#china high quality custom cnc turning parts

Explore tagged Tumblr posts

Text

Maintenance Tips for Your CNC Turning Machine by MechPlus China

As a leading CNC turning machine manufacturing, MechPlus China understands the importance of proper maintenance to ensure precision and efficiency. Regular upkeep not only extends the machine's lifespan but also maximizes productivity and quality. Here are essential maintenance tips from MechPlus China to keep your CNC turning machine running smoothly and efficiently.

Keeping your CNC turning machine in top condition is crucial for optimal performance. Regular maintenance not only extends the machine's lifespan but also ensures precision and efficiency in your operations. Here are essential maintenance tips to keep your CNC turning machine running smoothly.

Daily Inspection and Cleaning

Start each day with a thorough inspection of your CNC turning machine. Check for any signs of wear and tear, and ensure all components are in good working order. Clean the machine daily to remove any debris, chips, and coolant residue. This prevents buildup that can affect performance and accuracy.

Lubrication

Proper lubrication is vital for the smooth operation of your CNC turning machine. Lubricate all moving parts as recommended by the manufacturer. This includes the spindle, guideways, and ball screws. Regular lubrication reduces friction, prevents wear, and extends the machine’s life.

Coolant Maintenance

Maintaining the coolant system is essential for the longevity of your CNC machine. Regularly check the coolant level and concentration. Replace or refill the coolant as needed. Also, clean the coolant tank and filters to avoid contamination that can damage the machine and workpieces.

Alignment and Calibration

Ensure that your CNC turning machine is properly aligned and calibrated. Misalignment can lead to inaccuracies in your machining processes. Regularly check and adjust the machine’s alignment and calibration according to the manufacturer’s guidelines. This ensures precision in your operations.

Check Electrical Components

Inspect the electrical components of your CNC turning machine regularly. Look for any loose connections, worn-out wires, or faulty switches. Address any electrical issues immediately to prevent machine downtime and potential safety hazards.

Monitor Machine Vibration

Excessive vibration can lead to poor machining quality and damage to your CNC turning machine. Monitor the machine for any unusual vibrations or noises during operation. Identify and address the source of the vibration to maintain optimal performance.

Regular Software Updates

Keep your CNC machine’s software up to date. Manufacturers often release updates that improve functionality and fix bugs. Regularly updating the software ensures your machine operates efficiently and takes advantage of the latest technological advancements.

Tool Maintenance

Regularly inspect and maintain the cutting tools used in your CNC turning machine. Sharp and well-maintained tools are crucial for high-quality machining. Replace worn or damaged tools promptly to ensure precise and efficient operation.

Preventive Maintenance Schedule

Implement a preventive maintenance schedule for your quick response machining tool. Follow the manufacturer’s recommended maintenance intervals for all components. Regular preventive maintenance helps identify potential issues before they become major problems, reducing downtime and repair costs.

Training and Safety

Ensure that all operators are properly trained in the maintenance and operation of the CNC turning machine. Regular training updates and adherence to safety protocols are crucial for preventing accidents and ensuring smooth operations.

Document Maintenance Activities

Keep detailed records of all maintenance activities performed on your CNC turning machine. Documenting maintenance helps track the machine’s condition over time and provides valuable information for troubleshooting and repairs with all types of customized machining parts.

In conclusion, regular maintenance of your CNC turning machine is essential for its longevity and performance. By following these tips, you can ensure your machine operates efficiently, reducing downtime and improving the quality of your machining processes. Implement these maintenance practices to keep your CNC turning machine in optimal condition.

#Prototyping solutions#SLA Rapid Prototyping manufacturing#SLS Rapid machining manufacturing#5 Axis CNC machining manufacturing#3D metal printing manufacturing

2 notes

·

View notes

Text

Custom cnc aluminium turning parts in china

At Hsmolds.net, discover precision-engineered custom CNC aluminum turning parts in china tailored to your specifications. Our China-based facility employs cutting-edge technology and skilled craftsmanship to deliver high-quality components for diverse industries. With a commitment to excellence and efficiency, we ensure prompt delivery and competitive pricing. Experience superior performance and reliability with our custom CNC aluminum turning parts, visit Hsmolds.net today.

0 notes

Text

Top Aluminum CNC Machining Service in China

Aluminum CNC machining is a procedure that uses computer numerical control (CNC) machines to produce accurate and complicated Aluminum components. With technological improvements, the demand for high-quality Aluminum parts has skyrocketed. As a result, several Chinese enterprises are providing aluminium CNC machining services to suit the expanding demand.

China has quickly emerged as a top provider of CNC machining services because to its trained labor, superior technology, and cost-effective solutions. This has made it a popular choice for businesses wishing to outsource their CNC machining requirements. Aluminum CNC machining services provide a numerous benefits, including quick turnaround times, competitive pricing, and high-quality goods.

Our Aluminum CNC Machining Capabilities

We specialise in a variety of Aluminum CNC machining services, such as milling, turning, drilling, tapping, and more. Whether you need prototypes, small batches, or large-scale production runs, we can handle projects of any size or complexity. Our staff uses cutting-edge CNC machining equipment to enable quick turnarounds without sacrificing quality.

Benefits of Aluminum CNC Machining

Aluminum is regarded as being lightweight, sturdy, and corrosion-resistant, making it an excellent material for a variety of applications. Aluminium CNC machining allows you to make parts and components that are robust, reliable, and visually appealing. Additionally, aluminum is a cost-effective option that offers excellent thermal conductivity, making it suitable for various industries.

