#parylene conformal coating services

Text

Parylene Conformal Coating Process & Services

Parylene conformal coating process is a critical step in ensuring the longevity and performance of electronic components. At Dawntechsb, we specialize in providing top-notch Parylene Coating Process services to protect your devices from environmental factors such as moisture, chemicals, and temperature fluctuations. Our team of experts is well-versed in the intricacies of the coating process, ensuring a flawless application every time. Trust Dawntechsb to safeguard your electronics with our superior Parylene coating services.

#coatings chemicals suppliers#parylene coating in malaysia#parylene af4 polymer#parylene coating process#conventional coating suppliers#nano ceramic coatings manufacturer

0 notes

Text

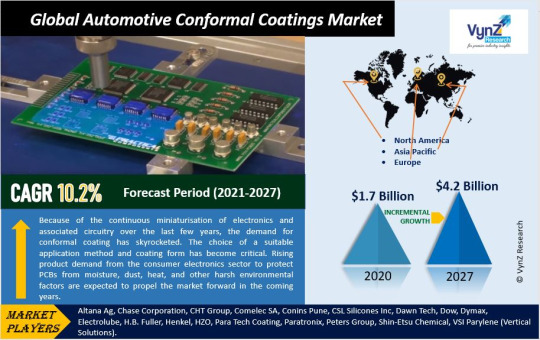

Global Automotive Conformal Coatings Market - Growth, Trends, COVID-19 Impact, and Forecasts (2021-2027)

The global automotive conformal coatings market is expected to reach USD 4.2 billion by 2027, from USD 1.7 billion in 2020. The market is growing at a CAGR of 10.2%, driven by the increasing adoption of electronics in vehicles and the development of new technology.

Market Overview

The global automotive conformal coatings market is segmented by material, component, vehicle type, application, and region.

By material: The market is segmented into acrylic, silicone, epoxy, polyurethane, and parylene. Acrylic is the most widely used material, followed by silicone.

By component: The market is segmented into ECU, PCB, sensor, battery casing, LED, and infotainment system. ECUs are the largest application segment, followed by PCBs and sensors.

By vehicle type: The market is segmented into passenger vehicles, light commercial vehicles, and heavy commercial vehicles. Passenger vehicles are the largest application segment, followed by light commercial vehicles and heavy commercial vehicles.

By application: The market is segmented into brush coating, dipping, spray coating, selective coating, and vapor deposition. Brush coating is the most widely used application method, followed by dipping and spray coating.

By region: The market is segmented into North America, Europe, Asia Pacific, Middle East & Africa, and South America. Asia Pacific is the largest market for automotive conformal coatings, followed by Europe and North America.

Get a free sample copy of the research report: https://www.vynzresearch.com/automotive-transportation/automotive-conformal-coatings-market/request-sample

Key Players

The key players in the global automotive conformal coatings market are:

• Altana Ag

• Chase Corporation

• CHT Group

• Comelec SA

• Conins Pune

• CSL Silicones Inc

• Dawn Tech

• Dow

• Dymax

• Electrolube

• H.B. Fuller

• Henkel

• HZO

• Para Tech Coating

• Paratronix

• Peters Group

• Shin-Etsu Chemical

• VSI Parylene (Vertical Solutions)

Trends and Opportunities

The global automotive conformal coatings market is expected to witness significant growth in the coming years. This growth will be driven by a number of factors, including:

The increasing adoption of electronics in vehicles

The development of new technology, such as self-driving cars and electric vehicles

The growing demand for conformal coatings in harsh environments

Challenges

The automotive conformal coatings market faces a number of challenges, including:

The high cost of conformal coatings

The complexity of the application process

The need for regular maintenance

Conclusion

The global automotive conformal coatings market is expected to grow significantly in the coming years. This growth will be driven by a number of factors, including the increasing adoption of electronics in vehicles, the development of new technology, and the growing demand for conformal coatings in harsh environments. The key players in the market are major suppliers of conformal coatings to OEMs and aftermarket distributors. The market faces a number of challenges, including the high cost of conformal coatings, the complexity of the application process, and the need for regular maintenance.

About Us:

VynZ Research is a global market research firm offering research, analytics, and consulting services on business strategies. We have a recognized trajectory record and our research database is used by many renowned companies and institutions in the world to strategize and revolutionize business opportunities.

Source: VynZ Research

0 notes

Text

Conformal Coatings Market Size and Analysis, Trends, Recent Developments, and Forecast Till 2030

Conformal coating is a chemical or polymer coating type that helps protect the circuit board from any adverse or abrasive environment. The coating also aids in keeping the circuit away from any chemical contaminants. The global conformal coatings market, according to the recently published report by the team of Market Research Future (MRFR), is expected to grow with an impressive growth rate during the forecast period between 2021 and 2030. Furthermore, the valuation is forecasted to go beyond the previously reported market valuation by the end of the forecast period.

Conformal Coatings Market is projected to be worth USD 17.02 Billion by 2030, registering a CAGR of 5% during the forecast period (2021 - 2030).

The conformal coatings market is driven by the demand from the electronics industry. The market is expected to grow due to the increasing demand for gadgets from an expanding population. Increasing adoption of AI and IoT and proliferation of adoption are also key factors pushing the market growth further. The market is also gaining considerable traction from the aviation industry, which is, in turn, supporting the growth of the market.

Market Segmentation

The Global Conformal Coatings Market has been segmented into type, end-use industry, and region.

On the Basis of the Type, the market is divided into acrylics, epoxy, urethane, silicone, parylene and others.

Based on End-Use Industry, the market is segmented into electronics, automobile, aerospace, marine and others.

Geographically, the market is divided into five regions including North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa.

Key Players

The Dow Chemical Industry (U.S.)

Specialty Coatings System Inc.

Global Manufacturing Services Inc (U.S.)

HemiSeal (U.S.)

Henkel AG & Co. kgaA (Germany)

Chemtronics (India)

H.B.Fuller Company (U.S.)

Electrolube (UK)

Europlasma NV (Belgium)

Shin-Etsu Chemical Co. Ltd (Japan).

Regional Analysis

North America was the dominant region in the Global Conformal Coatings Market due to its increasing use in the electronic devices mainly in automobile and aerospace industry. Additionally, increasing expenditure on consumer electronics mainly in home appliances, smart watches, and wireless devices.

