#machine deburring tools

Text

High-Efficiency Deburring Machine for Mass Production: Boosting Productivity and Precision

In the world of manufacturing, efficiency and precision are paramount. As industries strive to meet increasing demands while maintaining quality, high-efficiency deburring machines have become essential for mass production. These machines are designed to remove burrs—unwanted material on the edges of workpieces—ensuring that products meet exact specifications. This article delves into the benefits, features, and applications of high-efficiency machine deburring tools, highlighting why they are indispensable in modern manufacturing.

The Importance of Deburring in Mass Production

Deburring is a crucial step in the manufacturing process, particularly in industries such as automotive, aerospace, and electronics, where precision is vital. Burrs, or rough edges, can occur during cutting, drilling, milling, or other machining processes. If not removed, these imperfections can lead to poor fit, increased wear, and even complete product failure.

In mass production, where thousands of components are produced daily, manual deburring is not feasible due to time constraints and the need for consistency. High-efficiency deburring machines address these challenges by automating the process, reducing cycle times, and ensuring uniformity across all parts.

Key Features of High-Efficiency Deburring Machines

Automated Operation: High-efficiency deburring machines are fully automated, allowing for continuous operation with minimal human intervention. This automation ensures consistent results and significantly reduces labor costs.

Multi-Surface Deburring: These machines can handle complex geometries and multiple surfaces, making them suitable for a wide range of products, from simple flat surfaces to intricate parts with internal passages.

Precision and Control: Advanced deburring machines offer precise control over the process, allowing manufacturers to fine-tune settings for different materials and burr sizes. This precision ensures that the final product meets strict quality standards.

High Throughput: Designed for mass production, these machines can process large volumes of parts quickly, reducing lead times and increasing overall productivity.

Energy Efficiency: Modern deburring machines are designed with energy efficiency in mind, reducing operational costs and minimizing environmental impact.

Applications of High-Efficiency Deburring Machines

High-efficiency deburring machines are used across various industries, each with its specific requirements:

Automotive Industry: In automotive manufacturing, deburring is critical for components like gears, engine blocks, and transmission parts, where precision is essential for optimal performance.

Aerospace Industry: Aerospace components require the highest level of precision. Deburring machines ensure that parts like turbine blades and aircraft structures are free of burrs, reducing the risk of failure in critical applications.

Electronics: In electronics manufacturing, even the smallest burr can lead to short circuits or poor connections. High-efficiency deburring machines ensure that components like circuit boards and connectors meet strict tolerances.

Medical Devices: The medical industry demands the highest quality standards. Deburring machines are used to process surgical instruments, implants, and other medical devices, ensuring patient safety.

Benefits of Using High-Efficiency Deburring Machines

Increased Productivity: Automation and high throughput enable manufacturers to produce more parts in less time, meeting high demand without compromising on quality.

Consistency and Quality: Automated deburring ensures that every part meets the same quality standards, reducing the risk of defects and rework.

Cost Efficiency: By reducing manual labor and minimizing waste, high-efficiency deburring machines lower overall production costs.

Enhanced Safety: Removing burrs reduces the risk of injury during assembly and use, improving safety for both workers and end-users.

Environmental Impact: Energy-efficient designs and reduced material waste make these machines more sustainable, helping manufacturers meet environmental regulations.

Selecting the Right Deburring Machine for Your Needs

When choosing a deburring machine, several factors should be considered:

Material Type: Different materials may require specific deburring techniques. Ensure the machine is compatible with the materials you work with.

Part Geometry: Consider the complexity of the parts you produce. Machines with multi-surface capabilities are ideal for intricate components.

Production Volume: High-efficiency machines are best suited for high-volume production environments. Ensure the machine’s throughput matches your production needs.

Budget: While high-efficiency machines may have a higher upfront cost, their long-term savings in labor and waste reduction make them a worthwhile investment.

Ease of Integration: Look for machines that can easily integrate into your existing production line without extensive modifications.

FAQs: High-Efficiency Deburring Machines

Q1: What is deburring, and why is it important?

A1: Deburring is the process of removing unwanted material from the edges of workpieces after machining. It is crucial for ensuring that parts fit together correctly, operate smoothly, and meet quality standards.

Q2: How does a high-efficiency deburring machine work?

A2: These machines use various methods, such as brushing, abrasive media, or chemical processes, to remove burrs. The process is automated, allowing for consistent results across large production runs.

Q3: Can these machines handle complex parts?

A3: Yes, advanced deburring machines are designed to handle parts with complex geometries, including those with internal passages and multiple surfaces.

Q4: What industries benefit most from high-efficiency deburring machines?

A4: Industries such as automotive, aerospace, electronics, and medical devices benefit greatly due to the precision and high-quality standards required in these sectors.

Q5: Are these machines cost-effective?

A5: While the initial investment may be higher, the long-term savings in labor, reduced rework, and lower operational costs make them highly cost-effective.

Q6: How do I choose the right deburring machine for my production needs?

A6: Consider factors such as the type of material, part geometry, production volume, budget, and how easily the machine can integrate into your production line.

Q7: Are high-efficiency deburring machines environmentally friendly?

A7: Yes, modern deburring machines are designed with energy efficiency in mind, reducing operational costs and minimizing environmental impact.

