#aircraft component design and manufacturing

Explore tagged Tumblr posts

Text

#Specialising in aircraft interiors#aircraft component design and manufacturing#Aviation MRO#Aircraft maintenance cost optimization.

0 notes

Text

adventures in aerospace

So I recently started working at Large Aircraft Manufacturer. (LAM) The plant I work at employs 30,000 people. The company as a whole employs 170,000. Usually you only hear about LAM when something goes wrong. But no matter how bumbling it seems from the outside, it's way worse on the inside.

Three months after my first day, I have been "graduated" from "training." In reality, I'm still completely worthless on the floor: the training center has given me a paltry subset of the production certificates I need to actually to do my assigned job. A commonly cited statistic at LAM is that a hundred men a day are retiring, each one representing decades of experience, walking out the door, forever. The training center is in the unenviable position of managing a generational replacement, and have resorted to shoveling heaps of zoomers through as fast as possible. (As one of the few people with a visible hairline and who is not wearing a Roblox graphic tee; I am frequently mistaken for an instructor, and asked where the bathroom is, what time the next class starts, etc)

In theory, the training center knows what shop I'm assigned to, and can simply assign me all the required classes. In practice, they do the absolute minimum amount of training in a desperate attempt to relive the crowding in their handful of computer labs and tell graduates to pick up their certs later.

Of course, the irresistible force of the schedule meets the immovable object of the FAA. If you don't have the required production certificate to perform a particular job, you don't touch the airplane. Full stop, end of story.

And so the curtain opens on the stage. It reveals a single senior mechanic, supervising a mechanic who finally received all the certs and is being qualified on this particular job, surrounded by another three trainees. Trainees are less than nothing, absolute scum. At best we can fetch and carry. Mostly we are expected to stay out of the way. And the senior mechanic is only senior in title. He is one of six assembler-installers who is certified to actually work on the plane, out of twenty people on the crew, and spends every day with a permanent audience. He is 23 years old.

("Mechanic"? If you think the jargon at your job is bad, try joining a company that's a century old. Assembler-installers are universally referred to as "mechanics", despite doing work that's nothing like what a car mechanic does, and who are generally paid far worse than FAA certified A&P mechanics. Mechanics are the 11 bravos of LAM, grunts, the single largest category of worker. The tip of the spear. Hooah!)

Large Aircraft Manufacturer is in a dilly of a pickle. All of its existing airframe designs are hilariously antiquated. It tried designing a brand new plane from a clean sheet, and lost billions of dollars to a decade-long integration hell. After that, to save money, it tried just tacking bigger engines on an older design without changing anything else, and the stupid things plowed into the ground in an excruciatingly public manner.

LAM is now trying a middle road. It is upgrading one of its designs that is merely middle aged, rather than ancient, and with proven, de-risked components built in-house, rather than scattering them to subcontractors across the world. And it's still blowing past deadlines and burning billions of dollars LAM really doesn't have to spare.

This is the program I've been assigned to.

Advanced Midbody - Carbon Wing has taken the bold step of just tacking on carbon fiber wings to a conventional aluminum fuselage. Shockingly, AMCW is now stuck in lightning strike testing, due to that troublesome join between conductive aluminum and conductive...ish carbon fiber. But LAM, confident as ever, or perhaps driven by complaints of its customers, has announced that full rate production will begin just next year. Thus the tide of newhires. According to the schedule, we're supposed to jerk from one wingset a month to one wingset a week. That's not going to happen, but, oh well, orders from above move down at the speed of thought, while reality only slowly trickles upwards.

"120 inch pounds? Really?"

I startle upright. I have observed one hundred pi bracket installs, and I will observe a hundred more before I can touch aircraft structure. This is the first disagreement I've witnessed. A more advanced trainee is questioning the torque spec on a fastener. It is not an entirely foolish question-- most sleeve bolts we use are in the 40 in-pounds range. Doubling it that is unusual. I cough the dust off my unused vocal cords and venture an opinion.

"Well hey I could look it up? I guess"

The lead mechanic glances at me, surprised that I'm still awake, then looks away. Excuse enough for me!

I unfold myself from the stool I've been sitting on for the last four hours then hobble over to the nearest Shared Production Workstation.

We do not get Ikea-style step by step instructions on how to put together the airplane. Like any company that's been around for long enough, LAM is a tangled wad of scar tissue, ancient responses to forgotten trauma. If you state a dimension twice, in two different places, then it is possible for an update to only change one of those dimensions, thereby making the engineering drawing ambiguous. Something real bad must have happened in the past as a result of that, so now an ironclad rule is that critical information is only stated once, in one place, a single source of truth.

As a result, the installation plan can be a little... vague. Step 040 might be something like "DRILL HOLE TO SIZE AND TORQUE FASTENERS TO SPEC". What hole size? What torque spec?

Well, they tell you. Eventually.

(Image from public Google search)

You are given an engineering drawing, and are expected to figure out how things go together yourself. (Or, more realistically, are told how it's done by coworkers) Step by step instructions aren't done because then dozens of illustrations would have to be updated with every change instead of just one, and drawings are updated surprisingly frequently.

Fasteners are denoted by a big plus sign, with a three letter fastener code on the left and the diameter on the right, like so: "XNJ + 8"

To get the actual part number, we go to the fastener callout table:

(Note the use of a trade name in the table above. There is nothing a mechanic loves more than a good trademark. Permanent straight shank fasteners are always called HI-LOKs™. It's not a cable tie, it's a Panduit™. It's not a wedgelock, it's a Cleco™. Hey man, pass me that offset drill. What, you mean a Zephyr™? Where'd the LAMlube™ go? This also means you have to learn the names of everything twice, one name on the installation plan, and one name it's referred to in conversation.)

We find XNJ on that table, and fill in the diameter: BACB30FM8A. Now we look up the spec table for that fastener:

The eagle eyed among you might note that there is no "diameter: 8" on that table. As a LAM mechanic, you are expected to simply know that "diameter" is measured in 32nds of an inch, which simplifies down to 1/4.

(LAM preserves many old-school skills like fraction reduction and memorizing decimal equivalents like this, like flies caught in amber. Not least is the universal use of Imperial units. Many American manufacturers have been browbeaten into adding parenthetical conversions. Not LAM! Any risk at all of a mechanic seeing a second number and using it by accident is too great, and anyway, it violates SSOT. Lengths are in inches and feet, weights are in pounds, volume is in gallons and if you don't like it then you can go eat shit!)

After 10 minutes of following references, I arrive at that table, print it off, highlight the correct row, and hand it off to my senior mechanic.

"Great, thanks."

Gratified that I have enhanced shareholder value, I sit back down, and immediately fall asleep. Another day living the dream.