Europe is expected to drive the market growth due to the introduction of high quality and technically advanced products. Increasing expenditure on research and development in electronics by Germany is likely to fuel the product demand in this region.

Asia Pacific region is growing substantially due to rapid urbanization and digitalization in the developing economies such as India and China. Moreover, implementation of various initiatives such as Smart City and Startup in India is encouraging the Indian companies to focus on product innovation and R&D.

Get Complete Report @ https://www.marketresearchfuture.com/reports/conformal-coatings-market-5786

Contact us:

Market Research Future (part of Wantstats Research and Media Private Limited),

99 Hudson Street, 5Th Floor,

New York, New York 10013

United States of America

+1 628 258 0071

Email: [email protected]

0 notes

Text

Chemical vapor deposition modification of Parylene

Since Parylene and its derivatives have many excellent properties, the research on them is very meaningful. Parylene reactive coatings prepared by the CVD method can be applied to various substrates, such as polymers, metals, composite materials, etc. These coatings are a general platform and do not depend on changes in the chemical composition of bulk materials.

In addition to being used as protective coatings, insulating coatings, interlayer dielectrics, electroluminescent polymers, and sensors, Parylene can also be used as biomaterials. Commercial Parylene coatings have been successfully used in stents, pacemakers, nerve Metaprobes, biological MEMS, and other devices, but these coatings are all non-functionalized and lack further modified active functional groups, so they cannot be effectively used as carriers of biomolecules.

Bioactive surface functionalization

The preparation of reactive polymer coatings is powerful biotechnology for complex surface engineering. Bioactive surface functionalization, which enables precise control of biomaterial surfaces and biomimetic design, is crucial in many biomedical applications such as drug delivery, biosensors, medical implants, and tissue engineering.

These functionalized biomolecules can be immobilized to substrate-independent active CVD polymer coatings to suit the needs of various biomedical applications. As a recognition site, the functionalized substrate surface can induce and alleviate a series of vital physiological functions in cells, such as adhesion, migration, and differentiation, and then regulate cell proliferation, survival, and other processes closely related to cell fate.

Cell-protein interactions play a central role in advanced applications in biology, medicine, and biotechnology, where the key lies in the precise control of signaling molecules on the surface of substrates, which can be used in implants, stents, cardiac In addition, it can be used as a bioanalytical tool for the detection of proteins, nucleic acids, and polysaccharides.

The CVD method is a simple and versatile method to prepare functionalized Parylene films, which can provide a range of different kinds of functional groups and adhere well to any substrate. These reactive coatings can improve the implant surface. Interface compatibility, or compatibility with complex biological properties, and stable existence under biological detection conditions. Amino or carboxyl groups can control surface charge and electroosmotic flow, and alkyl groups can provide a hydrophobic interface for electrochromatography.

All in all, functional Parylene is a unique class of aromatic polymers with unique advantages in synthesis, physical properties, and biomedical fields.

Maggie Nano Technology (Suzhou) Co., Ltd. provides customers with high-quality Parylene conformal coating services for supporting automated intelligent equipment. We are committed to manufacturing professional parylene conformal coating equipment. Parylene conformal coating equipment Model MQP-6001 is one of our products, you can click to view more details.

Equipment Model

Main Parameter

6001

Voltage

3 phases 380V 50Hz

Power

5KW

Overall Dimensions

2000*1500*1000mm

Cavity Size

ø550*700mm

If you are interested in our products, please get in touch with us as soon as possible.

Related news of parylene

The Role Of Parylene Vacuum Coating Machine-Maggie Nano

Application Of Parylene Nano Vacuum Coating In Magnetic Materials

Preparation Process Of Parylene Vacuum Nano Coating-Maggie Nano

0 notes

Link

Parlyene coatings are becoming highly popular in metallic industries, medical applications, aerospace, and electronics due to their high protective quotient. While conformal coatings are liquid, Parylene coatings don't pass through the liquid stage.

0 notes

Text

Conformal Coatings Market Report by Growth Enablers, Geography, Restraints and Trends –Forecast To 2026

Reports and Data recently published a report on the Conformal Coatings Market, which offers an in-depth overview of the factors that are impacting the state and progress of the worldwide business. The research report incorporates all the vital data that will help you updated with the latest market trends and get ahead in the competition in the various market segments and the leading geographies studied in the report. The study gives valuable insights into the future progress of the market and all essential aspects of the Conformal Coatings market for the forecast period from 2020 to 2026. The Conformal Coatings Market research report gives the latest market information, highlighting the product range and services offered in the market. The report provides key facts and figures relating to the market status, size, share, and growth aspects of the Conformal Coatings industry. The research comprises of elaborate profiles of the leading companies operating in the global sector by taking into account their gross revenue, total sales, market share, and competitive landscape.

The report includes the latest coverage of the impact of COVID-19 on the Conformal Coatings industry. The incidence has affected nearly every aspect of the business domain. This study evaluates the current scenario and predicts future outcomes of the pandemic on the global economy.

Read more at: https://www.reportsanddata.com/report-detail/conformal-coatings-market

Key Players included in this Report are:

Henkel (Germany), Illinois Tool Works (US), Shin-Etsu Chemical Co., Ltd (Japan), DOW Corning (US), H.B. Fuller (US), Chase Corporation (US), Europlasma NV (Belgium), MG Chemicals (Canada), Dymax Corporation (US) and Kisco Conformal Coatings LLC (US).

Market Trends:

Rising awareness of the latest technologies

Increasing number of product launches

Drivers:

Increasing demand for Conformal Coatings in emerging industries

Rapid Urbanization Worldwide

Opportunities:

Growing demand for Conformal Coatings in newer industries

Increasing Dependency on Conformal Coatings for diverse applications

The Conformal Coatings Market has been segmented for better coverage of the industry based on:

Type (Kilo Tons) (Revenue, USD Million; 2016-2026)

Acrylics

Epoxy

Urethane

Silicone

Parylene

Others

Coating Type (Kilo Tons) (Revenue, USD Million; 2016-2026)

Brush Coating

Dip Coating

Selective Coating by Machine

Spray Coating

Application (Kilo Tons) (Revenue, USD Million; 2016-2026)

Electronics

Automotive & Transportation

Aerospace & Defense

Industrial

Marine

Others

Regions mapped in the study: North America, Europe, Asia Pacific, Latin America, Middle East & Africa

Countries included: United States, Canada, Mexico, Brazil, Argentina, Colombia, Chile, South Africa, Nigeria, Tunisia, Morocco, Germany, United Kingdom (UK), the Netherlands, Spain, Italy, Belgium, Austria, Turkey, Russia, France, Poland, Israel, United Arab Emirates, Qatar, Saudi Arabia, China, Japan, Taiwan, South Korea, Singapore, India, Australia, and New Zealand.

