Text

Denison's innovative beginnings are shown in the quality of flexible parts

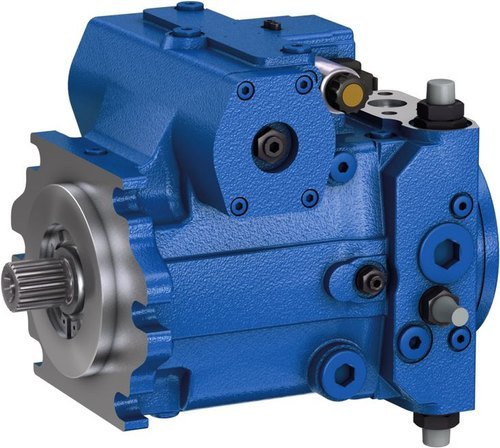

The Rexroth hydraulic pump exporter specializes in four product lines: Vickers, Denison, Rexroth A10VSO series, servo valves and proportional valves. Part of a series on the origins of each of the major hydraulic brands we offer, we focus on Denison Hydraulics in this article.

Denison's high-quality flexible products have a reputation for standing the test of time and being particularly useful when applied to a variety of mobile and industrial applications.

Denison has a long history of innovation, beginning with the emergence of hydraulics and continuing through tough economic times as a leader in new and versatile products.

HPS' comprehensive line of Denison products includes pumps, motors, valves and servomotors/proportional parts of this power. These products continue to provide the versatility and quality needed to recycle year after year.

Who is Denison?

Denison Hydraulics Inc. It is owned by Parker Hannifin and is based in Marysville, Ohio.

With revenues of approximately $180 million, the Rexroth pump manufacturer has 1,150 employees in North America, Europe and Asia.

Denison Hydraulics serves the global market with reliable hydraulic equipment and systems for mobile, industrial, power, defense and marine applications.

And while the manufacturer has gone through some tough times in its 120-year history, Denison remains the world's preferred choice of hydraulic products for applications that demand high performance, reliability and flexibility.

Original origin

Founded in 1900 in Delaware, Ohio as the Cook Motor Company, Denison manufactures heavy-duty industrial single-cylinder gasoline engines only.

After World War I, Bill Dennison acquired the Cook Motor Company while the motor market was dying.

But Denison had the idea ofdeveloping a machine designed to slowly move clay-filled wagons through the kiln. It was the first hydraulic machine and the beginning of a long history of innovation.

The advent of hydraulics, called Hydraulics’ at the time, helped keep the company going through tough times. (If you have time, Google the word "Hydraulics’" and you might find some operable machines approaching their 100th birthday.)

Cook Motor Company went into receivership and reorganized into Denison Engineering during the Great Depression. They continue to innovate with products such as the rail pusher and the "compact" power unit.

Denison hydraulics: truly unparalleled quality

Today, Denison's well-designed, competitive products are among the products that hold up well in the remanufacturing process and can easily be brought back to life with the help of HPS.

Its impressive and successful 120-year history of innovation and longevity leaves no mystery as to why Denison is the preferred hydraulic brand worldwide, and the preferred choice here at HPS.

Of the more than two million HPS Rexroth Motors on the shelf, Denison products continue to lead with high performance, reliability and flexibility that stand the test of time.

Source URL:- https://rexrothpump.blogspot.com/2022/08/denisons-innovative-beginnings-are.html

0 notes

Text

Types of hydraulic pumps

There are generally three types of hydraulic pump structures found in mobile hydraulic applications. These include gears, pistons and blades. However, there are also clutch pumps, vacuum pumps, and dump truck pumps, such as Muncie Power Products' Dry Valve Pumps and Live PakTM.

A hydraulic pump is a component of a hydraulic system that takes mechanical energy and converts it into fluid energy in the form of an oil flow. This mechanical energy is taken from what is called the main engine (rotational force) such as the PTO or directly from the truck's engine.

