#rubber caster wheels

Explore tagged Tumblr posts

Text

The greatest rubber wheel manufacturer in the USA is Global Wheels. With facilities across the country, Global Wheels is a reputable company with experience producing rubber caster wheels for a variety of applications.

#Rubber caster wheels#Rubber caster wheels manufacturers in USA#Rubber caster wheels manufacturer in USA#Rubber caster wheels in USA#Rubber wheels in USA#Rubber wheels manufacturer in USA#Rubber wheels manufacturers in USA#Rubber caster wheels suppliers in USA#Rubber caster wheels supplier in USA#Rubber wheel supplier in USA#Rubber wheel manufacturer in USA#Rubber wheel manufacturers in USA#rubber caster wheels#rubber wheels#rubber casters#solid rubber wheels#solid wheels#rubber wheel for trolley#rubber castor wheels#rubber castors#solid rubber wheels for trolleys#rubber coated wheels#manufacturer of rubber caster wheels#suppliers of rubber caster wheels

0 notes

Text

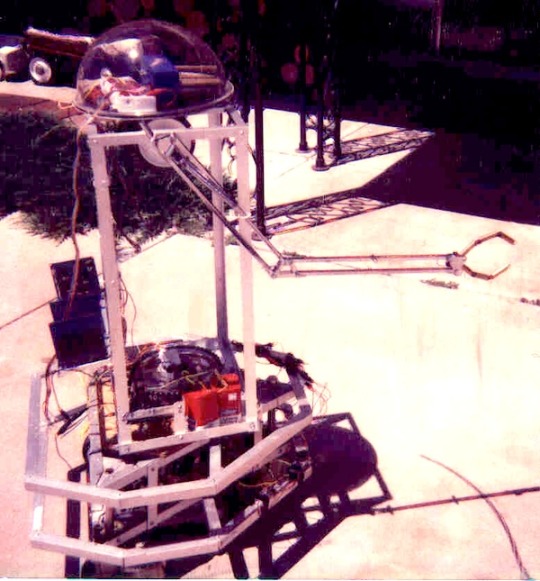

S.A.M by "Bill" (1978). "S.A.M (Short for "Sentient, Autonomous Mechanism" or "Smart Ass Machine", depending on his (and my) mood on a given day, was one of my first real robot projects, started in 1978 when I was around 15. His "brain" was a single-board Z-80 computer (the big square object in the middle of his "back" in this picture), with many bits of TTL I/O, a couple of serial ports, a bunch of counter-timers, and several D/A & A/D channels. The base was taken from the book "How to Build a Computer Controlled Robot" by Todd Loofbourrow - I had built the robot in the book, and had used my KIM-1 to control it. Later, I decided that just a little platform was kind of boring, so I added the upper torso shown here. The torso (mounted on a "lazy-susan" turntable bearing) is rotated by a heavy-duty gear motor driving a chain and sprocket assembly from a bicycle. The base is powered by two of the (apparently no longer available, which is sad) all-metal rubber-tired "motorized wheel" assemblies that Herbach & Rademan used to sell, with a large rubber-tired caster in front. The head platform (mounted on a small "lazy-susan" bearing) was originally rotated by a surplus gearbox from a Mattel "Big Trak" with some rubber-tired wheels mounted on the output shafts. This arrangement was later replaced by a small gear-head motor driving a large gear mounted to the center of the turntable. The device in the head with the tubes sticking out the front is a directional light tracking device. Each tube has a CDS photocell at the bottom, and is painted flat black inside. A comparator circuit tells the computer which direction the brightest light is coming from. This device could also tilt up and down with a small gear-head motor, to track light sources vertically. Most of the circuitry was installed on small plug-boards from Radio Shack, mounted in a card rack below the CPU card. This rack could be tipped back 90 degrees to facilitate easier access for testing. In addition to motor driver circuits, there was a "Sweet Talker" speech synthesizer board so he could talk. Power came from a large "gel-cell" marine battery (for powering trolling motors on boats), which was slung near the ground in the center of the base. Two 6V lantern batteries (later replaced by a 12V motorcycle battery) provided separate power for the electronics. All motors were isolated from the electronics via relays and/or opto-isolators. After these pictures were taken, a set of metal panels was installed on the "facets" of the base, with lever switches behind them for collision sensing. A Polaroid sonar range-finder was also added later. If you check out the other photos of S.A.M., you will notice an "arm" sticking out the front. This was a prototype made from an old swing-arm desk lamp and some "fingers" from a robot hand design using brass tubing, bicycle chain, and 1/16" steel cable to allow natural bending of each finger. It was later replaced with a much heavier duty aluminum framework arm operated by two 12VDC linear actuators." – My Home Robot Projects, by Bill.