Read full Press Release at: https://www.reportsanddata.com/press-release/global-conformal-coatings-market

Highlights of the Report:

Conformal Coatings Market Summary

Financial Standing of the Leading Companies in the Market

Conformal Coatings Market Competitive Assessment

Conformal Coatings Market Analysis by Product

Conformal Coatings Market Analysis by Application

Value Chain, Downstream Buyers, Raw Material Sourcing Strategy

Vendor Landscape, Strategic Initiative

Factors Influencing Market Growth

Market Forecast

Latest trends, product portfolio, consumer base, regional segmentation, and regulatory framework of the Conformal Coatings Market have also been included in the study.

You can also get a customized report for specific regional markets or countries as per your research requirements.

Table of Contents:

Chapter 1: Executive Summary

Chapter 2: Abbreviation and Acronyms

Chapter 3: Preface

3.1 Research Scope

3.2 Research Methodology

3.2.1 Primary Sources

3.2.2 Secondary Sources

3.2.3 Assumptions

Chapter 4: Market Landscape

4.1 Market Overview

4.2 Classification/Types

4.3 Application/End Users

Chapter 5: Market Trend Analysis

5.1 Introduction

5.2 Drivers

Continued…

Key queries addressed:

Who are the leading players in the sector, and what are the prevalent expansion strategies adopted by them to get ahead in the Conformal Coatings market?

What are the outcomes of SWOT analysis and Porter’s five forces analysis conducted on the Conformal Coatings market?

What are the growth prospects and threats encountered by players in the Conformal Coatings market?

What are the strengths and weaknesses of the key companies operating in the Conformal Coatings industry?

Data Collection & Research Methodology:

The primary sources of data collection employed for the research include surveys and interviews of industry experts from the Conformal Coatings Market, comprising of management organizations, processing organizations, and analytics service providers across the industry’s value chain. All primary sources were interviewed to collect and validate both qualitative and quantitative information, and to decipher the growth prospects existing in the industry. The analysts perform primary research by way of postal surveys, telephonic interviews, and online surveys, to obtain and authenticate both quantitative and qualitative information for the research study.

In case of secondary sources of data collection, the analysts rely on annual reports of leading companies, press releases, websites, investor presentation, conference calls, webinars, journals, regulatory policies, official documents, and other authoritative bodies to derive relevant information about the current scenario of the global market and the players engaged in the industry to give the readers a holistic view of the industry and accurate market forecast.

Report Customization:

Reports and Data also provides customization options to tailor the reports as per client requirements. This report can be personalized to cater to your research needs. Feel free to get in touch with our sales team, who will ensure that you get a report as per your needs.

Find more research reports on Paints and Coatings Industry, by Reports and Data:

Hybrid Non-Isocyanate Polyurethanes (HNIPU) Market - https://www.reportsanddata.com/report-detail/hybrid-non-isocyanate-polyurethanes-hnipu-market

Sustained Release Coatings Market - https://www.reportsanddata.com/report-detail/sustained-release-coatings-market

Contact Us:

John Watson

Head of Business Development

Direct Line: +1-212-710-1370

E-mail: [email protected]

0 notes

Text

Investigating Parylene and Nano-Ceramic Coatings to Promote Surface Protection Continues

Two prominent actors in the ever-changing field of advanced coatings are Parylene coating and nano-ceramic coatings. Innovation is king as sectors like electronics and medical equipment aim for better performance and longer product lifespans. These state-of-the-art technologies push the envelope of what's feasible by providing unmatched protection and improved functions. Let's explore this area and highlight the experience of a prominent industry pioneer while examining the benefits and uses of these cutting-edge technologies.

Parylene AF4: Exposing the Mysteries of an Amazing Polymer

Parylene AF4 Polymer, one of the leading innovators in protective coatings, is a very exceptional polymer. It is the material of choice for demanding applications because of its excellent qualities, which include high dielectric strength, great chemical resistance, and thermal stability. Because this material is conformal and pinhole-free, it guarantees perfect coverage even on the most complicated and elaborate patterns.

Applications of Parylene Coating:

● Electronics Industry: Moisture, corrosive chemicals, and inclement weather are persistent hazards to delicate components in the electronics industry, which include circuit boards, sensors, and connectors. As a trustworthy barrier, Parylene coating protects these parts and guarantees peak performance.

● Medical Marvels: In the medical industry, precision and dependability are critical, and Parylene coating provides both. Its stability and biocompatibility make it perfect for implanted devices, such as sensors and pacemakers, providing longer device life and patient safety.

● Automobile Advancements: To improve the performance and lifespan of important components, the automobile sector is progressively using Parylene coating. Its remarkable resilience to severe temperatures benefits sensors, electrical equipment, and other components, providing smooth functioning in challenging settings.

Revamping Surface Protection with Nano Ceramic Coatings:

A significant advancement in surface protection technology is represented by nano-ceramic coatings. These nanoparticle-based coatings provide improved hardness, scratch resistance, and hydrophobic qualities, among other advantages, by bonding with the substrate to produce a strong, transparent layer.

Flexibility in Utilisation

● Marine Industry: These coatings guarantee optimum performance and lifespan on the sea by shielding boats and marine equipment from the harsh realities of saltwater corrosion and severe UV exposure.

● Aerospace Industry: Nano ceramic coatings provide lightweight alternatives for aircraft parts and improve resistance to abrasion, friction, and high temperatures, resulting in safer and more effective air travel.

● Medical Device Manufacturing: Nano ceramic technology's biocompatible coatings provide medical implants and equipment with greater longevity and a lower risk of infection, improving patient outcomes.