With each hydraulic pump, the pump will be of either a single-rotor or two-role design. As its name suggests, the single-rotating pump is designed to operate in one direction of shaft rotation. On the other hand, a bi-circulating pump has the ability to work in any direction.

Gear pumps

For truck-mounted hydraulic systems, the most common design in use is a gear pump. This design has fewer moving parts, is easier to maintain, is more tolerant of pollution than other designs, and is relatively inexpensive. Gear pumps are fixed displacement pumps, also called positive displacement pumps. This means that the same volume of flow is produced with each rotation of the pump shaft. Gear pumps are rated for maximum pump pressure rating, displacement in cubic inches, and maximum input speed.

Gear pumps are generally used in open center hydraulic systems. Gear pumps trap oil in the areas between the pump gear teeth and the pump body, move it around the circumference of the gear bore, and then force it out through the outlet port when the gears are engaged. Behind the copper alloy drive plates, or wear plates, a small amount of pressurized oil pushes the plates firmly against the gear tips to improve pump efficiency.

Piston pumps

When high operating pressures are required, piston pumps are often used. Piston pumps traditionally withstand higher pressures than gear pumps of similar displacement; however, there is a higher initial cost associated with piston pumps, as well as lower resistance to contamination and increased complexity.

The equipment designer and service technician must understand this complexity to ensure that the piston pump operates correctly with its additional moving parts, stricter filtration requirements, and stricter tolerances. Piston pumps are often used with truck-mounted cranes, but they are also found in other applications, such as snow and ice control, where it may be desirable to vary the flow of the system without changing the engine speed.

A cylinder block containing pistons that move in and out is located inside a piston pump. It is the movement of these pistons that pulls the oil from the supply port and then pushes it through the port. The angle of the discontinuous plate, against which the sliding end of the piston slides, determines the length of the stroke of the piston. While the powder plate remains stationary, the cylinder block, which includes the pistons, rotates with the pump's input shaft. The pump displacement is then determined by the total volume of the pump cylinders. Fixed and variable displacement designs are available.

Source URL:-https://eatonhydraulicpumps.blogspot.com/2022/07/types-of-hydraulic-pumps.html

Related Blogs

Rexroth hydraulic pump

Rexroth hydraulic valve

Eaton hydraulic pump

Eaton hydraulic valve Rexroth a4vg

A4VG Series Piston Pumps

A10VG Series Piston Pumps

PGH Series Internal Gear Pumps

A4VSO Series Piston Pumps

A7VO Series Piston Pumps

A8VO Series Piston Pumps

A2FO Rexroth hydraulic pumps Series

PV7 Series Vane Pumps

A10VO 52R Series Pumps

A10VO 31R Series Pumps

Atos PVL Vane Pumps

Denison Vane Pumps

External Gear Pumps

Axial Piston Pumps Fixed Pumps

Axial Piston Variable Pumps Open Circuit

Dowty Gear Pumps

Vane Pumps PV7

4WE6 Valves

3WH and 4wh Series

3WE6 Valves

DB/DBW/DBDS Series

ZD/ZDR Series Valves

2FRM Series Valves

Directional Control Valve

Z2S/Z2FS/SV/SL Series

A6VM Series Piston Motors

A2M Series Piston Motors

3A10VM Series Piston Motors

0 notes

Text

Eaton Hydraulic Pumps

Eaton Hydraulic Pumps

Eaton hydraulic pumps provide the functionality and durability required to succeed in the most demanding industrial and mobile applications. They are backed by an experienced global engineering and manufacturing organization focused on meeting customer needs and delivering high-value products that give Eaton’s customers a competitive advantage.

External gear pumps

Eaton began manufacturing gear pumps and engines for the growing aerospace industry in the 1960s. Today, these products are delivered to customers worldwide for a wide range of mobile and industrial applications that demand higher pressure, higher quiet operation, a long service life and a wide range of options and functions.

Eaton hydraulic pump

Eaton external gear pumps are available in a wide range of standard configurations, including many with integrated valves and controls. Multiple pump assemblies and special designs are also available to suit application needs.

