#Agricultural Film and Bonding Market

Explore tagged Tumblr posts

Text

Agricultural Films and Bonding Market

Agricultural Films and Bonding Market Size, Share, Trends: Berry Global Leads

Rising Adoption of Biodegradable Agricultural Films to Address Environmental Concerns

Market Overview:

The global Agricultural Films and Bonding Market is projected to grow at a CAGR of 6.8% from 2024 to 2031, reaching a value of USD 14.7 billion by 2031. Asia-Pacific currently dominates the market, accounting for a significant share. Key metrics include film consumption volume, crop yield improvement rates, and adoption across different agricultural sectors. The market is expanding rapidly, driven by rising food demand, technological breakthroughs in film materials, and a growing trend of covered farming. Government measures supporting sustainable agriculture, as well as the transition to more efficient farming practices, are accelerating industry growth.

DOWNLOAD FREE SAMPLE

Market Trends:

The Agricultural Films and Bonding market is shifting significantly towards biodegradable and eco-friendly film solutions, driven by rising environmental concerns and strict plastic waste regulations. Leading film makers are investing in biodegradable alternatives. For example, a large European agricultural film manufacturer announced a 45% year-on-year rise in sales of biodegradable mulch films in 2023. These films, comprised of polymers like polylactic acid (PLA) and thermoplastic starch (TPS), perform similarly to traditional polyethylene films while degrading naturally in the soil after use. Farmers are increasingly open to these eco-friendly options, motivated by both environmental concerns and potential economic savings.

Market Segmentation:

LLDPE dominates the agricultural film market, driven by superior mechanical properties and cost-effectiveness. Linear Low-Density Polyethylene (LLDPE) currently accounts for a significant share of the market. Its superior mechanical properties, including high tensile strength, puncture resistance, and elongation, make it perfect for various agricultural uses. Recent data from the Plastics Industry Association indicates that LLDPE consumption in agricultural films increased by 7.5% in 2023. Technological advances in LLDPE manufacture, such as the introduction of metallocene catalysts, have resulted in improved film characteristics and processing efficiency.

Market Key Players:

Berry Global

Coveris

RKW Group

Armando Alvarez Group

Plastika Kritis

BASF SE

Contact Us:

Name: Hari Krishna

Email us: [email protected]

Website: https://aurorawaveintellects.com/

0 notes

Text

Spun Bond Non Woven Cloth Meaning in Industries

Spun bond non-woven cloth has emerged as a vital material across various industries due to its unique properties and versatility. Unlike traditional woven fabrics, spun bond non-woven cloth is manufactured by directly bonding fibers together through heat, pressure, or chemical processes. This innovative approach results in a fabric that is lightweight, strong, and cost-effective, making it suitable for a wide range of applications.

Key Characteristics

Durability: Spun bond non-woven cloth is known for its strength and durability. The bonding process creates a fabric that can withstand stress and strain, making it ideal for products that require long-lasting performance.

Breathability: This type of fabric is breathable, allowing air and moisture to pass through. This characteristic is particularly beneficial in applications such as medical textiles and agricultural covers, where ventilation is essential.

Customization: Spun bond non-woven cloth can be easily customized in terms of color, weight, and texture, allowing manufacturers to create products tailored to specific needs and preferences.

Eco-Friendly Options: With increasing awareness of environmental issues, many manufacturers are producing spun bond non-woven fabrics using recycled materials or biodegradable options, further enhancing their appeal.

Applications in Various Industries

Healthcare: In the medical field, spun bond non-woven cloth is widely used for disposable surgical gowns, masks, and drapes. Its barrier properties and ease of sterilization make it a preferred choice for maintaining hygiene and safety.

Agriculture: Farmers use spun bond non-woven fabrics as crop covers and mulch films to protect plants from pests, frost, and harsh weather conditions. The breathable nature of the fabric allows sunlight and moisture to reach the plants while providing protection.

Packaging: Spun bond non-woven cloth is increasingly utilized in packaging applications, such as bags for groceries and promotional items. Its strength and lightweight nature make it a sustainable alternative to traditional plastic bags.