(next post in this series)

416 notes

·

View notes

Text

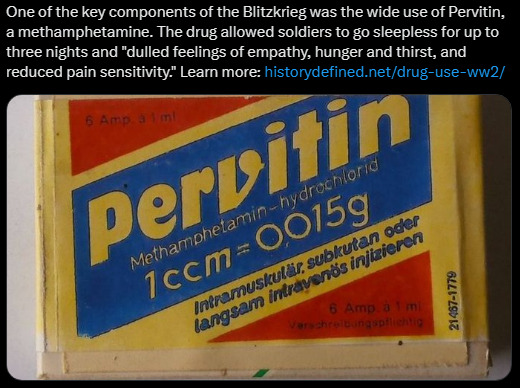

Re: Pervertin or how German Supersoldiers High on Crack travelled through Space and Time Buy my Book

I came across a post on the bird site yesterday calling into attention the use of pervitin, more or less adderall, among German troops during WW2. For context pervitin tablets were indeed issued to a lot of military personnel back in those days, specifically to aircraft pilot and sometimes tank crews on long missions. The drug as some of you may have heard keeps you awake and alert, along with a slew of side effects and a non negligible chance of addiction. In a discussion that brought to view just how willing people are to buy into Nazi propaganda in the year of our f*cking lord 2023, I pointed out a few things, uphill and having to indulge a lot of sidetracking. The use of pervitin has always been a little overstated ever since it came to the internet's attention, and I certainly would never call it a key component of the Blitzkrieg when, in the theaters of war where actual Blitzkrieg was employed, its success was more due to a combination of innovative doctrines, intact fuel supplies and a big fat helping of dumb luck. It was a bold move highly relying on capturing enemy fuel depots with fast, surprise deep strikes supported by a lot of armored and air forces, and it was only sustainable in neighboring, industrialized countries. One can argue if the USSR was industrialized at the time, but it stopped mattering when the Russians removed their entire industry from the West to beyond the Ural mountains. The Blitz stalled there.

"But if it didn't work, then why did the Nazis do it so often ?" Well the answer to that is twofold. The first, longer answer is that Nazis were a bunch of f*cking morons. Maybe not one by one, but as a government in charge of military procurement, they were one bunch of goofy motherf*ckers. Gaggle of functional shit-for-brains really. The Nazis gave every one of their tanks in the middle of the war two coats of anti-magnetic paint, which took almost a full day to cure, despite being the only major nation to use magnetic antitank mines. The Nazis kept using slave labor drawn from their prisoners of war, including in the manufacturing of their overengineered armored vehicles, resulting in poor quality products or, you know, a few rivets in your magnificent Tiger tank being replaced by a cigarette butt. The Nazis spent more than half the cost of a strategic bomber on every V2 rocket, not including design costs, for less than half the payload. It ended up killing more Germans and slave workers than British people in London, for literally no strategic or tactical result with 0.4 person killed per every rocket. The second, shorter answer is that pervitin was not used that much. A lot of the arguments trying to boost its importance come from a single book, "Blitzed" by Norman Ohler, now available in twenty languages apparently, where grand claims are made by a historian who was probably more than a little tired of seeing Buzzfeed rack in the big bucks instead of him.

End note; I was called out by a bird siter after the conversation that inspired this post for even beginning to fact-check this, which they considered, and I quote, "fangirling over nazi stats". I cannot stress this enough, learning the 'bad' parts of history does not make you bad person, it is how you interact with the resulting knowledge. Unlike what they implied, I had to look for those supporting evidence. I had a hunch that such a grabbing headline about super-drugs would be fake, I knew offhand that V2 rockets killed more blues than reds, but when I had to research all that jazz about Nazis and their superweapons it was to dunk on them, not make another History Channel documentary about a time-travelling bell. Stay critical, fascists can eat shit.

844 notes

·

View notes

Text

According to research by the Campaign Against the Arms Trade (CAAT), the UK has licensed more than £472 million in arms exports to Israel since 2015. This includes tank components, armour-piercing ammunition and small arms, but, in keeping with the structure of the British weapons industry, aerospace components for fighters and drones predominate. It’s difficult to get clear numbers from the arms industry. The headline figure is taken from the value of standard licences, but the UK also operates a system of open licences that permit transfers of unlimited – and unspecified – quantities of particular military goods. Since 2015, 57 such licences have been granted for export to Israel, ten of those in 2022. They include British components for the American-designed F-35 aircraft, which campaigners estimate have been worth £336 million to the companies (primarily BAE Systems) producing them. Because the quantities of goods issued under open licences are not made public, groups such as CAAT have to back-engineer their value. In recent years the government has become increasingly hostile to Freedom of Information requests on arms, but there is enough publicly available data to be certain that the planes currently flattening apartment blocks and refugee camps in Gaza rely on components engineered and manufactured in Britain. There is little appetite in Westminster for reform of the domestic arms industry. For one thing, it is a rare economic success story. The UK is the second largest exporter of defence items in the world and, according to the Stockholm International Peace Research Initiative, the sixth largest exporter of major conventional weapons (which means everything short of weapons of mass destruction), primarily aircraft. The total value of standard licences issued in 2021 was £10.7 billion, and the industry depends on its aerospace sector, which accounts for 72 per cent of export business. More than half of all British defence exports go to the Middle East – but to Saudi Arabia rather than Israel. Human rights organisations, including Amnesty International, accuse BAE Systems of being party to Saudi war crimes in Yemen, where BAE-supplied (and serviced) fighters have bombed schools and hospitals.

James Butler, Up in Arms

122 notes

·

View notes

Text

Cataphract

The Cataphract is a heavy BattleMech and one of the first original designs since the start of the Succession Wars, though it had inauspicious beginnings. Desperate for a heavy 'Mech design that their failing infrastructure could sustainably produce and maintain, the Capellan Confederation designed the Cataphract in 3025 to be assembled from parts they could still manufacture. Dubbed a FrankenMech for its appearance, and using components from the Marauder, Shadow Hawk and Phoenix Hawk, the Cataphract was set to become the Confederation's new standard heavy 'Mech. It entered service just before the Fourth Succession War when the production line on Tikonov fell to the Federated Suns. This embarrassing failure was further compounded when many Davion units, including the Crucis Lancers, adopted the Cataphract as their own. However, the product quality from Tikonov left the Federated Suns wanting (at least in part due to deliberate obstruction by workers still loyal to the Confederation). It was not until 3032 that the Confederation finally replaced the lost factory with one on Betelgeuse, producing their own Cataphracts in time for the Andurien Crisis.

Shortly after conquering Tikonov, the Federated Commonwealth began work on the CTF-3D, intended to stand toe-to-toe with an assault 'Mech and be as versatile as possible. Despite the upgrades the CTF-3D was only marginally deployed by the Armed Forces of the Federated Commonwealth and eventually relegated to the Crucis March Militia as an insult to the Capellans. The onset of the Clan Invasion caused everything still in production, including the Cataphract, to be rushed to the front lines. For their part the Capellans were able to produce the CTF-3D from stolen plans and went about creating their own variant, the CTF-3L, which would go on to make up twenty-five percent of all their newly acquired heavy 'Mechs during the 3050s. In the years afterwards use of the design would wane, though a few new variants would continue to be produced as new technology and new demands arose.