Their combination of efficiency and economy makes Eaton outdoor gear pumps the first choice for many customers in the construction, agriculture, material handling, aerial lift, lawn care, utilities, forestry, mining, earthmoving, molding, primary metals, automobile manufacturing, entertainment and machine tool industries. It is also widely used in mobile fan drive systems.

The Eaton S26 and L2 pumps use a die-cast aluminum housing, end cap and flange to house the constant, pressure-balanced inner bushings to produce a compact and rigid body that can incorporate multiple functions.

Eaton offers three lines of pumps to bring the potential energy density, flexibility and energy efficiency of this design to the widest possible range of mobile, off-road and marine applications.

Open circuit movable piston

Eaton offers three lines of pumps to bring the potential energy density, flexibility and energy efficiency of this design to the widest possible range of mobile, off-road and marine applications.

Vickers PVM, PVH, PVE and PVB series pumps are time-proven designs used in construction, agricultural and automotive applications around the world.

Eaton’s medium pressure/flow compensation MD PFC pumps are built on Cessna designs. These also have a long history of performance and reliability.

The new 420 and 620 Series X20 pumps deliver higher power density and higher operating pressures in a smaller, lighter package.

All Eaton open circuit mobile pistons can be easily customized for a variety of application needs.

Associated Brands: Eaton, Vickers

420 Series: Eaton’s 420 Series pumps deliver high pressure in a compact package to maximize energy density. They are ideal solutions for space-constrained applications. Eaton’s 420 series pumps are available in displacements from 41 to 80 cc (2.5 to 4.88 in 3) at operating pressures up to 280 bar (4000 psi). Eaton 410 pump configurations are available to fit common transmission and tee packages, including Torque Control.

620 Series: Eaton’s 620 Series pumps deliver high pressure in a small package for maximum power density. They are ideal solutions for space-constrained applications. Eaton’s 620 series pumps are currently available with a displacement of 98 cc (5.98 in3) for operating pressures up to 280 bar (4000 psi) and inlet speeds of up to 2,220 rpm. Versions with a displacement of 65, 74 and 120 cc (4.0, 4.51 and 7.32 in 3) were planned.

Eaton offers a wide range of open circuit piston pumps with the flexibility to operate a wide range of fluid power systems in the industrial market.

Industrial open circuit piston

Eaton open circuit piston pumps provide the performance and flexibility to drive a wide range of medium duty industrial fluid power systems. These pumps are widely used in machine tools, molding machines, manufacturing equipment, power generation equipment, port machinery, and in the oil and gas, civil engineering, and leisure industries.

Eaton Dura Force™ axial piston pumps are available in displacements from 55 to 280 cc (3.57 to 17.1 in3) at operating pressures up to 280 bar (4,060 psi). They are engineered for high efficiency, precise control and durability, ensuring years of highly productive, profitable and reliable service.

The compact, versatile PVB series pumps are available in displacements from 10 to 94 cc (0.6 to 5.74 in3) with operating pressures up to 210 bar (3,045 psi).

The PVH series pumps are available in displacements from 57 to 141 cc (3.48 to 8.67 in3) at operating pressures of up to 250 bar (3,625 psi). These pumps have the widest range of control options, including torque limiting.

PVW pumps are available in displacements from 130 cc to 750 cc (7.93 to 44.55 in 3) at operating pressures up to 350 bar (5,075 psi).

Vickers® Hydrokraft™ PVX and PFX Open Circuit Constant and Variable Circuit Pumps

PVX pumps are available in displacements from 66 to 250 cc (4.03 to 15.26 in3) at operating pressures up to 350 bar (5,075 psi).

Vickers® M . Series Variable Displacement Piston Pumps

The PVM series pumps feature the widest displacement range, from 18 to 141 cc (1.1 to 8.6 in3), at operating pressures of up to 280 bar (4,061 psi). The design incorporates advanced features that reduce noise levels by more than 50%.