Home Textiles: The versatility of spun bond non-woven cloth extends to home textiles, including tablecloths, curtains, and upholstery. Its ease of cleaning and maintenance makes it an attractive option for interior design.

Conclusion

Spun bond non-woven cloth plays a significant role in various industries, offering durability, breathability, and customization options. Its wide range of applications—from healthcare to agriculture and packaging—demonstrates its versatility and importance in modern manufacturing. As industries continue to seek sustainable and efficient materials, spun bond non-woven cloth is likely to remain a key player in the fabric market.

0 notes

Text

0 notes

Text

An Introduction to How Inflation Impacts Savings and Investments

Inflation is a measurement of the increase in cost for a service or good over a set period, usually a year or more, which impacts savings. The domestic box office provides a basic example of how inflation works.

The film Gone with the Wind, released in 1939, sold over 202.2 million tickets and grossed upwards of $200 million. If the film had released in 2024 and sold a comparable number of tickets, the domestic gross would have eclipsed $1.85 billion.

According to the Bureau of Labor Statistics, the rate of inflation in the United States was 6.4 percent between January 2022 and January 2023. However, this rate can change considerably in response to the state of the economy.

Inflation impacts the lives of everyday consumers in several ways. When inflation rises dramatically, individuals may suddenly stretch their budget to pay for utilities, groceries, and other necessities. Individuals and families should also be aware of inflation’s impact on savings and investments.

In most cases, inflation negatively impacts savings by increasing prices as time progresses. Inflation is especially harmful when it comes to cash savings. If a person stores $10,000 in a safe for 20 years, the goods and services that money can buy will have diminished. The amount of cash has not changed, but the purchasing power has, resulting in a decreased net worth.

Keeping savings with a reputable financial institution can help mitigate the effects of inflation. For example, banks offer interest rates on savings accounts to offset inflation rates. If inflation is unusually high, financial institutions may provide more robust interest rates. However, interest rates are usually not high enough to completely negate inflation: the average national interest rate for savings is just .45 percent. It is rare to find rates above five percent. Even if an individual secures an account with six or seven percent rates, they only manage the impact of inflation rather than growing their money.

Individuals can grow their money more effectively by diversifying their investments and searching for revenue streams that outpace inflation. Unfortunately, inflation can also impact investments. Different investment categories are more or less susceptible to inflation. For example, any investment that provides a set annual return is vulnerable to inflation, including bank certificates of deposit and regular bonds. If one of these investments pays out a $1,000 interest payment each year, the purchasing power of that payment decreases annually.

Identifying inflation’s impact on stocks can be more challenging. Inflation is often at its highest when the economy is strong. Companies sell more stock during these periods, which drives up share prices. At the same time, businesses must pay higher wages and raw materials costs, which hurts the company’s value. An individual company’s market positioning can indicate stock performance compared to inflation.

Investments in select commodities, including agricultural goods and precious metals, thrive during periods of high inflation. Investors often use these commodities as a hedge against inflation. Some investments are indexed for inflation risk, meaning they are more valuable during high inflation and less valuable when inflation is low. Certain bonds and annuities can be indexed for inflation risk.

Individuals concerned about the impact of inflation on their investments should discuss matters with a reputable financial advisor. Diversifying investment portfolios is one of the best strategies for planning against inflation. Otherwise, investors risk losing purchasing power as inflation rises or falls.

