#lab extruder machine

Text

Navigating Ease Of Operation And Adjustment In Lab Extruder Machines

Lab extruder machine serves as an indispensable tool in research and development environments, enabling precise material processing and experimentation. Central to their utility is the ease with which operators can navigate their operation and make adjustments as needed. In this article, we delve into the intricacies of operating and adjusting lab extruder machines, exploring features and considerations that contribute to their user-friendliness and versatility.

Before delving into the ease of operation and adjustment, it's essential to grasp the fundamental principles governing lab extruder machines. These devices utilize a combination of heat, pressure, and mechanical force to melt, mix, and shape materials into desired forms. Operators feed raw materials into the extruder, where they are heated and forced through a die to produce uniform products such as filaments, sheets, or pellets.

One of the key factors contributing to the ease of operation is the design of the machine's interface. A user-friendly interface features clear labeling, intuitive controls, and ergonomic layout, allowing operators to navigate functions effortlessly. Touchscreen displays, digital readouts, and graphical interfaces provide real-time feedback and facilitate precise adjustment of parameters such as temperature, speed, and pressure.

Lab extruder machines equipped with programmable settings offer good convenience and flexibility. Operators can save and recall predefined recipes or processing parameters, eliminating the need for manual adjustments between experiments. This feature streamlines workflow enhances reproducibility, and reduces human error, particularly in multi-step processes or complex formulations.

Efficient changeover between different materials or processing conditions is essential for improving productivity and versatility. Lab extruder machines with quick-changeover systems feature tool-less access to key components such as screws, barrels, and dies, facilitating rapid cleaning, maintenance, and adjustment. Modular design and standardized interfaces further simplify changeover procedures, reducing downtime and enhancing operational efficiency.

Real-time monitoring and control capabilities enable operators to oversee the extrusion process and make adjustments on the fly. Advanced sensors and feedback mechanisms continuously measure key parameters such as temperature, pressure, and torque, providing operators with actionable insights into process performance. Automated control systems can dynamically adjust operating parameters to maintain conditions and prevent deviations from target values.

Comprehensive user training and support resources play a crucial role in ensuring the ease of operation of lab extruder machines. Manufacturers should provide detailed user manuals, instructional videos, and hands-on training sessions to familiarize operators with machine functionality and safety protocols. Additionally, prompt technical support and troubleshooting assistance empower operators to address issues quickly and effectively, reducing disruptions to research activities.

The ability to customize machine settings and adapt to specific research requirements enhances the overall user experience. Lab extruder machines equipped with adjustable parameters such as screw geometry, die configurations, and processing profiles allow operators to tailor extrusion conditions to suit diverse materials and applications. This flexibility fosters innovation and experimentation, enabling researchers to explore new formulations and optimize process parameters with ease.

Feedback from operators and ongoing evaluation of user experiences are invaluable for driving continuous improvement in lab extruder machine design. Manufacturers should actively solicit feedback through surveys, focus groups, and user forums to identify pain points, usability issues, and feature requests. Incorporating user feedback into product development cycles ensures that future iterations of lab extruder machines are increasingly intuitive, efficient, and user-friendly.

Lab extruder machines are indispensable tools for researchers and engineers engaged in materials development, formulation, and processing. The ease with which operators can navigate machine operations and make adjustments directly impacts productivity, efficiency, and experimental outcomes. By prioritizing intuitive interface design, programmable settings, quick changeover systems, real-time monitoring, and control, user training and support, customization, and continuous improvement, manufacturers can empower operators to master precision and unlock the full potential of lab extruder machines in advancing scientific discovery and innovation.

1 note

·

View note

Video

youtube

HMMA lab extruder machine high moisture meat analogue extrusion machine ...

#youtube#HMMA#lab extruder#lab machine#high moisture meat analogue#HMMA extruder#hmma machine#meat analogue#vagan#vagan meat#vagan meat machine#vagan meat extruder#vagan meat equipment#extrusion machine

0 notes

Text

The most unexpectedly superstitious people according to my experiences: software engineers, scientists, and health care workers.

It's unexpected because those are all seemingly logic based, but it's also completely expected because those all have a large number of random variables that will mess your life up.

#some of the scientists at my school (me included) invented ice cream machine fortune telling#The ice cream machine in the dining hall is sometimes dodgy. if it extrudes a good firm ice cream that's a good fortune#if it excrews a liquid or an inconveniently solid ice cream that's not a good fortune#This may affect your labs for the rest of the day

1 note

·

View note

Text

How To Find Best Micro Lab Extruder Factory

Extrusion molding is an early technology in polymer processing, which plays an important role in plastic processing. After more than 100 years of development, extruded products have accounted for more than 1% of the total plastic products.

In the extensive production practice, the theory and technology of extrusion molding have been continuously deepened and expanded; the types, structure and forms of machinable polymers are more and more; the extrusion process has been continuously developed; the extrusion equipment has been continuously improved and innovated.

The micro lab extruder is an ideal tool for use in testing labs, universities, and research and development departments. It is well-suited for tasks such as teaching, developing formulations, prototyping, and producing small batches. The following article will provide some tips on how to finda trustworthy micro lab extruder factory.

Where can you find micro lab extruder factories?

1. Google search

You can search for ” Granuwel micro lab extruder” on Google, the first page will show results such as the following:

Professional Laboratory Extruder Manufacturer

Laboratory twin screw extruder

A specific keyword search will allow you to narrow down the micro lab extruder manufacturers that produce that particular micro lab extruder.

2. Sourcing agents

These companies are not selling their own products; Instead, they are more specialized in sourcing services. You will benefit from import services, which include sourcing, production supervision, quality control and shipping schedule.

For this reason, many micro lab extruder sellers are attracted to the services of sourcing agents. Sourcing agents are more flexible than trading companies. They can assist you in finding the micro lab extruder products you are looking for in China.

3. Trade shows

If you are more into face-to-face interaction with potential manufacturers and suppliers, visiting trade shows is a great way to interact with them in China and locally. Attending such trade fairs will give you a better idea of the large scale and detailed offerings.

As you might expect, there are many trade fairs in China, both large and small. One of the most popular trade shows in China is The Canton Fair.

One big drawback to visiting trade shows, however, is that you have to go to China in person. The pandemic now sweeping the world is making it impossible to go to China for trade shows.

A step-by-step guide on how to find the best micro lab extruder factory online

Step 1: Decide what you need

Before you start searching and contacting micro lab extruder factories, you must determine what kind of micro lab extruder you want. Not sure which micro lab extruder is best for your needs?

Please contact us and our team of experts will help you decide on the right micro lab extruder according to your requirement.

You need to, first of all, get a clear idea of what you want, since this will help you find the best micro lab extruder manufacturer.

This is important because although micro lab extruder manufacturers produce different kinds of micro lab extruders, they may not match your specific requirements and needs.

Step 2: Analyze your options

Here are some factors to consider when selecting a micro lab extruder factory:

Variety

The best micro lab extruder factory produces various kinds of extruder production Line products.

For example, they also manufacture twin screw extruder, single screw extruder and triple screw extruder, pelletizing systems, PET/PLA/PBAT SheetExtrusion Line and so on.

Information

A good micro lab extruder factory provides a wide range of relevant information about their micro lab extruder products on their websites.

Broad information including the main features of eco-friendly, a variety of raw material sources, recyclable and high-temperature resistance as well as specifications of density range and dimension is important when buying a micro lab extruder.

If you can’t find these details on the micro lab extruder factory’s website, you won’t be able to decide if their products are right for you.

Services

The Services provided by the micro lab extruder manufacturer determine your micro lab extruder purchasing experience.

A good micro lab extruder factory will keep in touch with its clients throughout the whole purchase cycle. They provide customers with excellent pre-sale service, sale service and after-sale service.

Geographical Location

China is not exactly a small country where manufacturers are located in different cities and the specialization of factories varies from region to region.

