#cad design automation

Explore tagged Tumblr posts

Text

Revolutionizing data-driven construction with Scan to BIM

Scan to BIM is reshaping how we capture and utilize construction data. Moving away from outdated surveying methods, this technology-driven approach focuses on precision, efficiency, and enhanced project outcomes. By leveraging the latest in 3D laser scanning, Scan to BIM allows construction professionals to gather and process detailed point cloud data with ease, creating accurate 3D and 2D models that bring clarity to complex projects.

Gone are the days of manual measurements and traditional surveying techniques. With Scan to BIM, field data is captured through advanced scanning technology, enabling the creation of accurate as-built models. This data provides a solid foundation for architects, engineers, and construction teams, helping them understand existing structures down to the smallest detail. The precision of 3D laser scanning supports the creation of reliable models that are integral to the design and planning phases.

Collecting field data has always been a challenging task, particularly with older equipment that can be cumbersome and time-consuming. nCircle’s Scan to BIM services simplify this process, allowing for faster, more intricate 3D model generation. This innovative workflow not only accelerates data collection but also ensures higher levels of accuracy, giving construction professionals confidence in the information they’re working with.

By facilitating the creation of as-built models with unmatched precision, Scan to BIM supports improved documentation and streamlined project management. Within the Architecture, Engineering, and Construction (AEC) industry, this technology provides a clear advantage, enhancing workflow efficiency and project representation. To dive deeper into the benefits and applications of Scan to BIM, read our latest article.

0 notes

Text

nCircle Tech is transforming CAD design automation in India.

It is more important than ever to find effective and creative design solutions in the quickly changing field of technology. nCircle Tech, a trailblazing Indian business at the forefront of CAD design automation, is spearheading this change. nCircle Tech is revolutionizing the design process by utilizing state-of-the-art technology and a thorough understanding of the industry to make design processes faster, more precise, and highly efficient.

In fields like engineering, manufacturing, and architecture, computer-aided design, or CAD, has long been a mainstay. It enables experts to produce intricate 2D and 3D models of their projects. But the conventional method of CAD design can be laborious and prone to human error, particularly for intricate projects that demand painstaking attention to detail. In this situation, nCircle Tech can help by providing cutting-edge CAD automation solutions that greatly expedite the design process.

With the automation tools from nCircle Tech, designers may spend more time on creativity and innovation and less time on tedious activities. Project completion is accelerated and accuracy is improved with nCircle Tech's automation of repetitive tasks including draughting, modeling, and rendering. This shortens the product's time to market and improves the design's overall quality.

Furthermore, nCircle Tech's solutions are very adaptable and can be tailored to meet the unique requirements of various sectors. nCircle Tech offers specialized solutions that are customized to meet the particular needs of each project, whether it is automating the design of intricate mechanical components or optimizing architectural draughting.

Businesses like nCircle Tech are essential in propelling India's continued rise to prominence as a global leader in innovation and technology. nCircle Tech is revolutionizing CAD design automation to help organizations remain competitive in an increasingly digital environment while establishing new benchmarks for productivity and design quality.

0 notes

Text

Revolutionizing Manufacturing: Discovering the Game-Changing Advantages of CAD Automation for Companies

Introduction

In the dynamic landscape of modern manufacturing, the integration of advanced technologies is reshaping the way companies operate. One such transformative technology is Computer-Aided Design (CAD) automation. CAD automation refers to the use of computer software and algorithms to streamline and optimize the design and drafting processes in manufacturing. In this blog post, we will delve into the myriad benefits that CAD automation brings to manufacturing companies, from enhanced productivity to improved product quality.

1. Increased Efficiency in Design Iterations

Traditionally, manual drafting processes in design can be time-consuming and prone to errors. CAD automation revolutionizes this aspect by providing a platform for rapid prototyping and design iterations. Engineers and designers can make quick changes to a digital model, test variations, and explore multiple design options effortlessly. This iterative process not only accelerates the design phase but also allows for the exploration of more innovative and efficient solutions.

2. Time and Cost Savings

Time is money, and CAD automation is a potent tool for saving both. The efficiency gained through automated design processes significantly reduces the time required to bring a product from conception to production. Moreover, as design iterations become quicker and more accurate, the overall development cycle is shortened. This time compression results in substantial cost savings, making manufacturing processes more cost-effective and competitive.