0 notes

Text

0 notes

Text

Hydrogenated Polyisobutene Market Dynamics: Exploring Growth Factors

Introduction

Hydrogenated polyisobutene, also known as PIB, is a synthetic hydrocarbon polymer that is produced through the addition polymerization of isobutene. It is a waxy, colorless solid or highly viscous liquid substance. Hydrogenation is then used to saturate the double bonds in the polymer, increasing stability. This process produces hydrogenated polyisobutene (HPIB). Chemical Structure and Properties HPIB is a long hydrocarbon chain made up of repeating isobutylene units. Through the hydrogenation process, all carbon-carbon double bonds in the polymer backbone are converted to single bonds. This gives HPIB a fully saturated linear structure. It has good thermal and oxidative stability as a result. HPIB is non-toxic, non-irritating to skin and is compatible with a wide range of materials. However, it is not soluble in water and has low polarity. Uses in Personal Care Products Due to its emollient properties, HPIB is commonly used as a thickening and conditioning agent in personal care products like moisturizers, lotions and creams. As an occlusive agent, it helps reduce water loss from the skin's surface for better hydration. HPIB forms a protective film on skin that softens and soothes dryness. It also boosts the spreadability of cosmetic formulas without feeling heavy or greasy. The uniform distribution of HPIB molecules acts as an effective binder as well. Role in Makeup Formulations In makeup items, HPIB serves as an emollient base for foundations, tinted moisturizers and BB creams. It provides a smooth, silky feel upon application. The non-oily nature of HPIB prevents clogged pores and acne breakouts. Lip treatments and balms utilize its skin conditioning effects too. Eye products leverage HPIB to soften delicate areas while also suspending pigments evenly. As a fixative, it enhances the longevity of color payoff on lips and lids. Functions in Hair Care Products Shampoos, conditioners and hair masks benefit from HPIB's moisturizing functions. It coats individual strands to impart a healthy sheen and reduce frizz. Combined with other humectants, HPIB helps hair better absorb and retain moisture from the surroundings. This nourishes hair fibers from within. The molecule's small size allows it to seep into hair cuticles for effective sealing of the hair cortex as well. Together with nourishing oils, HPIB improves combability and manages flyaways. Other Industrial Applications Beyond personal care, HPIB has wide applications due to its stability and compatibility features. It is used as a polymeric plasticizer and processing aid in PVC, improving flexibility, durability and heat resistance of finished goods. HPIB acts as an anti-static agent in textiles, a tackifier in rubber and an additive for pesticide formulations too. In agriculture, it helps disperse and absorb active ingredients evenly on targeted surfaces. Printing inks also benefit from HPIB's viscosity modification abilities. Conclusion As a non-polar, non-ionic emollient polymer, hydrogenated polyisobutene effectively hydrates, softens and soothes skin and hair. Its good spreadability and mildness make HPIB suitable for diverse cosmetic formulations. Combined with complementary ingredients, it delivers moisturization and improves manageability. HPIB also finds wide usage in manufacturing due to properties like lubrication, plasticization and adhesion promotion. When sourced from reputed suppliers following good production practices, it can be safely utilized in personal and industrial products.

#Hydrogenated Polyisobutene Market Growth#Hydrogenated Polyisobutene Market Size#Hydrogenated Polyisobutene Market Share

0 notes

Text

Global Top 5 Companies Accounted for 73% of total Retransfer ID Card Printers market (QYResearch, 2021)

A retransfer ID card printer that uses a two-step print process instead of a traditional dye-sub direct-to-card technology. The card design is first printed onto a durable overlay transfer film, which is then bonded onto the card’s surface using a combination of heat and pressure.

Using a retransfer printer will allow you to produce high-definition ID cards that are known as ‘over-the-edge ID cards. This means there is no white border left around the edge of the card; something that happens if you’re using a direct-to-card machine. You can watch more about the differences between direct-to-card and retransfer printers in the video below.

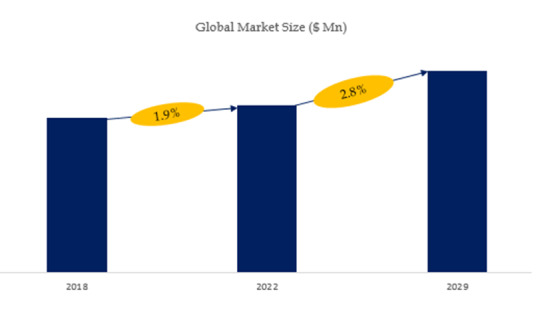

According to the new market research report “Global Retransfer ID Card Printers Market Report 2023-2029”, published by QYResearch, the global Retransfer ID Card Printers market size is projected to reach USD 0.22 billion by 2029, at a CAGR of 2.8% during the forecast period.