For instance, Nanjing-which is located in southwestern Jiangsu, is the second-largest city in East China-has developed into a major city in the Energy Saving Technology industry.

Nanjing has fostered a distinctive ecosystem to support the manufacturing supply chain, and as a result, many excellent socially responsible micro lab extruder factories have emerged there, Granuwel micro lab extruder factory is one of them.

Document Check

Business licence

In China, all registered businesses carry a business license. The business license contains important information about the supplier, including the scope of their business.

This is a statement describing the supplier’s activities and an indication of if they are a manufacturer or a reseller. Production” and “assembly” identify a manufacturer, while “wholesale” and “distribution” indicate a trading company.

Certificates

A good way to check a micro lab extruder factory’s credibility is through their certificate. A quality management certificate (ISO 9001) implies that the supplier complies with certain statutory and regulatory requirements and has passed the relevant audits.

A social responsibility certificate shows that their workplace is safe and ethical. Environmental certificates show that their processes do not damage the environment. For social responsibility and environmental certificates, suppliers are required to pass a professional audit.

Step 3: Contact the manufacturers you have selected

You’ve already done your research and selected a shortlist of micro lab extruder factories, so what’s the next step?

Here are some considerations for communicating with a few of your selected suppliers to check whether they can meet your business requirements.

Enquire about production times

Production time usually depends on the micro lab extruder factory’s capacity. This is a vital factor to consider because it allows you to better understand your supplier’s micro lab extruder production line turnaround time.

Working hand in hand while requesting samples also gives you an understanding of other important factors like coordination, shipping schedule and product quality.

Minimum order quantities

Minimum Order Quantity (MOQ) refers to the supplier’s minimum order requirement. According to a basic interpretation of economies of scale, a reduction in your MOQ will result in an increase in production costs.

Thus, it is essential to calculate the optimal amount of inventory required to avoid a negative impact on profitability by holding too much inventory.

Nanjing Granuwel Machinery CO., LTD is specializing in R&D design and manufacture of high polymer extruders, our team of top-level extrusion professionals provides the right extruder for your exact application.We possess excellent capability of innovation and product development, and desire to provide best products for our customers through the improvement of equipment structure and reduction of equipment energy consumption through our practical experiences and technical innovation. For more details about micro lab extruder factory visit our website https://www.granuwelextruder.com

1 note

·

View note

Text

Visitor: 8

good lord finally-

(chapter under cut)

A handful of guards, each with a full belt of capture balls on their belts, AND in a relatively small corridor, all combine into not a pleasant sight. With both hands full, Denko couldn't make quick work of the trainers, either.

It's only a matter of time before internal security gets ramped up to the max; There was no time to waste, he had to reach Jake and the Ion as soon as possible! Denko had to find a way to minimize the time burnt humoring these guards.

Taking a deep breath, Denko glared through the Ultra Balls opening before him as the Zeraora Battle Flow™ came into effect.

Leavanny and Sandslash…both Pokemon strong against Electric attacks. Ground moves are the one weakness of electric types, so Sandslash must be the primary attacker. Leavanny is more difficult to discern, though Denko had two ideas: Status effects or stat changes.

Whichever job the bug nanny may fill, Denko must be prepared for anything, even WITH an alien Carnivine on his side. George stood protectively in front of Denko, snarling, drooling, and staring at the bug hungrily.

"String shot!" Shoot…! Denko was too absorbed in figuring out a plan for the Sandslash. The feline leapt into the air, trying to avoid the oncoming white string, though to no avail. One of his hind paws got caught, yanking it - and him - to the cold steel floor and gluing him in place.

Before long, his entire body was covered with the substance, restricting movement to an uncomfortable degree. He stumbled and hit the ground hard, getting a glimpse of George swatting at its own bindings as he fell. While he struggled, the Sandslash screamed and swiped its claws, stirring up a thick sandstorm, hurtling straight at Denko! Sand Tomb, shit…!

He braced, but the rough sting never came. A second later, his cocoon loosened enough he could burst clean out of it thanks to a purple acidic substance.

...George-?!

He thanked his lucky star that this little monster was on his side, then stood up. George was spinning his leaves like a propeller blade, blowing the sand tomb straight back at the trainers and pokemon. They cried out, rubbing their eyes in a vain attempt to clear them.

Sandslash remained unaffected, but thorny vines from George tied it down for a moment. He looked back at Denko, grunting and indicating for him to go on ahead. He hesitates, but returns a nod. George should be able to handle himself; The guards will be more concerned with Denko, anyways.

The plant lowers his head, though maintaining a horizontal angle. One may assume he was just leaning forward in focus as if he was engaged in a difficult challenge, though his subtle jolts up told Denko everything he needed to know.

He jumps up into the air, onto George's squishy head, before being thrust onwards and upwards, over the recovering group of guards.

"Thank you..." While he hated leaving George to deal with all that on his own, this at least allowed him to find and save Jake faster.

Plus, he was allowed time to potentially figure Jake's device out.

"Uh, Haywire!"

An irritated and confused BWOOP?! issued forth.

"Got any info about this place, where Jake and his ship are?"

Much to his dismay, the machine returned a droning couple of beeps. No good.

All Denko could really do is explore untouched territory and follow any clues, which isn't going to be very fast. Not to mention, the facility was on full alert…The feline heaved a sigh, shifting his focus to the winding path ahead.

!

Oh, there's a map just ahead, Score! "Hmm...Cafeteria, Reception, Barracks...ooh. Armory?? Oh that doesn't bode well at all…" He was looking for any kind of holding cell or lab, but was getting nowhere fast.

A curt whistle draws his attention to Haywire. The tool head extruded a small radar dish that jerked forward like it was pointing. Following the point led to the side of the map's screen. There was a series of elevator buttons, which changed the map when pressed...Talk about an obtuse UI, almost reminded him of a game he used to play-

No time to waste. He scans each floor, being sure to occasionally check the hallways for any oncoming guards. To his surprise, there were never any.

...He wasn't sure if he should be thankful or nervous.

The minutes crawled, until…Aha, the prison!

If his intuition is correct, Jake is there. Fist pumping the air, just about to rocket off before Haywire vibrates in his paw. He was forgetting something…The Ion's location was still a mystery. He grunts in irritation, but gets back to looking.

Searching for a holding compartment for a large ship was surprisingly difficult. There didn't seem to be many mapped areas large enough to house such a contraption. Shoot...

"Hey!"

Double shoot, A guard spotted him!! The Taka,Taka, Taka of multiple rapid footsteps approached their position. Dammit...he had to hope that Jake could find it once they'd reunited. He had the route, he just needed to get there. Stealth was out the window; time to go fast. "Brace yourself, Haywire."

He sprinted down the hall with the boom of a thunderclap, barreling past the guards as he rushed through the path he mapped in his head. Down a few flights of stairs, through the halls (weaving around more than a couple other humans on the way), up another flight of stairs, then a final leap over a deep pit to the cells.

"...What an inconvenient floor plan."

It didn't matter, he had arrived. Hopefully Haywire was okay. Disoriented, judging by the slightly rattling panels, but alright nonetheless. Denko presses himself up against the wall, sneaking just beyond the doorway. A small two-way peephole was the only thing granting a view within, so he takes a chance to peer within.

X.x.X

"Hey, who's there?"

The voice of the guard, seldom used, yanked Jake's mind out of sulking. He hadn't really moved for a good while, his mind elsewhere and elsewhen, thinking and overthinking, ears primed but not much else.

Stiff all over, he tried to stand up to press his ear against the wall, but tripped, faceplanting. "Mrrrrrrg....!" He felt his fur flare up, and his frustrations arced out of him like lightning, decorating the sterile walls with bitter purple scorch marks.