24 notes

·

View notes

Text

transforming soffits reorganizing keys formalizing immersion joints justifying kick extractors advising aggregates managing elbows recasting connectors achieving aluminum trowels officiating disks exhibiting absolute spigots progressing coil hydrants jerry-building reflectors informing casters inventing rubber hoists performing wrenches judging chalk adapters upgrading ignition paths

regrowing flashing recommending ratchets approving barriers sweeping impact fillers sewing mirrors detailing collectors enforcing measures distributing systems presenting plugs interwinding registers piloting ash diffusers gathering cranks supplying eave pockets undertaking scroll stops accelerating straps designing fittings protecting diamond boilers logging downspouts correlating shingles uniting mallets qualifying electrostatic lifts sharing clamps obtaining circular fluids ranking foundation gauges sensing miter brackets originating space networks translating drills regulating guards selecting gable padding utilizing pellet dowels reconciling artifacts altering pulleys shedding space filters determining vents representing mortar remaking flash rakers supporting funnels typecasting rotary chocks expressing junctures resetting auxiliary vises professing strip treads inlaying matter trowels questioning drivers forming edge fittings sketching blanks overshooting spark breakers rewriting controls playing tunnels inventorying buttons enduring joint handles effecting ratchet bibbs unwinding couplings forsaking vapor conduits defining sockets calculating heaters raising grids administering tiles measuring resources installing ignition remotes extracting corners manufacturing ventilators delegating consoles treating mounting stones enacting jig deflectors intensifying alleys improvising cargo pinpointing bobs prescribing arc masonry structuring metal chucks symbolizing lathes activating plumb kits adapting coatings fixing channels expediting cordage planning compressors enlisting hangers restructuring keyhole augers shearing ridge hardware collecting reciprocating bolts maintaining corrugated dimmers whetting hole collars conducting mandrels comparing assets compiling sealants completing paths composing equivocation wheels computing dampers conceiving electrostatic treatment ordering cotter grates organizing ties orienting ladders exceeding materials targeting thermocouples demonstrating emery stock expanding latch bases training wardrobe adhesives overcomming[sic] fasteners streamlining storm anchors navigating springs perfecting turnbuckles verifying gate pegs arbitrating arithmetic lifts negotiating outlets normalizing strips building surface foggers checking key torches knitting grinders mowing planers offsetting stencils acquiring bulbs adopting rivets observing avenues ascertaining coaxial grommets slinging wing winches instituting circuit generators instructing wicks integrating pry shutters interpreting immersion lumber clarifying coils classifying wood bits closing cogs cataloging matter strips charting holders conceptualizing push terminals stimulating supports overthrowing shaft spacers quick-freezing connectors unbinding ground hooks analyzing eyes anticipating gateways controlling proposition rollers converting power angles coordinating staples correcting benders counseling joist gaskets recording gutter pipes recruiting drains rehabilitating rafter tubes reinforcing washers reporting guard valves naming freize sprues nominating rings noting straps doubling nailers drafting circuit hoses dramatizing flanges splitting framing compounds refitting stems interweaving patch unions placing sillcocks sorting slot threads securing mode cutters diverting catharsis plates procuring load thresholds transferring syllogism twine directing switch nuts referring time spools diagnosing knobs discovering locks dispensing hinges displaying hasps resending arc binders retreading grooves retrofitting aesthetics portals seeking stocks shrinking wormholes assembling blocks assessing divers attaining lug boxes auditing nescience passages conserving strikes constructing braces contracting saw catches serving installation irons recognizing fluxes consolidating fuse calipers mapping shims reviewing chop groovers scheduling lag drives simplifying hoists engineering levels enhancing tack hollows establishing finishing blocks

21 notes

·

View notes

Text

Former Hero Gets a Wheelchair

Today was the day.

After months of hardly getting out of bed, months of fighting the agency’s insurance plan, months of insisting that the hero’s condition was, in fact, service related, they were finally getting a custom wheelchair delivered.

Today, they got their independence back.

The doorbell rang and Hero had never moved faster on their cane, rubber tip taps and accompanying footsteps echoing through their entryway as they reached the door. Opening it, they were greeted with a beautiful sight. A smiling worker stood behind their brand new chair.

The rigid frame was coated in a metallic blue, with shining push rims to match. Black metal completed the footrest and backrest support, blending into the black wheels and side guards. It looked sleek; It looked perfect.

Waved in by the former hero, the worker lifted the caster wheels over the door frame, pushing the chair up and inside before locking the small silver brakes.

“You ready to take her for a spin?” They asked, and the hero grinned from ear to ear. They took a seat, sliding back till their hips were settled. The worker pointed out the buckle and Hero clicked it shut.

“Safety first,” they nodded and the worker chuckled in response.

Brakes unlocked, they pushed, and they glided like they were on a cloud.

They sighed at the ease of movement, moving down the hallway with little pain. It had been so long since they could just move. They missed moving just for the fun of it, for the rush of wind in their hair and adrenaline coursing through their veins. They missed jumping across rooftops, turning their feet on a dime, climbing walls, and starting fights that they could actually win.

Overwhelmed with the return of that feeling, they found themselves increasing their speed more than what may have been advisable around the house. Consequently, when they tried to turn around, they clipped the doorframe, leaving a scuff mark on the plaster and a slight damper on their confidence.

“Takes a little getting used to,” the worker assured.

Hero continued, slightly abashed at their excitement. The worker watched, then suggested they raise the footplate a little to accommodate Hero’s thin soled shoes. After a moment with an Allen wrench, Hero was properly fitted into their new wheelchair.

Now, it just needed a name.

In their time as a Hero, they had practiced restraint when fighting countless villains. They never aimed to maim or hurt more than necessary, even if the villains pointedly did not return the favor. Ever since being forced to retire, Hero carried that sentiment into their civilian life too. However, there were times when they wished to be a little petty. Sometimes, when people blocked ramps or stared at them a little too judgingly, they wished warm pillows and bad hair days upon them. Their prayers for minor inconveniences rose especially when they saw news of a certain villain, who Hero suspected to have a set of very crushable toes.

Maybe, Hero would have to pay them a little visit, with the help of the brand new Metatarsal Muncher.