Vickers® Q . Series Industrial Variable Displacement Open Circuit Piston Pumps

Quiet and versatile, the PVQ Series delivers a displacement of 10 to 45 cc (0.6 to 2.75 in3) at operating pressures of up to 210 bar (3,045 psi).

Eaton Hydrokraft axial piston pumps use a cradle-type fly-plate design that provides reliable operation and long life in high pressure, closed-loop industrial applications.

Source URL:- https://eatonhydraulicpumps.blogspot.com/2022/06/eaton-hydraulic-pumps.html

Related Blogs

Rexroth hydraulic pump

Rexroth hydraulic valve

Eaton hydraulic pump

Eaton hydraulic valve Rexroth a4vg

A4VG Series Piston Pumps

A10VG Series Piston Pumps

PGH Series Internal Gear Pumps

A4VSO Series Piston Pumps

A7VO Series Piston Pumps

A8VO Series Piston Pumps

A2FO Rexroth hydraulic pumps Series

PV7 Series Vane Pumps

A10VO 52R Series Pumps

A10VO 31R Series Pumps

Atos PVL Vane Pumps

Denison Vane Pumps

External Gear Pumps

Axial Piston Pumps Fixed Pumps

Axial Piston Variable Pumps Open Circuit

Dowty Gear Pumps

Vane Pumps PV7

4WE6 Valves

3WH and 4wh Series

3WE6 Valves

DB/DBW/DBDS Series

ZD/ZDR Series Valves

2FRM Series Valves

Directional Control Valve

Z2S/Z2FS/SV/SL Series

A6VM Series Piston Motors

A2M Series Piston Motors

3A10VM Series Piston Motors

#rexrothhydraulicpump#rexrothhydraulicvalve#rexrothpump#rexrothvalve#eatonhydraulicpump#eatonhydraulicvalverexrotha4vg#rexrothdealer#rexrothdistributor

0 notes

Text

Eaton Hydraulic Valve

AxisPro Proportional Valves – Based on proven KB servo proportional valve technology, Eaton’s next generation AxisPro® proportional valves provide multiple levels of performance for a wide range of applications;

Directional Control Valves – Easy to install on industrial standard surfaces, Eaton DG directional valves provide three-way or four-way control of hydraulic cylinders or actuators;

Proportional Flow Valves – With external electrical wires housed within a closed enclosure, Eaton Proportional Flow Valves improve moisture resistance;

Eaton hydraulic valve

Proportional Fuse Electronics – Eaton’s proportional valve electronics features easy-to-use LED front panels and a variety of system feedback displays to control systems with precision and accuracy:

Servo Valves: Eaton Servo valves are the perfect solution for closed loop control applications. They provide systems with precise positioning, repeatable speed and predictable power;

System Stak: System Stak provides a full range of supplemental pressure, flow and check valve functions, while saving space, reducing installation costs and increasing efficiency in hydraulic systems;

Sub plates and bolt groups.

Eaton moving valves | Eaton mobile valves are a reliable solution for mobile machinery in a wide range of industries. Scope includes:

CLS Load Sensing CT Mobile Valves: Eaton CLS Load Sensing CT Mobile Valves are a range of pre- and post-compensation mobile valves with a highly versatile design;

Advanced CMA Movable Valve with Independent Measurement – The Eaton CMA valve features built-in electronics and advanced software algorithms;

HRC4, HRC2 and HRCP hydraulic remote controls;

VLC, VLE and VLH priority load sensing valves.

Eaton Threaded Cartridge Valves | providing a reliable solution for mobile machinery in a wide range of industries. Scope includes:

Check Valves – Direct or pilot operated check valves for cartridge or inline hydraulic circuit applications. Choose from simple and inexpensive bearing hardware to optional adjustable bypass versions;

Coils – Control the opening and closing of solenoid valves and proportional valves using a quick-change zip coil featuring the Eaton Tough Coil Series;

Directional Control Valves – choose from a variety of manual control options to meet your design needs, including rotary, lever, push and pull valves, or choose hot oil or push-pull shuttle valves;