Low speech was uttered by the human, though it was too quiet for the fox to hear clearly. Only one word was able to register in his mind, that being 'intruder.' Yeah, of course they'd be wary of intruders. It's not often that an otherworldly spaceship drops into your lap; Of course they'd want to protect it.

The sound of the electronic door sliding open was faint, making Jake fear the stress was fucking up his hearing, and the lack of much action afterwards seemed to cement the fact.

Suddenly, there was a thud of someone collapsing onto the floor. Then a voice.

"Jake, you there?"

?!

No way.

's1R?' AND he found Haywire?! He scrambled to his paws, a surge of energy momentarily pushing aside his fatigue as he rushed towards the voices, accidentally knocking his head against the wall in his haste.

Footsteps approached the locked door of the cell, followed by the sounds of electrical sparks. Shortly after, the door lifts up to reveal the muscular Zeraora he had accompanied up till a few hours ago.

"Jake! Thank Arceus you're okay, I was so worried!"

Oh, Denko wrapped both arms around him in an embrace. Jake's... oddly comforted by it...?

"Uh- I mean-"

The hug's brief, Denko breaking contact and backing away out of slight embarrassment.

"...I'm glad you're... okay?"

It's only now when Denko notices his appearance differing from the last time they'd seen each other. Jake's not fond of it, shaking his head and averting his gaze when the feline displayed his curiosity. A silent 'don't ask,' a memo that Denko seemed to catch, prying no further.

He raises an arm, upward palm opening to reveal... shattered amber shards?

...Wait, that's...! "...we found it pretty beat, and it gave up within my grasp."

Jake snatched the bits of his charm out of the giant's paw, muscle memory trying to activate it in vain but only breaking it down more. "No, no, nononono no!" It crumbled into dust in his paws, and his heart followed. "No....!"

Crumpling to the floor with stinging eyes and ringing ears, Jake never felt more…lost. A fog overtook his senses. His chest tightened like a vise.

"Hey..." Denko crouches down to be level with the vulpes. "I'll get you out of here."

"...That thing was how I hid." The words spilled out, Thick tears rolling down his muzzle. "It let me be someone different. Now it's…it's gone, and…no matter where I go for 10 star systems, this face is on missing posters with a 50 million reward."

X.x.X

"That..."

There weren't many words he could find to respond with. "I…I'm sorry..."

Denko wasn't responsible for the gem breaking, but he sure as hell was responsible for getting him into this situation in the first place. "Jake, I'll do anything I can to help. I promise."

Denko slightly extends a paw for Jake to grab, both to help him up and rekindle their partnership at the same time. After a moment, Jake raised his hand, but then planted it on the ground to rise on his own.

"...Well, I guess this primitive place isn't Starbound yet, so nobody will look for me here." He was trying to sound chipper, but his expression was unreadable behind his glasses and his fur twitched erratically. "Just gotta get my ship back before they figure it out."

He must be itching to get the hell off this planet…He couldn't help a tinge of sadness at how badly things had gone to get to this point.

"Eurgh..." A groan not belonging to Denko nor Jake befouled their ears. The guard Denko knocked out was just coming to, seconds from noticing the pair and calling for maximum security. Not if Denko had anything to say about it. He dashed behind and kept the guard pinned with a foot, covering their mouth with a paw.

...An idea comes to mind, seeing the firearm dropped nearby.

"Jake, you can speak English, right? Interrogate this guy!" Almost instantly, the weapon was snatched up and pressed to the poor fool's forehead. "...Where's. My. Ship." It was less a question and more a threat.

"I…I don't-" the guard yelped as Jake whipped the gun upwards and fired a shot. "Don't fuck with me," his fur flared and eyes turned solid yellow. "You work here. You guarded a high security prisoner like me. You know where important shit goes." The barrel swung around and fired again, the shot missing the demihuman's head by centimeters.

"Now I'll make this real simple. Where did. The rest. Of my shit. Go?"

Denko briefly tightened the hold, the bare strength nearly enough to snap bones. "Spit. It. Out." The cat didn't care that they couldn't understand him, he wanted the information squeezed out of the human like they were a sponge.

"It's... ack- C-Contraband Research!"

Bingo!

"Good boy." With a CRACK, Jake pistol-whipped the guard, sending them back out cold.

Breathing a subtle sigh, Denko rests them back onto the ground. "I saw a map on the way here, but I don't remember it well enough to know where to go." He presumes they'll need to find another map or rush back to the first one, though the current security level already made that quite tricky.

He's about to speak another thought when the electronic beeping of Haywire interrupts the cat. "Hm?"

X.x.X

Denko didn't understand it, but Jake had designed Haywire's code, so he knew what it said. '4ctua7ly, 1 have it pr33ty m4ch m3m0rized.' "Thank The Eye-

Haywire's got it, actually."

"Oh, thank goodness. What's the best route, then?"

The device then displayed a hologram, showing one of the floorplans of the map Denko had discovered. It's quickly identified as their current floor, as a green dot appears inside one of the room outlines marked 'prison.' That must be their current location.

Jake scanned the map for their target, though with no luck. "Haywire, run text recognition and search for 'contraband research,' English please."

'Y3s s1r.'

The hologram began swapping through the various floors, scouring each piece of text for a match. Eventually, a yellow point appears on the last floor detailed on the map.

'M4tch f0und.'

"That it?" Denko inquired, approaching the hologram to have a closer look.

"Yep. Could you identify the best route to take?"

Flipping back to the floor they're on, Haywire begins to draw a continuous line through the corridors to a flight of stairs, then all the way down to the floor of their destination.

"Got it. Jake, we're gonna have to move fast. Hop on my back." Denko turns to offer Jake the chance to climb up his back, though... Wouldn't it feel a little uncomfortable? His tail extruded from near the top of his spine, it didn't extend from the bottom like most felines.

"What about your tail?...Scarf?...T-Thing?" It was odd that he never noticed it until now. Still, he stashed haywire and the guard's gun in his vest pocket and tried to climb on. Time was of the essence after all.

"It'll be fine. Hang on tight!" Jake manages to wrap his arms around Denko's torso as he squatted. Once he got a good grip, the vulpes nodded his head, giving the green light. Just like that, they were off at lightning speed.

The feeling of static amplified tenfold came roaring back, just like it had when they first embarked on this journey. Despite the familiar uncomfortableness, Jake... was confident he could power through. Denko's set aside his own comfort to accommodate the fox throughout the past few days, it's only fair he does the same.

When they came to a stop, it took longer than last time for the haze to fade. "Guh…Okay." Jake didn't want to risk anything by letting go right now, so he remained clung to the feline as he scoured for their destination. Denko approached one of the nearby doors, placed a palm flat against the metal, and exerted some electricity to trigger its opening.

"Score," he muttered under his breath, before walking in with Jake still recovering.

"Hey, we're here."

The fox glanced up to see most of the rest of his gear, stored in transparent containers save for his Oppressor, a jet bike he'd constructed a while back for fun. At that point, the vulpes was good to go, the mere sight of his equipment boosting his energy to full.

He wastes no time smashing all the containers apart and taking back his Shine-n-Spark Reflector, Infini³, Assassin's Dagger, and Ol' Reliable. "...You guys don't have electric guns, do you?"

"...Tasers, though I imagine they're nothing like that beaut of a revolver." "Ah. Yeah, that ain't nothing compared to this. Fires metal shavings at mach speeds. Effectively infinite ammo, since it's so common and uses so little at once."

Denko eyes the remaining shelves for anything that might benefit him, but decides against taking anything. It seems he's been trying to maintain a zero-kill infiltration, and it's something the cat would probably wish to uphold.

"Remember: Shoot to stun, not to kill."

Knew it-

Jake, after some hesitation to think, gave a nod and sealed off the ammo chamber, turning the lethal weapon to more of an overcharged taser. Won't be able to shoot as fast, though it was enough to remain nonlethal.