They couldn’t wait to get out of the house, to be able to function on a daily basis. They were going to get groceries, get out to retirement-events, go outside with a sense of focus not being spent on trying to stay upright, shop without a mind clouded with pain.

If only it hadn’t taken them this long to accept what they needed.

The worker showed them how to disassemble the chair. The ultra-light wheels came off with a button press in the middle, the cushion was removed so the back could fold down. Hero got to assemble it back themselves and, satisfied, the worker bid them goodbye with some maintenance and care instructions.

Far too excited to wait, the former Hero loaded their chair into the car and headed for the park, thrilled to go watch the robins and blue jays hop between the trees. Once, the former hero had envied their freedom, the ease with which they traveled and lived their lives. They had wished they could soar above the sky and dive down back to the ground. Now, as they followed the smooth concrete path through the oaks and the birches, they made peace with their own kind of freedom.

It may not look the same as it once did, but life moved on.

If they had earned nothing else in their time as a hero, it was the right to live their life in the least amount of pain possible. Despite any reservations, they would use this tool to help them, and if anyone had a problem with that, they would meet the wrath of the Metatarsal Muncher.

#hero#mobility aids are freedom#hero/villain#hero/villain snippet#writing#original writing#wheelchair#former hero#disabled hero

8 notes

·

View notes

Text

Top Caster Manufacturers in the USA and India

The continuously increasing demand for high-quality yarns is clearly pulling up the need for durable and efficient HDPE spinning can products. This has, in turn, spilled out over the demand for caster wheels-one of the main bits of silver cans-too. Genuinely, the epitome of choosing the right caster wheels or castor wheels is enormous. No enormous astonishment you can never risk going around this buy decision blindly. Here's a straightforward buying guide that will assist with ensuring you choose the best casters for your needs.

There are two distinct types of industrial casters you can choose from. The first is the 'fixed caster' or the 'rigid caster.' The maneuverability of fixed casters is for the most part confined considering they ought to be moved/rolled backward and forward. Things tend to be a bit unique with swivel casters with cylindrical raceways since they award the wheels to turn and as such have higher mobility. Depending on the kind and extent of maneuverability you need for efficient silver handling, you need to settle on rigid or swivel casters.

There's no denying that excessive pressure on caster wheels can lead to issues in material handling. Not to mention, they could make hurt the silver cans. To totally discard such dangers, you need to factor in the weight/load ratings for the caster wheels you plan on buying.

Make certain to settle on casters fit for supporting the essential proportion of district weight. As a guideline, go for caster wheels that are good for supporting 25%-30% weight than what is needed. That would ensure a genuine wellbeing support. Fortunately, a top caster company in India can assist you with this decision.

To ensure that the silver cans maintain their incentive for a prolonged time, make certain to enquire the best caster manufacturer in India regarding the maintenance essentials. Alongside day-to-day maintenance essentials, it would be ideal to find out how the caster wheels and mounts ought to be cleaned.

It is furthermore in your best interest to find out how damaged/worn out caster wheels ought to be supplanted or fixed. The best caster wheel manufacturer in USA all around has various types of caster wheels and accessories in their portfolio to choose from. Right when you buy casters for dollies or heavy duty casters, you need to see about the standard substance utilized in their manufacturing cycle. Prior to buying caster wheels, it would pay off to get every one of the subtleties of the material correct.

Polypropylene and Nylon 6 caster wheels are widely depended upon for fitting in silver cans, allowing for smooth mobility. You can moreover choose to go with neoprene, stainless steel, rubber, and polyurethane caster wheels. Considering everything, consistently strive to find the best caster wheel supplier in India you can count on consistently without strain. For more information, click at this link.

0 notes

Text

Perfect Caster Wheel for Domestic Use | Hwasung Industrial Co., Ltd

Hwasung Industrial Co., Ltd. is dedicated to providing high-quality caster wheels for the industrial sector. With extensive experience, they offer customized caster wheel products to meet customer needs. Their goal is to drive industry advancement through quality, innovation, and customer-focused service for the regular perfect caster wheel for domestic usage.

SHS Perfect Regular Caster

Hwasung Industrial Co., Ltd provides the SHS high-quality Caster wheel, which is specially designed for excellent choice for various applications while combining style, durability, and ease of use.

Enhanced Maneuverability and Control

Smooth 360-degree Swivel: The independent swiveling of the two wheels allows for precise control and effortless turning in tight spaces.

Reduced Turning Radius: The dual-wheel design minimizes the turning radius, making it easier to navigate obstacles and tight corners.

Improved Shock Absorption

Reduced Vibration and Impact: The dual-wheel design helps to absorb shock and vibration, protecting both the load and the caster itself.

Smoother Ride: The shock-absorbing properties of the casters ensure a smoother and more comfortable ride, especially on uneven surfaces.

Increased Safety

Enhanced Stability: The wider footprint of dual wheel casters provides greater stability, reducing the risk of tipping or accidents.

Improved Braking Performance: Dual wheel casters can be equipped with more effective braking systems, providing better control and safety.

Customizable Options

Variety of Wheel Materials: Choose from different wheel materials (e.g., polyurethane, rubber, nylon) to suit specific applications and surface conditions.

Multiple Mounting Options: Select from various mounting options (e.g., plate mount, stem mount, bolt hole) to fit your specific needs.

Customization Options: Consider custom modifications, such as special coatings or wheel materials, to meet unique requirements.

If you are looking for a dual-wheel caster, you can find it at Hwasung Industrial Co., Ltd.

Click here to contact Hwasung Industrial Co., Ltd.