One of the primary benefits of choosing aluminium CNC machining services in China is the country's extensive network of suppliers and manufacturers. This provides organisations with access to a diverse choice of aluminium materials and machining techniques, guaranteeing that they can discover the optimum solution for their individual requirements. Furthermore, Chinese manufacturers are known for their meticulous attention to detail and precision, which ensures that the finished items satisfy the highest standards.

Another advantage of using Aluminum CNC machining Service is cost reduction. The country's competitive labor market and lower production costs result in lower prices for customers. China offers a cost-effective manufacturing choice without sacrificing quality.

In conclusion, Aluminum CNC Machining Service in China offers high-quality precision machining for aluminum parts. With state-of-the-art equipment and experienced technicians, we can produce custom aluminum components with tight tolerances and excellent surface finishes. Whether you need prototypes or large production runs, our CNC machining service can meet your specific requirements efficiently and cost-effectively. Trust us to deliver top-notch aluminum parts that meet your exact specifications and exceed your expectations.

0 notes

Text

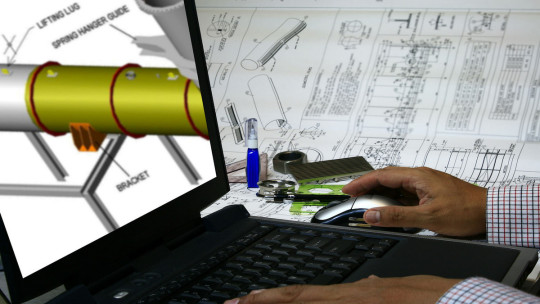

Subtractive Manufacturing Mastery: CNC's Role in Rapid Prototyping

Many innovators and manufacturers turn to rapid prototyping to speed up product development. Through subtractive manufacturing, these professionals can streamline their time to market without compromising the strength and quality of their parts. This fast-evolving technology delivers CNC machined parts and helps businesses cut manufacturing and development costs.

Subtractive manufacturing is set to drive the growth of the rapid prototyping market by 14.9% from 2022 to 2031, with the aerospace industry likely being the largest contributor. Moreover, the increased availability of CNC machining services in China should encourage more industries to adopt and benefit from this rapid prototyping solution. Continue reading to learn more about CNC machining’s role in rapid prototyping.

A great way to make physical models

CNC machining is a subtractive manufacturing solution that helps manufacturers, product engineers, production planners, and designers make a tangible model, prototype, or sample of their product. These professionals can save time and money by using CNC machined parts to test and review their products in the real world.

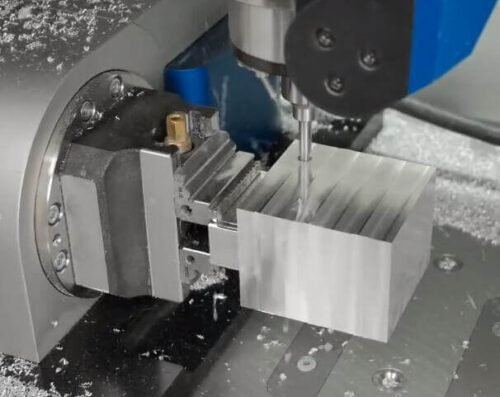

Subtractive manufacturing creates a prototype by removing material from a block or billet of metal or plastic. That said, the process is fully automatic and computer-controlled, making it more reliable and capable of delivering results faster than hand-carving and other manual processes. Some service providers can even reduce lead times to 4 business days with CNC machining.

Ensuring accurate, high-quality parts

Rapid prototyping with CNC machining delivers robust, high-precision parts, especially when service providers apply industry-standard tolerances. The best CNC machined parts are controlled to DIN-2768-1 Medium for plastics and Fine for metals to ensure accurate-to-CAD results. In addition, manufacturers use the latest and proven equipment and tools, such as sink and wire EDMs, CNC mills, and surface grinding machines, to deliver CNC milling and turning solutions.

How it benefits rapid prototyping

CNC machining supports rapid prototyping because of the following reasons:

Quick and repeatable, making it ideal for low-volume manufacturing.

Delivers on high tolerance and precise specifications.

Service providers offer a wide range of rapid prototyping materials.

Master CNC machining with the experts

Learn more about subtractive manufacturing and get high-quality CNC machined parts from the experts at HLH Proto. The rapid prototyping and low-volume manufacturing company has extensive experience in providing custom solutions to various industries, including automotive, aerospace, electronics, industrial automation, robotics, oil and gas, and medical. Request a quote now to see how they can help your next project!

0 notes

Text

https://www.advancemarketanalytics.com/reports/61827-global-flame-cutting-machines-market

Flame Cutting Machines Market Growth Prospect: Is the tide Turning?

Advance Market Analytics released a new market study on Global Flame Cutting Machines Market Research report which presents a complete assessment of the Market and contains a future trend, current growth factors, attentive opinions, facts, and industry validated market data. The research study provides estimates for Global Flame Cutting Machines Forecast till 2029*.

Flame cutting is a thermal cutting process that uses oxygen and a fuel source to create a flame with enough energy to melt and sever material. The process is a thermo-chemical Process requiring a source of intense heat, referred to as “Preheatâ€, and pure oxygen. There are various types of flame cutting machines available for different cutting applications in different industries such as automotive, aerospace, etc. CNC machines are the most widely used machines in advanced countries like China, Japan, Korea, etc. for cutting of the metal sheet for applications ranging from airplane parts to domestic household products.

