmental Regulations and Sustainability

The steel industry is facing mounting pressure to tackle environmental issues by cutting carbon emissions and enhancing sustainability efforts. Meeting stringent environmental regulations demands substantial investments in technology and infrastructure, presenting a formidable challenge for many companies. Despite the financial hurdles, embracing these changes can pave the way for a more sustainable and eco-friendly future for the industry.

Steel Market - Competitive Landscape

The companies referred in the study include Baosteel Co., Ltd., Posco Holding Inc, Nippon Steel Corporation, JFE Holdings, Tata Steel Limited, United States Steel Corporation, Anshan Iron and Steel Group Corporation, Hyundai Steel Co., Ltd., ThyssenKrupp AG, ArcelorMittal S.A., among others. Technology launches, acquisitions, and R&D activities are key strategies adopted by the key players in the Steel Market.

0 notes

Text

Global Bolts Market Size Expected To Reach USD 43,099.31 Million With CAGR 5.10% By 2030

Market Overview:

The global bolts market has witnessed substantial growth and is expected to continue its upward trajectory. In 2022, the market size was reasonably estimated to be approximately USD 28,950.00 Million, and it is projected to reach USD 43,099.31 Million by the end of 2030, exhibiting a CAGR of around 5.10% from 2022 to 2030. Bolts are essential threaded fasteners with external male threads requiring matching pre-formed female threads, such as nuts. They play a vital role in securing various components mechanically and are widely used in construction, automotive, aerospace, and other industries.

Major Key Players:

Würth Industries Service GmbH & Co. KG (Germany), REYHER (Germany), AB Steel Inc. (Canada), Keller & Kalmbach GmbH (Germany), Rockford Fastener Inc. (U.S.), Viha Steel & Forging (India), Brunner Manufacturing Co. Inc. (U.S.), Kd Fasteners Inc. (U.S.), Big Bolt Nut (India), Fabory (Netherlands), Fastenal Company (U.S.), B&G Manufacturing (U.S.), Jignesh Steel (India), Other Major Players.

Request for Sample: -

https://introspectivemarketresearch.com/request/16634

Updated Version 2024 is available our Sample Report May Includes the:

Scope For 2024

Brief Introduction to the research report.

Table of Contents (Scope covered as a part of the study)

Top players in the market

Research framework (structure of the report)

Research methodology adopted by Worldwide Market Reports

Moreover, the report includes significant chapters such as Patent Analysis, Regulatory Framework, Technology Roadmap, BCG Matrix, Heat Map Analysis, Price Trend Analysis, and Investment Analysis which help to understand the market direction and movement in the current and upcoming years.

Inquire Before Purchase: -

https://introspectivemarketresearch.com/inquiry/16634

Bolts Market Segmentation:

Segment Analysis of the Bolts Market:

Type:

Half Screw Bolt

Full Screw Bolt

Material:

Metal

Plastic

Application:

Construction

Automotive

Aerospace

Others

For this report, Introspective Market Research has segmented the Bolts Market based on region:

Market Segment by Regions: -

North America (US, Canada, Mexico)

Eastern Europe (Bulgaria, The Czech Republic, Hungary, Poland, Romania, Rest of Eastern Europe)

Western Europe (Germany, UK, France, Netherlands, Italy, Russia, Spain, Rest of Western Europe)

Asia Pacific (China, India, Japan, South Korea, Malaysia, Thailand, Vietnam, The Philippines, Australia, New Zealand, Rest of APAC)

Middle East & Africa (Turkey, Bahrain, Kuwait, Saudi Arabia, Qatar, UAE, Israel, South Africa)

South America (Brazil, Argentina, Rest of SA)

Recent Developments:

In March 2022, Fabory acquired Fastto Nederland BV, a well-known fastener expert with a relevant product line and dedicated patrons, showcasing a strong strategic fit between the two experts in fasteners.

In February 2021, Würth Industry announced the acquisition of Atlantic Fasteners Inc., a major player in the structural industry, manufacturing structural bolts, and distributing standard and specialty fasteners.

Acquire This Report: -

https://introspectivemarketresearch.com/checkout/?user=1&_sid=16634

About us:

Introspective Market Research (introspectivemarketresearch.com) is a visionary research consulting firm dedicated to helping our clients grow and successfully impact the marketplace. Our team at IMR is ready to help our clients grow their businesses by offering strategies to achieve success and monopoly in their respective fields. We are a global market research company, specializing in the use of big data and advanced analytics to gain a broader picture of market trends. We help our customers to think differently and build a better tomorrow for all of us. As a technology-driven research company, we consider extremely large data sets to uncover deeper insights and provide conclusive consulting. We don't just provide intelligence solutions, we help our clients achieve their goals.