3. Precision and Accuracy

Manual drafting is inherently susceptible to human errors, which can lead to costly mistakes during the manufacturing phase. CAD automation, on the other hand, ensures a high level of precision and accuracy in design. Measurements and specifications are consistently maintained, minimizing the risk of errors in the final product. This not only improves product quality but also reduces the likelihood of defects and the need for rework.

4. Seamless Collaboration and Communication

CAD automation facilitates seamless collaboration among multidisciplinary teams involved in the product development process. Designers, engineers, and other stakeholders can work on the same digital model in real time, fostering effective communication and coordination. This level of collaboration ensures that everyone is on the same page throughout the design process, reducing misunderstandings and enhancing overall project efficiency.

5. Enhanced Product Lifecycle Management (PLM)

CAD automation integrates seamlessly with Product Lifecycle Management (PLM) systems, providing a comprehensive solution for managing the entire lifecycle of a product. From initial design and prototyping to manufacturing, distribution, and maintenance, CAD automation ensures that all aspects of the product's lifecycle are interconnected and efficiently managed. This holistic approach improves traceability, reduces time-to-market, and optimizes resource utilization.

6. Adaptability to Customization

In today's manufacturing landscape, customization is becoming increasingly important to meet diverse customer demands. CAD automation empowers manufacturing companies to easily customize products without significant disruptions to the production process. Whether it's adapting a design for a specific client requirement or making quick adjustments to respond to market trends, CAD automation enables manufacturers to be agile and responsive.

Conclusion

The benefits of CAD automation for manufacturing companies are profound and multifaceted. From accelerated design iterations and significant time and cost savings to enhanced precision and adaptability, the integration of CAD automation technology is a game-changer. As manufacturing continues to evolve, companies that embrace these advancements position themselves at the forefront of innovation, setting the stage for a more efficient, competitive, and sustainable future.

#CAD Automation#Manufacturing Design#Machine Design#Manufacturing Companies#CAD Services#CAD Design Automation#CAD Design

0 notes

Text

Below are the 3 simple steps to understand how the procedure of 3D Scanning & Reverse Engineering works.

➡️ The client provides the physical components, Parts, or share detailed picture for our teams for examination. ➡️ We perform a laser scan of the component and extract cloud point data to our systems. ➡️ Using this data, our team generates a 2D or 3D CAD model for use in product enhancement. This may include failure analysis, reproduction, general study, inspection, or application for a new product or design.

3D Scanning and Reverse Engineering both are not the same, they both are two different technologies but they are so much perfect when work together.

For more details, Call us on 📞 +91 9574 024 279 Mail us at [email protected] or Visit: https://www.designautomations.com/

#designautomation#design#automation#designautomationservices#engineering#engineeringservices#3dscanning#reverseengineering#designing#failureanalysis#automationservices#cad#3dcad#reverseengineeringindia#designautomationindia

1 note

·

View note

Text

HOW CAD AUTOMATION TOOLS STREAMLINE WORKFLOW & BOOSTS PRODUCTIVITY

Discover the transformative impact of CAD Automation in simplifying intricate design tasks and enhancing the overall quality of your final product.

Read our latest article to explore how CAD Automation tools are revolutionizing workflows, reducing errors, and optimizing productivity.

0 notes

Text

Can ChatGPT Automate AutoCAD Based on AI Voice Input?

In recent years, the field of artificial intelligence (AI) has made remarkable advancements, revolutionizing various industries. One area that has seen significant transformation is computer-aided design (CAD) and drafting. AutoCAD, a widely used software for 2D and 3D design and drafting, has become a staple tool for architects, engineers, and designers. With the emergence of AI voice…

View On WordPress

#AI models#AI voice input#artificial intelligence#AutoCAD#automation#CAD#Chatgpt#computer-aided design#design workflow#drafting#efficiency#future of automation#integration#precise measurements#productivity#third-party solutions#voice commands#voice recognition technology#voice-driven interface

1 note

·

View note

Text

Designing and manufacturing custom doors is a complex task due to the bespoke design needs of customers. Technological advancements, such as design automation using visual CAD configurators, have accelerated design development time for custom doors. These configurators simplify door design customization and generate accurate manufacturing drawings faster. Read the full article.

0 notes

Text

Randee Butrus, the Mechanical Designer & CAD Specialist

Randee Butrus is a highly skilled mechanical designer and CAD expert, with years of experience in the field. With a keen eye for detail and a passion for innovative solutions, she has built a reputation as one of the top designers in the industry. Randee's expertise extends across a wide range of projects, from small-scale components to complex industrial machinery, and she is known for her ability to work closely with clients to bring their ideas to life.