The Knowledge Underpinning the Invention

Leading Parylene Coatings Manufacturer and nano-ceramic manufacturers are committed to pushing technological limits and are the force behind these cutting-edge coating solutions. This business, which is dedicated to quality and innovation, serves a variety of sectors via the development and application of these coatings.

Entire Services Provided:

● Custom Coating Solutions: The business specialises in offering coating solutions that are specifically designed to satisfy each client's particular needs. Their experience guarantees the best outcomes, whether it's a unique application or a particular industry standard.

● Modern Application Methodologies: The firm uses state-of-the-art equipment to apply coatings consistently and precisely. Their sophisticated application methods maximise the efficiency of the coatings by ensuring consistent coverage.

● Quality Control: Strict quality control procedures are used to guarantee that each coated product satisfies the highest requirements. Customers are reassured about the dependability of the coatings by this dedication to quality, which starts with the selection of the raw materials and finishes with the final application.

In conclusion, the incredible potential of nano-ceramic coatings and Parylene coatings defines the realm of advanced coatings. A continually changing industry will always need dependable and creative solutions. The firm responsible for these solutions is committed to quality and is always pushing the envelope in the field of protective coatings.

Source URL:

#Parylene AF4 Polymer#Parylene Coating Manufacturer#Parylene Coating in Malaysia#Coatings Chemicals Suppliers

0 notes

Text

Conformal Coatings Market Share 2022 Top Manufacturers, Segmentation, Future Plans, Competitive Landscape and Forecast to 2030

Conformal coating is a chemical or polymer coating type that helps protect the circuit board from any adverse or abrasive environment. The coating also aids in keeping the circuit away from any chemical contaminants. The global conformal coatings market share, according to the recently published report by the team of Market Research Future (MRFR), is expected to grow with an impressive growth rate during the forecast period between 2016 and 2023. Furthermore, the valuation is forecasted to go beyond the previously reported market valuation by the end of the forecast period.

The conformal coatings market share is driven by the demand from the electronics industry. The market is expected to grow due to the increasing demand for gadgets from an expanding population. Increasing adoption of AI and IoT and proliferation of adoption are also key factors pushing the market growth further. The market is also gaining considerable traction from the aviation industry, which is, in turn, supporting the growth of the market.

Market Segmentation

The Global Conformal coatings market share has been segmented into type, end-use industry, and region.

On the Basis of the Type, the market is divided into acrylics, epoxy, urethane, silicone, parylene and others.

Based on End-Use Industry, the market is segmented into electronics, automobile, aerospace, marine and others.

Geographically, the market is divided into five regions including North America, Europe, Asia Pacific, Latin America, and the Middle East Africa.

Key Players

The Dow Chemical Industry (U.S.)

Specialty Coatings System Inc.

Global Manufacturing Services Inc (U.S.)

HemiSeal (U.S.)

Henkel AG Co. kgaA (Germany)

Chemtronics (India)

B.Fuller Company (U.S.)

Electrolube (UK)

Europlasma NV (Belgium)

Shin-Etsu Chemical Co. Ltd (Japan).

Regional Analysis

North America was the dominant region in the Global Conformal coatings market share due to its increasing use in the electronic devices mainly in automobile and aerospace industry. Additionally, increasing expenditure on consumer electronics mainly in home appliances, smart watches, and wireless devices.

Europe is expected to drive the market growth due to the introduction of high quality and technically advanced products. Increasing expenditure on research and development in electronics by Germany is likely to fuel the product demand in this region.

Asia Pacific region is growing substantially due to rapid urbanization and digitalization in the developing economies such as India and China. Moreover, implementation of various initiatives such as Smart City and Startup in India is encouraging the Indian companies to focus on product innovation and RD.

Get Complete Report @ https://www.marketresearchfuture.com/reports/conformal-coatings-market-5786

Contact us:

Market Research Future (part of Wantstats Research and Media Private Limited),

99 Hudson Street, 5Th Floor,

New York, New York 10013

United States of America

+1 628 258 0071

Email: [email protected]

0 notes

Text

Examples of protective applications of parylene coatings

Compared with ordinary life clothing, the nature and characteristics of professional clothing are not universal in a certain industry. Every enterprise must have its professional clothing, and professional clothing is also required to be relatively durable. In large companies, the service life of general work clothes is very long, which can establish a corporate image for the enterprise for a long time, achieve repeated understanding, and deepen the degree of recognition. Economically, it is not practical to change clothes frequently, which requires work clothes' durability.

One of the parylene properties is protection. Parylene coating has a certain wear resistance on the surface of the fabric, so it is suitable for coating the part of work clothes, increasing the service life of the clothing, and reducing some economic costs for the company. burden. Parylene-coated clothing has a certain waterproof function. The service staff of the hotel must not only maintain the image of the company but also keep it clean at work. When serving guests, the clothes are often stained, so the clothing parts such as aprons are required to be waterproof. Features, improve its anti-fouling properties.

1 restaurant waiter's clothing

The starting point of the design is the farmer's characteristic restaurant clothing, which adopts the design of printed cloth and buckles to highlight the friendly and natural image of the farmer girl, which is in line with the professional image of the waiter's enthusiasm and generosity. The overall style of the clothing adopts a split collocation, which alternately combines blueprinting and white printing so that the professional wear remains elegant and solemn without losing dullness and rigidity.

The work status of the waiter is matched with the design of the apron. The apron is combined with the parylene coating, and the parylene coating process is used to make it waterproof, dirt-resistant, and wear-resistant so that the service personnel can serve enthusiastically. At the same time, it can maintain a clean and tidy professional image. Don't worry about getting your clothes dirty when you clean the dishes, so you can provide the best service for your guests.

Parylene coating can be applied to the fabric partially or completely, depending on the needs of the specific occupation. Here is an example to illustrate the specific application of parylene coating on tooling, especially the one-piece suit as an example.

2 Professional tooling

The design style is a one-piece suit, the fabric is made of pure cotton fabric, which is composed of red and gray. The neckline and cuffs of the overalls should be designed to be tight to prevent exposure to various parts of the body during activities. At the same time, the overalls are also required to have better air permeability, which is convenient for the operator to move freely. The overalls are specially designed for specific work needs. Clothing, this kind of clothing generally requires a lot of bending and squatting movements, such as lathe repairers, due to the need for waist movement, the design of the back waist should be folded, which is convenient for bending during work.