Conclusion

High-efficiency deburring machines are a vital component in modern mass production, offering unmatched precision, productivity, and cost savings. By automating the deburring process, manufacturers can ensure consistent quality across all parts, reduce lead times, and meet the high demands of today’s market. Investing in the right deburring machine not only enhances production efficiency but also contributes to overall business success.

0 notes

Text

Leading the Way with State-of-the-Art Sheet Metal Deburring Machine Technology in India

GVK Metal Forms Redefines Precision Machining in India with Cutting-Edge Sheet Metal Deburring Machines. Say goodbye to unsightly burrs and hello to flawless components, as GVK Metal Forms introduces innovative solutions for a smoother, safer, and higher-quality manufacturing process.

Top of Form

Read more on:https://gvkmetalforms.in/sheet-deburring-machine/

#gvk metal forms#metal fabrication#metalforming#sheet metal bending tools#Sheet Metal Deburring Machines#gvkmetakforms#india

0 notes

Text

Cubic Boron Nitride (CBN) inserts are cutting tools made from a synthetic material that is second only to diamond in hardness. They are widely used in machining applications due to their exceptional properties. Here are the key benefits of using CBN inserts in machining processes:

**1. High Hardness and Wear Resistance:

Exceptional Hardness: CBN is one of the hardest known materials, providing excellent wear resistance during cutting operations.

Long Tool Life: CBN inserts have a longer tool life compared to traditional carbide inserts, reducing the frequency of tool changes and increasing productivity.

**2. High Thermal Stability:

Heat Resistance: CBN inserts can withstand high cutting temperatures without losing their hardness or shape. This makes them suitable for high-speed machining and applications involving heat-resistant materials like hardened steels and superalloys.

Reduced Thermal Stress: CBN inserts generate less heat during cutting, leading to reduced thermal stress on both the tool and the workpiece.

**3. High Chemical Stability:

Chemical Inertness: CBN is chemically inert, making it resistant to chemical wear. This property allows CBN inserts to perform well in applications involving abrasive and corrosive materials.

**4. Superior Surface Finish:

Excellent Surface Finish: CBN inserts produce superior surface finishes on machined parts due to their sharp cutting edges and wear-resistant properties. This is especially important in applications where surface quality is critical, such as in the aerospace and automotive industries.

**5. Versatility and Adaptability:

Wide Range of Applications: CBN inserts are versatile and can be used for various machining operations, including turning, milling, boring, and threading.

Suitable for Hard Materials: CBN inserts are highly effective for machining hard materials such as hardened steels, cast iron, and heat-resistant alloys.

**6. Increased Productivity:

Higher Cutting Speeds: CBN inserts allow for significantly higher cutting speeds compared to conventional carbide inserts. This leads to increased machining efficiency and productivity.

Reduced Downtime: Due to their extended tool life, CBN inserts reduce downtime associated with tool changes and replacements.

**7. Cost Savings:

Longer Tool Life: CBN inserts have a longer operational lifespan, reducing the frequency of tool replacements and overall tooling costs.

Improved Efficiency: Higher cutting speeds and superior surface finishes contribute to improved efficiency, leading to potential cost savings in manufacturing processes.

**8. Environmental Benefits:

Reduced Material Waste: Longer tool life results in reduced material waste from used inserts, contributing to environmental sustainability.

In summary, CBN inserts offer significant advantages in terms of durability, performance, and cost-effectiveness in machining operations. Their ability to withstand high temperatures, maintain sharp cutting edges, and produce excellent surface finishes makes them invaluable tools for manufacturers across various industries.

#cbn#CBN Inserts#CBN#Cutting Tools#Machine Tools#Ceramic Inserts#cutting#ceramic#carbide#metalwork#tool#drill bits#grinder#2023#metal#distributor#cnctools#removals#deburring#grinding#shaping#automotive#aerospace#engineering

0 notes

Note

say more about "brain surgery tools and fixtures"

o well idk if theres that much to say about the tools and fixtures themselves but its obviously a similarly high stakes industry to aircraft & my gfs plant has just been having a lot of production & qa horrors recently lol. her plant produces all kinds of shit, bone screws and shit like that but also actual tools that go in your brain and the parts that hold it to your head or your spine, using cnc lathes & mills to make like EXTREMELY precision metal parts, like, if you run the machine at the wrong room temperature it'll go out of tolerance kind of precision. if you know the "surgery on a grape" robot thats the kind of thing im referencing. and this isnt a brag this is objective: my gf is like an actual machine savant. like horse whisperer shit. but recently she found out that a coworker was like either intentionally or just highly negligently making extremely bad parts, and then writing over all of the cmm data with a copy and paste of, specifically, her parts' measurements, sometimes even including leaving her name stamped on it, and had been doing this for every single part he made for like 6 months, & when she brought it to management they didnt want to do anything about it because this guy churning out scrap was keeping their "production volume" "passable". and like, Lower Stakes shit like incompletely deburring bone screws is the kind of thing that can give you blood infections and make you reject hardware, and actual brain & spine surgery parts failing can mean things like, for instance, driving a tool all the way through someones brain, and thats the kind of shit this guy was passing. a few years ago somebody got lobotomized by a tool failing that was made in another cell in this specific plant, so like, its not like this is an imaginary risk. and he was wrecking machines like multiple times every week so badly that she had to take like 6 hours replacing components on and recalibrating those machines instead of producing parts. he also was maybe trying to steal large volumes of blanks & scrap to resell. in the end he got fired for screaming at his boss

#she wanted me to add that he screamed at his boss because got caught after MELTING a $700 METAL TOOLHOLDER because he crashed the machine so#bad that it friction welded itself to the part and then he tried to hide it in the scrap bin instead of reporting that he#crashed the machine

4 notes

·

View notes

Text

Electropolishing for Deburring Critical Metal Parts

Stamping and machining processes can leave metal parts with burrs that can affect the fit, function and durability of metal parts.