0 notes

Text

Scan to BIM: 日本におけるデータ駆動型建設の革命

Scan to BIMサービスによる革新は、日本の建設業界に新しい時代をもたらしています。従来の測量による計測はもはや過去のものであり、今では自動化された先進技術であるScan to BIMがその役割を担っています。このワークフローを活用することで、正確な3Dモデルや2Dモデル���作成され、既存の建物の「アズビルト」3Dモデルの作成に必要な詳細情報が得られます。この戦略的なプロセスを支えるのが、3Dレーザースキャニングの最新技術です。

現場データを従来の測量機器で収集するのは非常に難しい作業ですが、nCircleのScan to BIMサービスでは、最新の3Dスキャン技術を駆使して複雑な3Dモデルを迅速に作成することが可能です。

Scan to BIMは、既存構造物の「アズビルト」モデルの作成プロセスを迅速化し、精度を最大限に高めます。これにより、AEC(建築・エンジニアリング・建設)分野におけるプロジェクトとワークフローの文書化と表現が向上します。詳しくはブログをご覧ください。

さらに、Scan to BIMはプロジェクトの初期段階からの情報共有を促進し、関係者間のコラボレーションを強化します。リアルタイムで更新されるデータを基にした意思決定が可能となるため、設計の修正や工事の進捗状況を迅速に把握できるようになります。このように、Scan to BIMはプロジェクトの透明性を高め、リスクの軽減にも寄与します。

最後に、Scan to BIMは持続可能な建設プラクティスをサポートする重要なツールでもあります。正確なデータを提供することで、無駄のない資源管理や効率的な施工方法が実現され、環境への影響を最小限に抑えることが可能です。日本の建設業界における持続可能性の向上を目指すために、Scan to BIMの導入は不可欠です。

#cad design automation#archicad#ncircletech#japan#power bi reporting#revit automation#bim dimensions#scantobim

0 notes

Text

nCircle Tech: Revolutionizing CAD Design Automation for Efficiency

Efficiency is critical in the fast-paced fields of engineering and design. The speed and accuracy with which CAD models may be created, edited, and managed has a big impact on project schedules and overall productivity. Now enter nCircle Tech, a leader in CAD design automation, providing cutting-edge solutions that are revolutionizing the workflow of designers and engineers.

CAD Design Automation's Necessity

Draughting, detailing, and updating models are examples of repetitive operations that are frequently involved in traditional CAD design processes. These manual procedures may take a long time and are prone to mistakes, which can cause delays and higher expenses. It is not only convenient, but also essential to automate these processes in a competitive business where speed and accuracy are critical.

nCircle Tech: Setting the Standard

By streamlining these tedious operations, nCircle Tech's sophisticated CAD design automation technologies free up engineers and designers to work on more intricate and imaginative project components. nCircle Tech's solutions automate normal procedures to minimize errors, improve accuracy, and save a substantial amount of time compared to manual tasks.

The seamless integration of nCircle Tech's CAD design automation with pre-existing CAD software is one of its most notable advantages. Whether you use SolidWorks, AutoCAD, or another well-known platform, nCircle Tech's solutions are made to improve your workflow without necessitating a whole rebuild of your present setup.

CAD Design Automation's advantages

There are many advantages to using nCircle Tech's CAD design automation. Projects can be finished more quickly, for less money, and with fewer mistakes. Increased productivity from efficiency improvements enables businesses to take on more projects and raise their bottom line.

Conclusion

For maximum productivity, nCircle Tech is automating CAD design in a field where every second matters. nCircle Tech enables engineers and designers to work smarter, not harder, by automating repetitive activities and improving accuracy. With nCircle Tech, you may experience the CAD design of the future and advance your projects.

0 notes

Text

🚀 Unlock the Future of Design with ProtoTech's CAD Automation Tools! 🛠️

🚀 Discover the Future of CAD with ProtoTech! 🚀

Struggling with repetitive design tasks? ProtoTech's 𝐂𝐀𝐃 𝐀𝐮𝐭𝐨𝐦𝐚𝐭𝐢𝐨𝐧 𝐓𝐨𝐨𝐥𝐬 are here to revolutionize your workflow! Discover how our innovative solutions can streamline your design process, enhance productivity, and elevate your projects to new heights. 💡

✨ Key Features:

𝐀𝐮𝐭𝐨𝐦𝐚𝐭𝐞𝐝 𝐂𝐀𝐃 𝐂𝐮𝐬𝐭𝐨𝐦𝐢𝐳𝐚𝐭𝐢𝐨𝐧: Tailor your designs effortlessly with our advanced automation capabilities.