Contact us:

Introspective Market Research

3001 S King Drive,

Chicago, Illinois

60616 USA

Ph no: +1-773-382-1049

Email: [email protected]

#Bolts#Bolts Market#Bolts Market Size#Bolts Market Share#Bolts Market Growth#Bolts Market Trend#Bolts Market segment#Bolts Market Opportunity#Bolts Market Analysis 2024#US Bolts Market#Bolts Market Forecast#Bolts Industry#Bolts Industry Size#china Bolts Market#UK Bolts Market

0 notes

Text

Power Tools Market Valuation to Reach $65.8 Billion by 2032

In 2022, the power tools market was valued at USD 31.7 billion and is anticipated to expand to USD 65.8 billion by 2032, boasting an 8.4% CAGR.

This market encompasses a wide array of electric and pneumatic devices essential for tasks across industries such as construction, manufacturing, automotive, woodworking, and DIY projects. Its growth is fueled by factors like urbanization, industrialization, infrastructure development, and technological advancements. Key players in the power tools industry consistently innovate to improve product performance, durability, and safety, with a keen focus on energy efficiency and sustainability.

Handheld power tools like drills, saws, grinders, and sanders, along with stationary tools such as benchtop drills, table saws, and planers, constitute the market's diverse offerings.

Request Sample Report: https://datahorizzonresearch.com/request-sample-pdf/power-tools-market-2559

Several key factors drive the power tools market:

Technological Advancements: Continuous innovation in power tool technology leads to improved performance, efficiency, and safety features, driving demand for newer products.

Industrialization and Infrastructure Development: The growth of industries such as construction, manufacturing, and automotive drives the demand for power tools used in various applications, including drilling, cutting, fastening, and polishing.

Urbanization: Rapid urbanization worldwide leads to increased construction activities, renovation projects, and infrastructure development, boosting the demand for power tools among professionals and DIY enthusiasts.

Preference for Cordless Tools: Advancements in battery technology have made cordless power tools more powerful and versatile, offering greater mobility and convenience, thus driving their popularity among consumers and professionals alike.

DIY Culture: The rise of do-it-yourself (DIY) culture, fueled by online tutorials and home improvement shows, has led to increased consumer spending on power tools for personal projects and home renovations.

Top Companies are:

Apex Tool Group, Atlas Copco AB, Emerson Electric Co., Hilti Corporation, Ingersoll-Rand PLC, Koki Holdings Co. Ltd., Makita Corporation, Robert Bosch, Stanley Black & Decker, and Techtronic Industries form a formidable lineup of leading players in the power tools industry. Each company brings its unique strengths and expertise to the market, contributing to innovation, quality, and competition.

From precision engineering to advanced manufacturing, these companies continually strive to meet the evolving needs of professionals and consumers alike, driving the growth and dynamism of the global power tools sector.

Market Segmentations:

By Product (2023–2032)· Drills· Saws· Wrenches· Grinders· Sanders· Others

By Mode of Operation (2023–2032)· Electric· Pneumatic· Others

By Application (2023–2032)· Industrial· Residential

For Further Information Regarding this Report: Ask For Discount:

https://datahorizzonresearch.com/ask-for-discount/power-tools-market-2559

Regional Analysis:

Asia Pacific commands a dominant position in the growth trajectory of the power tools market, holding over 30% of the market share and projected to maintain its supremacy with a robust compound annual growth rate (CAGR) of 5.7% throughout the forecast period. The power tools market in the region is valued at USD 10.4 billion, with China emerging as a pivotal player alongside major contributors such as India and Japan.

China stands out as a powerhouse in the power tools sector, boasting a significant market presence fueled by its diverse industrial landscape. With a multitude of industries driving demand, China secured the largest volume share of global demand in 2020 and is anticipated to remain a key driver of global power tools demand in the foreseeable future.

Key highlights of the report include:

1. The report delivers thorough Market analysis, furnishing valuable insights to guide strategic decision-making.

2. The comprehensive research outlined in the study enhances the depth of your presentations and marketing strategies.

3. By offering crucial insights into key market competitors, the study empowers businesses with a strategic edge.

4. It delivers a precise assessment of evolving market dynamics, ensuring readers stay abreast of the latest industry trends.

5. With meticulous breakdowns of various market niches, the report facilitates informed decision-making processes.

0 notes

Text

Turbocharged Waters: A Dive into the Automotive Turbocharger Hose Market

Welcome, dear readers, to the turbocharged extravaganza where hoses are not just for your garden or washing machine, but for your car’s turbocharger system! Today, we embark on a journey through the twists and turns of the Global Automotive Turbocharger Hose Market. Fasten your seatbelts; it’s going to be a bumpy, yet oddly informative ride.