When these parts are destined for food or pharmaceutical production equipment or fuel lines and gear assemblies used in aerospace manufacturing, burrs are more than just a surface imperfection – they’re a potentially catastrophic defect that can prevent the proper sealing or connection between two parts, become dislodged near moving parts, or cause seizing of screws and other fasteners.

To prevent such risks, manufacturers in many industries often specify electropolishing as the final step in finishing their critical metal parts.

How Does Electropolishing Work?

Electropolishing is a highly effective finishing process for removing metal surface defects like microburrs caused by processes like broaching, fine blanking, grinding, lapping or milling.

Using a combination of a chemical bath and a rectified electrical current, electropolishing removes a precise and uniform layer of surface material, leaving behind a shiny, smooth, passive and defect-free surface.

Among other advantages, electropolishing can remove a microscopically precise amount of surface material with surface roughness improvement of up to 50%, eliminating surface defects for high-quality results within very tight tolerances.

By eliminating microcracks and other defects that can harbor bacteria or become initiation sites for corrosion, electropolishing also leaves metal parts with significantly improved resistance to corrosion and pathogen growth. The ultrasmooth surface finish that electropolishing leaves behind has been shown to inhibit the formation of bacterial biofilms that can be resistant to ordinary cleaning methods. The finish also leaves behind a surface that is easier to clean, without cracks or defects where pathogens can hide – a critical advantage for medical, pharmaceutical and food and beverage production.

Why Use Electropolishing for Deburring?

Fragile or intricate metal parts, like those used for medical devices and implants, are not well suited for finishing processes like mechanical or vibratory polishing, which can damage fragile parts or create inconsistent results for parts with complex shapes.

Successful deburring for critical metal parts is contingent upon the ability to remove a precise layer of surface material. No other process can match electropolishing for its ability to control the material removal to +/- .0002”.

By deburring the threads on metal fasteners, for example, electropolishing can reduce the risk of adhesion between two mating surfaces, also known as “galling,” which can cause material between the surfaces to deteriorate and seize up when parts are pressed together.

Burrs can also shorten the lifespan of a part, by breaking off or becoming an initiation site for corrosion.

Larger burrs that occur as the result of rough milling or displaced metal from drilling operations, however, may need pre-treatment using other methods. Likewise, heavy die break burrs caused by improper tooling maintenance will generally require additional treatment.

Much in the way that lightning is drawn to the highest points, electropolishing delivers higher current density on the high points or edges which makes it ideal for micro-deburring The customized nature of the electropolishing process, from racking to chemical formulation to timing, would be of little value if it could not be reproduced consistently. But unlike other finishing processes, electropolishing is prized for its consistent results.

Electropolishing also offers a key advantage for parts with critical microfinishes or made from the lighter, more fragile materials increasingly used in the manufacturing of medical devices, electrical components and semiconductors, among other industries. These parts are not suitable for mass finishing techniques that can create distortion, nicks and scratches. Electropolished parts are individually racked to prevent contact and ensure the even application of the process for even the most fragile parts.

Advantages of Electropolishing for Deburring

The electropolishing process can be customized by alloy, by application and by the desired results. Beyond its ability to remove a uniform layer of surface material to eliminate surface defects like microburrs, microcracks, scale and staining, electropolishing offers many collateral benefits for the manufacturers of critical metal parts.

Microscopically precise removal of surface material with control to +/-.0002”

Customized racking to accommodate fragile and complex parts small and large

Leaves parts with enhanced durability and cycle life

Creation of a pathogen-resistant surface

Superior cleanability

Ultraclean finish

Decorative finish

One stop process for cleaning and removing surface defects

30X more corrosion resistance than passivation alone

Parts are also left passivated in the process

Improves conductivity of copper and aluminum alloys

What Alloys Can Be Electropolished?

A long list of alloys can be effectively deburred using electropolishing. The process is also equally effective on parts that are fully annealed or hardened. That is one reason that electropolishing is frequently specified for the final deburring and finishing of parts after all fabrication and heat treating processes have been completed.

Electropolishing is effective for a wide variety of alloys including:

Stainless Steel 200-300 Series

Stainless Steel 400 Series

Stainless Steel: Precipitating Hardening Grades

Nitinol

Titanium

Aluminum

Carbon Steels

Copper

Brass

Nickel Alloys

Specialty Alloys

And more

Electropolishing for Critical Metal Parts

As the world’s largest electropolishing specialist with seven decades of electropolishing expertise and innovation, Able Electropolishing provides consultation and collaboration from the earliest stages of prototyping through production to create highly customized electropolishing processes for a wide variety of metal parts.