Key Players included in the Research Coverage of Flame Cutting Machines Market are:

Messer Group (Germany), Koike Group (Japan), Mass Cutting Systems (India), BUG-O SYSTEMS (United States), ARCBRO Ltd. (China), Soitaab Impianti S.r.l. (Italy), SteelTailor (China), Technocrats Plasma Systems Private Limited (India), Th. Wortelboer B.V. (Netherlands), Shanghai Huawei Welding & Cutting Machine (China),

What's Trending in Market: Fully Integrated Oxy-Fuel Cutting System with Cutting Torch, Ignition, Height Sensing and Lifter All in One Package

Challenges: Reduction in Cutting Speed owing to Improper Connections, Bad Hoses, or Leaks Stringent Government Regulation for Safety of Labours

Opportunities: Fast-growing industries like automotive have fuelled the growth opportunities of sheet metalworking in numerous applications in car bodies, airplane wings, medical tables, roofs for buildings and many other things. Automatic and Cost-Effective Machine to Produce High-Quality Products at much Cheaper Rates

Market Growth Drivers: An increasing number of applications in the automotive and aerospace industry owing to high precision, accuracy, and reliability, is the key driving factor for the growth of the market. Growing Number of Manufacturing and Production Activities for High Volume Production in Emerging Economies Low Equipment Cost and No Power Supplies Needed

The Global Flame Cutting Machines Market segments and Market Data Break Down by Type (Manual Flame Cutting Machines, Semi-automatic Flame Cutting Machines, Automatic Flame Cutting Machines, CNC Flame Cutting Machines, Imitation Shape Flame Cutting Machines), Application (Metal Cutting, Glass & Ceramics Cutting, Others), End-User (Automotive, Aerospace & Defence, Construction, Marine, Electronics, Others), Fuel Type (Acetylene, MAPP, Propylene, Propane, Natural Gas)

Get inside Scoop of the report, request for free sample @: https://www.advancemarketanalytics.com/sample-report/61827-global-flame-cutting-machines-market

To comprehend Global Flame Cutting Machines market dynamics in the world mainly, the worldwide Flame Cutting Machines market is analyzed across major global regions. AMA also provides customized specific regional and country-level reports for the following areas.

• North America: United States, Canada, and Mexico.

• South & Central America: Argentina, Chile, Colombia and Brazil.

• Middle East & Africa: Saudi Arabia, United Arab Emirates, Israel, Turkey, Egypt and South Africa.

• Europe: United Kingdom, France, Italy, Germany, Spain, Belgium, Netherlands and Russia.

• Asia-Pacific: India, China, Japan, South Korea, Indonesia, Malaysia, Singapore, and Australia.

0 notes

Text

MxmParts, a trusted CNC machining parts supplier from China, specializes in offering a comprehensive Swiss Type CNC Machining service for precision machine parts. With advanced CNC lathes such as combination Mill Turn CNC and Swiss type CNC lathe, MxmParts provides a wide range of precision machining capabilities, ensuring the production of small and large machined parts with the highest level of accuracy. MxmParts offers the machining of various materials, including but not limited to steel and brass, through their precision CNC turning service. Their commitment to crafting parts that meet the highest standards ensures that customers receive quality machined parts that align with their specifications. The Swiss Type CNC Machining service by MxmParts caters to industries requiring precision machine parts, including but not limited to automotive, aerospace, medical, and electronics. Through their expertise in precision CNC turning, MxmParts serves as a reliable supplier for companies seeking high-quality machined parts for diverse applications. For further details and inquiries about the Swiss Type CNC Machining service for precision machine parts, provided by MxmParts from China, you can visit their official website at [mxmparts.com](https://www.mxmparts.com/) or get in touch with them directly through their contact information. For more information, MxmParts can be reached at [[email protected]](mailto:[email protected]). Using ChatG : Unlimited AI Chatbot Entire Chat Link: www.brutusai.com/c/ycAzPJnaPSYTCODnfnvTy004sZu1/064a4be4-3010-4718-b874-4204f94d9709

#Swiss Type CNC machining China#china supplier#cnc turning#CNC parts China#precision CNC Turning parts#precision machine parts#precision turned parts#precision CNC machining#precision CNC Turning#mxmparts#turned parts#custom parts#china turned parts#cnc turned parts#china steel parts#steel Parts machining#ball Studs

0 notes

Text

Look For CNC Machining Metal Materials

As an advanced CNC metal machining manufacturer in Guangdong, China, Flourish Legend is committed to providing high-quality and precision custom parts and component solutions. With years of experience and excellent technical capabilities, we can machine various metal materials, including aluminum, stainless steel, brass, steel, copper, titanium, and more. These materials are widely used in various industries, including automotive manufacturing, electronic devices, medical instruments, aerospace, and more.

Types of CNC Metal Materials Available

CNC Machining Aluminium

Flourish Legend specializes in CNC machining of aluminum alloys. With advanced technology and precision equipment, we ensure high precision and stringent quality standards in manufacturing complex aluminum alloy parts and meeting your fine machining requirements. We strive to deliver premium and durable aluminum alloy products that meet your highest expectations.

CNC Machining Stainless Steel

CNC machining stainless steel can provide precision products for various industries, the durability, corrosion resistance and aesthetics of stainless steel products make them the first choice in industries such as aerospace, automotive and medical. Use CNC technology to meet complex designs and tight tolerances, create complex product shapes, and improve product performance while maintaining the inherent strength and longevity of the material.

CNC Machining Tool Steels

CNC machining of tool steel enables high-precision part manufacturing. With its excellent hardness, wear resistance and heat resistance, tool steel is widely used in fields such as molds, knives and mechanical parts. CNC machining technology ensures the consistency of precision design and tight tolerances to manufacture components such as blades and molds. This process enables the fabrication of complex shapes, improving performance and reliability in harsh environments while maintaining the strength and durability of the material. Whether in the automotive, aerospace or manufacturing industries, CNC machining of tool steels provides the key support for the production of high-quality parts.