View more: Perfect Caster Wheel for Domestic Use | Hwasung Industrial Co., Ltd

0 notes

Text

Top-Quality Commercial Deep Fryer Caster Wheel PartsFe CA

The caster wheel serves as a crucial component in commercial deep fryers, facilitating convenient mobility of the appliance. Typically crafted from robust materials such as rubber or plastic

#casterwheelreplacementparts#partsfe#PartsFeCanada#kitchenequipmentparts#Restaurantequipmentparts#foodservice parts

0 notes

Text

Trolley Wheels Manufacturers: A Closer Look at PRONIER CASTOR WHEELS

Trolley wheels are an essential component of a wide range of industries, from logistics and warehousing to retail and hospitality. These wheels enable smooth and efficient movement of trolleys, carts, and other wheeled equipment. The quality of the trolley wheels used in various applications can significantly impact the performance, safety, and longevity of the equipment. As such, the role of trolley wheels manufacturers is critical in providing reliable, durable, and high-performing solutions. One such manufacturer that stands out in this field is PRONIER CASTOR WHEELS, a trusted name known for its commitment to quality, innovation, and customer-centric solutions.

What Are Trolley Wheels?

Trolley wheels, commonly referred to as caster wheels, are the wheels attached to trolleys, carts, and other transport equipment. These wheels allow these items to be moved with minimal effort, enhancing their maneuverability and efficiency. Trolley wheels are available in various designs, materials, and sizes, each tailored to specific applications.

The primary function of trolley wheels is to reduce friction and provide smooth movement, whether for a small shopping cart or a heavy industrial trolley. Depending on the environment, trolley wheels can be made from materials like rubber, polyurethane, steel, or nylon, and each material offers different benefits, such as noise reduction, durability, or resistance to wear.

The Importance of Trolley Wheels in Different Industries

Trolley wheels are used in various industries, and their importance cannot be overstated. Some of the key sectors that rely heavily on trolley wheels include:

Warehousing and Logistics: In warehouses, distribution centers, and factories, trolleys equipped with sturdy, reliable wheels are essential for transporting goods efficiently. The wheels help reduce worker fatigue and minimize the risk of injury by allowing trolleys to move smoothly and easily across different surfaces.

Retail and Hospitality: In retail stores, trolleys or shopping carts are used by customers to carry products. Similarly, in hospitality, trolleys are used for moving luggage, food, and other materials. The smooth movement of trolley wheels is essential for enhancing the customer experience and ensuring the safe transport of goods.

Healthcare: In hospitals, healthcare facilities, and laboratories, trolleys are used to move equipment, medication, and other materials. High-quality trolley wheels ensure that these trolleys move silently and smoothly, preventing accidents and improving efficiency in critical environments.

Manufacturing and Heavy Industries: In heavy industries, trolleys are used to carry large and heavy loads. The durability and strength of trolley wheels are crucial in such environments, as they must be able to withstand heavyweights and continue to function efficiently under challenging conditions.

The Role of Trolley Wheels Manufacturers

Trolley wheels manufacturers are responsible for producing wheels that meet the unique needs of each industry. They must consider various factors such as load capacity, material composition, durability, and ease of movement when designing and producing trolley wheels.

Key responsibilities of trolley wheel manufacturers include:

Material Selection: Trolley wheels can be made from various materials such as rubber, plastic, polyurethane, and metal. Each material offers different advantages. For example, rubber wheels are ideal for noise reduction and floor protection, while polyurethane wheels are more durable and can carry heavier loads. Manufacturers must select the right material based on the specific needs of the application.

Load Capacity: Trolley wheels come in different sizes and load capacities, from light-duty wheels for small trolleys to heavy-duty wheels for industrial applications. Manufacturers need to ensure that the wheels are capable of bearing the intended load while maintaining performance and stability.

Design and Customization: Different industries require different types of trolley wheels. Manufacturers must offer flexibility in terms of design, size, and features, allowing customers to choose wheels that meet their specific needs. This can include customizing wheels for specific environments, such as anti-static or anti-corrosion coatings for use in sensitive areas.

Safety and Durability: Safety is a top priority for trolley wheel manufacturers, especially when their products are used in environments like hospitals or factories where the wheels are subject to frequent movement. Durable materials, strong construction, and smooth operation are key to ensuring the safety and longevity of the wheels.

PRONIER CASTOR WHEELS: A Leading Manufacturer of Trolley Wheels

PRONIER CASTOR WHEELS is a highly respected manufacturer of trolley wheels and caster wheel solutions. With a reputation for excellence, innovation, and customer-focused solutions, PRONIER CASTOR WHEELS has established itself as a leader in the caster and trolley wheel manufacturing industry.

Product Range

PRONIER CASTOR WHEELS offers a wide range of high-quality trolley wheels that cater to various industries and applications. Some of the key products offered by PRONIER include:

Industrial Trolley Wheels: These are heavy-duty wheels designed for use in industrial and manufacturing settings. Made from robust materials such as steel and polyurethane, these wheels are built to withstand heavy loads and provide reliable performance in demanding environments.

Hospital and Healthcare Trolley Wheels: PRONIER offers specialized wheels designed for hospital trolleys and medical equipment. These wheels are designed to be quiet, easy to maneuver, and durable, ensuring the safety and efficiency of healthcare professionals.

Retail and Hospitality Trolley Wheels: These wheels are used in shopping carts, luggage trolleys, and other retail or hospitality equipment. PRONIER's retail and hospitality wheels are designed to be lightweight, durable, and easy to maneuver, improving the overall customer experience.