Figure. Global Retransfer ID Card Printers Market Size (US$ Million), 2018-2029

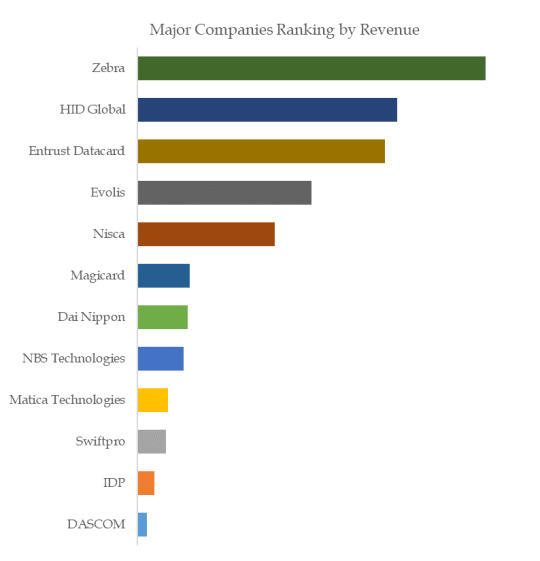

Figure. Global Retransfer ID Card Printers Top 12 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

The global key manufacturers of Retransfer ID Card Printers include Zebra, HID Global, Entrust Datacard, Evolis, Nisca, Magicard, Dai Nippon, NBS Technologies, Matica Technologies, Swiftpro, etc. In 2022, the global top five players had a share approximately 73.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

For more information, please contact the following e-mail address:

Email: [email protected]

Website: https://www.qyresearch.com

0 notes

Text

Polyvinyl Alcohol (PVA) Market Analysis: Assessing Growth Opportunities

Polyvinyl Alcohol (PVA) is a versatile polymer with a wide range of industrial applications, known for its excellent film-forming, adhesive, and barrier properties. This blog delves into the dynamics of the global PVA market, examining key drivers, applications across industries, emerging trends, and future growth prospects.

Understanding the PVA Market:

Polyvinyl Alcohol (PVA), synthesized from polyvinyl acetate through hydrolysis, is a water-soluble polymer used in sectors such as packaging, textiles, adhesives, construction, and pharmaceuticals due to its biodegradability, film-forming ability, and chemical versatility.

Market Dynamics:

Packaging Industry: PVA films find extensive use in packaging for food, pharmaceuticals, and industrial products due to their excellent barrier properties, moisture resistance, and biodegradability, reducing environmental impact.

Textile and Nonwoven Applications: PVA fibers and nonwovens are utilized in textiles, hygiene products, and filtration media for their strength, softness, and water absorption properties, contributing to diverse applications.

Adhesives and Binders: PVA-based adhesives are used in paper packaging, woodworking, construction, and textiles for bonding various substrates, providing good adhesion, flexibility, and water resistance.

Construction Materials: PVA is employed in construction as a polymer additive in cement-based formulations, mortars, and plasters to enhance workability, adhesion, and durability of building materials.

Applications Across Industries:

Packaging: Films, pouches, coatings, and barrier layers.

Textiles: Fibers, nonwovens, coatings for fabrics.

Adhesives: Paper packaging, woodworking, textiles.

Construction: Cement additives, mortars, plasters.

Market Trends:

Biodegradable and Sustainable Solutions: Growing demand for eco-friendly packaging materials and adhesives drives the adoption of biodegradable PVA films and formulations, aligning with sustainability goals and regulatory requirements.

Water-Soluble Films: Increasing use of water-soluble PVA films in detergent packaging, agriculture (seed coatings), and pharmaceuticals (dissolvable packaging) due to their solubility, biocompatibility, and safety.

Advanced Applications: Innovations in PVA nanocomposites, functionalized PVA derivatives, and cross-linked PVA products expand applications in electronics, medical devices, drug delivery systems, and specialty coatings.