0 notes

Text

CNC Manufacturing in the Medical Industry

CNC Manufacturing in the Medical Industry

In the medical industry, CNC manufacturing is essential for the creation of customized products. Many of these products are disposable and are intended to prevent the spread of infectious diseases. These installations also require speed, precision, and large volumes of production. This type of manufacturing is capable of creating a variety of parts for different medical devices. Here are some of the benefits of CNC machining. Read on to discover how this type of manufacturing can benefit your business.

Oil and gas fields, which require precise machining applications, can benefit from CNC machining. Historically, manufacturing in this sector has required large amounts of equipment, expensive labor, and relevant experience. CNC machining allows for much more flexibility in product manufacturing than was previously possible with traditional methods. After providing quality raw materials and instructions, CNC machining can produce the exact product. Ultimately, this technology saves money and time while ensuring quality and accuracy. CNC manufacturing provides many advantages for the American manufacturing sector. While manufacturing is no longer the backbone of the American economy, this sector remains strong in many areas. The rush to globalize may have overlooked the benefits of using a CNC manufacturing company in the United States. With oil prices at their lowest levels in many years, the allure of manufacturing cheap products in China has become a less appealing option for foreign buyers. As a result, the cost of CNC manufacturing is a valuable tool in your business's competitiveness. CNC machining is also useful for military parts. These components must be durable, long-lasting, and secret, which makes them particularly sensitive. If a part is not made properly, it may lead to serious delays and risks. The quick turn around time of CNC machining makes CNC manufacturing an excellent choice for military parts. Further, the military sector can be more efficient because of the precision and quality of the parts it needs. In addition to being more effective for military equipment, it also allows the military to use the most up-to-date technology and best homeland protection. CNC machining is an increasingly popular method of manufacturing. The automation of CNC manufacturing has removed many barriers to product design. Companies are able to produce complex, customized pieces with exceptional accuracy. Some industries are reliant on CNC machining for their products, while others are more likely to opt for mass production. The benefits of CNC machining are numerous. As mentioned, it has several advantages over traditional methods. Aside from the obvious benefits, CNC machining can cut off a lot of the oil and gas industry. Aerospace components are highly durable, but they also have to be constructed to exact specifications. Even a slight error can cause significant wear and drag, and even catch on air currents. To address these challenges, the aerospace industry uses high-strength, extra-durability materials. While these materials vary in composition, many of the most common raw materials used in CNC machining are metals and alloys. The aerospace industry uses many types of aluminum in its production processes. Bates Machine &Mfg. can help you with your manufacturing needs. Read the full article

0 notes

Text

PEEK material is a new type of semi-crystalline aromatic plastic engineering plastics, with extremely good physical and mechanical properties, in many special areas can replace metals, ceramics and other traditional materials, in reducing the quality, improving the performance of outstanding contribution to become one of today's most popular high-performance engineering plastics. PEEK material's high-temperature thermal performance is very outstanding, can be used for a long time at 260 ℃, instantaneous use Temperature of up to 300 ℃; its rigidity, dimensional stability, the coefficient of linear expansion is small, close to the metal aluminum materials.

What are The Advantages of PEEK CNC Machining?

◆ High-temperature resistance

The United States UL certification long-term use temperature of 260 ℃.

◆ Self-lubricating

With a low coefficient of friction, it can work without oil lubrication and can work in oil, water, weak acid and alkali medium for a long time.

◆ High strength

It has the best mechanical strength among plastics. It also has high rigidity and surface hardness.

◆ Corrosion resistance

It is insoluble in common solvents and has good corrosion resistance to various organic and inorganic chemical reagents.

◆ Abrasion resistance

It has excellent wear resistance in many extremely harsh environments such as high temperatures, high load and strong corrosion.

◆ Hydrolysis resistance

◆ Easy processing

Parts can be processed directly by an injection molding process. Post-processing such as turning, milling, drilling, tapping and ultrasonic welding can be performed.

◆ Flame retardant

◆ Low smoke and non-toxic

◆ Radiation resistance

It has excellent resistance to high dose γ-ray radiation, and the mechanical properties can be retained intact, so it can be used as radiation-resistant parts in nuclear equipment.

Electrical performance

◆ Dimensional stability

Features of PEEK Non-standard Parts

1. Resistance to dissolution.

2. Both toughness and rigidity.

3. High temperature, high frequency and high voltage electrical performance conditions.

4. Corrosion resistance, anti-aging.

5. Resistance to hydrolysis, high temperature and high pressure can still maintain excellent characteristics.

6. Irradiation resistance wear and corrosion resistance conditions;

7. Resistance to abrasion, anti-static electrical insulation properties;

8. Low soot and toxic gas emissions.

9. Lightweight instead of metal for fiber optic components.

10. Size requirements for precision conditions;

11. Mechanical strength requirements of high components

0 notes

Text

China Maijin

ShenZhen MaiJin Metal Works Co., Ltd. was founded in 2006. We have built up a good reputation for quality, service and reliability. With highly trained our sales people, experienced technical sales engineers and customer focus management systems, we have achieved the stable sales record at the forefront of our industry in providing high quality products and services to our customers.

cnc turned parts manufacturer

0 notes

Text

Cnc Turning Service

Aerospace CNC Machining - Prototool.com

Aluminium Turning We provide state-of-the-art CNC machining & Injection molding service. Our respective clients provide us with the product design idea along with the preferred material. The rest of the work is done by our experts. We buy quality material, refine the client’s designs, machining the product, and then deliver the finished product to the customer. We are also the market-leading CNC and injection molding material suppliers as well. We are an affiliate of First Part China Limited. Aluminum Cnc Machining