The specific application of Parylene coating can be determined according to occupational needs. Take mechanic clothing as an example. Generally, the working time under the car is longer, and there are many movements of squatting and digging. Therefore, Parylene is coated on the knees and elbows. To increase the service life of the clothing, the thickness of the coating can be adjusted according to the needs without affecting the texture of the coated clothing.

Clothing fabric is an indispensable part of clothing design. Only through the material carrier of clothing fabric can clothing design convey design ideas and be accepted and appreciated by people. The continuous innovation and breakthrough of clothing fabrics create conditions for the diversification and individualization of clothing design.

Maggie Nano Technology (Suzhou) Co., Ltd. provides customers with high-quality Parylene coating services for supporting automated intelligent equipment. We are committed to manufacturing professional parylene conformal coating equipment. Parylene conformal coating equipment Model MQP-8001 is one of our products, you can click to view more details.

Equipment Model

Main Parameter

8001

Voltage

3 phases 380V 50Hz

Power

10KW

Overall Dimensions

3000*1800*1500mm

Cavity Size

Ø750*900mm

If you are interested in our products, please get in touch with us as soon as possible.

Related news of parylene coating

Operating Procedures for Parylene Coating Equipment for sale

Applicability of properties of parylene coated apparel fabrics

0 notes

Text

Electronics Conformal Coating Market Value Of $2.41 Billion Forecast Till 2020

According to the new market research report "Electronics Conformal Coating Market by Material (Acrylic, Silicone, Parylene, Urethane/Polyurethane, Epoxy), Equipment (Curing, Coating), Method (Brush Coating, Dipping), Application and Geography - Global Forecasts to 2020", the Electronics Conformal Coating Market is estimated to reach USD 2.41 Billion by 2020, at a CAGR of 5.99% between 2015 and 2020. The increasing use of electronic components especially in automotive, and consumer electronics sector, and growing demand for highly reliable electronic devices/equipment are the major drivers for the above said market.

Acrylic conformal coating material segment expected to lead the electronics conformal coating material market

The acrylic conformal coating is expected to lead the global conformal coating material market during the forecast period. This is owing to the fact that among all the materials it is the easiest to re-work on the acrylic material. Besides this, acrylic material is also easy to apply, has low cost, takes less time to cure, and provides good resistance from chemical, moisture, and abrasion.

Get Free 10% Customization @ https://www.marketsandmarkets.com/requestCustomizationNew.asp?id=4692419

Automotive electronics sector expected to hold the largest share in the electronics conformal coating material market

The automotive electronics application segment is expected to hold the largest share in the global conformal coating material market during the forecast period. Automotive manufacturers are working hard towards offering products of higher quality and reliability at a competitive price. The electronics in the automobile are usually placed in the areas where they are subjected to harsh working conditions, chemical, moisture, dust, and vibration. These factors necessitate the use of conformal coating on automotive electronics so that a protective layer can be added on electronic components to protect them.

from harsh environment, and thus increasing the reliability of the product.

APAC expected to hold the largest market share and witness rapid growth during forecast period

The APAC region held the largest share of the conformal coating material market in 2014, and it is expected to grow at the highest growth rate during the forecast period. The rapid growth of the automotive industry in this region, in addition to the growth of consumer electronics, and aerospace & defense sectors has contributed to the growth of the conformal coating material in the APAC region.

Major players in this market include Chase Corporation (U.S.), MG Chemicals Ltd. (Canada), DOW Corning Corporation (U.S.), Chemtronics (U.S.), Dymax Corporation (U.S.), Electrolube (U.K.), Nordson Corporation (U.S.), Precision Valve & Automation, Inc. (U.S.), Shin-Etsu Chemical Co. Ltd. (Japan), Henkel AG & Co. KGaA (Germany), and Peters Group (Germany).

This research report categorizes the global electronics conformal coating market based on materials, equipment, methods, applications, and regions. This report describes the drivers, restraints, opportunities, and challenges for the growth of the conformal coating market. The Porter’s Five Forces analysis has been included in the report with a description of each of its force and their respective impact on the conformal coating market.

About MarketsandMarkets

MarketsandMarkets provides quantified B2B research on 30,000 high growth niche opportunities/threats which will impact 70% to 80% of worldwide companies’ revenues. Currently servicing 5000 customers worldwide including 80% of global Fortune 1000 companies as clients. Almost 75,000 top officers across eight industries worldwide approach MarketsandMarkets™ for their painpoints around revenues decisions.

Contact:

Mr. Shelly Singh

MarketsandMarkets™ INC.

630 Dundee Road

Suite 430

Northbrook, IL 60062

USA : 1-888-600-6441

Email: [email protected]

0 notes

Link

The global conformal coatings market size is expected to reach USD 17.3 billion by 2026, growing at a CAGR of 5.8% during the forecast period according to a new study published by Polaris Market Research. The Report ‘Conformal Coatings Market Share, Size, Trends, Industry Analysis Report, By Material Type (Acrylic, Epoxy, Urethane, Silicon, Parylene, and Others); By End-use (Consumer Electronics, Automotive, Aerospace & Defense, Industrial, Marine, Medical, and Others), By Regions, Segments & Forecast, 2019 – 2026” provides a thorough and detailed analysis about the market with an overview of present trends and future insights.

Conformal coatings are a protective cover that could be a polymer or a chemical film which is applied on electronic circuits to give them long-lasting protection from moisture content and chemical contaminants in the air. These products maintain insulation cover, ensure continuity of circuit board components and oversee functional integrity of the circuit board.

Request for sample copy of this report @ https://www.polarismarketresearch.com/industry-analysis/conformal-coatings-market/request-for-sample

Huge market for consumer electronics, rapid strides in medical equipment and emergence of driverless cars are some of the important factors driving conformal coatings industry. Furthermore, rise in disposable incomes and dependence on sleek electronic devices such as mobile phones, laptops and other gadgets have fueled the growth of particular products that are mandatorily used in electronic components.