Future Prospects:

The global PVA market is poised for significant growth, driven by sustainability trends, innovations in material science, and expanding applications in key industries such as packaging, textiles, and construction. Investments in R&D, recyclable formulations, and value-added products will shape market competitiveness and growth opportunities.

Conclusion:

Polyvinyl Alcohol (PVA) continues to be a versatile polymer with widespread applications across industries, particularly in sustainable packaging, textiles, adhesives, and construction materials. Understanding market dynamics, technological advancements, and customer preferences for eco-friendly solutions are critical for stakeholders in the PVA market to capitalize on growth prospects and contribute to sustainable industrial practices. With a focus on innovation, sustainability, and market diversification, the PVA market presents promising avenues for future development and market expansion globally.

0 notes

Text

0 notes

Link

0 notes

Text

Agricultural films & bonding market will reach an estimated valuation of USD 94.76 million by 2027. Growing prevalence for high quality food crops and increasing population has enhanced the demand for food is expected to enhance the demand for the market. Some of the other factors such as improvement in the standard of the global farming, rising awareness about the cost effectiveness of agricultural films as compared to the traditional films, increasing usage in the greenhouse industry, and increasing investment in R&D for better farming & agricultural practices is expected to drive the agricultural films & bonding market in the forecast period of 2020 to 2027.

0 notes

Text

BOPP Laminated Non Woven Fabric Rolls

In the dynamic world of textiles, BOPP laminated non-woven fabric rolls have emerged as a game-changer. Combining the resilience of non-woven fabrics with the enhanced properties of BOPP (Biaxially Oriented Polypropylene) lamination, these fabric rolls are setting new standards in various industries. Whether it's packaging, agriculture, or fashion, BOPP laminated non-woven fabric rolls offer unmatched benefits. This blog explores the unique features, advantages, and diverse applications of BOPP laminated non-woven fabric rolls.

What is BOPP Laminated Non-Woven Fabric?

BOPP laminated non-woven fabric is created by bonding a layer of BOPP film onto a non-woven fabric. Non-woven fabrics are produced by binding fibers together using various methods, such as thermal, chemical, or mechanical processes. The BOPP film is a thermoplastic polymer known for its exceptional clarity, strength, and resistance to moisture. When combined, these materials produce a fabric that is both durable and visually appealing.

Key Features and Benefits

1. Superior Durability

The lamination process significantly enhances the durability of non-woven fabrics. BOPP laminated non-woven fabric rolls are highly resistant to wear and tear, making them suitable for demanding applications where longevity is crucial.

2. Enhanced Printability

BOPP film provides an excellent surface for high-quality printing. The clear, smooth surface ensures vibrant, sharp, and long-lasting prints, making these fabric rolls ideal for branding and promotional purposes.

3. Moisture and Chemical Resistance

The BOPP layer adds a protective barrier against moisture and chemicals, extending the fabric's lifespan and maintaining its integrity in challenging environments. This makes it perfect for agricultural uses and packaging sensitive products.

4. Eco-Friendly

BOPP laminated non-woven fabrics can be made from recyclable materials and are themselves recyclable. This aligns with the growing demand for sustainable and eco-friendly products.

5. Versatility

The combination of non-woven fabric and BOPP lamination offers exceptional versatility. These fabric rolls can be tailored for various applications, providing both functional and aesthetic benefits.

Applications of BOPP Laminated Non-Woven Fabric Rolls

1. Packaging Industry

BOPP laminated non-woven fabric rolls are widely used in the packaging industry. They provide a durable and attractive solution for shopping bags, gift bags, and promotional bags. The enhanced printability allows businesses to showcase their branding effectively.

2. Agriculture

In agriculture, these fabric rolls are used for creating mulch films, plant covers, and weed control fabrics. The moisture and chemical resistance of BOPP laminated fabrics protect crops and promote healthy growth.

3. Fashion and Apparel

Designers are increasingly using BOPP laminated non-woven fabric rolls in fashion for creating innovative and durable garments and accessories. The fabric's unique properties allow for the creation of stylish yet practical items.