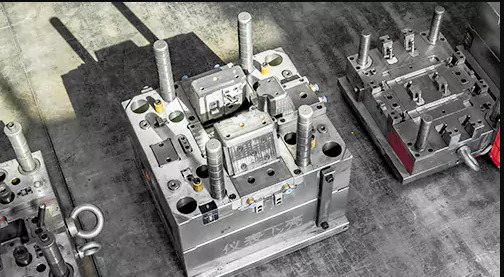

Machining Process of Injection Mold Parts Such as Core, Insert, Lifter and Slide

Aluminum Mold Making Part craftsmen typically provide mold design job books based on molded part task books. To assure the logic and consistency of the mold manufacturing process, optimize the processing process, and improve mold manufacturing progress, each mold factory normally develops a process standard fit for its factory, including using unique injection mold parts. Prototool.com

This article will discuss common injection mold parts, their applications, and things to consider when employing them throughout a factory’s machining process. Cnc Machining Services

The Most Suitable Metal Materials for your CNC Machined Parts

Material selection is essential to any manufacturing process, but engineers and CNC machining service providers must be extremely careful regarding CNC machined parts.

Because this procedure is suitable for a wide range of materials — from metal to fiberglass to wood — it’s easy to select an adequate material but not optimal for the job. However, you may want to select the best metal material for your CNC machining project. Cnc Milling Service

This blog will review several critical considerations to help you choose the best metal material for CNC machined parts.

Designing Top-Quality Plastic Molded Parts: 7 Proven Tips

Cnc Plastic Machining Thousands of designers create injection molded parts. However, a select group in this big community can create parts for injection molders. Before all parts are completely recorded and handed to molders for manufacturing, injection molded product design goes through many development stages. The last stage of development is essential since design adjustments or corrections can no longer be performed without dramatically raising expenses or project delays. So, how can you

ensure that your plastic molded parts are perfectly designed? Here’s a detailed guide on effectively designing the parts.

Material Selection and Its Implications:

Cnc Rapid Prototyping Materials are typically specified early in the design process, and both parties must agree. Molders can sometimes get large amounts of specialized resins at steep savings. Customers can benefit from these offers. For example, a designer can save tens of thousands of dollars if they select an ABS grade that matches the ABS grade that molders buy in bulk. Prototool.com

Due to viscosity, high glass content, or crystallinity, designers may discover that certain high-performance resins are not suited for molders. Resins can be chosen for certain physical or chemical resistance qualities. However, they can be difficult to mold and keep to specified tolerances. Molders must adhere to the prescribed resin and integral part specifications to mold the part. Cnc Turning Service

The Most Common Types of Machining Services and Processes

Consumer Electronics Manufacturers Machining services are crucial in manufacturing, as they shape and transform raw materials into finished products. Various machining services are available, each with its unique set of benefits and applications. From milling to drilling and turning, machining methods have revolutionized how products are made. This article will explore the seven most common types of machining methods, their advantages, and the industries that use them.

Understanding these services will help businesses determine the best machining processes for their manufacturing needs.

This article will discuss the seven different machining services and how they are conducted in the plastic injection molding/manufacturing industry. High Volume Manufacturing

Prior Materials Preparation and Pre-Molding Considerations for Effective Plastics Injection Molding

High-volume Production In plastics injection molding, the work done to prepare the mold before adding material to it and molding plastic to make a product is of critical importance. It includes evaluating and setting up for a wide variety of processes, such as material processing performance inspection (determination of plastic fluidity, moisture content, etc.); dyeing and granulating of raw materials before processing; preheating and drying of granules; cleaning and preheating of inserts; mold testing and cylinder cleaning, etc.; and so on. Prototool.com

Having a sound comprehension of all the procedures involved and commencing with the appropriate strategy to evaluate and prepare the material is crucial for ensuring the effectiveness of the plastic injection molding process. Now, in the event that you are uninformed of what occurs before the use of high-tech machinery, the phase of mold

inserting, and the phase of production form, let’s go ahead and investigate many aspects of preparing the production setup before formally beginning the production process.

Injection mold China

4-Axis CNC – The Various Features and Important Details about It

4-axis CNC machines are advanced versions of 3-axis CNC centers that have revolutionized the field of workpiece shaping. With the installation of the fourth axis, these machines have significantly enhanced the quality of machining. Injection Molding Manufacturers

A 4-axis CNC machine has four axes, which allows it to perform intricate operations such as milling, turning, drilling, and more. This multi-tasking capability allows the machines to perform multiple jobs simultaneously. In this comprehensive guide, we will explore the features and capabilities of 4-axis CNC machines to provide you with a complete understanding of their capabilities. Injection Molding Services

More Information - https://prototool.com/

0 notes

Text

Cnc Turning Service

Aerospace CNC Machining - Prototool.com

Aluminium Turning We provide state-of-the-art CNC machining & Injection molding service. Our respective clients provide us with the product design idea along with the preferred material. The rest of the work is done by our experts. We buy quality material, refine the client’s designs, machining the product, and then deliver the finished product to the customer. We are also the market-leading CNC and injection molding material suppliers as well. We are an affiliate of First Part China Limited. Aluminum Cnc Machining

Machining Process of Injection Mold Parts Such as Core, Insert, Lifter and Slide

Aluminum Mold Making Part craftsmen typically provide mold design job books based on molded part task books. To assure the logic and consistency of the mold manufacturing process, optimize the processing process, and improve mold manufacturing progress, each mold factory normally develops a process standard fit for its factory, including using unique injection mold parts. Prototool.com

This article will discuss common injection mold parts, their applications, and things to consider when employing them throughout a factory’s machining process. Cnc Machining Services

The Most Suitable Metal Materials for your CNC Machined Parts

Material selection is essential to any manufacturing process, but engineers and CNC machining service providers must be extremely careful regarding CNC machined parts.