Scattered footsteps could be heard outside, prompting the both of them to enter combat ready stances. Jake spares a glance at Denko, who swiftly mirrors his gaze.

"I'll take the range, you handle the swarm," Jake spoke, sharing his plan to the cat. A nod is returned, before Denko begins to approach the shut doorway.

X.x.X

Three guards waited just outside their exit, whether their goal to restrain or kill the pair of Pokemon mattered not. Denko expects more to join the struggle either up close or from a distance, so he has to make quick work of these grunts.

Jake, hopefully, would be able to find a corner or an indentation to find cover behind. For now, though, Denko ushers the vulpes off to the side, out of view from the other side of the door..

Breathe in, breathe out.

It's showtime.

The moment the steel door slid open, Denko leapt towards his first victim. Oddly enough, missing. That's fine, that's fair, he'll just rebound and recalibrate and...

Oh shit.

The three were armed to the teeth with an element each. Electric crackles leapt from the plates of one, fiery smoke rose up from another, and the third had sandy skin and left a short trail of it.

One more heavily armored guard from behind wasted no time lunging, ice crystalizing into spikes all over their arms and shoulders. This must be the 'Elite Four' of the place. The icicle spear brushing past his side catches him off guard, allowing another to thrust a handful of sand into his face. The perpetrator then slams him onto the wall, pinning him against the cold steel.

Despite Denko's best efforts, he proved unable to escape. The realization strikes him as suddenly as the past few seconds; The one keeping him against the wall harnessed the Ground typing, rendering any powerful attack against them worthless.

"Tell us where it is!"

Before Denko could even be given a chance to answer, an electrified gunshot rings out and the guard holding onto the cat collapses onto him. Whilst everyone is stunned, 'it' takes the opportunity to reveal himself.

Slinking out from beneath the door, twirling the firearm with the stench of ozone. "Change of plans, let's Smash these guys up."

"Jake!"

Denko beamed with awe as the vulpes mirrored a determined grin back. Briefly checking the collapsed guard's pulse (they were still alive), he stances up, head down and paws raised, ready to pounce at a moment's notice.

"Out of my way." Came Jake's voice, before another blast rang out and grazed the Flame Guard, ricocheting off the wall and straight into the arm of the Ice Guard. Denko shot out a punch at the Flame Guard, then another, before finishing the brief combo with a sharp knee to their stomach, knocking them a distance away.

"Behind you!" The cat yelled out to Jake, prompting him to turn to the Electric Guard throwing a ball of electricity right at him. Without skipping a beat, he grabbed out his Reflector, held it in front, and activated it. A flickering shield of blue energy formed between Jake and the attack.

The ball of electricity rebounded off and back quickly towards the attacker, knocking them down upon hitting its mark. A brief wave of icy air sprayed at his back, nearly freezing him if it weren't for Denko interrupting, sweeping the Ice Guard's legs before sending them into the air with an electrified uppercut.

Oh, but that wasn't all. Denko then leapt up and delivered a powerful arced punch that sent them back into the ground, shattering their icicle spikes.

"Focus the fire guy!"

Jake didn't need to be told twice, ducking into their shadow to avoid a searing stream of flames and jumping out of the floor. A rending attack with both claws sent the pyromancer back into Denko's waiting fist.

One solid punch to the stomach, and they're down for the count. Denko lets their limp body fall to the side, before shaking off any flames he may have caught by committing to the blow. Afterwards, his gaze then snaps to the last elite guard, the electromancer getting back up from the reflected shock from earlier.

Seeing their powerful comrades defeated by these creatures, one wouldn't blame them for being nervous. From the look of it, they were; Shaking the instant they got back up to their feet. Both Jake and Denko stared them down, waiting for their first move.

Electro took a deep breath and charged at the feline, attempting to ram into him. Denko, instead, caught the attack and held onto their forearms with an iron grip. A growl snapped out, as his grip adjusted to wrap around his upper arms.

The guard panicked as their specialized armor began to short out, the electricity being absorbed by Denko. Perhaps he not only had an immunity, but also a harsh thirst. It wasn't long before the illuminated displays on the armguards dimmed to black.

"Now, Jake." Narrowing his eyes, Denko let go of one arm only to grab it again from behind following a quick turn. "Interrogate them."

The spectre let out a low growl, and it may have been Denko's mind playing tricks, but he swore his glasses became less transparent with every step. "Alright, wiseass." There was a click and a hum as he pressed the barrel to the soldier's neck. "'It' would like to know where 'its' ship is…" He leaned in uncomfortably close, fur flaring. "And 'its' patience has long passed zero."

Intense yellow light poured out of Jake's lenses. "Start talking."

X.x.X

The guard's blue eyes shook from his penetrating stare. Dread filled their entire being, warning of a fate worse than death if they were to not comply. "It's, uh..." They struggled to articulate, feeling the cool end of the gun's barrel pushing against their neck. Denko strengthened his grip, trying to squeeze the answer out.

"The ship... It's in the lab on the secret floor..."

The... secret floor? "Tell us how to get there," Jake growled.

"Urk-

Find the... hidden elevator where you... ah, ack! Started."

The cat strengthened his hold even more, threatening to crush the guard's bones. Denko, despite knowing a human wouldn't be able to understand him, hissed into their ear in vain. "We're not too interested in cryptic clues, just give us what we want and we'll be on our way."

As expected, the guard hadn't understood, only sparing a confused glance at the feline.

"Specifics, Asshole." Jake rumbled, in a voice thrice his size.

"The... the freight elevator! It'll take you all the way down!"

"George and I entered going down a freight elevator, it's got to be that," Denko chimed in. "I couldn't see any floor options, though."

"How do we take it down?"

"That's... urk-

That's outside my power..."

Jake huffs. "Outside your power, OUTSIDE YOUR POWER?!" He mocked. "Somehow, I find that bullshit." They were part of the strongest squad they'd faced so far, the vulpes found it hard to believe that they wouldn't have access.

"Jake," Denko spoke. Seemed he had an idea. "I could override the mechanism and get us down that way." Override... Could he do that?

Well, it's not like they had any faster options.

Jake slowly backed away, still pointing his revolver at the guard. This allowed Denko to grip around their neck and strangle them. Within a matter of seconds, they pass out, prompting the feline to lay them flat onto the floor.

"Right. Let's go, then. Haywire could probably help a bit as well…"

'1t M4y take m3 a b1t…'

Anything is better than just standing around here. Wordlessly, Jake remounts his friend and prepares for the impending minor electrocution.

"Brace yourself." Clutching Jake close, Denko stances to take off. With a deep breath, the two vanish, leaving behind electric residue, the stench of ozone, and message to the rest of the complex.

That they messed with the wrong fox.

5 notes

·

View notes

Text

Sunkaier SK3000S-Extruding Kneader Reactor

DESCRIPTION

SK3000S Kneader is ideally suited for operations involving mixing, kneading, reaction, polymerization, crystallization, compounding and heating or cooling of materials up to many million-centipoise viscosity.

SUNKAIER Kneader is a horizontal, twin screw, closed type continuous kneading/reacting processor. The Kneader has a number of recent successful accomplishments as continuous polymerization / reacting processor for engineering plastics and others. Compared to twin screw extruder, SK3000S Kneader has compact structure such as short L/D and low power while having equivalent kneading and dispersion performance and contributing to rationalization of manufacturing process and cost reduction.

SK3000S KNEADER COMBINATION

Maintaining, repairing, and servicing large extruders is crucial for ensuring optimal performance, prolonging the lifespan of the equipment, and minimizing downtime. Large extruders, such as the ones used in the production of polymers and other materials, often require specialized knowledge and tools.