The longest ranged weapon carried by the CTF-3D Cataphract is a General Motors Nova-5 Ultra AC/5 in its right arm, boasting a rate of fire twice that of a standard autocannon. This is backed up by a Mydron Excel LB 10-X AC in its right torso, capable of firing both solid and cluster rounds. It is a more popular weapon than the Ultra AC/5, especially for use in an anti-conventional and anti-aircraft role without the possibility of jamming. Finally, the 'Mech has four Intek medium lasers for close range defense, one in each arm firing forward and two in its torso covering the rear. With only two tons of ammo for the LB 10-X AC and one ton for the Ultra, if it runs dry the Cataphract must fall back to be reloaded before continuing the fight.

Eleven tons of armor combined with CASE allowed the Cataphract to easily absorb damage. Sixteen heat sinks keep it cool while four HildCo Model 12 jump jets gave it a jumping distance of one hundred and twenty meters. Room for these improvements was made by using a GM 280 XL engine.

32 notes

·

View notes

Text

• The desire to push R&D costs off to the company’s suppliers meant that Boeing was essentially building its planes from kits that weren’t designed together, didn’t fit together, and didn’t meet the standard of quality the company had once been known for. This move may have been a short-term boon for company profits, the share price, or for CEO bonuses, but the reduction in quality has given rise to the phrase “If it’s a Boeing, I ain’t going.” I’m not sure there has ever been a more aggressive about-face on a company’s view by the global public. •

===================================

The problems are Systemic and require an expensive, extensive, and prolonged effort to correct.

Tying bonuses to safety - as announced by Boeing - ignores the potential and now realized Systemic catastrophes possiblities when mating components designed by different manufacturering entities. (As opppsed to subcontractors manufacturing to specifications and blueprints produced by Boeing.

The different components may all pass their individually manufacturers quality control as well as Boeing’s. As INDIVIDUAL components but FAIL to mesh in the completed aircraft.

The burgeoning examples are coming faster and faster. Executives aren’t going to solve these known issues let along figure out other weaknesses if Boeing has lost depth in engineering staff.

What a nightmare.

42 notes

·

View notes

Text

Achieving a goal is the beginning of a new challenge. To run really fast, HKS thinks.

A drag race scene where people compete for 0.001 seconds over a distance of about 400 meters in just a few seconds. '91 is a drag field that demands quick response and power from the engine, clutch, suspension, and even a single drop of oil or gasoline, as well as durability and transmission ability to handle instantaneous high power. -In '95-'96, the ``HKS R32 DRAG GT-R'' won the series championship in the RRC Drag Race Championship for three consecutive years. The following year, in 1997, the ``HKS DRAG 180SX'' in the BERC Drag Race Championship Pro Stock class and the ``HKS R33 DRAG GT-R'' in the Pro GT-R class achieved the Avec Championship. Having achieved one goal in 1997, what we aimed for in 1998 is:

Quarter mile time in 9 seconds with FF base vehicle. They then talked about their know-how from drag racing to date, and ``HKS FF DRAG CELICA'' made its debut. The first goal was achieved on October 9, 1998 at Sendai Highlands with a time of 9.886 seconds. He further improved his time to 9.727 seconds, and in 1999 he set a goal of breaking the quarter mile in the 6-second range, and has already begun a new challenge. "Achieving a goal is the beginning of a new challenge" - HKS' never-ending battle continues

HKS

■Company overview

●Name HKS Co., Ltd. Established October 31, 1971

●Capital 607,475/Kawa Representative Director and President Naruyuki Hasegawa

●Location Head Office 2266 Kamiogawa, Kunikami City, 418-0192

●Business details

Development, design, and product sales of automobile parts, racing engines, turbocharger-related parts, and automotive components and systems Design, development, and manufacturing of original mufflers, suspensions, and engine parts Development of complete cars, development of aircraft engines

●Number of employees: 407 (333%, 74 women)

●Equipment overview

Experiment building: Dynamometer (1,000/800/600~300/200/PS) Chassis dynamo, exhaust gas analyzer

Old experimental building: Dynamometer (600/600-500-200/PS)

Manufacturing factory: 10ft machining center, 5 NC lathes, 41 cam polishing machines, 21 biston narai, 11 turning centers, 21 crank Kenjoshi, Monzen Kendanmei, 21 surface grinders, 1 gun drill machine.

Muffler factory: Pipe bender, robot welding machine, 1 laser machine, shell machine, multi-spot welding machine 11, 100T press, TIG welding machine, CO2 welding machine multi-stage

Muffler 2nd factory: Pipe bender / shirring / Yasuda machining center 1 piece

Suspension factory: Cold solid coiling machine, continuous coiling machine, surface grinding machine, shot peening machine, automatic setting machine, automatic load testing machine, etc.

●Affiliated companies

HKS Aviation Co., Ltd. HKS Service Center (Tokyo/West/Kyu)

HKS USA, INC (USA)

HKS EUROPE()

25 notes

·

View notes

Text

South Korea will update its F-15K fighters

Fernando Valduga By Fernando Valduga 12/11/2023 - 17:00 in Military

Aerospace giant Boeing revealed plans for a comprehensive upgrade of the F-15K Slam Eagle fighters of the Air Force of the Republic of Korea (RoKAF).

According to Dong-A Ilbo, this transformation involves equipping the cockpit, radar and other components with state-of-the-art equipment to introduce an advanced variant.

Boeing representatives released ongoing discussions between the U.S. and South Korea during a meeting held on October 29 at the Boeing Mesa facility in Arizona. They highlighted the imminent change to a new model, integrating state-of-the-art technology throughout the front section of the aircraft, including the cockpit and radar systems.

Last year, during the 148ª meeting of the Defense Acquisition Program Administration, the South Korean military authorities ratified the fundamental strategy for the "F-15K Improvement Project". This strategy involves replacing the aircraft's mechanical radar with an EFSA radar and strengthening its electronic warfare capabilities. It is estimated that the project, scheduled to be executed from 2024 to 2034, requires a total investment of approximately US$ 2.62 billion.

The update initiative will focus on three main improvements: the installation of the AN/APG-82 radar, the strengthening of the cabin display features and the incorporation of the 'Eagle Passive/Active Warning and Survivability System' (EPAWS), a new electronic warfare set.

Rdar AESA AN/APG-82 from Raytheon.

Boeing officials anticipate that once the F-15K improvement is completed, the fighters will have an extended operational range and better performance, improving interoperability during joint U.S.-South Korea air operations.

EPAWS, a system also deployed in the latest variant of F-15 fighters operated by the U.S. Air Force, represents a crucial addition to South Korea's F-15K fleet.

TAP ARROW TO VIEW VIDEO 👇

youtube

South Korea has proposed the removal and replacement of the entire front section of the F-15K, which comprises the cabin and the front fuselage, due to its design that allows detachment between the cabin and the wings when necessary.