Because this procedure is suitable for a wide range of materials — from metal to fiberglass to wood — it’s easy to select an adequate material but not optimal for the job. However, you may want to select the best metal material for your CNC machining project. Cnc Milling Service

This blog will review several critical considerations to help you choose the best metal material for CNC machined parts.

Designing Top-Quality Plastic Molded Parts: 7 Proven Tips

Cnc Plastic Machining Thousands of designers create injection molded parts. However, a select group in this big community can create parts for injection molders. Before all parts are completely recorded and handed to molders for manufacturing, injection molded product design goes through many development stages. The last stage of development is essential since design adjustments or corrections can no longer be performed without dramatically raising expenses or project delays. So, how can you ensure that your plastic molded parts are perfectly designed? Here’s a detailed guide on effectively designing the parts.

Material Selection and Its Implications:

Cnc Rapid Prototyping Materials are typically specified early in the design process, and both parties must agree. Molders can sometimes get large amounts of specialized resins at steep savings. Customers can benefit from these offers. For example, a designer can save tens of thousands of dollars if they select an ABS grade that matches the ABS grade that molders buy in bulk. Prototool.com

Due to viscosity, high glass content, or crystallinity, designers may discover that certain high-performance resins are not suited for molders. Resins can be chosen for certain physical or chemical resistance qualities. However, they can be difficult to mold and keep to specified tolerances. Molders must adhere to the prescribed resin and integral part specifications to mold the part. Cnc Turning Service

The Most Common Types of Machining Services and Processes

Consumer Electronics Manufacturers Machining services are crucial in manufacturing, as they shape and transform raw materials into finished products. Various machining services are available, each with its unique set of benefits and applications. From milling to drilling and turning, machining methods have revolutionized how products are made. This article will explore the seven most common types of machining methods, their advantages, and the industries that use them. Understanding these services will help businesses determine the best machining processes for their manufacturing needs.

This article will discuss the seven different machining services and how they are conducted in the plastic injection molding/manufacturing industry. High Volume Manufacturing

Prior Materials Preparation and Pre-Molding Considerations for Effective Plastics Injection Molding

High-volume Production In plastics injection molding, the work done to prepare the mold before adding material to it and molding plastic to make a product is of critical importance. It includes evaluating and setting up for a wide variety of processes, such as material processing performance inspection (determination of plastic fluidity, moisture content, etc.); dyeing and granulating of raw materials before processing; preheating and drying of granules; cleaning and preheating of inserts; mold testing and cylinder cleaning, etc.; and so on. Prototool.com

Having a sound comprehension of all the procedures involved and commencing with the appropriate strategy to evaluate and prepare the material is crucial for ensuring the effectiveness of the plastic injection molding process. Now, in the event that you are uninformed of what occurs before the use of high-tech machinery, the phase of mold inserting, and the phase of production form, let’s go ahead and investigate many aspects of preparing the production setup before formally beginning the production process. Injection mold China

4-Axis CNC – The Various Features and Important Details about It

4-axis CNC machines are advanced versions of 3-axis CNC centers that have revolutionized the field of workpiece shaping. With the installation of the fourth axis, these machines have significantly enhanced the quality of machining. Injection Molding Manufacturers

A 4-axis CNC machine has four axes, which allows it to perform intricate operations such as milling, turning, drilling, and more. This multi-tasking capability allows the machines to perform multiple jobs simultaneously. In this comprehensive guide, we will explore the features and capabilities of 4-axis CNC machines to provide you with a complete understanding of their capabilities. Injection Molding Services

More Information - https://prototool.com/

0 notes

Text

Learn out more about the various types of spindle motors.

Changzhou Troy Machinery & Electric Co., Ltd. was established in 1998 and has since become a market leader in high-speed spindle motor design, production, and distribution.

We continually invest in new, cutting-edge production and testing equipment to make sure that our products are of the greatest calibre. Because of our cutting-edge technology and reliable quality, we have gained the trust of customers both domestically and internationally. Our “WHD” brand name is gaining popularity.

CNC routers, engraving machines, drilling machines, edge banding machines, and other related devices frequently use products from our STZ, STF, STM, STL, and STX family. In addition, we may create unique spindle motors based on the demands of our clients.

Air-cooled spindle motor

The spindle motors used in hard disc drives (HDDs) turn the HDD discs. These parts are crucial to the performance of HDDs since the accuracy of these motors impacts HDD capacity and speed. These motors therefore need to perform very well in terms of rotational speed and Non-Repeatable Run Out (NRRO).

Air-cooled spindle motors include, among others:

1. Square spindle motor: For all of your routing and engraving needs, WHD offers a selection of High-Speed Air Cooled Spindle Motors, including Round CNC Spindle Motors, Square CNC Spindle Motors, and CNC Spindle Motors with Flanges. For more than 20 years, WHD spindle motors have been shipped to the US, Europe, Brazil, India, Russia, and other nations.

2. Spindler motor with an electric fan: WHD provides a range of High-Speed Air Cooled Spindle Motors for CNC engraving and CNC wood routing applications, including CNC Spindle Motors with Flanges, Square CNC Spindle Motors, and Round CNC Spindle Motors.Brazil, India, Russia, the United States, and other nations across the world have all received WHD spindle motor exports.