PARTS FOR SK3000S KNEADER

SUNKAER reactive extruding kneader, specifically the SK3000S model, is designed to handle demanding processes that require precise and intensive mixing. The quality of the machine's components, especially the screw elements, is critical for achieving optimal performance and durability. Here's more information on the key aspects of the kneader's construction and the manufacturing process for its screw elements:

Key Components of SK3000S Reactive Extruding Kneader:

Screw Elements: The screw elements are the heart of the kneader, responsible for conveying, mixing, and reacting the materials. They are precision-machined to ensure high accuracy and reliability.

Barrel: The barrel is where the materials are processed. It is designed to withstand high temperatures and pressures. It is typically made from high-strength materials and may include heating/cooling jackets for temperature control.

Drive System: The drive system powers the rotation of the screw elements. It includes motors, gearboxes, and other components that are selected for their ability to handle the torque and speed requirements.

Controls: The kneader is equipped with sophisticated control systems to monitor and adjust process parameters such as temperature, pressure, and screw speed.

SK3000S JACKED REACTIVE EXTRUDER

The jacketed reactive extruder is an advanced piece of equipment used in polymer processing and chemical reactions where precise temperature control is essential. This type of extruder is designed with a jacket, which is a layer or casing around the barrel of the extruder that allows for heating or cooling media to be circulated through it. This feature provides better temperature control compared to non-jacketed extruders because it can manage the heat input more effectively during the extrusion process.

SPANDEX PROCESS KNEADERING REACTOR

SK3000E self-cleaning kneader reactor lab unit sounds like a specialized piece of equipment designed for use in laboratory settings, particularly for research and development purposes. This type of equipment is typically used for mixing, kneading, and reacting various materials under controlled conditions.

REACTIVE EXTRUSION KNEADER

SK3000S twin co-rotating reactive extruding kneader is a specialized piece of equipment designed for processing materials that require long residence times and intensive mixing. This type of machine is particularly useful for applications such as emulsion polymerization, where precise control over the mixing and residence time is crucial for achieving the desired product properties.

MODELS

If you have any need of equipment please contact me without hesitation, thanks.

Helena Xiao / Sales Manager

Email: [email protected]

Phone: +86 510 8758 8707

Mobile: +8618261586225

0 notes

Text

Exploring the World of Lab-Scale Plastic Extruders

Plastic extrusion is a widely used manufacturing process that involves melting raw plastic material and then shaping it into a continuous profile. While industrial-scale extruders dominate the manufacturing landscape, lab-scale extruders play a crucial role in research, development, and small-scale production. In this article, we delve into the intricacies of lab scale plastic extruder, exploring their significance, functionalities, and applications.

Understanding Lab-Scale Plastic Extruders

Lab-scale plastic extruders are compact machines designed for research laboratories, educational institutions, and small-scale production facilities. These extruders typically operate on a smaller scale compared to their industrial counterparts but offer similar functionalities. They allow researchers and engineers to experiment with different plastic materials, formulations, and processing parameters without the need for large-scale production setups.

Components of a Lab-Scale Plastic Extruder

Extrusion Barrel: This is where the raw plastic material is fed into the machine. The barrel contains a heating element to melt the plastic and a screw mechanism to push the molten material through the die.

Screw Mechanism: The screw inside the extrusion barrel plays a crucial role in plastic extrusion. It rotates and pushes the molten plastic forward while also mixing and homogenizing the material.

Die: The die is a crucial component that shapes the molten plastic into the desired profile. Lab-scale extruders often come with interchangeable dies, allowing researchers to create different shapes and sizes of extruded products.

Temperature Control System: Precise temperature control is essential in plastic extrusion to ensure the proper melting of the material and prevent degradation. Lab-scale extruders are equipped with temperature sensors and control systems to maintain optimal processing conditions.

Cooling System: After exiting the die, the extruded plastic needs to be cooled rapidly to maintain its shape. Lab-scale extruders typically have built-in cooling systems to achieve this.

Applications of Lab-Scale Plastic Extruders

Material Development: Researchers use lab-scale extruders to develop and test new plastic materials with specific properties, such as strength, flexibility, or thermal stability. By adjusting processing parameters and experimenting with different formulations, they can optimize material performance.

Prototyping: Lab-scale extruders are invaluable tools for prototyping new products or components. Engineers can quickly produce small batches of extruded parts for testing and evaluation before moving to full-scale production.

Education and Training: Educational institutions use lab-scale extruders to teach students about plastic processing techniques. Hands-on experience with these machines helps students understand the principles of extrusion and prepares them for careers in manufacturing and materials science.

Small-Scale Production: Some small businesses or research facilities use lab-scale extruders for limited production runs of specialized plastic products. These extruders offer a cost-effective solution for small-scale manufacturing without the need for large investments in industrial equipment.

Conclusion

Lab-scale plastic extruders play a vital role in research, development, and small-scale production within the plastics industry. These compact machines offer versatility, precision, and ease of use, making them indispensable tools for researchers, engineers, and educators alike. As advancements in materials science and manufacturing technology continue, the importance of lab-scale extruders in innovation and product development is expected to grow further.

0 notes

Text

This 3D printer can figure out how to print with an unknown material

New Post has been published on https://sunalei.org/news/this-3d-printer-can-figure-out-how-to-print-with-an-unknown-material/

This 3D printer can figure out how to print with an unknown material

While 3D printing has exploded in popularity, many of the plastic materials these printers use to create objects cannot be easily recycled. While new sustainable materials are emerging for use in 3D printing, they remain difficult to adopt because 3D printer settings need to be adjusted for each material, a process generally done by hand.

To print a new material from scratch, one must typically set up to 100 parameters in software that controls how the printer will extrude the material as it fabricates an object. Commonly used materials, like mass-manufactured polymers, have established sets of parameters that were perfected through tedious, trial-and-error processes.

But the properties of renewable and recyclable materials can fluctuate widely based on their composition, so fixed parameter sets are nearly impossible to create. In this case, users must come up with all these parameters by hand.

Researchers tackled this problem by developing a 3D printer that can automatically identify the parameters of an unknown material on its own.

A collaborative team from MIT’s Center for Bits and Atoms (CBA), the U.S. National Institute of Standards and Technology (NIST), and the National Center for Scientific Research in Greece (Demokritos) modified the extruder, the “heart” of a 3D printer, so it can measure the forces and flow of a material.

These data, gathered through a 20-minute test, are fed into a mathematical function that is used to automatically generate printing parameters. These parameters can be entered into off-the-shelf 3D printing software and used to print with a never-before-seen material.

The automatically generated parameters can replace about half of the parameters that typically must be tuned by hand. In a series of test prints with unique materials, including several renewable materials, the researchers showed that their method can consistently produce viable parameters.

This research could help to reduce the environmental impact of additive manufacturing, which typically relies on nonrecyclable polymers and resins derived from fossil fuels.

“In this paper, we demonstrate a method that can take all these interesting materials that are bio-based and made from various sustainable sources and show that the printer can figure out by itself how to print those materials. The goal is to make 3D printing more sustainable,” says senior author Neil Gershenfeld, who leads CBA.

His co-authors include first author Jake Read a graduate student in the CBA who led the printer development; Jonathan Seppala, a chemical engineer in the Materials Science and Engineering Division of NIST; Filippos Tourlomousis, a former CBA postdoc who now heads the Autonomous Science Lab at Demokritos; James Warren, who leads the Materials Genome Program at NIST; and Nicole Bakker, a research assistant at CBA. The research is published in the journal Integrating Materials and Manufacturing Innovation.

Shifting material properties

In fused filament fabrication (FFF), which is often used in rapid prototyping, molten polymers are extruded through a heated nozzle layer-by-layer to build a part. Software, called a slicer, provides instructions to the machine, but the slicer must be configured to work with a particular material.

Using renewable or recycled materials in an FFF 3D printer is especially challenging because there are so many variables that affect the material properties.

For instance, a bio-based polymer or resin might be composed of different mixes of plants based on the season. The properties of recycled materials also vary widely based on what is available to recycle.