Robert Novotny, Director of Programs and Development of Boeing's F-15, pointed out that although there were considerations for partial component replacements, the research conducted by the Korean Institute of Defense Analysis (KIDA) defended the effectiveness of a complete replacement of the front section.

Novotny specified that the rear section of the F-15K, which undergoes proper maintenance, is not included in this update initiative.

In addition, Novotny emphasized the need for these improvements to keep up with the modernized opponents and stay ahead in the evolving scenario of air combat. He mentioned the ongoing collaboration with the Administration of the South Korean Defense Acquisition Program on related matters.

The F-15K improvement project means a substantial leap in South Korea's defense capabilities, demonstrating a commitment to technological advances and operational capacity in safeguarding the country's airspace.

Source: defence-blog

Tags: Military AviationBoeing F-15K Slam EagleROKAF - Republic of Korea Air Force/South Korea Air Force

Sharing

tweet

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, has participated in several events and air operations, such as Cruzex, AirVenture, Dayton Airshow and FIDAE. He has work published in specialized aviation magazines in Brazil and abroad. Uses Canon equipment during his photographic work in the world of aviation.

Related news

First prototype of Turkey's KAAN fighter. (Photo: Cen Dogut)

MILITARY

Turkish manufacturer began assembling two more prototypes of the KAAN combat jet

11/12/2023 - 14:00

MILITARY

Russia plays reconnaissance drone against Ukrainian UAV hexacopter

11/12/2023 - 08:47

AERONAUTICAL ACCIDENTS

F-16 fighter accident in South Korea

12/11/2023 - 08:24

MILITARY

How did a Philippine attack jet manage to shoot down an F-22 in an air combat exercise?

10/12/2023 - 20:01

AIR SHOWS

Concert schedule of the main North American demonstration teams for 2024

10/12/2023 - 18:42

MILITARY

Belgium celebrates the presentation of its first F-35A

11/12/2023 - 08:17

11 notes

·

View notes

Text

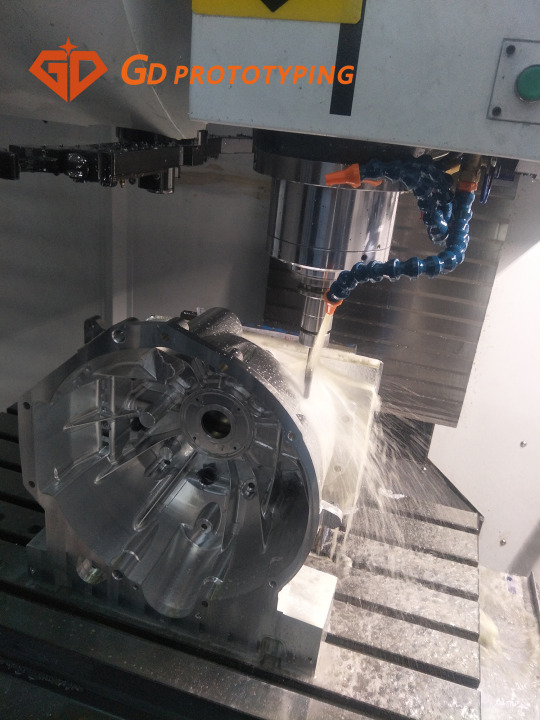

Elevating Precision Manufacturing: The Role of Mekalite’s CNC Machining Service

In today’s competitive manufacturing landscape, precision, efficiency, and adaptability are key to staying ahead. CNC machining has emerged as a vital technology, enabling manufacturers to produce complex and high-precision parts consistently. At Mekalite, we are redefining excellence in CNC machining services by combining advanced technology, a skilled workforce, and a commitment to quality.

https://mekalite.com/

What is CNC Machining?

CNC (Computer Numerical Control) machining is a process that uses computerized controls to operate machinery and tools with high accuracy. This enables the production of intricate parts from a variety of materials, including metals and plastics, while maintaining tight tolerances. CNC machining is critical in industries such as aerospace, automotive, medical devices, and electronics.

Why Choose Mekalite for CNC Machining?

Mekalite sets itself apart by offering a comprehensive approach to CNC machining, ensuring every project is handled with precision and care.

Advanced Machinery and Capabilities Our cutting-edge, multi-axis CNC machines allow us to handle even the most complex designs with precision and consistency. Whether you need rapid prototyping, low-volume manufacturing, or full-scale production, Mekalite’s technology enables us to meet your unique needs.

Customized Solutions We understand that every project is different. Mekalite works closely with each client to understand their specific requirements, delivering tailored solutions that align with their design and functionality goals.

Strict Quality Assurance At Mekalite, quality is our top priority. Our rigorous quality control protocols cover every step of the production process, from material selection to final inspection. This commitment ensures every part meets the industry’s highest standards.

Industries Served by Mekalite

Mekalite’s CNC machining services support a diverse range of industries, including:

Aerospace: High-precision components for engines, structural parts, and aircraft interiors.

Automotive: Custom engine parts, suspension components, and detailed bodywork.

Medical: Surgical instruments, implants, and diagnostic equipment requiring tight tolerances.

Electronics: Housing frames, connectors, and precision parts for delicate devices.

Benefits of Partnering with Mekalite

Choosing Mekalite as your CNC machining service provider offers numerous advantages:

High Precision and Accuracy Our state-of-the-art CNC machines, combined with skilled operators, enable us to achieve exceptional accuracy and repeatability across all projects.

Wide Range of Materials Mekalite’s expertise spans across various materials, from metals like stainless steel and aluminum to specialized plastics. This flexibility allows for innovative product designs and customized applications.

Cost Efficiency and Scalability With automated processes and minimal manual intervention, CNC machining reduces labor costs while enhancing efficiency. Whether you need a single prototype or a large production run, Mekalite’s scalable services can adapt to your requirements.

Timely Deliveries Time is crucial in manufacturing. Our efficient workflows and commitment to meeting deadlines ensure that your projects are completed on schedule, every time.

Looking Ahead: Mekalite’s Commitment to Innovation

Mekalite is committed to staying ahead of industry trends and technological advancements. By continually investing in the latest CNC machinery and refining our processes, we aim to provide even more innovative and reliable solutions to our clients. Our vision is to be a trusted partner in helping businesses achieve new levels of success through precision manufacturing.

Conclusion

CNC machining is revolutionizing the manufacturing industry, and Mekalite is at the forefront of this transformation. Our combination of cutting-edge technology, tailored solutions, and a dedication to quality makes us a preferred partner for businesses across various sectors.

If you’re looking for a reliable CNC machining service provider that delivers precision and value, Mekalite is here to help. Contact us today to discuss your next project!

https://mekalite.com/

2 notes

·

View notes

Text

CNC Machining for Aerospace Products

Precision CNC machining of aeronautical parts, as an indispensable part of the modern aeronautical industry, provides strong technical support for the manufacture of aircraft with its high-precision and high-efficiency machining characteristics. With the continuous progress of science and technology and the rapid development of the aviation industry, precision CNC machining technology is also constantly optimised and innovated to meet the more demanding aerospace parts machining needs.