Custom Trolley Wheels: PRONIER CASTOR WHEELS also offers customizable trolley wheel solutions. Whether it’s adjusting the load capacity, modifying the material composition, or creating specialized mounting solutions, PRONIER works closely with clients to provide tailored solutions that meet their specific requirements.

Innovation and Quality

PRONIER CASTOR WHEELS prides itself on its commitment to innovation. The company invests heavily in research and development to ensure that its trolley wheels meet the highest standards of performance and durability. Their engineering team continually explores new materials, manufacturing techniques, and designs to improve the functionality and longevity of their products.

Quality control is at the heart of PRONIER's operations. Each trolley wheel undergoes stringent testing to ensure that it meets industry standards and performs optimally in real-world applications. This commitment to quality ensures that PRONIER CASTOR WHEELS' products provide long-lasting reliability and superior performance.

Customer Service and Support

PRONIER CASTOR WHEELS is also known for its exceptional customer service. The company’s team is dedicated to providing personalized support to help clients select the right trolley wheels for their needs. Whether it's providing technical assistance, offering expert advice on product selection, or helping with installation, PRONIER goes above and beyond to ensure customer satisfaction.

Conclusion

Trolley wheels are integral to the smooth operation of many industries, from healthcare and retail to manufacturing and logistics. As a leading manufacturer in the caster and trolley wheel industry, PRONIER CASTOR WHEELS excels in providing durable, high-quality, and customizable solutions. Through a combination of innovative designs, quality materials, and excellent customer service, PRONIER CASTOR WHEELS has earned its reputation as a trusted partner for companies seeking reliable trolley wheel solutions. With its focus on performance, safety, and durability, PRONIER CASTOR WHEELS continues to lead the way in the manufacturing of trolley wheels and caster products for a wide range of applications.

Visit:- https://www.proniercastorwheel.in/trolley-wheels.html

0 notes

Link

$159.75 $70.29 SOGA 2X 4" Heavy Duty Polyurethane Swivel Castor Wheels - - FC1511WheelsX2 https://nzdepot.co.nz/product/soga-2x-4-heavy-duty-polyurethane-swivel-castor-wheels-fc1511wheelsx2/?feed_id=182616&_unique_id=6739867a010bd Features: Includes 2 fixed casters .Rotate 360 degrees. Smooth & Silent & Sturdy. Loading Capacity: 20-25kg each wheel and 80-90kg for four wheels 4″ Diameter PU Wheel. Polyurethane (PU) wheels offer the elasticity of rubber wheels combined with the toughness and durability of metal wheels. Safe for all floor types Wide range of uses: commonly used in both industrial and residential applications such as workbenches, tool carts, tool chest, shopping carts, cabinets, bookshelves, coffee table and other movable furniture, etc… Specifications: Wheel Size: 99.8cm Screw: 35.2cm x 10.8cm Usage: Home Commercial Package Includes: 2 x Fixed Food Cart Wheels Business […] #

0 notes

Text

Casters Wheel | Replacement Caster Wheels - PartsFe

Casters wheel is an essential component of commercial deep fryers, as they allow for easy movement of the fryer from one place to another. They are normally constructed from sturdy materials like rubber or plastic and are built to resist the weight and heat of the fryer. Caster wheels, however, may need to be replaced if they become worn out or damaged over time.

Find the perfect caster wheel for your fryer at PartsFe. We have a huge selection of wheels designed to fit various brands and models. Our caster wheels are made of durable materials, so you can trust them to last.

#Casters#casterwheel#partsfe#partsfebuzz#restaurantowner#restaurantequipmentparts#kitchenequipmentparts#foodserviceparts#ovenparts#icemachineparts#dishwasherparts#griddleparts

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Product Description WHEELS FOR HEAVY FURNITURE FOR EVERY HEAVY FURNITURE. WE GOT YO COVERED! HEAVY HEAVIER HEAVIEST Heavy Duty Construct These wheels are created with steel caster wheel housing, thick plate and double sealed ball bearings, high quality vibration-absorptive PVC rubber. It is safe to work under high load. Ample Feautures These wheels provides you smooth mobility and low noise during movement. It also absorbs shocks ad keeps low vibration transport . Wheels are flexible , tough & durable . It can be used in versatile operations. Package Content This 3 inch Heavy Duty Wheels comes in set of 4 which includes 4 Swivel plate caster wheels, 2 of them are brake rigid plate casters. . The heavy duty outdoor casters can rotate 360 degrees very Smoothly.Aloso it comes in black & orange color

Add to Cart Add to Cart Add to Cart Customer Reviews 4.1 out of 5 stars 485 4.1 out of 5 stars 485 4.2 out of 5 stars 176 3.6 out of 5 stars 18 Price ₹899.00₹899.00 ₹1,849.00₹1,849.00 ₹854.05₹854.05 — Brand ZAROONI ZAROONI ZAROONI ZAROONI Body Material Mild Steel Mild Steel Mild Steel Mild Steel Net Quantity 4 pcs 8 pcs 4 pcs 8 pcs Wheels Materials Polypropylene Polypropylene Polypropylene Polypropylene Wheel Size: diameter 32mm (1.25") 32mm (1.25") 50mm (2") 50mm (2") Wheels load Capacity 1600lbs 1600lbs 600lbs 450lbs Overall height (from top of plate) 60mm (2.5'') 60mm (2.5'') 75mm (3'') 75mm (3'') Contain Accessories ✓ ✓ ✓ ✓ BALL BEARINGS SINGLE SINGLE DOUBLE SINGLE