Automotive is one of the most far-reaching segments for these products. The development of hybrid cars is consistently empowered by technology and witnesses comfortably high growth rate being touted as an energy-efficient alternative. Electric cars and hybrid vehicles could give a more comfortable ride, optimum fuel efficiency and use more electronic gadgets, giving rise to sophistication that are the foundation of EV’s.

Initially, these products were the mainstays in medical and military products but with high cost per unit. But, with innovations and with rise of material science, prices have reduced considerably over the last few years. Recent technological nuances in the market include low viscosity solvent free conformal coating, parylene-like hydrophobic conformal coating, and single component conformal coating material to protect sensitive information on PCB’s.

These products are unique based on their material of formulation. These coatings are used, bringing to the fore their characteristics and required efficiency. Acrylic conformal coating is the largest product segment by material. Polyurethane, epoxy and parylene are amongst the fast-growing segments.

Most of the product manufacturers, device fabricators and Printed circuit board (PCB) assemblers favor conformal coatings for economic and environmental reasons though solvent based ones prop up performance. A move towards green chemicals has certain resins moving at a faster rate as compared to traditional ones such as acrylics.

The key players operating in the conformal coatings market includes Electrolube, Kisco Conformal Coatings, H.B. Fuller, Chase Corporation, Henkel AG & KGaA, Illinois Tool Works and Dow Corning.

Request for Discount on This Report @ https://www.polarismarketresearch.com/industry-analysis/conformal-coatings-market/request-for-discount-pricing

About Polaris Market Research

Polaris Market Research is a global market research and consulting company. The company specializes in providing exceptional market intelligence and in-depth business research services for our clientele spread across different enterprises. We at Polaris are obliged to serve our diverse customer base present across the industries of healthcare, technology, semi-conductors and chemicals among various other industries present around the world

Contact us

Polaris Market Research

Phone: 1-646-568-9980

Email: [email protected]

Web: www.polarismarketresearch.com

0 notes

Text

Conformal Coatings Market Key Players & Their Different Growth Strategies 2026

The global conformal coatings market size is expected to reach USD 17.3 billion by 2026, growing at a CAGR of 5.8% during the forecast period according to a new study published by Polaris Market Research. The Report ‘Conformal Coatings Market Share, Size, Trends, Industry Analysis Report, By Material Type (Acrylic, Epoxy, Urethane, Silicon, Parylene, and Others); By End-use (Consumer Electronics, Automotive, Aerospace & Defense, Industrial, Marine, Medical, and Others), By Regions, Segments & Forecast, 2019 – 2026” provides a thorough and detailed analysis about the market with an overview of present trends and future insights.

Conformal coatings are a protective cover that could be a polymer or a chemical film which is applied on electronic circuits to give them long-lasting protection from moisture content and chemical contaminants in the air. These products maintain insulation cover, ensure continuity of circuit board components and oversee functional integrity of the circuit board.

Huge market for consumer electronics, rapid strides in medical equipment and emergence of driverless cars are some of the important factors driving conformal coatings industry. Furthermore, rise in disposable incomes and dependence on sleek electronic devices such as mobile phones, laptops and other gadgets have fueled the growth of particular products that are mandatorily used in electronic components.

Automotive is one of the most far-reaching segments for these products. The development of hybrid cars is consistently empowered by technology and witnesses comfortably high growth rate being touted as an energy-efficient alternative. Electric cars and hybrid vehicles could give a more comfortable ride, optimum fuel efficiency and use more electronic gadgets, giving rise to sophistication that are the foundation of EV’s.

Request for a sample copy of this research report @ https://www.polarismarketresearch.com/industry-analysis/conformal-coatings-market/request-for-sample

Initially, these products were the mainstays in medical and military products but with high cost per unit. But, with innovations and with rise of material science, prices have reduced considerably over the last few years. Recent technological nuances in the market include low viscosity solvent free conformal coating, parylene-like hydrophobic conformal coating, and single component conformal coating material to protect sensitive information on PCB’s.

These products are unique based on their material of formulation. These coatings are used, bringing to the fore their characteristics and required efficiency. Acrylic conformal coating is the largest product segment by material. Polyurethane, epoxy and parylene are amongst the fast-growing segments.

Most of the product manufacturers, device fabricators and Printed circuit board (PCB) assemblers favor conformal coatings for economic and environmental reasons though solvent based ones prop up performance. A move towards green chemicals has certain resins moving at a faster rate as compared to traditional ones such as acrylics.

The key players operating in the conformal coatings market includes Electrolube, Kisco Conformal Coatings, H.B. Fuller, Chase Corporation, Henkel AG & KGaA, Illinois Tool Works and Dow Corning.

Complete Summary with TOC Available @ https://www.polarismarketresearch.com/industry-analysis/conformal-coatings-market

Polaris Market Research has segmented the conformal coatings market report based on material type, end-use and region.

Conformal Coatings Material Type Outlook (Revenue USD Million, 2015-2026)

Acrylic

Epoxy

Urethane

Silicon

Parylene

Others

Conformal Coatings End-Use Outlook (Revenue USD Million, 2015-2026)

Consumer Electronics

Automotive

Aerospace & Defense

Industrial

Marine

Medical

Others

Conformal Coatings Regional Outlook (Revenue USD Million, 2015-2026)

US

Canada

France

Germany

UK

India

Japan

China

Mexico

Brazil

Purchase This Report @: https://www.polarismarketresearch.com/checkouts/3951

About Polaris Market Research

Polaris Market Research is a global market research and consulting company. The company specializes in providing exceptional market intelligence and in-depth business research services for our clientele spread across different enterprises.

Contact Us:

Polaris Market Research

Phone: 1–646–568–9980

Email: [email protected]

Web: www.polarismarketresearch.com

0 notes

Text

Conformal Coating Market by Type (Acrylic, Silicone, Epoxy, Urethane, and Parylene), End-Use (Consumer Electronics, Automotive, Aerospace & Defense, Industrial and Telecommunication), and Region - Global Forecast to 2025 published on

https://www.sandlerresearch.org/conformal-coating-market-by-type-acrylic-silicone-epoxy-urethane-and-parylene-end-use-consumer-electronics-automotive-aerospace-defense-industrial-and-telecommunication-and-region-glo.html

Conformal Coating Market by Type (Acrylic, Silicone, Epoxy, Urethane, and Parylene), End-Use (Consumer Electronics, Automotive, Aerospace & Defense, Industrial and Telecommunication), and Region - Global Forecast to 2025

“The global conformal coatings market is projected to witness a CAGR of 5.3% during the forecast period.”