Why is CNC important in the aerospace industry?

There is very high and even demanding requirements in aerospace industry for structural design, functionality, performance, product quality and reliability. A large number of new materials and structures were first applied to aircraft components. National defence needs and market competition require a significant reduction in the development and production cycles of space products. In addition, the average cost of the final product needs to be constantly reduced, thus placing higher demands on the aerospace manufacturing industry and requiring advanced manufacturing technologies. Modern CNC machining is a key part of advanced manufacturing technology and has become a decisive key technology, especially in aerospace manufacturing. The following advantages of CNC machining services make them important in the aerospace industry: ①It is the process of synthesising a variety of advanced technology types, including computer technology, communication technology, modern manufacturing technology, digital control technology and so on. ②During CNC machining, the development of a new product and the machining of another batch can be realised by simply changing the settings and parameters of the CNC machine, greatly increasing automation and flexibility. ③Multiple CNC machining can be done automatically on a single machine or in a single clamping, greatly reducing machining time and production cycle time, as well as increasing efficiency. ④CNC machining technology improves the accuracy and precision of aerospace products, reduces or minimises manufacturing errors and results in CNC aircraft parts of higher quality and durability. ⑤Most materials for aerospace components need to be cut and machined during the manufacturing process.

CNC Aircraft Part Features and Application

What are aerospace products? Aircraft can be classified by structure into fuselage, engines, on-board equipment and components, including wings, large wall and tail frames, casings, valve bodies, hydraulic valves, optical tubes, rotor blades, fasteners, connectors, etc. ①Aircraft engine parts: Aircraft engine is one of the core components of the aircraft, the machining accuracy and performance of its parts directly affect the performance and safety of the entire aircraft. ②Fuselage Structural Components: Structural components are the backbone of the aircraft and are subject to a variety of complex loads. Precision CNC machining technology enables high-precision machining of fuselage structural parts, such as beams, frames, plates and other components, to ensure the stability and reliability of their dimensions and shapes. ③Avionics equipment parts: With the continuous development of avionics technology, avionics are more and more widely used in aircraft. Precision CNC machining technology enables high-precision machining of avionics parts, such as circuit boards, connectors and other components, to ensure their accuracy and reliability.

The main features of CNC machining of aerospace parts are as follows:

①High performance: use of new hard-to-machine materials such as titanium ②High Precision: Aerospace parts require a high degree of precision, and any small error may affect the performance and safety of the entire aircraft. Precision CNC machining technology meets the aerospace industry's need for high precision by machining in the micron level of accuracy, ensuring that the size and shape of the part is exactly as designed. ③High Efficient: Precision CNC machining technology can greatly improve productivity by automating and controlling the machining process. After one programming, the CNC machine can run continuously, reducing manual intervention time and increasing production speed. ④Flexibility: Parts in the aerospace industry are varied and complex in shape. Precision CNC machining technology can be quickly adapted to the machining needs of different parts by changing tools and adjusting the programme, without the need for cumbersome manual adjustments, and is suitable for small batch and multi-species production modes. ⑤Lightweight: Extensive use of thin-walled structures. ⑥Consistency: In mass production, part consistency is critical. Precision CNC machining technology ensures that the machining parameters of each part are exactly the same, avoiding quality fluctuations caused by human factors, thus ensuring product consistency and stability. ⑦Reliability and economy: Increasingly stringent quality and cost controls. ⑧Environmental protection and energy saving: The future of precision CNC machining of aerospace parts will pay more attention to environmental protection and energy saving. Adopting more energy-saving and environmentally friendly materials and processes to reduce resource waste and environmental pollution and realise green manufacturing.

In summary, precision CNC machining of aviation parts, as one of the important technologies in the modern aviation industry, provides strong technical support for the manufacture of aircraft with its high-precision and high-efficiency machining characteristics. With the continuous innovation and progress of technology, the future of precision CNC machining of aviation parts will move towards the direction of intelligence, automation, high-speed and high-precision, multi-axis and environmental protection and energy saving, injecting a new impetus for the development of the aviation industry.

#design#autos#business#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#cnc precision machining#aerospace parts#cnc precision#machining parts#aerospace#aviation#aircraft

2 notes

·

View notes

Text

Mechanical Engineering Basics: A Beginner's Guide

Welcome to the world of mechanical engineering—a field that drives innovation, shapes our daily lives, and fuels industries from aerospace to automotive. Whether you're contemplating a career in mechanical engineering or just curious about what it entails, this guide will walk you through the essentials. We'll break down what mechanical engineering is, its key areas, essential skills, educational pathways, and much more. By the end of this post, you’ll have a solid understanding of what it means to be a mechanical engineer and how you can embark on this exciting career.

Mechanical engineering is everywhere—from the cars we drive to the smartphones we use. It’s a diverse field that combines principles of physics, mathematics, and material science to design and build machines and systems. But what exactly does a mechanical engineer do? And why should you consider a career in mechanical engineering?

In this guide, I’ll help you unravel the mysteries of mechanical engineering. Whether you’re thinking about pursuing a degree in this field or just want to understand it better, we’ll cover all the basics you need to know.

1. What is Mechanical Engineering?

Definition

Mechanical engineering is a branch of engineering that focuses on the design, analysis, and manufacturing of mechanical systems. It involves applying principles of physics and materials science to solve engineering problems and create new technologies. Essentially, it’s about making things work efficiently and effectively.

Historical Background

Mechanical engineering has a rich history that dates back to ancient civilizations. From the early water wheels and windmills to the revolutionary steam engines of the Industrial Revolution, mechanical engineering has been instrumental in technological advancements. Understanding its history gives us insight into how far the field has come and its impact on modern technology.

Core Principles

At the heart of mechanical engineering are three core principles:

Forces and Motion: Understanding how forces interact with objects and how they move is fundamental. This includes studying concepts like torque, momentum, and kinematics.

Energy: Mechanical engineers work with various forms of energy, including thermal, mechanical, and potential energy, to design efficient systems and processes.

Materials: The properties of materials—such as strength, elasticity, and thermal conductivity—are crucial in selecting the right materials for different applications.

2. Key Areas of Mechanical Engineering

Thermodynamics

Thermodynamics deals with the principles of heat and energy transfer. It’s essential for designing systems like engines, refrigerators, and air conditioners. Understanding concepts like the laws of thermodynamics, heat cycles, and entropy helps engineers optimize energy use and improve system efficiency.

Fluid Mechanics

Fluid mechanics involves the study of fluids (liquids and gases) and their behavior under various conditions. It’s crucial for applications such as designing pumps, aircraft, and hydraulic systems. Engineers use fluid mechanics to analyze and predict how fluids will interact with surfaces and move through systems.