Flow Control Valves – Eaton’s flow control valves accurately calculate temperature, pressure and flow rate for efficient handling of every application, whether the hydraulic system requires compact, pressure-equilibrated threaded vent cartridge valves or a more specific set of features;

Logical Element Valves – Designed to provide complete control of pressure, flow and direction, Logical Element Valves cover a wide range of pressure ratings and applications;

Motion Control Valves – Improves machine stability and efficiency while eliminating valve noise. The range includes standard, partially balanced, fully balanced and differential-free differential designs;

Pressure Control Valves: A wide range of manual or pilot operated pressure control valves for hydraulic systems. Eaton pressure control valves are ideal for applications requiring load retention, numerous guide ratios, efficient control and excellent stability;

Proportional Valves – Get smooth, precise control of your pressure and flow applications with Eaton Threaded Cartridge Proportional Valves (SiCV). When applied in conjunction with Eaton Logic Element Valves and other SiCVs in a custom manifold assembly, Eaton Proportional Valves create an efficient and reliable hydraulic system.

Source URL:-https://eatonhydraulicvalve.blogspot.com/2022/06/eaton-hydraulic-valve.html

Rexroth hydraulic pump

Rexroth hydraulic valve

Eaton hydraulic pump

Eaton hydraulic valve Rexroth a4vg

A4VG Series Piston Pumps

A10VG Series Piston Pumps

PGH Series Internal Gear Pumps

A4VSO Series Piston Pumps

A7VO Series Piston Pumps

A8VO Series Piston Pumps

A2FO Rexroth hydraulic pumps Series

PV7 Series Vane Pumps

A10VO 52R Series Pumps

A10VO 31R Series Pumps

Atos PVL Vane Pumps

Denison Vane Pumps

External Gear Pumps

Axial Piston Pumps Fixed Pumps

Axial Piston Variable Pumps Open Circuit

Dowty Gear Pumps

Vane Pumps PV7

4WE6 Valves

3WH and 4wh Series

3WE6 Valves

DB/DBW/DBDS Series

ZD/ZDR Series Valves

2FRM Series Valves

Directional Control Valve

Z2S/Z2FS/SV/SL Series

A6VM Series Piston Motors

A2M Series Piston Motors

3A10VM Series Piston Motors

#rexrothhydraulicpump#rexrothhydraulicvalve#rexrothpump#rexrothvalve#eatonhydraulicpump#eatonhydraulicvalverexrotha4vg#rexrothdealer#rexrothdistributor#rexrothproportionalvalve

0 notes

Text

Rexroth hydraulic pump

Rexroth Hydraulic Pumps

Rexroth’s complete line of hydraulic pumps serves nearly every industry in manufacturing and technology applications, such as railroad engineering, chemical process plants, energy and environmental engineering, automotive engineering, plastics processing machinery, papermaking, presses, test benches and simulation systems, marine/marine.

Engineering, Special Projects, Civil/Water Engineering, Transportation Technology, and Machine Tools. By seeking a thorough understanding of these application areas and working closely with customers, our engineers have developed unique electro-hydraulic innovations in control technology. The result is hydraulic pumps with greater accuracy, safety and reliability.

Rexroth Distributor Rexroth Pump

Taking into account market expectations, Rexroth Distributor sets a new standard for hydraulic pumps with the continuous development of the highest standards and quality. Rexroth pumps are designed for reliability and high efficiency.

The pump line includes: Axial Piston Pumps, Internal Gear Pumps, External Gear Pumps, Gerotor Pumps, Vane Pumps, Electro-hydraulic Pumps and Radial Piston Pumps. Rexroth pumps are designed from a solution point of view where products are compatible with each other to provide a complete range for our customers.

To help your systems operate safely and at peak efficiency, Rexroth offers a wide range of pump accessories. Replacement seals, safety valve, mounting flanges, brackets and adapters make installation easier and faster.

Source URL:- https://rexrothdistributor.blogspot.com/2022/06/rexroth-hydraulic-pump.html

1 note

·

View note