The Conformal coatings market is estimated to be USD 977 million in 2020 and is expected to reach USD 1,265 million by 2025 at CAGR of 5.3%. The high growth is attributed to the increase in the number of PCB manufacturers in countries such as China and Taiwan, and other factor is the growing demand from the high-end applications which require conformal coatings. These coatings are used in various industries such as consumer electronics, automotive, aerospace & defense, industrial, and telecommunication.

“Telecommunication is the fastest-growing end-use in the conformal coatings market.”

The introduction of 5G has brought the need for the development of communication infrastructure. The commercial use of 5G worldwide is expected to bring endless opportunities for upstream and downstream industries. PCB majorly has four areas of application during the construction of a communication network, namely wireless network, transmission network, data communication, and fixed-line broadband. Similarly, for the construction of 5G infrastructure, various types of PCBs are required such as PCB backplanes, high-frequency PCB and high-speed multilayer PCBs. In addition to this, the establishment of large 5G macro base stations will also boost the demand for PCB as it is an indispensable electronic material used in the construction of the base station.

“Acrylic conformal coating is the largest type for conformal coating.”

Acrylic conformal coatings are transparent insulating and quick-drying acrylic-based coatings. These are easy to apply and do not require special equipment for application. Acrylic coatings account for alarge share of the conformal coatings market, with wide applications in electronics. These coatings protect electric circuits from moisture, dirt, dust, thermal shocks, and scratches that could corrode, short circuit, or otherwise damage the electronic component. They also provide insulation against high-voltage and static discharges. Acrylic-based conformal coatings are fast cure, free from solvents, and easily reparable. It is considered an essential level protection because they are economical and provide protection against a broad level of contamination.

“APAC is expected to be the fastest-growing market for conformal coating during the forecast period.”

APAC is expected to be the fastest-growing market during the forecast period. Due to the presence of huge volume of PCB manufacturers in the region, the demand for conformal coating is expected to grow. Apart from that India is projected to have a rapidly growing consumer electronics market in the coming years due to the rising middle class and increasing disposable income. Thus these scenario is expected to drive the market in the region.

The breakup of primary interviews is given below.

By Company Type – Tier 1 – 55%, Tier 2 – 30%, and Tier 3 – 15%

By Designation – C level – 45%, Director level – 35%, and Others – 20%

By Region – APAC – 40%, Europe – 30%, North America – 25%, and Rest of World – 5%

The leading players in the market are Henkel (Germany), Illinois Tool Work (US), Shin-Etsu Chemicals (Japan), Dow (US), H.B. Fuller (US), Chase Corporation (US), Electrolube (UK), Dymax Corporation (US), MG Chemicals (Canada) and Specialty Coatings System (US).

Research Coverage:

This research report categorizes the global conformal coating market on the basis of type, end-use, and region. The report includes detailed information regarding the major factors influencing the growth of the market, such as drivers, restraints, challenges, and opportunities. The detailed analysis of key market players provides insights into business overviews, products & services, key strategies, investments & expansions, mergers & acquisitions, and recent developments in the market.

Reasons to Buy the Report:

This report segments the global conformal coatings market comprehensively and provides the closest approximations of sizes for the overall market and sub segments across various verticals and regions.

The report will help stakeholders understand the pulse of the market and provide them with information on the key market drivers, restraints, challenges, and opportunities.

This report will help stakeholders understand the major competitors and gain insights to enhance their positions in the business. The competitive landscape section includes expansions, new product developments, and mergers & acquisitions undertaken in the market.

0 notes

Text

Parylene Market Share by 2025: QY Research

This recently published report examines the global Parylene market for the projected period of 7-years, i.e. between 2018 and 2025. The report highlights the accomplishments and opportunities lies in the market throughout the forecasted period. The report offers the thorough information about the overview and the scope of the global Parylene market along with its drivers, restraints, and trends. It also classifies the market into different segments such as by type, by applications and by-product. In short, this report comprises of all the necessary details of the global Parylene markets such as value/volume data, marketing strategies, and expaeasrt views. The comprehensive information about distribution channels such as suppliers, dealers, wholesalers, manufacturers, distributors, and consumers have also given in this report.

The report represents the statistical data in the form of tables, charts, and info-graphics to assess the market, its growth and development, and market trends of the global Parylene market during the projected period. QY Research has used a framework of primary and secondary research to make this report a full-proof one.

Get a complete sample PDF of the global Parylene market report at http://www.qyresearchglobal.com/goods-1848847.html

Global Parylene market research report can be used by the following group of people:

Distributors, dealers, suppliers, and manufacturers

Journalists, school students, writers, universities, authors, and professors

Major service providers, huge corporates and industries

Existing and current market players, private firms, event managers and annual product launchers

Breakdown analysis of Global Parylene market research report:

Major competitors that head the global Parylene market includes

Key Players:

Kisco

VSI Parylene

Paratronix

Para Tech

Plasma Ruggedized Solutions

Curtiss-Wright

Anhui Sule Medical Material

Suzhou Jiangnan Fine Chemical

Dongguan Huaxing Nanotechnologies

Diamond MT

Chireach Group

TiXX Conformal Coatings

Shanghai Parylene Biotechnology

La Chi Enterprise

Suzhou Kary Nano Tech

Shanghai PAL Chetech

Stratamet Thin Film

Product types:

Parylene N

Parylene C

Parylene D

End-user/applications:

Military and Aerospace

Electronics

Medical

Automotive

Renewable Energy Coating

LED Coating

QY Research offers a crystal clear view of the various sections such as segmental analysis, regional analysts, product portfolios, followed by detailed information about key players and their strategies about mergers and acquisitions.

In terms of region, this research report covers almost all the major regions across the globe such as North America, Europe, South America, the Middle East, and Africa and the Asia Pacific. Europe and North America regions are anticipated to show an upward growth in the years to come. While Parylene market in Asia Pacific regions is likely to show remarkable growth during the forecasted period. Cutting edge technology and innovations are the most important traits of the North America region and that’s the reason most of the time the US dominates the global markets. Parylene market in South, America region is also expected to grow in near future.