The Turbocharged Tale

Picture this — a world where cars not only move forward but also do a little dance called turbocharging. The hero of our story? Automotive Turbocharger Hoses. These unsung heroes supply air to turbochargers, the rockstars of your car’s engine. Why? Because compressed air equals better engine performance, fuel efficiency, and fewer emissions. It’s like a superhero movie, but with hoses.

Rise of the Turbochargers — A Necessary Drama

As emission regulations tighten their grip worldwide, automakers are desperately searching for a sidekick to help them meet these stringent standards. Enter turbochargers, with hoses in tow. The demand for turbocharged vehicles skyrockets, and our hoses become the unsung MVPs of the automotive world.

But wait, there’s more! Technological advancements in turbocharger design and hose manufacturing materials take the stage. Lightweight, durable hoses capable of withstanding turbocharged engine pressures become the Beyoncé of the automotive world — everyone wants them.

Challenges — The Villains in Our Story

Every hero’s journey has its fair share of challenges. In our turbocharged tale, intense competition among hose manufacturers, volatile raw material prices, and the intricate design of turbocharger hoses play the role of villains. It’s like a never-ending battle to create the perfect hose that can withstand the heat and pressure of turbocharged engines.

And then, lurking in the shadows, we have the electric and hybrid vehicles — the potential disruptors of our turbocharged utopia. Will they steal the spotlight from our hoses in the long run? Only time will tell.

Into the Future — Fasten Your Seatbelts

Hold onto your hats (and hoses), folks! The show must go on. The Global Automotive Turbocharger Hose Market is gearing up for a sequel, and it’s promising a blockbuster. With ongoing technological advancements, a surge in vehicle production, and even stricter emissions regulations, our hoses are set to shine.

What’s the secret formula for success in this turbocharged universe? Market players are turning to innovation, material advancements, and strategic collaborations. It’s like a superhero team-up, but for hoses.

For More Information: https://www.skyquestt.com/report/automotive-turbocharger-hose-market

Market Snapshot — The Turbocharged Numbers

Let’s take a quick pit stop to look at the numbers:

Market Size (2022): USD 2.30 billion

Projected Growth (2031): USD 3.92 billion

CAGR (Compound Annual Growth Rate): 6.1%

Segmental Analysis — Hoses in the Limelight

By Type of Turbocharger Hose:

Largest Segment: Extruded Charge Air Hoses

Fastest Growth: Suction Blow Molded Plastic Hoses

By Region:

Dominant Region: Asia-Pacific (Because who doesn’t love turbocharged cars in Asia?)

Fastest-Growing Region: Europe (Where turbocharged engines and efficiency unite)

By Product:

The Hero Hoses: Extruded Charge Air Hoses (Versatile, durable, and the heartthrobs of the market)

Rising Stars: Wrapped Charge Air Hoses (Affordable, flexible, and stealing the spotlight)

Competing in the Turbocharged Arena — The Players

Meet the A-listers of the turbocharged automotive world:

Honeywell International Inc.

BorgWarner Inc.

Continental AG

Cummins Inc.

And many more…

Recent Developments:

Continental AG introduces silicone rubber turbocharger hoses — because regular rubber is so last season.

Trelleborg AB acquires Flexfab Horizons International, making a power move in the hose industry.

Hutchinson SA releases turbocharger hoses for commercial vehicles — because even trucks and buses deserve a turbocharged makeover.

Wrapping Up — A Turbocharged Finale

As our turbocharged tale comes to an end, one thing is clear — the automotive turbocharger hose market is not just about hoses; it’s about innovation, efficiency, and a touch of drama. The journey through this market is like a rollercoaster — exhilarating, unpredictable, and filled with twists and turns.

So, whether you’re a car enthusiast, a hose aficionado, or just someone along for the ride, the turbocharged automotive world awaits. Buckle up, rev your engines, and let the hoses lead the way!

Disclaimer: No hoses were harmed in the making of this blog. All turbocharger hoses are living their best, pressurized lives.

Note: This blog is a humorous take on the Global Automotive Turbocharger Hose Market and is not intended for professional or investment advice.

About Us-

SkyQuest Technology Group is a Global Market Intelligence, Innovation Management & Commercialization organization that connects innovation to new markets, networks & collaborators for achieving Sustainable Development Goals.

Contact Us-

SkyQuest Technology Consulting Pvt. Ltd.

1 Apache Way,

Westford,

Massachusetts 01886

USA (+1) 617–230–0741

Email- [email protected]

Website: https://www.skyquestt.com

0 notes

Text

Turbocharged Waters: A Dive into the Automotive Turbocharger Hose Market

Welcome, dear readers, to the turbocharged extravaganza where hoses are not just for your garden or washing machine, but for your car’s turbocharger system! Today, we embark on a journey through the twists and turns of the Global Automotive Turbocharger Hose Market. Fasten your seatbelts; it’s going to be a bumpy, yet oddly informative ride.