6 notes

·

View notes

Text

OUR SPECIALIZATION ON HOLLOW TUBE & PIPE PUNCHING :

PROBLEM : Due to material & dimensional variations in steel tubing, making distortion free holes over the entire length of the tube is impractical. (using traditional techniques). Most often they are drilled and deburred, or laser cut.

SOLUTION : sing proprietary punch, ID Mandrel die tooling techniques, METALMAN has developed CNC Tube Punching Machines that can be programmed to punch distortion free hole patterns on tubes of any shape including rounds, rectangle without collapsing the tube.

For more details visit website

0 notes

Text

The Benefits of Using a Pink Grinding Wheel: A Smart Choice for Precision Grinding

When it comes to grinding tools and materials, the type of grinding wheel you choose can significantly affect your results. One standout option in the market is the pink grinding wheel. Known for its unique properties and performance advantages, this grinding wheel has gained popularity among both professionals and DIY enthusiasts. In this article, we’ll explore the benefits of using a pink grinding wheel and why it might be the perfect addition to your toolkit.

What is a Pink Grinding Wheel?

A pink grinding wheel is made from aluminum oxide, enhanced with chromium oxide, which gives it its distinctive pink color. This specialized composition provides several advantages, making it an ideal choice for various grinding applications.

Key Benefits of Pink Grinding Wheels

1. Enhanced Durability

Pink grinding wheels are renowned for their toughness and durability. The addition of chromium oxide increases the wheel's lifespan, allowing it to withstand rigorous grinding tasks without wearing down quickly. This means fewer replacements and more efficient grinding over time.

2. Cool Grinding Action

One of the most significant advantages of using a pink grinding wheel is its ability to reduce heat build-up during grinding. This cool grinding action minimizes the risk of overheating, which can damage both the wheel and the workpiece. It’s especially beneficial for sharpening high-speed steel tools and working with sensitive materials.

3. Precision and Control

The hardness of pink grinding wheels allows for precise control during grinding operations. Whether you’re sharpening tools or finishing surfaces, you can expect a smooth, even cut that enhances the quality of your work. This precision is crucial for tasks that require intricate detail and accuracy.

4. Versatility in Applications

Pink grinding wheels are versatile and can be used on a wide range of materials, including stainless steel, carbon steel, and non-ferrous metals. Their ability to handle different types of grinding tasks makes them a valuable asset in any workshop, from metalworking to woodworking projects.

Best Uses for Pink Grinding Wheels

Tool Sharpening Pink grinding wheels are particularly effective for sharpening high-speed steel tools. They provide a sharp, clean edge without causing excessive heat, ensuring the longevity of your tools.

Surface Finishing For projects that require a polished finish, pink grinding wheels deliver excellent results. They help achieve smooth surfaces, making them ideal for both industrial applications and DIY home projects.

Deburring When it comes to removing burrs and rough edges from machined parts, pink grinding wheels excel. Their toughness and precision make it easy to achieve clean, smooth finishes.

Precision Grinding For jobs that demand accuracy, such as grinding intricate parts or achieving tight tolerances, pink grinding wheels provide the reliability and control needed for high-quality results.

Conclusion

The pink grinding wheel is a powerful tool that offers numerous advantages for various grinding applications. Its durability, cool grinding action, and precision make it an ideal choice for professionals and hobbyists alike. If you’re looking to enhance your grinding capabilities, consider adding a pink grinding wheel to your toolkit. You’ll be impressed by the quality of work you can achieve!

0 notes

Text

High-Performance Vibratory Finishing Equipment for Smooth and Efficient Surface Finishing

Examine premium vibratory finishing tools made to achieve quick, effective, and consistent surface enhancement. For applications ranging from automotive to aerospace, our equipment offers a cost-effective solution for deburring, polishing, and cleaning. These machines are designed to last and be precise. They may be used on metal, plastic, and other materials with consistent results, giving you polished and smooth surfaces faster. ideal for specific uses or large-scale manufacturing.

0 notes

Text

Effective Tips and Techniques for Using a Deburring Tool

https://www.mideburring.com/ - Ensure precision and safety in your machining projects with Michigan Deburring Tool. Our range of deburring tools, including Micro, Modular, AutoLock, and Custom tools, is designed to remove imperfections effectively. Select the right tool based on material and volume, prepare both tool and workpiece, and execute the process with the right RPM, feed rates, and consistent motion. Follow safety measures, such as wearing protective gear and adhering to guidelines. With our CNC programming support, optimize your cycle times and achieve exceptional results. Contact us at 810.227.1000 for expert advice and precision tools.

Contact UsMichigan Deburring Tools2155 Pless Dr. Suite B, Brighton, MI 48114

Email: [email protected]

Phone: (810) 227-1000

https://www.mideburring.com/

0 notes

Text

Getting Started with CNC Machining

CNC machining, while complex, can be a rewarding skill to learn. Here's a basic outline of the steps involved:

1. Understanding CNC Basics

How CNC machines work: Familiarize yourself with the different types of CNC machines (mills, lathes, routers, etc.) and their capabilities.

G-code and M-code: Learn the basic syntax of these programming languages used to control CNC machines.

Safety protocols: Understand the safety measures required when operating a CNC machine.

2. Mastering CAD/CAM Software

CAD (Computer-Aided Design): Create 2D or 3D models of the parts you want to machine using software like AutoCAD, SolidWorks, or Fusion 360.