Mechanics of Materials

This area focuses on how materials deform and fail under different types of stress. Mechanics of materials is important for designing structures and components that can withstand forces without breaking. Engineers study stress, strain, and material properties to ensure reliability and safety in their designs.

Dynamics and Control

Dynamics deals with the motion of objects and forces acting on them. Control systems involve regulating and managing the behavior of dynamic systems. Together, they help engineers design systems that can move and operate smoothly, like robotics or automated manufacturing systems.

Manufacturing Processes

Manufacturing processes cover the techniques used to produce parts and products. This includes methods like casting, machining, welding, and additive manufacturing (3D printing). Understanding these processes helps engineers select the best methods for producing high-quality, cost-effective components.

Mechanical Design

Mechanical design involves creating and developing mechanical systems and components. It requires a combination of creativity and technical knowledge to develop designs that meet specific requirements and constraints. Engineers use design principles, CAD software, and prototyping to bring their ideas to life.

3. Essential Skills for Mechanical Engineers

Mathematical Proficiency

Mechanical engineering relies heavily on mathematics, including calculus, algebra, and differential equations. These mathematical tools are used to model physical systems, analyze forces, and solve complex problems. A strong grasp of math is essential for success in this field.

Problem-Solving Skills

Engineers are often faced with complex problems that require innovative solutions. Strong analytical and critical thinking skills help engineers identify issues, evaluate options, and implement effective solutions. Being a creative problem solver is a key trait of successful mechanical engineers.

Technical Knowledge

Mechanical engineers need a solid understanding of engineering principles, materials science, and mechanics. This technical knowledge allows them to design, analyze, and optimize mechanical systems effectively. Staying current with technological advancements is also important.

Software Skills

In today’s digital world, proficiency with engineering software is crucial. CAD (Computer-Aided Design) software, simulation tools, and other engineering applications help engineers create designs, test simulations, and visualize their projects. Familiarity with these tools enhances productivity and accuracy.

Communication Skills

Effective communication is essential for collaborating with team members, presenting ideas, and documenting work. Mechanical engineers often work in teams and must be able to explain complex concepts clearly and concisely. Strong communication skills help ensure that projects run smoothly and meet objectives.

4. Educational Pathways

Degrees and Certifications

To become a mechanical engineer, you typically need a bachelor’s degree in mechanical engineering or a related field. Advanced degrees, such as a master’s or Ph.D., can open up additional opportunities for specialization and research. Certifications, such as Professional Engineer (PE) licensure, may also be required for certain positions.

Accreditation

When choosing an educational program, it’s important to select a school that is accredited by a recognized body. Accreditation ensures that the program meets industry standards and provides a quality education. Look for programs accredited by organizations like the Accreditation Board for Engineering and Technology (ABET).

Continuing Education

Mechanical engineering is a constantly evolving field. To stay competitive and up-to-date, engineers often engage in continuing education and professional development. This can include attending workshops, earning certifications, or participating in industry conferences.

5. Tools and Technologies

Engineering Software

Modern mechanical engineers rely on various software tools to assist with design, analysis, and simulation. CAD software helps create detailed 2D and 3D models of components and systems. Simulation tools allow engineers to test and validate their designs under different conditions. Mastery of these tools is essential for modern engineering practice.

Lab Equipment

Mechanical engineering labs are equipped with a range of instruments and machinery used for testing and experimentation. Common lab equipment includes tensile testers, flow meters, and thermal chambers. Hands-on experience with these tools is crucial for understanding how theoretical concepts apply in practice.

Emerging Technologies

The field of mechanical engineering is rapidly advancing with new technologies. Innovations such as robotics, 3D printing, and artificial intelligence are transforming the way engineers design and manufacture products. Staying informed about these trends can open up exciting opportunities and keep your skills relevant.

6. Career Opportunities

Industry Sectors

Mechanical engineers work in a variety of sectors, including automotive, aerospace, energy, and manufacturing. Each sector offers unique challenges and opportunities. Whether you’re interested in designing vehicles, developing renewable energy solutions, or working on cutting-edge technologies, there’s likely a niche for you.

Job Roles

Mechanical engineers can pursue various roles, including design engineer, manufacturing engineer, project manager, and research scientist. Each role involves different responsibilities and requires a unique set of skills. Exploring different job roles can help you find a career path that aligns with your interests and goals.

Career Growth

Mechanical engineering offers numerous opportunities for career growth. With experience, you can move into higher-level positions, such as senior engineer or engineering manager. Specializing in a particular area or pursuing advanced degrees can also enhance your career prospects.

7. Real-World Applications

Case Studies

Mechanical engineering projects can range from developing new medical devices to designing efficient energy systems. For example, engineers working on medical devices might design prosthetic limbs that enhance patients' mobility, while those in energy might work on optimizing wind turbines for better performance.

Problem-Solving Examples

Mechanical engineers tackle a wide range of problems, from improving the fuel efficiency of cars to designing safer buildings. By applying engineering principles and creative solutions, they address real-world challenges and contribute to technological advancements.

8. Challenges and Future Trends

Current Challenges

Mechanical engineers face several challenges, including sustainability, resource management, and integrating new technologies. Addressing these challenges requires innovative thinking and a commitment to finding solutions that balance performance with environmental and economic considerations.

Future Trends

The future of mechanical engineering is bright and full of potential. Emerging trends such as smart materials, advanced robotics, and sustainable manufacturing are shaping the industry. Engineers who stay abreast of these trends will be well-positioned to lead and innovate in the coming years.

Mechanical engineering is a dynamic and rewarding field that plays a crucial role in shaping the world around us. By understanding its core principles, key areas, and career opportunities, you can gain a clearer picture of what it means to be a mechanical engineer. If you’re considering a career in mechanical engineering, it’s an exciting field with endless possibilities and opportunities for growth.

FAQs

What is mechanical engineering? Mechanical engineering is a branch of engineering that involves designing, analyzing, and manufacturing mechanical systems. It combines principles of physics, mathematics, and materials science to create and improve technologies.

What are the core principles of mechanical engineering? The core principles include forces and motion, energy, and materials. These principles help engineers understand how to design and build efficient mechanical systems.

What skills are important for a mechanical engineer? Important skills include mathematical proficiency, problem-solving abilities, technical knowledge, software skills, and strong communication skills.

What degree do I need to become a mechanical engineer? Typically, you need a bachelor’s degree in mechanical engineering or a related field. Advanced degrees and certifications can enhance career opportunities.

What types of industries employ mechanical engineers? Mechanical engineers work in various industries, including automotive, aerospace, energy, manufacturing, and robotics.

What are some common tools used in mechanical engineering? Common tools include CAD software for design, simulation tools for testing, and various lab equipment for experimentation.

What is thermodynamics, and why is it important? Thermodynamics is the study of heat and energy transfer. It’s crucial for designing systems like engines and refrigerators to ensure they operate efficiently.