✅ [PREMIUM MATERIAL] With heavy duty steel caster wheel housing, thick plate and double sealed ball bearings, high quality vibration-absorptive PVC rubber, steadier and safer to work under high load-bearing conditions. Max Load Capacity 1100lb. ✅ [SAFETY TOTAL LOCK] This brake simultaneously locks the wheel and the swivel, holding the equipment firmly in place to reduce accidents. This combination wheel brake and swivel lock is essential for safety in some applications, such as on worktables, tablesaws, medical equipment, and used on uneven floors. ✅ [SMOOTH AND SILENT] Thanks to double precision ball bearings which contribute to smooth mobility and low noise during movement, these swivel casters can keep smooth and silent even under heavy load. PVC material also will absorb shocks to keep low-vibration transport. ✅ [RELIABLE & HEAVY DUTY CASTER SET OF 4] This caster set includes 4 Swivel plate caster wheels, 2 of them are brake rigid plate casters. . The heavy duty outdoor casters can rotate 360 degrees very Smoothly, Silent & Sturdy. ✅ [FLEXIBILITY AND SAFETY] Polyurethane (PU) industrial castors offers the elasticity of rubber wheels combined with the toughness and durability of metal casters.Caster wheel are safe for all floor types. The loading capacity of 1100Lbs - (275Lbs per Wheel). ✅ [MULTIPLE USEAGE] These wheels are ideal for a huge variety of uses DIY to industrial applications. Moving Caster wheels can be used in home, schools, garage, shops, trolleys and hospitals, Perfect caster wheels for furniture and other small space moving furniture including ottoman, coffee table, plant stands, bookshelves, shoe bins, toy bins, shopping carts, workbench, underbed storage. ✅ [RELISH SMOOTH & QUIET GLIDING] Swivel caster wheels have internal bearings that are quick rolling & the surface is sleek that wouldn't allow it to get stuck by hair, crumbs and grit. The pack comes with 2 caster wheels with brakes + 2 casters without brakes/swivel & 16 Screw & Washers for easy installation ✅ [EASY INSTALLATION CASTOR WHEELS SETS 4] You can easily install ZAROONI heavy duty casters set of 4 with brake. The outdoor caster wheels can be used in homes, schools, garages, shops, trolleys and hospitals. The castors heavy duty can be used to move ottoman, coffee table, plant stands etc. ✅ [NO NOISE CASTER WHEELS] : 3 inch casters, very quiet when walking, especially suitable for indoor use, does not hurt the ground, flexible movement, leaving no marks on the ground Show Less [ad_2]

0 notes

Text

Black trolley wheels caster rubber furniture casters

0 notes

Text

Maximizing Efficiency: How to Select the Perfect Platform Truck for Your Business

Maximizing Efficiency: How to Select the Perfect Platform Truck for Your Business In today’s fast-paced business environment, efficiency is key. One of the most effective ways to enhance productivity in material handling is by choosing the right platform truck. This guide will help you navigate the various options and select the perfect platform truck tailored to your business needs.

Understanding Platform Trucks Platform trucks, also known as platform trolleys, are versatile tools used for transporting heavy loads in various settings, including warehouses, retail stores, and manufacturing facilities. They come in different sizes, materials, and designs, each suited for specific tasks. >ForkLift | China Manufacturer Trade price on Materials Handling internal combustion Fork-lifts Truck Sale Buy Online Importer of Industrial Equipment in USA/UK/India/Australia/canada | forklift Key Factors to Consider Load Capacity The first and foremost factor to consider is the load capacity. Determine the maximum weight your platform truck needs to carry. Overloading can lead to accidents and damage to the truck. Platform Size The size of the platform should match the dimensions of the items you intend to transport. A larger platform can accommodate bigger items but may be harder to maneuver in tight spaces. Material Platform trucks are made from various materials, including steel, aluminum, and plastic. Steel trucks are durable and can handle heavy loads, while aluminum trucks are lightweight and resistant to corrosion. Plastic trucks are ideal for lighter loads and environments where hygiene is crucial. Wheels and Casters The type of wheels and casters is crucial for smooth movement. Consider the floor surface and choose wheels that provide stability and ease of movement. Pneumatic wheels are suitable for rough terrains, while rubber or polyurethane wheels are ideal for smooth surfaces. Handle Design Ergonomic handle designs can reduce strain on the operator and improve maneuverability. Some trucks come with foldable handles for easy storage. Additional Features Look for additional features such as brakes, foldable platforms, and side rails. These can enhance safety and functionality. Types of Platform Trucks Standard Platform Trucks These are the most common type, suitable for general-purpose use. They come in various sizes and load capacities. Folding Platform Trucks Ideal for businesses with limited storage space, these trucks can be folded when not in use. Heavy-Duty Platform Trucks Designed for transporting extremely heavy loads, these trucks are built with reinforced materials and larger wheels. Specialty Platform Trucks These include trucks designed for specific tasks, such as drum handling or furniture moving. Making the Right Choice To make an informed decision, assess your business’s specific needs. Consider the frequency of use, the types of items to be transported, and the working environment. Consulting with suppliers and reading reviews can also provide valuable insights.

Conclusion Choosing the right platform truck can significantly enhance your business’s efficiency and safety. By considering factors such as load capacity, platform size, material, wheels, handle design, and additional features, you can select a truck that meets your specific requirements. Invest in the right platform truck today and experience the benefits of streamlined material handling.