The Turbocharged Tale

Picture this — a world where cars not only move forward but also do a little dance called turbocharging. The hero of our story? Automotive Turbocharger Hoses. These unsung heroes supply air to turbochargers, the rockstars of your car’s engine. Why? Because compressed air equals better engine performance, fuel efficiency, and fewer emissions. It’s like a superhero movie, but with hoses.

Rise of the Turbochargers — A Necessary Drama

As emission regulations tighten their grip worldwide, automakers are desperately searching for a sidekick to help them meet these stringent standards. Enter turbochargers, with hoses in tow. The demand for turbocharged vehicles skyrockets, and our hoses become the unsung MVPs of the automotive world.

But wait, there’s more! Technological advancements in turbocharger design and hose manufacturing materials take the stage. Lightweight, durable hoses capable of withstanding turbocharged engine pressures become the Beyoncé of the automotive world — everyone wants them.

Challenges — The Villains in Our Story

Every hero’s journey has its fair share of challenges. In our turbocharged tale, intense competition among hose manufacturers, volatile raw material prices, and the intricate design of turbocharger hoses play the role of villains. It’s like a never-ending battle to create the perfect hose that can withstand the heat and pressure of turbocharged engines.

And then, lurking in the shadows, we have the electric and hybrid vehicles — the potential disruptors of our turbocharged utopia. Will they steal the spotlight from our hoses in the long run? Only time will tell.

Into the Future — Fasten Your Seatbelts

Hold onto your hats (and hoses), folks! The show must go on. The Global Automotive Turbocharger Hose Market is gearing up for a sequel, and it’s promising a blockbuster. With ongoing technological advancements, a surge in vehicle production, and even stricter emissions regulations, our hoses are set to shine.

What’s the secret formula for success in this turbocharged universe? Market players are turning to innovation, material advancements, and strategic collaborations. It’s like a superhero team-up, but for hoses.

For More Information: https://www.skyquestt.com/report/automotive-turbocharger-hose-market

Market Snapshot — The Turbocharged Numbers

Let’s take a quick pit stop to look at the numbers:

Market Size (2022): USD 2.30 billion

Projected Growth (2031): USD 3.92 billion

CAGR (Compound Annual Growth Rate): 6.1%

Segmental Analysis — Hoses in the Limelight

By Type of Turbocharger Hose:

Largest Segment: Extruded Charge Air Hoses

Fastest Growth: Suction Blow Molded Plastic Hoses

By Region:

Dominant Region: Asia-Pacific (Because who doesn’t love turbocharged cars in Asia?)

Fastest-Growing Region: Europe (Where turbocharged engines and efficiency unite)

By Product:

The Hero Hoses: Extruded Charge Air Hoses (Versatile, durable, and the heartthrobs of the market)

Rising Stars: Wrapped Charge Air Hoses (Affordable, flexible, and stealing the spotlight)

Competing in the Turbocharged Arena — The Players

Meet the A-listers of the turbocharged automotive world:

Honeywell International Inc.

BorgWarner Inc.

Continental AG

Cummins Inc.

And many more…

Recent Developments:

Continental AG introduces silicone rubber turbocharger hoses — because regular rubber is so last season.

Trelleborg AB acquires Flexfab Horizons International, making a power move in the hose industry.

Hutchinson SA releases turbocharger hoses for commercial vehicles — because even trucks and buses deserve a turbocharged makeover.

Wrapping Up — A Turbocharged Finale

As our turbocharged tale comes to an end, one thing is clear — the automotive turbocharger hose market is not just about hoses; it’s about innovation, efficiency, and a touch of drama. The journey through this market is like a rollercoaster — exhilarating, unpredictable, and filled with twists and turns.

So, whether you’re a car enthusiast, a hose aficionado, or just someone along for the ride, the turbocharged automotive world awaits. Buckle up, rev your engines, and let the hoses lead the way!

Disclaimer: No hoses were harmed in the making of this blog. All turbocharger hoses are living their best, pressurized lives.

Note: This blog is a humorous take on the Global Automotive Turbocharger Hose Market and is not intended for professional or investment advice.

About Us-

SkyQuest Technology Group is a Global Market Intelligence, Innovation Management & Commercialization organization that connects innovation to new markets, networks & collaborators for achieving Sustainable Development Goals.

Contact Us-

SkyQuest Technology Consulting Pvt. Ltd.

1 Apache Way,

Westford,

Massachusetts 01886

USA (+1) 617–230–0741

Email- [email protected]

Website: https://www.skyquestt.com

0 notes

Text