4. Advertising and Promotion

The high-quality printability of BOPP laminated non-woven fabric rolls makes them ideal for banners, posters, and other promotional materials. The prints are vivid and long-lasting, ensuring effective communication of marketing messages.

5. Home Furnishings

These fabric rolls are also used in home decor for making items such as cushion covers, table runners, and curtains. The combination of durability and aesthetic appeal makes them a popular choice for enhancing home interiors.

Conclusion

BOPP laminated non-woven fabric rolls are transforming various industries with their superior durability, printability, and versatility. Whether used in packaging, agriculture, fashion, or home decor, these fabric rolls offer unmatched benefits. Their eco-friendly nature and enhanced properties make them a sustainable and practical choice for businesses and consumers alike. Embrace the innovation of BOPP laminated non-woven fabric rolls and explore their potential to elevate your products and projects to new heights.

Factory Gata No. 34, Mauza Khadwai, Tehsil Kirawali, Runkata, Agra, Uttar Pradesh, India-282007 📩 [email protected] Contact no 918800775462

0 notes

Text

Agricultural Films And Bonding Market Size, Share And Trends Report Till 2024 Focusing on Key Players : Kuraray & Nova Mont

The global Agricultural Films and Bonding Market is estimated to touch US$ 14.19 billion by the completion of the prediction period. The market was appreciated at US$ 7.60 billion in the year 2015. It is estimated to develop at a substantial CAGR for the duration of the prediction. The agricultural films and bonding industry on the source of Type of Application could span Netting- Anti-insect, Shade, Anti-hail and Others.

The market on the basis of packaging could span Twine (Vegetable Packing, Fruit Packing [Bale and Others]), Agricultural Films (Mulching, Green House, Silage [Sheets, Stretch wrap, Bags]). The application of mulching, in the international market of agricultural films, is estimated to touch US$ 5,787.2 million by the completion of the prediction period. Mulching films are maximum extensively utilized in the nations such as China and Rest of Asia owing to huge areas of cultivable land and unlimited agrarian actions. The greenhouse coverings are extensively utilized in gardening and floriculture schemes in the Middle East and Europe to decrease the properties of severe climatic conditions in these areas.

Enquire About This Report: https://www.millioninsights.com/industry-reports/agricultural-films-bonding-market/request-sample

The subdivision of Shading was the prominent use sector and responsible for the market stake of more than over 40% of the netting market during the year 2015. The Shading nets are likewise utilized to extend or postponement of the reaping period in sunlit areas mostly in European markets for example Italy.

The agricultural films and bonding on the source of Type of Raw Material could span Netting (Polypropylene, HDPE, LDPE and Others), Twine (LDPE, Sisal, Polypropylene, and others), Agricultural Films (LDPE and others).The subdivision of Polypropylene [PP] discovers an extensive variety of uses in agriculture and agribusiness. They are utilized in the production of twines and netting for the wrapping and guarding the products from destruction. The Polypropylene [PP] twines are utilized for tie and corrugated Polypropylene [PP] for irrigational uses. Polypropylene [PP] demand in twine was responsible for more than 70% stake of the international market during the year 2015.

The agricultural films & bonding market on the source of Type of Product could span Netting, Agricultural Films, Twine, and others. The subdivision of Agricultural Film was the most important sector of the product type and responsible for a stake of more than 75% of the general market for the duration of the year 2015. This segment is anticipated to see the quick expansion above the prediction period because of increasing necessity for the first-class harvests.

The subdivision of Twine was responsible for a stake of more than 10% of the market during the year 2015. Baling twines are utilized for binding and piling of the crops. They are likewise appropriate in packaging crates for fruits and vegetables, those are very much appropriate for the transportation.

The agricultural films and bonding market on the source of Area with respect to Trades in terms of intake, Profits, Market stake, and Development percentage in these areas for the duration of the prediction could span North America [U.S.A {Texas, Iowa, Kansas, Wisconsin, Nebraska, California} Canada, Mexico], Europe [France, Spain, Germany, U.K., Italy], Asia Pacific, Central & South America [Brazil], Middle East & Africa.