0 notes

Text

Caster Wheels Manufacturers: PRONIER CASTOR WHEELS

Caster wheels are an essential part of modern-day mobility solutions, used across various industries to enable smooth movement of equipment, furniture, and heavy machinery. As industries evolve, the demand for high-quality, durable, and versatile caster wheels grows. Manufacturers play a pivotal role in providing solutions that ensure stability, ease of movement, and reliability. One such company making significant strides in the caster wheel industry is Caster Wheels Manufacturers, renowned for its commitment to quality, innovation, and customer satisfaction.

Understanding Caster Wheels

Caster wheels are small wheels mounted to a swivel or fixed assembly, allowing movement in multiple directions. These wheels are used in a wide range of applications, from industrial carts and hospital beds to office chairs and shopping trolleys. The core function of caster wheels is to make it easier to move heavy or bulky objects without straining the user or causing damage to the floor.

There are two main types of caster wheels:

Swivel Casters: These allow free movement in any direction. The wheel is mounted on a rotating base, providing full 360-degree rotation.

Fixed Casters: These only move in a straight line and are typically used for stable, directional movement.

In addition to these, caster wheels vary in terms of materials, size, load capacity, and mounting options, making it crucial to select the right type based on the specific application.

The Role of Caster Wheel Manufacturers

Caster wheel manufacturers are responsible for designing, producing, and distributing caster wheels that meet a variety of performance criteria. The quality of a caster wheel can directly affect the safety, functionality, and lifespan of the equipment it is attached to. As such, manufacturers must adhere to strict standards, ensuring that their products are not only durable but also safe and easy to maintain.

Key factors that caster wheel manufacturers consider include:

Material Composition: Caster wheels are typically made from materials such as rubber, polyurethane, stainless steel, and nylon, with each material offering different properties. Rubber wheels, for example, provide shock absorption and noise reduction, while polyurethane wheels are more durable and resistant to wear.

Load Capacity: The load-bearing capacity of caster wheels varies widely. Depending on the application, some caster wheels are designed to carry light loads, while others are engineered for heavy-duty use, such as industrial machinery.

Durability and Maintenance: High-quality caster wheels are built to last and require minimal maintenance. Manufacturers focus on producing wheels with long-lasting materials and efficient designs to minimize wear and tear.

Design and Customization: Depending on the specific requirements, manufacturers also offer customization options. These might include specific wheel sizes, colors, or unique mounting options tailored to customer specifications.

PRONIER CASTOR WHEELS: A Leading Manufacturer

PRONIER CASTOR WHEELS is one of the most reputable brands in the caster wheel manufacturing industry. Known for its dedication to product innovation, customer-centric approach, and high standards of quality, PRONIER has established itself as a key player in the market. With a wide range of caster wheel solutions, PRONIER CASTOR WHEELS caters to industries ranging from logistics and transportation to healthcare and furniture manufacturing.

Product Range

PRONIER CASTOR WHEELS offers a broad spectrum of caster wheels designed to meet the needs of different industries. Some of the key products include:

Industrial Caster Wheels: These heavy-duty wheels are engineered for robust applications in factories, warehouses, and heavy machinery. Made from high-strength materials such as steel and polyurethane, they are designed to bear significant loads while offering smooth and controlled movement.

Furniture Caster Wheels: These caster wheels are designed for use in furniture such as office chairs, tables, and shelving units. They come in a variety of materials, from soft rubber for noise reduction to hard plastic or metal for durability and strength.

Medical Caster Wheels: PRONIER CASTOR WHEELS manufactures high-quality wheels for medical equipment like hospital beds, stretchers, and carts. These wheels are designed for ease of movement and often include features such as non-marking treads and quiet operation to enhance patient comfort and safety.

Swivel and Fixed Casters: As mentioned earlier, caster wheels come in two main types: swivel and fixed. PRONIER CASTOR WHEELS provides both options, with a focus on ensuring smooth, reliable movement regardless of whether the wheel needs to rotate freely or move in a straight line.

Innovation and Customization

PRONIER CASTOR WHEELS prides itself on its commitment to innovation. The company constantly invests in research and development to enhance the performance and durability of its caster wheels. This drive for innovation allows PRONIER to offer cutting-edge solutions that not only meet but often exceed the expectations of its clients.

One notable aspect of PRONIER’s approach is its focus on customization. Recognizing that different industries have unique requirements, the company offers tailor-made caster wheel solutions that cater to specific needs. Whether it's adjusting the load capacity, changing the material composition, or providing special mounting options, PRONIER CASTOR WHEELS is known for its flexibility and attention to detail.

Quality and Safety Standards

Quality is at the core of PRONIER CASTOR WHEELS' operations. All products undergo rigorous testing to ensure they meet global standards of durability, safety, and performance. The company's adherence to international quality standards ensures that their caster wheels provide long-lasting service without compromising on performance.

Furthermore, safety is a priority for PRONIER, especially when manufacturing wheels for industries like healthcare. With a focus on smooth movement, shock absorption, and easy maneuverability, the company's wheels contribute to safer, more efficient environments, whether in a hospital or industrial setting.

Customer Support and Service

PRONIER CASTOR WHEELS goes beyond just providing high-quality products by offering excellent customer service. The company’s knowledgeable team is always ready to assist clients in selecting the right caster wheels based on their specific requirements. Whether it’s offering guidance on the best product for a particular application or assisting with installation, PRONIER ensures a seamless experience for its customers.