“In ‘Back to the Future,’ there is a ‘Mr. Fusion’ blender where Doc just throws whatever he has into the blender and it works [as a power source for the DeLorean time machine]. That is the same idea here. Ideally, with plastics recycling, you could just shred what you have and print with it. But, with current feed-forward systems, that won’t work because if your filament changes significantly during the print, everything would break,” Read says.

To overcome these challenges, the researchers developed a 3D printer and workflow to automatically identify viable process parameters for any unknown material.

They started with a 3D printer their lab had previously developed that can capture data and provide feedback as it operates. The researchers added three instruments to the machine’s extruder that take measurements which are used to calculate parameters.

A load cell measures the pressure being exerted on the printing filament, while a feed rate sensor measures the thickness of the filament and the actual rate at which it is being fed through the printer.

“This fusion of measurement, modeling, and manufacturing is at the heart of the collaboration between NIST and CBA, as we work develop what we’ve termed ‘computational metrology,’” says Warren.

These measurements can be used to calculate the two most important, yet difficult to determine, printing parameters: flow rate and temperature. Nearly half of all print settings in standard software are related to these two parameters.

Deriving a dataset

Once they had the new instruments in place, the researchers developed a 20-minute test that generates a series of temperature and pressure readings at different flow rates. Essentially, the test involves setting the print nozzle at its hottest temperature, flowing the material through at a fixed rate, and then turning the heater off.

“It was really difficult to figure out how to make that test work. Trying to find the limits of the extruder means that you are going to break the extruder pretty often while you are testing it. The notion of turning the heater off and just passively taking measurements was the ‘aha’ moment,” says Read.

These data are entered into a function that automatically generates real parameters for the material and machine configuration, based on relative temperature and pressure inputs. The user can then enter those parameters into 3D printing software and generate instructions for the printer.

In experiments with six different materials, several of which were bio-based, the method automatically generated viable parameters that consistently led to successful prints of a complex object.

Moving forward, the researchers plan to integrate this process with 3D printing software so parameters don’t need to be entered manually. In addition, they want to enhance their workflow by incorporating a thermodynamic model of the hot end, which is the part of the printer that melts the filament.

This collaboration is now more broadly developing computational metrology, in which the output of a measurement is a predictive model rather than just a parameter. The researchers will be applying this in other areas of advanced manufacturing, as well as in expanding access to metrology.

“By developing a new method for the automatic generation of process parameters for fused filament fabrication, this study opens the door to the use of recycled and bio-based filaments that have variable and unknown behaviors. Importantly, this enhances the potential for digital manufacturing technology to utilize locally sourced sustainable materials,” says Alysia Garmulewicz, an associate professor in the Faculty of Administration and Economics at the University of Santiago in Chile who was not involved with this work.

This research is supported, in part, by the National Institute of Standards and Technology and the Center for Bits and Atoms Consortia.

0 notes

Text

This 3D printer can figure out how to print with an unknown material

New Post has been published on https://thedigitalinsider.com/this-3d-printer-can-figure-out-how-to-print-with-an-unknown-material/

This 3D printer can figure out how to print with an unknown material

While 3D printing has exploded in popularity, many of the plastic materials these printers use to create objects cannot be easily recycled. While new sustainable materials are emerging for use in 3D printing, they remain difficult to adopt because 3D printer settings need to be adjusted for each material, a process generally done by hand.

To print a new material from scratch, one must typically set up to 100 parameters in software that controls how the printer will extrude the material as it fabricates an object. Commonly used materials, like mass-manufactured polymers, have established sets of parameters that were perfected through tedious, trial-and-error processes.

But the properties of renewable and recyclable materials can fluctuate widely based on their composition, so fixed parameter sets are nearly impossible to create. In this case, users must come up with all these parameters by hand.

Researchers tackled this problem by developing a 3D printer that can automatically identify the parameters of an unknown material on its own.

A collaborative team from MIT’s Center for Bits and Atoms (CBA), the U.S. National Institute of Standards and Technology (NIST), and the National Center for Scientific Research in Greece (Demokritos) modified the extruder, the “heart” of a 3D printer, so it can measure the forces and flow of a material.

These data, gathered through a 20-minute test, are fed into a mathematical function that is used to automatically generate printing parameters. These parameters can be entered into off-the-shelf 3D printing software and used to print with a never-before-seen material.

The automatically generated parameters can replace about half of the parameters that typically must be tuned by hand. In a series of test prints with unique materials, including several renewable materials, the researchers showed that their method can consistently produce viable parameters.

This research could help to reduce the environmental impact of additive manufacturing, which typically relies on nonrecyclable polymers and resins derived from fossil fuels.

“In this paper, we demonstrate a method that can take all these interesting materials that are bio-based and made from various sustainable sources and show that the printer can figure out by itself how to print those materials. The goal is to make 3D printing more sustainable,” says senior author Neil Gershenfeld, who leads CBA.

His co-authors include first author Jake Read a graduate student in the CBA who led the printer development; Jonathan Seppala, a chemical engineer in the Materials Science and Engineering Division of NIST; Filippos Tourlomousis, a former CBA postdoc who now heads the Autonomous Science Lab at Demokritos; James Warren, who leads the Materials Genome Program at NIST; and Nicole Bakker, a research assistant at CBA. The research is published in the journal Integrating Materials and Manufacturing Innovation.

Shifting material properties

In fused filament fabrication (FFF), which is often used in rapid prototyping, molten polymers are extruded through a heated nozzle layer-by-layer to build a part. Software, called a slicer, provides instructions to the machine, but the slicer must be configured to work with a particular material.

Using renewable or recycled materials in an FFF 3D printer is especially challenging because there are so many variables that affect the material properties.

For instance, a bio-based polymer or resin might be composed of different mixes of plants based on the season. The properties of recycled materials also vary widely based on what is available to recycle.

“In ‘Back to the Future,’ there is a ‘Mr. Fusion’ blender where Doc just throws whatever he has into the blender and it works [as a power source for the DeLorean time machine]. That is the same idea here. Ideally, with plastics recycling, you could just shred what you have and print with it. But, with current feed-forward systems, that won’t work because if your filament changes significantly during the print, everything would break,” Read says.

To overcome these challenges, the researchers developed a 3D printer and workflow to automatically identify viable process parameters for any unknown material.

They started with a 3D printer their lab had previously developed that can capture data and provide feedback as it operates. The researchers added three instruments to the machine’s extruder that take measurements which are used to calculate parameters.

A load cell measures the pressure being exerted on the printing filament, while a feed rate sensor measures the thickness of the filament and the actual rate at which it is being fed through the printer.

“This fusion of measurement, modeling, and manufacturing is at the heart of the collaboration between NIST and CBA, as we work develop what we’ve termed ‘computational metrology,’” says Warren.

These measurements can be used to calculate the two most important, yet difficult to determine, printing parameters: flow rate and temperature. Nearly half of all print settings in standard software are related to these two parameters.

Deriving a dataset

Once they had the new instruments in place, the researchers developed a 20-minute test that generates a series of temperature and pressure readings at different flow rates. Essentially, the test involves setting the print nozzle at its hottest temperature, flowing the material through at a fixed rate, and then turning the heater off.

“It was really difficult to figure out how to make that test work. Trying to find the limits of the extruder means that you are going to break the extruder pretty often while you are testing it. The notion of turning the heater off and just passively taking measurements was the ‘aha’ moment,” says Read.

These data are entered into a function that automatically generates real parameters for the material and machine configuration, based on relative temperature and pressure inputs. The user can then enter those parameters into 3D printing software and generate instructions for the printer.

In experiments with six different materials, several of which were bio-based, the method automatically generated viable parameters that consistently led to successful prints of a complex object.

Moving forward, the researchers plan to integrate this process with 3D printing software so parameters don’t need to be entered manually. In addition, they want to enhance their workflow by incorporating a thermodynamic model of the hot end, which is the part of the printer that melts the filament.