CAM (Computer-Aided Manufacturing): Convert your CAD design into machine code (G-code) using CAM software like Mastercam, Fusion 360, or CAMWorks. This process involves defining toolpaths, speeds, and feeds.

3. Choosing and Setting Up Your CNC Machine

Machine selection: Consider factors like workspace, budget, and the types of materials you plan to work with when choosing a CNC machine.

Machine setup: Learn how to install and calibrate your CNC machine, including setting up the controller, workholding systems, and tool changers.

4. Material Selection and Preparation

Material compatibility: Choose materials suitable for CNC machining, considering factors like machinability, strength, and cost.

Material preparation: Prepare the material by cutting it to size and securing it properly on the machine bed.

5. Tool Selection and Setup

Tool types: Select the right cutting tools based on the material, machining operation, and desired surface finish.

Tool setup: Install the cutting tools in the machine's tool holder or turret, ensuring correct alignment and tightness.

6. Machining Process

G-code input: Transfer the generated G-code to the CNC machine's controller.

Machine operation: Start the machining process and monitor the machine's performance.

Toolpath verification: Use simulation tools to check the toolpath before starting the actual machining process.

7. Post-Machining Processes

Deburring: Remove sharp edges and burrs from the machined parts.

Finishing: Apply surface treatments like polishing or coating if required.

0 notes

Text

Revolutionizing Surface Preparation: Partnering with Portable Shotblasting Machine Manufacturers

6

Introduction

In the modern industrial landscape, surface preparation plays a crucial role in ensuring the quality and longevity of various products. Whether it’s for cleaning, descaling, deburring, or surface finishing, the methods and machinery used significantly impact the final result. One of the most effective and versatile tools in this domain is the portable shotblasting machine. This…

0 notes

Text

Transforming Precious Metals with Machine Tool Traders: A Glimpse into Our Innovative Machinery

Welcome to Machine Tool Traders, your trusted partner in metalworking and Jewellery manufacturing. Based in India, we specialize in a wide range of machines designed to transform precious metals into exquisite works of art. Whether you're involved in gold coin and bar making, Jewellery polishing, or industrial metalworking, our cutting-edge machinery ensures precision, quality, and efficiency. Let’s explore some of our key offerings.

Gold Coins and Bar Making Machines

Gold coins and bars are timeless investments and cherished collectibles. Our gold coins and bar making machines are engineered to meet the highest standards of purity and accuracy. These machines automate the entire process, from melting the raw gold to minting the final product, ensuring consistent weight and perfect finishes. Ideal for mints and bullion manufacturers, our machines offer robust performance and are built to handle high production volumes with ease.

Gold Refinery Machine

Purity is paramount when dealing with precious metals. Our gold refinery machines are designed to refine gold to its purest form. Utilizing advanced refining techniques, these machines can handle various gold alloys and scraps, delivering gold of 99.99% purity. With user-friendly interfaces and efficient processing capabilities, our refinery machines are a valuable asset for any business looking to maximize the value of their gold reserves.

Jewellery Polishing Machines

In the Jewellery industry, the final polish is what gives each piece its brilliance. Our jewellery polishing machines are crafted to deliver a flawless finish, enhancing the allure of your creations. Suitable for various metals, including gold, silver, and platinum, these machines ensure that every piece of Jewellery shines with a professional touch. Whether you're a large manufacturer or an artisan, our polishing machines will help you achieve a superior polish every time.

Circle Cutting Machine

Precision cutting is essential in Jewellery and metalworking. Our circle cutting machines are designed for accuracy and efficiency, capable of cutting perfect circles in various metals. These machines are ideal for producing components such as coins, medals, and decorative elements, providing clean cuts and reducing material wastage. With easy operation and reliable performance, our circle-cutting machines are a must-have for any workshop.

Bangle Cutting Machine

Creating intricate designs on bangles requires precision and skill. Our bangle cutting machines are engineered to facilitate detailed cutting and engraving, allowing for the creation of unique and intricate patterns. These machines cater to both traditional and contemporary designs, ensuring versatility and creativity in your bangle manufacturing process.

Abrasive Belt Grinders from India

Abrasive belt grinders are essential for surface finishing and material removal. Our grinders from India are built to handle heavy-duty grinding tasks with ease. They are perfect for smoothing out rough edges, deburring, and preparing surfaces for further processing. Durable and efficient, these machines are a valuable addition to any metalworking shop, providing consistent results and enhancing productivity.

Sheet Folding Machine

Sheet metal fabrication often requires precise folding and bending. Our sheet folding machines are designed to deliver accurate folds with minimal effort. Whether you're working with thin sheets or thicker materials, our machines provide the control and precision needed to achieve perfect bends. Ideal for creating components such as enclosures, panels, and brackets, our sheet folding machines ensure high-quality results every time.

At Machine Tool Traders, we are committed to providing innovative solutions that meet the diverse needs of our clients. Our extensive range of machinery is designed to enhance productivity, ensure precision, and deliver exceptional quality. Explore our offerings and discover how we can help you achieve excellence in metalworking and Jewellery manufacturing. For more information, visit us at Machine Tool Traders.