How can I stay updated with advancements in mechanical engineering? Staying updated involves continuing education, attending industry conferences, and following emerging technologies and trends.

What career opportunities are available for mechanical engineers? Career opportunities include roles such as design engineer, manufacturing engineer, project manager, and research scientist.

What are the future trends in mechanical engineering? Future trends include advancements in robotics, smart materials, and sustainable manufacturing practices.

I hope this guide has provided you with a comprehensive understanding of mechanical engineering. If you're considering a career in this field, it offers exciting opportunities and challenges that can make a significant impact on the world. Feel free to dive deeper into each topic and explore how you can contribute to the future of engineering.

2 notes

·

View notes

Text

#design-manufacturing#Defence Aircraft Manufacturing & Fabrication#Defence Aircraft Component Manufacturing#Defence Aircraft Parts Fabrication

0 notes

Text

Innovative Applications of Customised Insulators in Modern Engineering

In the rapidly evolving field of modern engineering, the demand for high-performance materials and components is ever-growing. One such critical component is the insulator, which plays a pivotal role in ensuring the efficiency and safety of electrical systems. This article delves into the innovative applications of customized insulators, focusing on the contributions of leading manufacturers in India.

The Importance of Customized Insulators in Engineering

Insulators are essential for preventing electrical failures and ensuring the safe operation of electrical systems. In modern engineering, the customization of insulators has become crucial to meet the specific requirements of various applications. Customized insulator manufacturers in India are at the forefront of this innovation, offering tailored solutions that cater to diverse industrial needs.

Epoxy Insulator: A Game-Changer in Electrical Engineering

Epoxy insulators have emerged as a preferred choice for many electrical engineering applications due to their exceptional properties. These insulators offer superior mechanical strength, excellent electrical insulation, and high resistance to environmental factors. As a result, they are widely used in applications ranging from power distribution to advanced electronic systems.

Leading Customized Insulator Manufacturers in India

India has become a hub for the production of high-quality insulators, with manufacturers focusing on customization to meet global standards. These manufacturers provide a wide range of insulators designed to cater to specific industrial requirements, ensuring optimal performance and reliability.

Applications of Medium Voltage Support Insulators

Medium voltage support insulators are critical components in power transmission and distribution systems. These insulators are designed to withstand medium voltage levels while providing robust mechanical support. Medium voltage support insulator manufacturers in India are known for their innovative designs and high-quality materials, making them a trusted choice for electrical infrastructure projects.

Innovative Applications of Customized Insulators

Power Transmission and Distribution:

Customized insulators, such as epoxy insulators and medium voltage support insulators, are extensively used in power transmission and distribution networks. Their ability to withstand high mechanical stress and environmental conditions ensures reliable operation and minimal maintenance.

Renewable Energy Systems:

In renewable energy systems, such as solar and wind power installations, customized insulators play a crucial role in enhancing efficiency and safety. Manufacturers in India are developing insulators specifically designed to meet the unique requirements of renewable energy applications, ensuring long-term performance and sustainability.

Advanced Electronic Devices:

The miniaturization and complexity of modern electronic devices necessitate the use of specialized insulators. Epoxy insulators, with their excellent electrical insulation properties and versatility, are widely used in advanced electronics to ensure optimal performance and protection.

Automotive and Aerospace Industries:

Customized insulators are also making significant strides in the automotive and aerospace sectors. These insulators are designed to meet the stringent requirements of high-performance vehicles and aircraft, providing reliable electrical insulation and mechanical support under extreme conditions.

Conclusion

The innovative applications of customized insulators are transforming the landscape of modern engineering. With the expertise of customized insulator manufacturers in India, industries can access tailored solutions that enhance efficiency, reliability, and safety. Whether it's for power transmission, renewable energy, advanced electronics, or high-performance vehicles, customized insulators are essential components driving progress in engineering.

As the demand for high-performance insulators continues to grow, the role of Indian manufacturers in providing cutting-edge solutions will remain pivotal. Their commitment to innovation and quality ensures that customized insulators will continue to meet the evolving needs of modern engineering, paving the way for a more efficient and sustainable future.

#Epoxy insulator#Customised insulator manufacturers in India#Medium voltage support insulator manufacturers in India

4 notes

·

View notes

Text

What are the Uses of Custom Plastic Manufacturing ?

In this day and age, custom plastic manufacturing has turned into a foundation of current industry, giving custom-made solutions across a wide cluster of areas. From medical services to auto, the versatility of plastics and the accuracy of custom manufacturing methods have made it conceivable to address explicit issues with unmatched productivity. We should probably dig into the main purposes of custom plastic manufacturing and grasp its effect on different businesses.

1. Medical and Healthcare Applications

Custom plastic manufacturing is reforming the medical services industry. Medical gadgets, prosthetics, and parts of symptomatic machines are progressively being produced using custom-planned plastics. A plastic manufacturing company offers a few benefits, including solidness, lightweight properties, and the capacity to be cleaned. Custom plastic parts are utilized in creating needles, IV cylinders, catheters, and, surprisingly, perplexing parts of medical imaging machines. The accuracy presented by custom manufacturing guarantees that these parts fulfill severe medical guidelines, adding to better understanding consideration and results.

2. Automotive Industry

In the automotive sector, custom plastic parts are fundamental for both execution and style. From dashboard parts to many-sided motor parts, custom plastics give arrangements that assist with lessening the general load of vehicles, further developing fuel efficiency. They also offer resistance to corrosion and wear, enhancing the longevity of parts. Custom plastics are used in manufacturing bumpers, interior trims, and even under-the-hood components. Their versatility, akin to the innovations seen with plastic bottle manufacturers, allows for innovative designs and improved safety features, making modern vehicles more reliable and efficient.

3. Consumer Electronics

The consumer electronics industry depends intensely on custom plastic assembling for making solid and smooth items. Cell phones, workstations, and domestic devices frequently consolidate custom plastic parts that are intended to fit definitively and capability perfectly. These parts need to withstand day to day wear and tear while keeping an engaging look. Custom plastics are utilized in housings, buttons, connectors, and different inward parts, offering both underlying respectability and plan adaptability.

4. Packaging Solutions

Custom plastic manufacturing assumes an urgent part in the packaging business. It empowers the formation of packaging arrangements that are custom fitted to secure and protect items during transportation and capacity. Custom plastic packaging can be intended to meet explicit necessities, for example, being lightweight, strong, and impervious to dampness and synthetics. This is especially significant in the food and refreshment industry, where keeping up with the newness and security of items is principal. Custom packaging likewise takes into consideration creative shapes and plans that upgrade brand character and purchaser advance.

5. Industrial and Mechanical Parts

Businesses that require hearty and high-performance components frequently go to custom plastic manufacturing. Plastics can be designed to display properties like high rigidity, protection from outrageous temperatures, and compound strength. This makes them ideal for making parts utilized in apparatus, gear, and different modern applications. Custom plastic pinion wheels, orientation, seals, and lodgings are normally utilized in manufacturing settings, adding to the productivity and dependability of modern tasks.