This collaboration is now more broadly developing computational metrology, in which the output of a measurement is a predictive model rather than just a parameter. The researchers will be applying this in other areas of advanced manufacturing, as well as in expanding access to metrology.

“By developing a new method for the automatic generation of process parameters for fused filament fabrication, this study opens the door to the use of recycled and bio-based filaments that have variable and unknown behaviors. Importantly, this enhances the potential for digital manufacturing technology to utilize locally sourced sustainable materials,” says Alysia Garmulewicz, an associate professor in the Faculty of Administration and Economics at the University of Santiago in Chile who was not involved with this work.

This research is supported, in part, by the National Institute of Standards and Technology and the Center for Bits and Atoms Consortia.

#3-D printing#3d#3D printing#additive manufacturing#Administration#atoms#Capture#cell#Center for Bits and Atoms#chemical#Collaboration#collaborative#Composition#data#development#Economics#Engineer#engineering#Environmental#environmental impact#Fabrication#Faculty#fossil#Fossil fuels#fuels#Fusion#Future#genome#Greece#hand

0 notes

Text

Best Food 3D printers

Introduction

3D food printing is a fairly new technology that creates intricate and customized food items. From personalized candy to elaborate chocolate sculptures, 3D food printers have the prospects to revolutionize the way we think about food production.

In this article, we will discuss the 10 best food 3D printers currently available on the market.

What is a Food 3D Printer?

A 3D printer is printing some chocolates. Image source: Imaginarium

A food 3D printer is a machine that uses food-grade materials, such as chocolate, cheese, dough, and pureed fruits and vegetables, to create detailed and specialized food items.

These machines typically work by depositing layers of food material in precise patterns, building up the food item layer by layer.

This process allows for the creation of a wide range of food items with complex designs and shapes that would otherwise be difficult or impossible to achieve with traditional food preparation methods.

Food 3D printers are used in a variety of settings, including professional kitchens, research labs, and even at home. They are becoming increasingly popular in the culinary industry as they allow chefs to create unique and personalized dishes that can impress customers.

10 Best Food 3D Printers

Natural Machines Foodini

Natural Machines Foodini 3D printer. Image source: DigitalFoodLab

The Natural Machines Foodini is a versatile 3D food printer that can create various foods, including pasta, chocolate, and even burgers.

The machine utilizes fresh ingredients, allowing for the creation of healthy and natural foods.

Advantages:

Diverse Ingredient Compatibility: Works with a wide range of food materials, including vegetables, meats, and dough.

Can create complex shapes and designs

Artistic Freedom: Allows users to create intricate and customized chocolate designs

Disadvantages:

Expensive, with a price tag of around $5,000

The Choc Edge Chocolate 3D Printer

The Choc Edge Chocolate 3D Printer is printing the chocolate. Image source: Medium

The Choc Edge Chocolate 3D Printer is specifically designed for printing chocolate.

The machine features a precision chocolate extruder and a heated build plate that helps make detailed and intricate chocolate designs. The printer also comes with a range of pre-loaded patterns and the ability to import custom designs.

Advantages:

Chocolate Specialization: This printer is dedicated to chocolate printing, ensuring high-quality and artistic chocolate creations..

Ease of Use: Offers a straightforward and user-friendly experience for chocolate enthusiasts.

Professional Results: Known for producing professional-grade chocolate items with precision.

Disadvantages:

Limited to just chocolate printing

Expensive, with a price tag of around $4,000

The byFlow Focus

The byFlow focus is printing the chocolates. Image source: byFlow

The byFlow Focus is a compact and portable 3D food printer that can make a wide variety of foods.

The machine features a precision food extruder and a heated build plate that permits detailed and complicated food designs to be created. The printer also comes with a range of pre-loaded plans and the ability to import custom designs.

Advantages:

Portability: Its portable and compact design makes it easy to transport and set up for various culinary events and locations.

Versatility: Offers versatility in printing various food types, from savory to sweet dishes.

User-Friendly Interface: Features an intuitive interface that simplifies the food printing process.

Disadvantages:

Expensive, with a price tag of around $5,000

The ChefJet Pro

The ChefJet Pro is a professional-grade 3D food printer that can make numerous foods, including candy, chocolate, and even sugar.

The machine features a precision food extruder and a heated build plate that enables the production of detailed and exciting food designs. The printer also comes with a range of pre-loaded methods and the ability to import custom designs.

Advantages:

Professional Culinary Tool: Designed for professional chefs and confectioners, it meets high culinary standards.

Intricate Sugar Creations: Can create complex sugar decorations and designs, adding a touch of artistry to desserts.

Reliable Performance: Known for its consistency and reliability in producing high-quality edible designs.

Disadvantages:

Expensive, with a price tag of around $5,000

The 3D Solutech Food Printer

The 3D Solutech Food Printer is a budget-friendly 3D food printer that can create several foods.

The machine features a precision food extruder and a heated build plate, supporting the development of detailed and ornate food designs. The printer also comes with a range of pre-loaded strategies and the ability to import custom designs.

Advantages:

An affordable price tag of around $1,000

Affordable Entry Point: Provides an affordable option for experimenting with food printing, making it accessible to more users.

Compact Design: Its compact size makes it easy to fit into smaller kitchens or workspaces.

Versatile Printing: Offers versatility in terms of the types of food materials it can work with, allowing for experimentation.

Disadvantages:

Limited in terms of the types of food it can print

Not as high quality as more expensive models

The 3D Systems Culinary Lab

The 3D Systems Culinary Lab is a professional-grade 3D food printer that can be used to create a wide variety of foods, including pasta, chocolate, and even ice cream.

The machine features a precision food extruder and a heated build plate that aids in making thorough and attractive food designs. The printer also comes with a range of pre-loaded designs and the ability to import custom designs.

Advantages:

Professional Grade: Backed by 3D Systems' reputation and technology, it's suitable for professional culinary applications.

Advanced Features: Offers advanced features and capabilities for chefs and culinary experts.

Diverse Material Compatibility: Can handle a wide range of food materials, enabling experimentation and creativity.

Disadvantages:

Expensive, with a price tag of around $10,000

Not as versatile as other models

The Foodini Plus

The Foodini Plus is an advanced 3D food printer that can create a wide variety of foods, including pasta, chocolate, and even burgers.

The machine utilizes fresh ingredients, resulting in preparing healthy and natural foods. One of the major advantages of the Foodini Plus is its ability to print complex shapes and designs with ease. The machine also features a user-friendly interface, making it smooth to operate for both professional and home chefs.

Advantages:

Ingredient Compatibility: It can work with a wide range of ingredients, including fruits, vegetables, and dough, offering culinary versatility.

Convenience: Streamlines the food preparation process, saving time and effort in the kitchen.

Healthy Options: Encourages the use of fresh and natural ingredients for healthier food choices.

Disadvantages:

Expensive, with a price tag of around $7,000

The Choc Creator V2 Pro

The Choc Creator V2 Pro is a professional-grade 3D chocolate printer that can make fancy and detailed chocolate designs.

The machine features a precision chocolate extruder and a heated build plate that brings forth high-quality chocolate sculptures. The printer also comes with a range of pre-loaded designs and the ability to import custom designs.

Advantages:

Chocolate Specialization: This printer is designed specifically for chocolate printing, ensuring high-quality chocolate creations.

Artistic Freedom: It provides users with the freedom to create intricate and artistic chocolate designs.

Precision: Offers precise control over the chocolate material, resulting in detailed and professional chocolate items.

Durability: Built to withstand the demands of chocolate printing, ensuring longevity.

Disadvantages:

Limited to just chocolate printing

Expensive, with a price tag of around $6,000

The 3D Food Printer

The 3D Food Printer is a budget-friendly 3D food printer that can create various foods. The machine features a precision food extruder and a heated build plate, allowing for the creation of attractive and complex food designs.