0 notes

Text

Using sheet metal laser cutting to produce cheap components offers numerous advantages, making it a popular choice for various industries. Laser cutting, a precise and efficient method, employs a high-powered laser beam to cut through sheet metal. This technology ensures accuracy and consistency, significantly reducing production costs.

Firstly, laser cutting minimises material wastage. The high precision of the laser beam allows for intricate designs to be cut with minimal kerf, or material removed during cutting. Using either Nitrogen, Oxygen or compressed air can be used as the laser cutting assist gas making laser cutting a versatile production method across a wide range of materials types. Consequently, manufacturers can utilise more of the sheet metal, maximising material usage and reducing overall costs. Additionally, this method reduces the need for secondary processing, such as deburring, further lowering expenses.

Furthermore, laser cutting is highly versatile. It can handle various metals, including stainless steel, aluminium, and mild steel, and different thicknesses, ranging from thin sheets to thicker plates. Offcuts of material can easily be used from past projects further saving money. This adaptability means that manufacturers can use a single machine for multiple projects, saving on equipment and maintenance costs. For instance, a laser cutter can effortlessly switch between producing components for automotive, aerospace, and consumer electronics industries without the need for extensive retooling.

The speed of laser cutting also contributes to its cost-effectiveness. Modern fibre laser cutters, such as those used by V and F Sheet Metal, operate at very high speeds, drastically reducing production time. This efficiency means that large quantities of components can be produced quickly, meeting tight deadlines without compromising quality. As a result, businesses can reduce labour costs and increase throughput, making their operations more efficient.

Moreover, the precision of laser cutting enhances the quality of the final product. With computer-controlled accuracy, laser cutters can produce components with tight tolerances and complex geometries. This precision reduces the likelihood of errors and defects, leading to fewer rejected parts and lower costs associated with rework or scrap.

In summary, laser cutting offers a cost-effective solution for producing cheap components from sheet metal. Its ability to minimise material waste, handle various metals, and operate at high speeds makes it an invaluable tool for manufacturers looking to optimise production and reduce costs. By leveraging the advantages of laser cutting, businesses can achieve high-quality results while maintaining economic efficiency.

Ask us for a quote today.

0 notes

Text

The Significance of Tablet Press Machines and Accessories in the Pharmaceutical Industry

Overview

Tablet press machines are crucial components for any pharmaceutical manufacturing operation. These machines compress pharmaceutical powder formulations into tablet form, ensuring uniform shape, size, and weight. Referred to as tablet compressing machines, they are invaluable not only to the pharmaceutical industry but also to sectors such as cosmetics and petrochemicals.

Types of Tablet Press Machines

There are two primary types of tablet press machines: single station and multiple station machines.

Single Station Tablet Press Machine

Single station machines are ideal for batch and laboratory production due to their precise filling and tablet size capabilities. High speed tablet machines can be operated manually or automated, and they are particularly effective for producing chewable tablets and effervescent tablets containing ingredients like tartaric acid, citric acid, and sodium bicarbonate.

Multiple Station Tablet Press Machine

Multiple station machines, on the other hand, are designed for high-volume production and require minimal maintenance. They are accurate and efficient, suitable for wet powder granulation and the formulation of tablets. These machines support single-process granulating, tablet compression, and coating, making them versatile for applications in medical food (nutraceuticals) and biotechnology.

Accessories for Tablet Press Machines

Several accessories enhance the functionality of tablet press machines, offering numerous benefits:

Pneumatic Product Feeding System: Improves product inlet feed.

Ejection Force Reducer: Reduces the ejection force needed.

Tablet Quality Control Unit: Ensures uniform weight, thickness, and hardness.

Dedusting, Deburring, and Metal Check Unit: Combines these tasks into a single unit.

Component Carts: Speed up the changeover of product contact parts.

Safer Die Table Transportation: Enhances the safety of transporting die tables.

Importance to the Pharmaceutical Industry

Tablet press machines are essential for several reasons:

High Accuracy

These machines ensure that tablets contain precise dosages as prescribed by doctors, maintaining accurate measurements of all ingredients to produce tablets of perfect size, shape, and weight.

Easy Prescription Management

Patients often need to take multiple medications daily. Tablet press machines facilitate the combination of various ingredients into a single tablet, simplifying the patient's regimen and enhancing compliance.

Affordability and Custom Design

These machines are affordable and can be tailored to produce tablets for specific needs. They streamline the design process, making it easier to create specialized tablets.

Comprehensive Role in Production

The pharmaceutical production process involves numerous specialized machines from ingredient preparation to final packaging. Among these, the tablet press machine is one of the most critical, ensuring uniformity in tablet manufacturing by compressing essential medicinal powders.

Tablet Compression Tooling

Different tooling systems, such as rotary tablet press tooling, involve major components like dies and punches. Tooling systems are classified into several types, including B, D, BB, and DB, each with specific characteristics:

D Tooling: Features a barrel diameter of 1 inch, a head diameter of 1 ¼ inches, a length of 5.25 inches, and dies with an outer diameter of 0.945 inches. This tooling is suitable for compressing large tablets.

BB Tooling: Has a barrel diameter of 0.75 inches, a head diameter of 1 inch, a length of 5.25 inches, and dies with an outer diameter of 30.16 mm.

B Tooling: Similar to BB tooling, but with a lower punch length of 3 9/16 inches.

DB Tooling: Punch length and diameter are similar to D tooling, but with different die diameters.