Conclusion

Caster wheels play a crucial role in enhancing mobility and functionality across a wide range of industries, from healthcare to logistics and manufacturing. As one of the leading manufacturers in the industry, PRONIER CASTOR WHEELS continues to set the standard for high-quality, durable, and innovative caster wheel solutions. Through a combination of product variety, customization options, and a commitment to excellence, PRONIER CASTOR WHEELS remains a trusted name for companies seeking reliable and efficient mobility solutions.

By focusing on the unique needs of each industry and investing in continuous innovation, PRONIER CASTOR WHEELS ensures that its products remain at the forefront of the caster wheel manufacturing sector. For those seeking high-quality, customizable caster wheels, PRONIER CASTOR WHEELS offers unmatched performance and reliability.

Visit:- https://www.proniercastorwheel.in/caster-wheels.html

0 notes

Video

youtube

260x85 Hand truck Tires, Hand trolley PU foam wheels, Hand Truck Rubber ...

Provide polyurethane PU foaming equipment, processes, formulas and raw material services Web: www.modicasterwheels.com Email: [email protected] #Lawnmower #Tooltrolley #aerospacemanufacturing #equipment #Lawnmowertire #rollen #Lawnmowerflatfreetire #factories #productionengineering #flatfreetire #punctureprooftire #industrialsolutions #nhsengland #hospitalmanagement #castors #government #amazing #movingforward #aerospace #automation #gbmfg #innovationculture #innovation #quality #safety #automotiveindustry #engineering #supplychainsolutions #Trolley #manufacturingexcellence #automotive #manufacturinguk #industry #nhslongtermplan #ukmfg #wheels #engineeringuk #manufacturers #retweeet #protectthenhs #blickle #supportthenhs #nhs #supplychain #sourcing #industrial #b2b #industrialsupplies #casters #manufacturing #manufacturingindustry #materialhandling #Wheelbarrow #Dolly #Tools #garden #barrow #carts #caster #castor #cart #pu #Plastic #Solidtire #gardentools #tire #Tyre #weeder #Kart #gokart #shoppingcart #tractor #Handtruck #Handcart #toolcart #Toolbox #wheelchair #stroller #Constructiontools #manufacturer #manufacture #Factory #machine #production #plasticbox #wheelsandtires #casterwheels #wheelchairaccessories #solidtires #wheelchairwheels #wheelchairparts #mobilityscooteraccessories #solidtyres #solidtires #mobilityscooterparts

0 notes

Text

Custom Chair Caster Wheels Manufacturer & Supplier | LPHY

Caster wheels are critical components in various applications, from industrial machinery to office furniture. Selecting the right supplier can make all the difference in terms of quality, durability, and performance. In this blog, we explore the essential factors to consider when choosing a caster wheels supplier, the benefits of working with reputable companies, and how to identify the best suppliers in the market.

Why the Right Caster Wheel Supplier Matters

The quality of your caster wheels directly impacts the efficiency, safety, and longevity of your equipment. A reliable supplier ensures you receive high-quality products that meet your specific needs, whether for light-duty applications or heavy industrial use. Our blog delves into why choosing the right supplier is crucial and how it can save you time, money, and hassle in the long run.

Key Factors to Consider When Choosing a Caster Wheel Supplier

When evaluating potential suppliers, several factors should guide your decision:

Product Range: A good supplier should offer a wide variety of caster wheels, including different sizes, materials, and load capacities. This ensures you can find the perfect fit for your application.

Material Quality: The durability and performance of caster wheels depend heavily on the materials used. Look for suppliers that use high-grade materials like polyurethane, rubber, and steel, known for their strength and longevity.

Customization Options: In some cases, standard caster wheels may not meet your specific needs. Leading suppliers offer customization options, allowing you to tailor the wheels to your exact requirements.

Reputation and Reviews: A supplier’s reputation in the market can give you insights into the quality of their products and customer service. Our blog discusses how to research suppliers and read customer reviews to make an informed decision.

Customer Support and Service: A reliable supplier provides excellent customer support, offering guidance on product selection, installation, and maintenance. They should be readily available to answer questions and address any issues that arise.

Top Caster Wheel Suppliers in the Industry

In a competitive market, certain suppliers stand out for their commitment to quality, innovation, and customer satisfaction. Our blog features a list of top caster wheels supplier known for their extensive product offerings, superior material quality, and excellent service. We provide an overview of each supplier’s strengths and what makes them a preferred choice for various industries.

The Advantages of Partnering with a Trusted Supplier

Working with a reputable caster wheel supplier comes with numerous benefits:

Consistent Quality: Trusted suppliers ensure that all products meet high standards, providing consistent performance and durability across different applications.

Expert Guidance: Experienced suppliers can offer valuable advice on selecting the right caster wheels for your specific needs, helping you avoid costly mistakes.

Long-Term Support: Reliable suppliers offer ongoing support, including replacement parts and maintenance services, ensuring your equipment stays in top condition.

Case Studies: Success Stories with Top Suppliers

Our blog includes case studies and testimonials from businesses that have successfully partnered with leading caster wheels supplier. These real-world examples highlight how choosing the right supplier can enhance operational efficiency, reduce downtime, and improve overall satisfaction.

Conclusion

Choosing the right caster wheel supplier is essential for ensuring the quality and performance of your mobility solutions. By considering factors like product range, material quality, and customer support, you can find a supplier that meets your needs and supports your business for the long term. Explore our blog for a comprehensive guide to selecting the best caster wheels supplier and discover top-rated companies that excel in delivering quality and reliability.

1 note

·

View note