By the source of geography, the Asia Pacific’s agricultural films & bonding steered the international business and was responsible for the market stake of more than 70% of international demand during the year 2015. Above 80% of the agriculturalists in the area practice mulch. Encouraging backing from the government for R&D of safe farming practices are likely to take an optimistic influence on the progress of the business.

The Europe is expected to observe motionless development above the following eight years due to strict ecological rules regarding discarding of the film and the manufacturing. Yet, the consumer emphasis is shifting in the direction of recyclable materials in the area. It expected to power the progress of the business.

The statement revises Trades in terms of intake of agricultural films & bonding in the market; particularly in North America, Europe, Asia Pacific, Central & South America, and Middle East & Africa. It concentrates on the topmost companies operating in these regions. Some of the important companies operating in the field are Ab Rani PlastOy, BASF, Bar bier Groupe, BP Industries [BPI], Kuraray, Nova Mont, Armando Alvarez SA, Trioplast Industrier AB, ExxonMobil Corporation.

Browse Complete Report Summary with TOC here https://www.millioninsights.com/industry-reports/agricultural-films-bonding-market

Get in touch

At Million Insights, we work with the aim to reach the highest levels of customer satisfaction. Our representatives strive to understand diverse client requirements and cater to the same with the most innovative and functional solutions.

Contact Person:

Ryan Manuel

Research Support Specialist, USA

Email:[email protected]

0 notes

Link

The growing demand for high-quality crops is expected to foster healthy growth of the agricultural films and bonding market during the forecast period, “Agricultural Films and Bonding Market Size, Share and Industry Analysis, By Type (Agricultural Films, Twine, Netting, Others), By End Use Industries (Greenhouse, Mulching, Silage, Vegetable and fruit Packing, Shade, Anti-insect, Others) Others and Regional Forecast, 2019-2026.” The increasing need for high crops yields is expected to enable speedy expansion of the market.

0 notes

Text

Visit Cranberry Bogs in Massachusetts

You'll be hard-pressed to find a more photogenic crop of cranberries that ripen and drop in fall. In Massachusetts, the cranberry harvest coincides with the fall foliage season and provides a double dose of visual splendor. According to the Cape Cod Cranberry Growers Association, 400 of North America's 1,000 cranberry farms are concentrated in Massachusetts: most are south of Boston in Plymouth County and on Cape Cod.

Related: Best Limo Service Cape Cod

Any drive in this area during the Massachusetts cranberry harvest, which usually begins in the last week of September and runs through October and sometimes into November, is likely to offer views of cranberry swamps, as growers work hard to nurture and pick the state's top agricultural crop. There's a good chance, too, that you'll find yourself driving behind dump trucks full of red berries.

The Pilgrims discovered cranberries growing in swamps near their settlement in Plymouth and introduced them to "Crane berries" because their spring flowers resemble the shape of a bird's head and beak. From their Native American neighbors, the Pilgrims learned to use cranberries not only for food and medicinal but as a natural dye.

Cranberries are one of three fruits native to North America that are now grown commercially. Like blueberries and Concord grapes, cranberries are in greater demand worldwide as knowledge of their nutritional properties has increased.

If you want to set out on a driving landing tour to visit the cranberry swamps of Massachusetts, here are some of your best bets to see the harvest in progress and buy fresh cranberry and cranberry products.

Mayflower Cranberry

If you want to make sure you don't miss the harvest activity on this small cranberry farm, which has three berry-producing bogs, book in advance with one of the Mayflower Cranberries' harvest viewing tours, available on select dates in October and November. If you'd like to wear a lighter hip and get into a bog to help with the harvest, you can opt for the two-hour Mayflower "Be the Grower" experience. It's expensive, but it may help you appreciate your daily work! All of these experiences sell out long before the harvest season.

Mayflower Cranberries also own a farmer's shop and sell fresh berries anywhere in the United States.