Conclusion

Tablet press machines are indispensable to the pharmaceutical industry, ensuring the accurate and efficient production of tablets. With the appropriate accessories and tooling, these machines enhance productivity, quality control, and ease of operation, contributing significantly to the advancement of pharmaceutical manufacturing.

youtube

0 notes

Text

Abrasives Market Outlook Report 2024-2030: Trends, Strategic Insights, and Growth Opportunities | GQ Research

The Abrasives Market is set to witness remarkable growth, as indicated by recent market analysis conducted by GQ Research. In 2023, the global Abrasives Market showcased a significant presence, boasting a valuation of US$ 53.41 billion. This underscores the substantial demand for Acetophenone technology and its widespread adoption across various industries.

Get Sample of this Report at: https://gqresearch.com/request-sample/global-abrasives-market/

Projected Growth: Projections suggest that the Abrasives Market will continue its upward trajectory, with a projected value of US$ 74.16 billion by 2030. This growth is expected to be driven by technological advancements, increasing consumer demand, and expanding application areas.

Compound Annual Growth Rate (CAGR): The forecast period anticipates a Compound Annual Growth Rate (CAGR) of 4.8%, reflecting a steady and robust growth rate for the Abrasives Market over the coming years.

Technology Adoption:

In the Abrasives market, technology adoption encompasses the development and utilization of advanced abrasive materials, manufacturing processes, and surface finishing techniques. Abrasives are used for grinding, polishing, cutting, and shaping materials such as metals, ceramics, composites, and stones. Various abrasive types include bonded abrasives (e.g., grinding wheels, honing stones), coated abrasives (e.g., sandpaper, abrasive belts), and superabrasives (e.g., diamond, cubic boron nitride). Advanced technologies such as precision grinding, electroplated coatings, and laser machining enhance abrasive performance, precision, and efficiency in diverse applications across industries.

Application Diversity:

The Abrasives market serves diverse applications across industries such as automotive, aerospace, metalworking, construction, electronics, and healthcare. In manufacturing, abrasives are used for surface preparation, deburring, and precision grinding of components in automotive and aerospace production. Additionally, abrasives find applications in metal fabrication for cutting, shaping, and finishing metal parts in construction, machinery, and consumer goods. Moreover, abrasives are utilized in electronics manufacturing for wafer dicing, circuit board fabrication, and precision polishing of semiconductor materials.

Consumer Preferences:

Consumer preferences in the Abrasives market are influenced by factors such as abrasive performance, durability, surface finish quality, and cost-effectiveness. End-users prioritize abrasives that offer high material removal rates, consistent surface finish, and long tool life for efficient machining and finishing operations. Additionally, consumers value abrasives with low clogging tendency, heat resistance, and compatibility with specific materials and machining processes. Moreover, cost considerations, including abrasive price, availability, and overall process economics, play a significant role in consumer purchasing decisions.

Technological Advancements:

Technological advancements in the Abrasives market focus on improving abrasive material properties, manufacturing processes, and tooling technologies to enhance performance, productivity, and sustainability. Research efforts aim to develop new abrasive formulations with enhanced hardness, toughness, and self-sharpening characteristics for improved cutting and grinding efficiency. Additionally, advancements in abrasive coating technologies, such as nanostructured coatings and engineered grain geometries, enhance abrasive adhesion, wear resistance, and tool life in coated abrasive products. Moreover, integration with digital manufacturing technologies, such as CNC machining and robotic automation, enables precise control and optimization of abrasive processes for increased productivity and quality consistency.

Market Competition:

The Abrasives market is characterized by robust competition among abrasive manufacturers, distributors, and end-users, driven by factors such as product performance, quality, pricing, and customer service. Major players leverage their manufacturing scale, R&D capabilities, and global distribution networks to maintain market leadership and gain competitive advantage. Meanwhile, smaller manufacturers and specialty abrasive suppliers differentiate themselves through niche product offerings, customized solutions, and technical expertise in specific applications or industries. Additionally, strategic partnerships, acquisitions, and product innovations are common strategies for companies to expand market presence and enhance competitiveness in the dynamic Abrasives market.

Environmental Considerations:

Environmental considerations are increasingly important in the Abrasives market, with stakeholders focusing on sustainable sourcing, manufacturing processes, and waste management practices. Manufacturers strive to minimize environmental impact by using recycled and eco-friendly abrasive materials, reducing energy consumption, and optimizing water usage in abrasive production processes. Additionally, efforts are made to develop environmentally friendly abrasive coatings and surface treatments that minimize emissions, VOCs (volatile organic compounds), and hazardous waste generation during abrasive machining operations. Moreover, initiatives such as product life cycle assessment (LCA), eco-labeling, and certification programs promote sustainable practices and responsible consumption in the Abrasives market.

Top of Form

Regional Dynamics: Different regions may exhibit varying growth rates and adoption patterns influenced by factors such as consumer preferences, technological infrastructure and regulatory frameworks.

Key players in the industry include:

3M Company

Saint-Gobain Abrasives

Robert Bosch GmbH (Bosch)

Norton Abrasives (A brand of Saint-Gobain Abrasives)

Klingspor AG

Tyrolit Group

Fujimi Incorporated

Deerfos Co., Ltd.

Asahi Diamond Industrial Co., Ltd.