3. Spindle motor with flange: For CNC engraving and CNC wood routing applications, WHD offers a variety of High-Speed Air Cooled Spindle Motors, including Round CNC Spindle Motors, Square CNC Spindle Motors, and CNC Spindle Motors with Flanges. Brazil, India, Russia, the United States, and other nations across the world have all received WHD spindle motor exports.

Water-cooled spindle motor

An electromechanical assembly known as an electric spindle consists of a motor, a spindle shaft with bearings, and a tool holder of some sort. It might also include cooling features.

Water-cooled spindle motors include, among others:

Wood/plastic spindle motor: WHD, one of China’s top spindle motor manufacturers, has over 20 years of experience manufacturing and selling Water Cooled Spindle motors for many CNC applications industries. In addition to other countries, our spindle motors have now been exported to the United States, Europe, Brazil, India, and Russia.

2. A stone spindle motor: Being one of China’s top manufacturers of spindle motors, WHD has more than 20 years of experience producing and providing water-cooled spindle motors for numerous CNC applications industries. In addition to other countries, our spindle motors have now been exported to the United States, Europe, Brazil, India, and Russia. The STZ140–11-ER32 model has a power output of 11.0kW, a diameter of 140 mm, a speed of 24 rpm, a voltage of 380V, a current output of 20.9A, a frequency output of 100–800Hz, and many other features.

3. Metal spindle motor: Being one of China’s top spindle motor manufacturers, WHD has more than 20 years of experience producing and selling Water Cooled Spindle motors for various CNC applications industries.

0 notes

Text

The importance of metal machining in CNC manufacturing

Metal machining is a critical aspect of CNC (Computer Numeric Control) manufacturing and has a significant impact on the overall production process. This technique involves shaping and cutting metal materials into specific shapes and sizes to produce high-quality, accurate parts and components for a wide range of industries. Here you will get a guide from Xielifeng Tech.

Precision

One of the biggest and prime advantages of machining is its precision and repeatability. CNC machines are equipped with advanced technology that enables them to produce parts with a high degree of accuracy, which is essential for many industries, including aerospace, medical, and automotive. The machines also can repeat the same process multiple times, ensuring consistent quality and reducing waste.

Versatility

In addition to precision, it offers versatility in terms of the types of materials that can be used. The process can be applied to a wide range of metal materials, including steel, aluminum, and brass, among others. This versatility allows manufacturers to produce parts that meet specific requirements, such as strength, durability, and resistance to corrosion or wear.

Moreover, this is also cost-effective. CNC machines are highly automated, which reduces the need for manual labor and increases efficiency. This, in turn, reduces production costs, making it a cost-effective solution for many manufacturers.

Metal machining is an essential aspect of CNC manufacturing. It offers precision, versatility, and cost-effectiveness, making it an ideal solution for many industries. Whether you are producing parts for aerospace, medical, or automotive applications, it can help you achieve your production goals and ensure that your customers receive high-quality products. If you wish to meet the best CNC machining company in China, consider taking the services of Xielifeng Tech.

0 notes

Text

Spindle Motor.

Since its establishing in 1998, Changzhou Troy Hardware and Electric Co., Ltd. has been an imaginative forerunner in the plan, assembling, and circulation of Rapid Spindle Motors.

To guarantee that our items are of the greatest quality, we are continually putting resources into new, best in class apparatus for creation and testing. Clients both at home and abroad have come to trust us in light of our state of the art innovation and reliable quality. Our “WHD” image is turning out to be progressively notable.

Items from our STZ, STF, STM, STL, and STX series are generally found in CNC routers, etching machines, boring machines, edge banding machines, and other comparable gadgets. Moreover, we can make custom axle engines to meet our client’s particular necessities. We have traded our items everywhere, including to the US, Russia, Europe, India, Brazil, Iran, and numerous different nations, all for the sake of keeping up with our organization’s fundamental belief of putting the client first.

A spindle is a slight, adjusted bar with tightening closes that is utilized close by turning to bend and twist string from a mass of fleece or flax carried on a distaff.

Spindle grinding machine

High requests are regularly made on the mathematical resistances of the workpiece surface while crushing. Thus, crushing machine shafts are ordinarily developed with models for a base position change of the crushing circles inferable from outer powers and twisting minutes.

ATC — Automatic Tool Change Spindler Motor: — Shaft ATC The engine can utilize a few instruments consequently. Water Cooled 5.5 kW ATC Shaft, Water Cooled 7.5 kW ATC Axle, and Air Cooled 9.0 kW ATC Shaft are accessible from WHD. WHD offers Fast Air-Cooled Axle engines for CNC etching and CNC wood directing, with north of 20 years of involvement with making and providing shaft engines. WHD spindle engines have been sent to the US, Europe, Brazil, India, and Russia, among different spots.

ATC — Automatic Tool Change Spindle motor: — ATC represents Programmed Apparatus Change Shaft Engine. The ATC Spindle Motor can utilize a few devices naturally. WHD gives Water Cooled 5.5 kW ATC Spindle, Water Cooled 7.5 kW ATC Spindle, and Air Cooled 9.0 kW ATC Spindle are the accessible choices. WHD offers Fast Air-Cooled Axle engines for CNC etching and CNC wood directing, with more than 20 years of involvement with making and providing shaft engines. WHD Spindle engines have been delivered to the US, Europe, Brazil, India, and Russia, among different spots. A portion of its applications are carpentry, plastic acrylic, and light metal etchings like Aluminum and copper. Other data is that installment terms are T/T, Shanghai, China is the stacking port, Froth Box in Container Box Major areas of strength for with Across Container Box.