𝐒𝐞𝐚𝐦𝐥𝐞𝐬𝐬 𝐈𝐧𝐭𝐞𝐠𝐫𝐚𝐭𝐢𝐨𝐧: Easily integrate with popular CAD software for a smooth, efficient workflow.

𝐀𝐝𝐯𝐚𝐧𝐜𝐞𝐝 𝐒𝐜𝐫𝐢𝐩𝐭𝐢𝐧𝐠: Utilize powerful scripting tools to automate complex tasks.

𝐀𝐮𝐭𝐨𝐦𝐚𝐭𝐞𝐝 𝐏𝐫𝐨𝐜𝐞𝐬𝐬𝐞𝐬: Save time with automated repetitive tasks, allowing you to focus on creativity.

𝐄𝐫𝐫𝐨𝐫 𝐑𝐞𝐝𝐮𝐜𝐭𝐢𝐨𝐧: Minimize manual errors and ensure design accuracy.

🔍 Dive into our latest blog post to learn more about how ProtoTech is transforming the CAD landscape with cutting-edge technology.

🔗 Read the full article here: https://prototechsolutions.com/blog/key-features-and-capabilities-of-prototechs-cad-automation-tools/

#Automation#CAD#CAD Design#Design Automation#CAD Workflow#Design Innovation#CAD Automation#ProtoTech Tools#Efficiency In Design#Engineering#ProtoTech Solutions

0 notes

Text

Our professional design experts streamline your resources more effectively with shifting workloads, thus improving, and optimizing results. As a trusted design extension for global businesses in various industries, you can count on us offshore for all your CAD needs.

Get in touch with us, for more information Visit: https://www.designautomations.com/ or Call us on 📞 +91 9574 024 279

1 note

·

View note

Text

CAD Product Configurator Software | Prescient Technologies

#https://pre-scient.com/offerings/cad-plm-customization/product-configurator.html#CAD Product configurator software is a design automation solution that works on parameter-driven design. It allows customers to choose certa

0 notes

Text

This is very interesting: a novel CAD package built on a text based file format that should allow you to check files into version control and automate tasks, plus a geometry engine optimized for GPU compute.

It's also got some noteworthy backers, the appeal of this is obvious to anyone who has ever tried to integrate CAD into a larger workflow, it takes a lot of manual shunting of files and tagging of releases and fighting with export formats, even with all the features SolidWorks and Inventor and SolidEdge have added over the years.

It's not parametric, of course, because that's a totally different approach to modelling that's much harder to automate this way. I'm not sure if that's reasonably possible without just doing SVG bullshit.

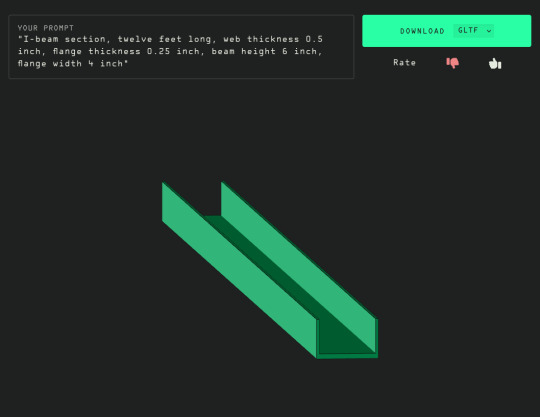

There's an LLM powered Text To CAD thing where you are meant to be able to just describe an object and get back the CAD for it but at least for now it can only do things that are relatively simple, it feels a little like a crutch to deal with how slow generating simple parts through code CAD can be. Defining an I-beam parametrically is the kind of thing you can do basically without thinking. I guess you'd probably want to have a library of parametrically defined common parts to pull from once you've been doing this for five minutes.

Close but no cigar! It does get the flange and web the right way around. Using inches because I assume it's trained in Freedomheit.

They're keeping their geometry solver closed source, but I'd be interested to see if declarative cad like this takes off in industry, it's a slow moving space but hardware design is increasingly available to startups and small businesses who might be willing to throw away a lot of old CAD philosophy.