Carborundum Universal Limited

Sia Abrasives Industries AG

Abrasiflex Pty Ltd

Hermes Schleifmittel GmbH

Abrasive Technology

Mirka Ltd.

The research report provides a comprehensive analysis of the Abrasives Market, offering insights into current trends, market dynamics and future prospects. It explores key factors driving growth, challenges faced by the industry, and potential opportunities for market players.

For more information and to access a complimentary sample report, visit Link to Sample Report: https://gqresearch.com/request-sample/global-abrasives-market/

About GQ Research:

GQ Research is a company that is creating cutting edge, futuristic and informative reports in many different areas. Some of the most common areas where we generate reports are industry reports, country reports, company reports and everything in between.

Contact:

Jessica Joyal

+1 (614) 602 2897 | +919284395731

Website - https://gqresearch.com/

0 notes

Text

From Design to Delivery: The Excellence of China's Die Casting Manufacturers

In the intricate world of manufacturing, the journey from design to delivery is a testament to precision, innovation, and excellence. China's die casting manufacturers stand at the forefront of this journey, leveraging advanced technologies, expertise, and a commitment to quality to deliver exceptional products to customers worldwide. In this article, we delve into the comprehensive process of China's die casting manufacturers, highlighting their excellence every step of the way.

Designing for Success

The journey of excellence begins with design. China's die casting manufacturers employ skilled engineers and designers who leverage advanced CAD/CAM software to create intricate designs with precision and efficiency. These designs are meticulously crafted to meet the specific requirements and performance standards of each customer.

Using computer simulation tools, engineers can predict and optimize the casting process, ensuring that the final product meets the desired specifications. By identifying potential issues early in the design phase, manufacturers can minimize waste, reduce costs, and optimize production efficiency.

Precision Mold Making

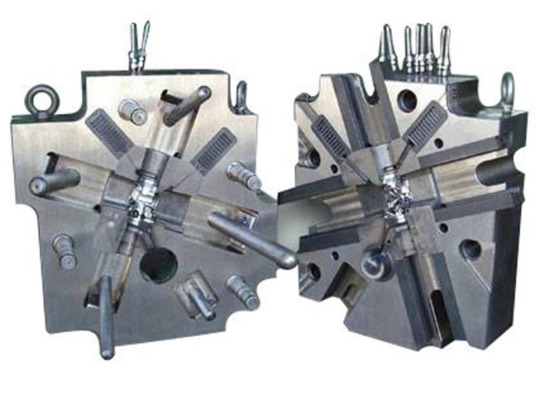

Once the design is finalized, the next step is mold making. China's die casting manufacturers are renowned for their expertise in mold making, leveraging advanced machining techniques and state-of-the-art equipment to produce high-quality molds with unparalleled precision.

Advanced CNC machining centers allow manufacturers to fabricate molds with intricate details and complex geometries, ensuring that every component meets the strictest quality standards. By employing skilled craftsmen and adhering to rigorous quality control measures, manufacturers can deliver molds that exceed customer expectations.

The Art of Die Casting

With the molds in hand, the die casting process begins. China's die casting manufacturers utilize advanced die casting machines and automation technology to produce components with speed, accuracy, and consistency.

During the casting process, molten metal is injected into the mold cavity under high pressure, resulting in precise replication of the mold's geometry. Advanced monitoring systems ensure that each component is produced to the exact specifications, with minimal variation and defects.

Finishing Touches

After the casting process is complete, the components undergo finishing operations to achieve the desired surface finish and dimensional accuracy. China's die casting manufacturers employ a variety of techniques, including machining, polishing, and coating, to enhance the appearance and functionality of the components.

Advanced finishing equipment and skilled craftsmen ensure that every component meets the highest standards of quality and aesthetics. Whether it's removing burrs, deburring edges, or applying surface treatments, manufacturers take great care to deliver components that are ready for assembly and use.

Quality Assurance

Throughout the entire journey from design to delivery, quality assurance is paramount. China's die casting manufacturers implement rigorous quality control measures at every stage of the production process to ensure that every component meets the strictest quality standards.

Advanced inspection techniques, such as coordinate measuring machines (CMMs) and optical metrology systems, are used to verify dimensional accuracy and surface finish. Non-destructive testing methods, such as X-ray and ultrasound, are employed to detect internal defects and ensure structural integrity.

On-Time Delivery

Finally, the journey culminates in on-time delivery to the customer. China's die casting manufacturers understand the importance of timely delivery and work tirelessly to meet customer deadlines and commitments. See it here Aluminum die Casting

By optimizing production schedules, streamlining logistics, and maintaining open communication with customers, manufacturers ensure that components are delivered on schedule and in accordance with customer requirements. This commitment to on-time delivery is a testament to their dedication to customer satisfaction and excellence.

Conclusion: A Journey of Excellence

In conclusion, the journey from design to delivery is a testament to the excellence of China's die casting manufacturers. From the precision of design to the quality of production, every step of the journey is characterized by innovation, expertise, and a commitment to excellence.

As China's die casting manufacturers continue to push the boundaries of what is possible, they will shape the future of manufacturing and drive progress and innovation in industries around the world. With their dedication to quality, reliability, and customer satisfaction, they are poised to lead the way in the journey from design to delivery for years to come.

0 notes