The printer also comes with a range of pre-loaded designs and the ability to import custom designs.

Advantages:

An affordable price tag of around $500

Simplicity: Known for its ease of operation, this 3D food printer is suitable for beginners in food printing.

Speed: The printer can produce food items relatively quickly, saving time in food preparation.

Reliability: Users can rely on consistent performance for their food printing needs.

Disadvantages:

Limited in terms of the types of food it can print

Not as high quality as more expensive models

The Print2 Taste FoodJet Pro

The Print2Taste FoodJet Pro is a professional-grade 3D food printer that can develop several foods, including pasta, chocolate, and even ice cream.

The machine features a precision food extruder and a heated build plate that produce attractive and delicate food designs. The printer also comes with a range of pre-loaded designs and the ability to import custom designs.

Advantages:

Precision Printing: The FoodJet Pro offers precise control over food materials, allowing for intricate and accurate designs.

Customization: Users can create personalized food designs, making it ideal for culinary professionals and special events.

Versatile Ingredients: It can work with a variety of ingredients, from sweet to savory, expanding its culinary possibilities.

Ease of Use: The interface is user-friendly, making it accessible to a wide range of users.

Disadvantages:

Expensive, with a price tag of around $8,000

Not as versatile as other models

Overall, 3D food printers have the potential to revolutionize the way we think about food production. They offer the ability to make elaborate and customized food items, from personalized candy to complex chocolate sculptures.

However, it's important to note that these printers are currently quite expensive, with most models priced in the thousands of dollars.

Additionally, many of these printers are limited in terms of the types of food they can print, and some models may not be suitable for home use.

SelfCAD is a 3D modeling and printing software. It is designed to be user-friendly and accessible, particularly for those new to 3D modeling software. It also comes with an in-built online slicer to help users to prepare 3D models for 3D printing, all within a single software environment. Get to know how to slice 3D designs in SelfCAD in the video below.

youtube

Conclusion

3D food printers are an exciting new technology that can potentially change food production methods. They are not economical, and some models are restricted in the food they can print.

However, if you're a professional chef or a food enthusiast with a passion for innovation, a 3D food printer could be the perfect addition to your kitchen.

purchasing decisions.

1 note

·

View note

Text

Berlin Week 3: Lab Work Gets Intense

By Ilyana Smith, Aerospace Engineering major

This week in Berlin has been an intense week of classes. Every day this week started with German class, followed by an afternoon of lab work. My German skills are definitely improving, and I've learned more about polymer manufacturing than I ever thought possible. The 3-4 hour labs in the afternoons have been a lot, but they've also taught me so much.

Polymer Identification

On Monday, we learned how to identify polymers based on their properties. This involved dropping them on the ground, putting them into a bucket of water, and even burning them! It was very cool to see how we could puzzle out what polymer a sample was made out of through just a few physical tests. And then it was humbling when, after about an hour of hard work, we put the samples into a spectrometry machine which identified the polymer with utter certainty in only a few seconds.

When PVC is melted onto a copper wire, it produces a green flame when heated. This is because PVC contains chlorine, a halogen.

Extrusion

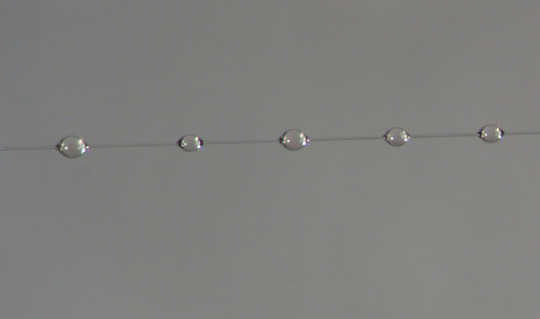

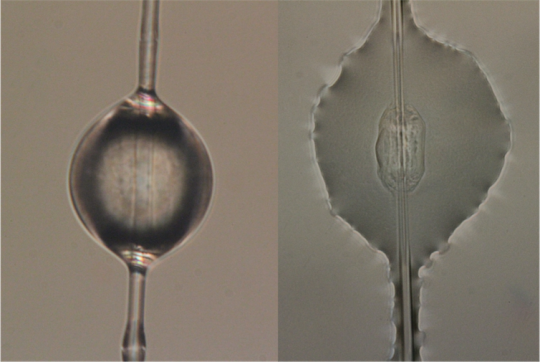

One of the major methods of polymer manufacturing is extrusion, which involves pushing a molten polymer through a small hole to create a long stream of material. The extrusion mechanism is actually fairly complex, and it involves using a long screw to compress and melt the polymer before pushing it through the die that helps define the final shape. Since the polymer doesn't like being compressed, though, it actually expands slightly when it leaves the die, so we did an experiment to measure the "die swell" of the extruded polymer. That is to say, we measured how thick the stream of material was and compared that to the diameter of the hole the material was extruded from.

Clear polymer is extruded from an extruder. You can see that once it cools in the water bath, it turns white/opaque. This is due to crystals forming.

Injection Molding

Yesterday, we learned about injection molding, which is the biggest method for mass-manufacturing of polymer products. It has high initial costs, but if you're making a lot of a product, those costs are worth the high speed and very low cost per manufactured part. Injection molding machines are very simple in principle, but because they often deal with very high pressures, they tend to be very complex and expensive. We got to watch an injection molder in action, and it was very cool to see how easily it produces many parts consistently and quickly.

Additive Manufacturing

Today, we learned about 3D printing and additive manufacturing. Compared with the conventional manufacturing methods we learned about earlier in the week, there are a lot of benefits to 3D printing in the form of waste reduction and the ability to produce more complex parts. However, the downside is that 3D printing is a comparatively slow process and is not cost-effective for producing many, many parts.

Overall

This week, the lab class really kicked into high gear, and we started really getting into the weeds of how polymers are processed and manufactured. It's been a lot of work but also a lot of learning, and I'm excited to keep diving into everything else there is to learn!

Thanks for reading! I look forward to sharing more with you soon!

This is the Engineering Laboratory Experience at TUB in Berlin, Germany

0 notes

Text

The Role of Precision in the Performance of China Lab Extruder Machines

The precision of the China lab extruder machine is a topic of significant interest, as it directly impacts the efficiency and effectiveness of the extrusion process. These machines are designed to transform raw materials into finished products with a high degree of accuracy and consistency, a process that is vital for the quality of the end product.

The China lab extruder machine is engineered to provide a controlled environment for the extrusion process, ensuring that the material is heated, shaped, and cooled uniformly. This precision is achieved through a combination of advanced mechanical design, temperature control systems, and automation technology. The machine's ability to maintain a consistent temperature profile across the barrel and die is crucial for the uniformity of the extrudate.

One of the primary factors contributing to the precision of the China lab extruder machine is its robust construction. The use of high-quality materials in the construction of the barrel, screws, and dies ensures that the machine can withstand the high pressures and temperatures associated with the extrusion process. This durability is essential for maintaining the machine's performance over time, as wear and tear can significantly impact the precision of the extrusion process.

The control systems of the China lab extruder machine are another critical aspect of its precision. Modern machines are equipped with sophisticated software that allows for precise control of the extrusion parameters, such as temperature, pressure, and screw speed. These controls are essential for achieving the desired output in terms of shape, size, and surface finish. The software also allows for real-time monitoring and adjustments, ensuring that any deviations from the desired parameters can be quickly corrected.

The precision of the China lab extruder machine is also influenced by the quality of the components used in its construction. High-precision bearings, for example, are essential for ensuring that the screws rotate smoothly and consistently, which is crucial for the uniform mixing and melting of the material. Similarly, the quality of the die used in the extrusion process can significantly impact the precision of the final product. A well-designed die will ensure that the material is extruded with distortion or variation.