A lot of industry uses constructive CAD like this, the US military has BRL-CAD. Never could get my head around it.

25 notes

·

View notes

Text

6 BEST PRACTICES OF CAD AUTOMATION GIVEN BY INDUSTRY EXPERTS

Discover top CAD automation tips from industry experts.

Optimize workflows with these 6 best practices for efficient and precise design processes.

0 notes

Text

IEEE Project Center in Tirunelveli

AB Technologies: The Leading IEEE Project Center in Tirunelveli

Engineering students across Tamil Nadu often seek out the best resources for their final year projects, and AB Technologies has become the top choice for students in Tirunelveli. Known for its exceptional quality, innovation, and focus on practical learning, AB Technologies is recognized as the leading IEEE project center in Tirunelveli. Specializing in IEEE-certified projects, the center has carved a niche for itself by providing students with the tools, mentorship, and technical support they need to excel.

The Importance of IEEE Projects

IEEE (Institute of Electrical and Electronics Engineers) projects hold significant value for engineering students. These projects are based on international standards, representing the latest technological advancements and innovations across various fields of engineering. An IEEE-certified project not only strengthens a student’s academic performance but also boosts their resume, providing a strong competitive advantage in the job market. With industries increasingly focusing on cutting-edge technology and innovation, completing an IEEE-certified project from a reputable center like AB Technologies opens up greater career opportunities for students.

Diverse Project Offerings

AB Technologies offers a comprehensive range of project options across several branches of engineering, ensuring that every student can find a project that aligns with their interests and academic requirements. Some of the most popular project domains offered include:

Electronics and Communication Engineering (ECE): AB Technologies provides a variety of IEEE-certified projects in areas like embedded systems, digital communication, IoT (Internet of Things), and VLSI design. Students have the opportunity to work with advanced technologies and tools, preparing them for real-world challenges.

Electrical and Electronics Engineering (EEE): From power systems and electrical machines to renewable energy solutions, AB Technologies offers projects that focus on sustainable and emerging technologies. These projects help students gain a deeper understanding of modern power systems and electrical circuits.

Computer Science and Information Technology: In a field where technological advancements are rapid, AB Technologies offers projects in trending areas like artificial intelligence (AI), machine learning, cybersecurity, web development, and data science. These projects are designed to provide students with hands-on experience in the technologies shaping the future of the industry.

Mechanical Engineering: Mechanical engineering students can explore projects involving robotics, automation, CAD/CAM, and industrial design, gaining practical exposure to cutting-edge mechanical systems and technologies.

Expert Guidance and Mentorship

What sets AB Technologies apart from other project centers is its dedication to providing personalized mentorship. Each student receives one-on-one guidance from experienced professionals and academic experts who ensure that the project is not only completed successfully but also understood in-depth by the student. This mentorship covers every phase of the project, from initial concept and design to development, testing, and final presentation.

Focus on Hands-On Learning

At AB Technologies, students aren’t just completing projects for the sake of academic requirements; they’re getting hands-on, practical experience. The center is equipped with state-of-the-art tools, software, and hardware, allowing students to work on real-world applications of their projects. This practical exposure is invaluable in helping students understand the complexities of modern engineering solutions and preparing them for the challenges they will face in their professional careers.

Building a Reputation of Trust and Excellence

Over the years, AB Technologies has earned a strong reputation for its quality and commitment to excellence. The center has become a trusted partner for engineering students and educational institutions in Tirunelveli, thanks to its consistent track record of delivering successful IEEE projects. Many students have benefited from the expert guidance and innovative project solutions provided by AB Technologies, allowing them to stand out in their academic and professional journeys.

Conclusion

For engineering students in Tirunelveli looking to undertake IEEE-certified projects, AB Technologies is the clear choice. With its wide range of project offerings, expert mentorship, and hands-on learning opportunities, the center ensures that students not only meet their academic goals but also acquire valuable skills that will set them apart in the job market. As the leading IEEE project center in Tirunelveli, AB Technologies continues to empower students to succeed in their engineering careers.

Best IEEE expert engineering project center, Nagercoil | Tirunelveli | Chennai (abtechnologies.in)

#IEEE Project Center in Tirunelveli

#IEEE#Project#Center#in#Tirunelveli

##IEEEProjectCenterinTirunelveli

2 notes

·

View notes