6. Aerospace and Defense

In aerospace and defense, the demand for lightweight yet solid materials is basic. Custom plastic manufacturing meets this need by providing components that can withstand harsh environments while reducing the overall weight of aircraft and defense equipment. From interior cabin parts to specialized components in satellites and military gear, custom plastics offer the necessary performance characteristics and design flexibility required in these high-stakes applications.

Ely Global Pte. Ltd - Leaders in Custom Plastic Manufacturing

Ely Global Pte. Ltd spends significant time in custom plastic manufacturing, giving fitted solutions to different businesses. With state of the art innovation and a pledge to quality, they convey accurately designed plastic parts that meet explicit client needs, upgrading item execution and productivity across multiple sectors.

#plastic manufacturing company#wholesale plastic bottle suppliers#plastic water bottle caps recyclable

2 notes

·

View notes

Text

What are all the types of aluminium fabrication?

Aluminum fabrication design encompasses a myriad of techniques and processes that transform raw aluminum into various finished products. Each method offers unique advantages, catering to diverse applications across industries ranging from aerospace to construction and automotive to electronics.

Extrusion stands as one of the most common aluminum fabrication techniques, involving the shaping of aluminum alloys by forcing them through a die. This process enables the creation of complex profiles with consistent cross-sectional shapes, ideal for applications requiring lightweight yet durable components such as window frames, structural beams, and heat sinks.

Sheet metal fabrication utilizes flat sheets of aluminum, which are cut, bent, and formed into desired shapes and sizes. From precision components for electronics to automotive body panels and aircraft fuselages, sheet metal fabrication offers versatility and efficiency in producing lightweight, corrosion-resistant parts with high structural integrity.

Casting processes, including sand casting, die casting, and investment casting, are employed to create intricate aluminum components with precise geometries. Sand casting is suitable for producing large, complex parts such as engine blocks and transmission housings, while die casting offers fast production of small to medium-sized components with tight tolerances. Investment casting, also known as lost-wax casting, enables the creation of finely detailed parts for aerospace, medical, and jewelry applications.

Welding plays a crucial role in aluminum fabrication, allowing for the joining of aluminum components through various techniques such as TIG (tungsten inert gas) welding, MIG (metal inert gas) welding, and resistance welding. TIG welding ensures precise control over the welding process, making it suitable for thin materials and intricate designs, while MIG welding offers higher deposition rates for thicker sections. Resistance welding methods like spot welding and seam welding are commonly used in automotive assembly and sheet metal fabrication.

The diverse types of aluminum fabrication techniques provide manufacturers and designers with a wealth of options to meet specific performance, cost, and design requirements. Whether it's extrusion, sheet metal fabrication, casting, or welding, each method contributes to the production of high-quality aluminum components for a wide range of applications. With expertise and quality materials from Alugrow Trading, manufacturers can leverage the full potential of aluminum fabrication to bring their designs to life.

Alugrow Trading

2 notes

·

View notes

Text

Unleashing Power and Precision: A Comprehensive Guide to Indian Air Force Fighter Planes

Introduction

The Indian Air Force (IAF) stands as a symbol of strength and prowess in the vast skies above the subcontinent. Over the years, it has acquired a formidable fleet of fighter planes, each a marvel of engineering and a testament to the nation's commitment to aerial defense. In this blog post, we will delve into the Indian Air Force Fighter Planes list, exploring the capabilities and features that make them the guardians of the Indian airspace.

Evolution of the Indian Air Force

The IAF has come a long way since its inception in 1932. From its humble beginnings with obsolete biplanes, the force has evolved into a modern and technologically advanced air arm. The backbone of the IAF's aerial might lies in its fleet of fighter planes, which have played a crucial role in safeguarding the nation's sovereignty.

Key Considerations in Fighter Plane Selection

Before diving into the list of Indian Air Force fighter planes, it's essential to understand the criteria that govern the selection of these aerial assets. The IAF considers factors such as range, speed, agility, firepower, and electronic warfare capabilities when choosing its fighter planes. These aircraft are designed to operate in diverse environments, from the scorching deserts of Rajasthan to the high-altitude regions of the Himalayas.

Indian Air Force Fighter Planes List

Sukhoi Su-30MKIThe Su-30MKI, a Russian-origin aircraft, has become the backbone of the IAF's fighter fleet. With its twin-engine design, long-range capabilities, and advanced avionics, the Su-30MKI is a versatile and lethal platform. It can carry a variety of air-to-air and air-to-ground missiles, making it a potent force in both aerial combat and ground attacks.

Dassault RafaleThe Dassault Rafale, a French-made multirole fighter, represents the cutting edge of modern military aviation. Its advanced radar systems, electronic warfare capabilities, and precision-guided munitions make it a force to be reckoned with. The Rafale has significantly bolstered the IAF's strategic capabilities, providing an edge in both air superiority and ground attacks.

MiG-29The MiG-29, a stalwart in the IAF's fleet, has undergone various upgrades to enhance its performance. Known for its agility and speed, the MiG-29 is a fourth-generation fighter that can hold its own in air-to-air combat. Its role in providing air defense and escorting other aircraft adds a layer of versatility to the IAF's operations.

TejasDesigned and manufactured indigenously, the Light Combat Aircraft (LCA) Tejas is a point of pride for India's aerospace industry. With its lightweight design and advanced avionics, the Tejas is tailored for maneuverability. As the IAF continues to induct Tejas variants, it marks a significant stride toward self-reliance in defense production.

JaguarWhile originally designed for ground attack missions, the Anglo-French SEPECAT Jaguar has been adapted for various roles within the IAF. Equipped with a combination of precision-guided munitions and a formidable gun, the Jaguar serves as a potent asset in both air-to-ground and anti-ship operations.

Strategic Importance of Fighter Planes

The role of fighter planes extends beyond just engaging in dogfights. They serve as a critical component of national defense, acting as a deterrent and providing a strategic advantage. The IAF's fighter planes play a pivotal role in ensuring air superiority, conducting reconnaissance, and delivering precision strikes when needed.

Challenges and Future Developments

While the IAF's fleet of fighter planes is formidable, it is not without challenges. The need for continuous upgrades, technological advancements, and the emergence of new threats require constant vigilance and adaptation. The IAF is actively pursuing modernization initiatives, including the development of next-generation fighter aircraft, to maintain its edge in an ever-evolving geopolitical landscape.

Conclusion

In conclusion, the Indian Air Force's fighter planes stand as a testament to the nation's commitment to aerial defense. From the iconic MiG-21s of yesteryears to the state-of-the-art Rafales and Tejas of today, each aircraft in the IAF's inventory plays a crucial role in securing the skies above India. As the nation continues to invest in indigenous defense production and embraces cutting-edge technology, the future of the IAF's fighter fleet looks promising, ensuring that the Indian skies remain safeguarded for generations to come.

3 notes

·

View notes