Air-cooled Spindle engine

Hard Circle Drive (HDD) axle engines are liable for the turn of HDD plates. Since the accuracy of these engines decides HDD limit and speed, these parts are mean quite a bit to HDD execution. Subsequently, these engines should give excellent execution regarding rotational speed and Non-Repeatable Run Out (NRRO).

A portion of the air-cooled shaft engines are:

1. Square Spindle engine: — WHD offers an assortment of Rapid Air Cooled Spindle Engines for CNC etching and CNC wood directing, including Round CNC Spindle Engines, Square CNC Shaft Engines, and CNC Spindle Engines with Spines, for all of your steering and etching needs. WHD axle engines have been sent out to the US, Europe, Brazil, India, Russia, and different nations across the world for more than 20 years.

2. Spindler motor with an electric fan: — WHD offers an assortment of Fast Air Cooled Shaft Engines for CNC etching and CNC wood directing applications, including Round CNC spindle Engines, Square CNC spindle Engines, and CNC spindle Engines with Ribs. WHD shaft engines have been traded to the US, Europe, Brazil, India, Russia, and different nations across the world.

3. Shaft motor with rib: — WHD offers an assortment of Rapid Air Cooled Shaft Engines for CNC etching and CNC wood steering applications, including Round CNC Shaft Engines, Square CNC Axle Engines, and CNC Axle Engines with Spines. WHD shaft engines have been traded to the US, Europe, Brazil, India, Russia, and different nations across the world.

Water-cooled Spindle engine

An electric Spindle is an electromechanical get together that incorporates an engine, an axle shaft and course, and an instrument holder of some sort. It might likewise have cooling arrangements.

A portion of the water-cooled shaft engines are:

1. Spindle motor for wood/plastic: — WHD has more than 20 years of skill in making and providing Water Cooled Shaft engines for different CNC applications fields as one of China’s driving Axle Engine producers. Our shaft engines have now been sent out to the US, Europe, Brazil, India, and Russia, among different spots.

2. Spindle motor for stone: — WHD has more than 20 years of ability in making and providing Water Cooled Shaft engines for different CNC applications fields as one of China’s driving Shaft Engine producers. Our axle engines have now been traded to the US, Europe, Brazil, India, and Russia, among different spots. The model is STZ140–11-ER32, the power is 11.0kW, the measurement is 140 mm, the speed is 24rpm, the voltage is 380V, the current is 20.9A, the recurrence is 100–800Hz and a lot more elements.

3. Spindle motor for metal: — WHD has north of 20 years of mastery in making and providing Water Cooled Axle engines for different CNC applications fields as one of China’s driving Shaft Engine producers. Our shaft engines have now been traded to the US, Europe, Brazil, India, and Russia, among different spots. The model is STM62–24Z/0.8, the power is 0.8kW, the width is 62mm, the speed is 24000rpm, the voltage is 220V, the current is 2.5A, the recurrence is 400Hz, and a lot more highlights.

Spindle motor

An edge bander is a machine that consequently makes enriching edges on boards and sheets. The machine cuts the edge of the wood and afterward sticks to beautiful edge strips or different materials with glue.

1. Edge banding spindle engine: — — WHD offers an assortment of Fast Air-Cooled spindle Engines for CNC etching and CNC wood directing applications, including Round CNC spindle motor, Square CNC spindle Engines, and CNC Axle Engines with Spines. WHD shaft engines have been sent out to the US, Europe, Brazil, India, Russia, and different nations across the world. The model is STFB40–63–12Z-0.75, the power is 0.75kW, the speed is 12000–18000rpm, the voltage is 380V/220V, the current is 1.75/3.0A, the recurrence is 200–300Hz, and a lot more elements.

2. Spindle motor customized: — . WHD offers High velocity Air-Cooled Shaft engines for CNC etching and CNC wood directing, with more than 20 years of involvement with making and providing axle engines. WHD axle engines have been delivered to the US, Europe, Brazil, India, and Russia, among different spots. A portion of its applications are carpentry, plastic acrylic, and light metal etchings like Aluminum and copper. Other data is that installment terms are T/T, Shanghai, China is the stacking port, Froth Box in Container Box Areas of strength for with Across Container Box. The model is STL70–24Z-9.0L-ER32, the power is 9.0kW, the speed is 12000–24000rpm, the voltage is 380V, the current is 18.2A, the recurrence is 800Hz, and a lot more highlights.

While settling on and setting up new items we go through nitty gritty preparation, elaborate plan, and steady support, and the items are handled by the item master. We even have corporate recordings on YouTube for more data.

0 notes

Text

CNC Precision Automatic Lathe

There are more than 10 professional international sales here to support your program. We cover both personal projects and large-scale business needs. We offer our customers a good service based on our quality oriented personnel modern production equipment, innovative methods, integrated operations. Atlas metal is here to support you on metal hardware by your request.

Specifications of CNC Precision Automatic Lathe

Micro Machining or not Micro Machining Material Capabilities Aluminium, Brass, Bronze, Copper, Hardened Metals, Stainless Steel, St Material Aluminium alloy Process CNC machining centre Model of Number Customized Place of Origin Guang Dong, China Tolerance 0.01-0.05mm MOQ 1 OEM/ODM OEM ODM CNC Milling Turning Machining Service Keyword CNC Machining Parts Colour Customized Color Size Customized Certificate ISO9001:2015 Surface Finish Anodized

0 notes