Al Baraka Farms

Flax Pond Farms is an ideal place to learn a little bit about the history of cranberry cultivation in Massachusetts. Inside the shop at Flax Pond Farms, you'll discover an antique Bailey Cranberry Separator dating from 1924. Kids watch an explosion watch the cranberries pass a "bounce" test for quality down filming and into a conveyor belt, where they can be manually sorted by color and size. You can observe the device in operation in this video.

Outside a swamp tour, you might meet farmer Jack Angle, who has been growing cranberries on 35 acres since 1967. Wet harvesting was a novelty in the late 1960s, but without a reliable source of water, critical to the process, and Angli, his wife Dott and their team set up Families and neighbors who work hard "with the dry harvest".

While picking cranberries with a robotic dry harvester is labor-intensive, it has an advantage. Cranberries harvested by flood swamps are only suitable for processing juice concentrates, dried cranberries, and other consumer products with an extended shelf life. Cut cranberries can only be sold as fresh, whole berries.

Cranberries are rich in antioxidants and nutrients, and those who have tasted Flax Bond Farms products return year after year. Some people who visited these swamps on bus trips even called to order cranberries picked up mail for delivery. While most of the farm's crop is marketed by Massachusetts-based Ocean Spray the world's largest cranberry cooperative—2,000 pounds can be sold annually from the family's lovely farm shop, sampling hot cranberry tea.

Rocky Maple Bogs

When radiant red cranberries rise to the surface of a flooded swamp, it's just a sight. When swamps are flooded using a sprinkler irrigation system, naturally floating cranberries loosen from their vines and fly to the surface. The wind pushes the berries toward one corner of the swamp, and a lever is used to flip the cranberries toward a pump truck or conveyor system on the shore.

You don't have to be on a guided tour to observe a wet cranberry harvest if this happens: just respect private property, stay out of swamps, and don't drink cranberries without permission. After all, these are working farms: no attractions. The Rocky Maple Bogs in Wareham is well worth the drive if you want to stumble upon a scene like this during cranberry season.

The cranberry beaters, sometimes called "eggbeaters," that you may see on the move do not cut the cranberries. Her paddlewheels stir the water, and she calls out to the reluctant cranberries to release the vine. Once the swamps are flooded, cranberry harvesters must work around the clock to get their products out of the swamp and off to the processing plant before the berries spoil.

Makepeace farms

If you don't want to leave your cranberry harvesting experience to chance, Makepeace offers guided tours on select dates during the season. View the schedule online, or call 508-322-4028 for more details.

Whether or not you book a spot on this tour, make Makepeace Farms stop on your cranberry swamp driving tour. This farm market is the best place to shop for cranberry food and souvenirs, as well as other delicious locally produced food and drinks including fresh cranberries, granulated dried cranberries, cranberry granola, cranberry salad, cranberry chain, and Richards' famous garlic dish. The seasoning is made in Carver, Massachusetts, at Cranberry Barn Kitchens.

Cranberry Bog Rounds

Learn about growing organic cranberries on a tour of Cape Cod's largest organic swamp. Starting in April and available daily during the fall harvest season, these kid-friendly and accessible tours require reservations. Before you leave, buy sweetened dried cranberries and organic cranberry sauce at the farm stand. Fresh cranberries by the pound are also available during the harvest season.

For traveling to cape code you can Get cape cod car service

Cape Cod Cranberry Bog Tours

You'll get an agricultural education on walking tours offered by this cranberry farmer, who has bred 75 acres of rusk on Cape Cod for more than a quarter-century. Make reservations in advance for daily picnics from mid-June through mid-December to view dogs in bloom, cranberries on the vine, and, eventually, the harvest.

Anne Cannes

Visit cape cranberry farms during harvest season for tours and to shop for fresh fruit and farm produce including Bogside Honey. Owner Annie Walker quit her job supervising a Broadway production in 1994 to tend this swamp, which was owned by her grandfather. Dennis is the first city in America where cranberries - a local wild fruit - have been successfully grown.

6 notes

·

View notes