Following are the objectives of the report on global Parylene market:

Major benefit and advanced factors that influence the global Parylene market

Future and present market trends that influence the growth rate and growth opportunities of the global Parylene market

The market share of the global Parylene market, supply chain analysis, business overview, grow revenue, and demand and supply ratio

New-market insights, investment return, export/import details, company profiles and feasibility study analysis of the global Parylene market

The maturity of trade and proliferation in global Parylene market

Finally, the global Parylene Market is a valuable source of guidance for individuals and companies. One of the major reasons behind providing market attractiveness index is to help the target audience and clients to identify the several market opportunities in the global Parylene market. Moreover, for the better understanding of the market, QY Research has also presented a key to get information about various segments of the global Parylene market.

Contact US

QY Research, INC.

Tina

17890 Castleton, Suite 218,

City of industry, CA – 91748

USA: +1 626 295 2442

Email: [email protected]

Web: www.qyresearchglobal.com

0 notes

Text

Conformal Coatings Market Growth, Size, Analysis, Outlook by 2018 - Trends, Opportunities and Forecast to 2026

The global Conformal Coatings Market generated revenues of worth USD 10.5 billion in 2017 and is anticipated to grow at a CAGR of 5.4% during the forecast period.

These products are a segment of coatings that are considered protective, chemically formulated, non-conductive and dielectric layers. These are applied primarily onto printed circuit boards (PCB) assembly. These coatings are used to prevent the damage to the electronic assembly due to moisture, salt spray, contamination, corrosion, and few other factors caused by harsh environment.

Get Sample Copy of this Report @ https://www.polarismarketresearch.com/industry-analysis/conformal-coatings-market/request-for-free-sample

Rising demand for consumer electronics, advancements in medical equipment, and emerging smart vehicle technologies are some of the prominent factors that broadly make use of conformal coatings and are driving its market. Increase rate of in consumer disposable income and the demand for modern electronic devices such as mobile phones, laptops, and other gadgets have tremendously driven the growth of demand for these products in electronic items.

Automotive, aerospace, and defense industries have also significantly contributed to the growth of the conformal coatings market. Several factors that have led to increased manufacturing of aircrafts manufacturing include recovery in GDP, stable commodity prices such as that of crude oil, and growth in passenger travel demand especially in Asia Pacific, Latin America, and the Middle East.

Different types of resin materials are used in the formulation of conformal coatings. Silicone based conformal coatings have witnessed recent developments in this industry. These products have lower environmental impact and superior reliability. However, silicone based conformal coatings have relatively higher purchase price and with material advancements in the industry, these are anticipated to have reduction in total cost of ownership lower or to be equal to the common conformal coatings.

Some other technological advancement for the market includes low viscosity solvent-free conformal coating, parylene-like hydrophobic conformal coating, and single component conformal coating material to protect sensitive information on PCBs.

Most of the manufacturers of these products, device fabricators, and PCB assemblers prefer solvent-free conformal coatings for environmental and economic reasons, though, solvent based ones enhance performance. On account of more demand for “green chemicals”, certain resins are growing at a faster pace as compared to the traditional ones such as acrylics.

Browse full research report with TOC on “Conformal Coatings Market by Application and End User – Global Industry Analysis and Forecast to 2026” at: https://www.polarismarketresearch.com/industry-analysis/conformal-coatings-market/

Competitive Landscape and Key Vendors

Asia Pacific is the dominant regional market. China, Japan, and South Korea are among the major contributing nations towards the growth of this regional market. In addition to this, the region has also witnessed strong demand in the consumer electronics products and semiconductor devices.

Global industry market constitutes of large number of multinational and domestic companies and is moderately competitive. Some of the major industry players for conformal coatings include Electrolube, Kisco Conformal Coatings, H.B. Fuller, Chase Corporation, Henkel AG & KGaA, Illinois Tool Works, and Dow Corning.

Enquiry Before Buying @ https://www.polarismarketresearch.com/industry-analysis/conformal-coatings-market/inquire-before-buying

Key Segments

Process Type

· Acrylic

· Epoxy

· Urethane

· Silicon

· Parylene

· Others

End-Use Segments

· Consumer Electronics

· Automotive

· Aerospace & Defence

· Industrial

· Marine

· Medical

· Others

Region

· North America

o U.S.

o Canada

· Europe

o Germany

o UK

o France

o Rest of Europe

· Asia-Pacific

o China

o India

o Japan

o Rest of Asia-Pacific

· Latin America

o Brazil

o Mexico

o Rest of Latin America

· Middle East and Africa

About us Polaris Market Research

Polaris Market Research is a global market research and consulting company. We provide unmatched quality of offerings to our clients present globally. The company specializes in providing exceptional market intelligence and in-depth business research services for our clientele spread across different enterprises. We at Polaris are obliged to serve our diverse customer base present across the industries of healthcare, technology, semi-conductors and chemicals among various other industries present around the world. We strive to provide our customers with updated information on innovative technologies, high growth markets, emerging business environments and latest business-centric applications, thereby helping them always to make informed decisions and leverage new opportunities.

We mainly focus on aiding our customers with substantial competitive intelligence, helping them to secure a competitive advantage in the market and accomplish sustainable growth in different market domains. Adept with a highly competent, experienced and extremely qualified team of experts comprising SMEs, analysts and consultants, we at Polaris endeavor to deliver value-added business solutions to our customers. Through dedicated qualitative and quantitative primary and secondary market research and consulting assignments, we adeptly formulate competitive strategies to address business challenges for our clients through analyzing market trends and emerging technologies.

Contact us-

Mr. Neel

Corporate Sales, USA

Polaris Market Research

Phone: 1-646-568-9980

Email: [email protected]

Web: www.polarismarketresearch.com

Follow us- LinkedIn | Twitter | Facebook

#Conformal Coatings Market#Conformal Coatings Market Size#Conformal Coatings Market Share#Conformal Coatings Market Growth#Conformal Coatings Market Trends#Conformal Coatings Market Forecast

0 notes