#Plastic Injection moulding machine

Text

Top C-PVC Injection Moulding Machine for Reliable Production

Patel Plastic Machinery is providing top line C-PVC injection moulding machine designed to delivering reliable production. Our engineered efficiency and built quality to the handle unique properties of C-PVC make sure that high quality output with minimal waste. Our C-PVC injection moulding machine to producing complex component or simple parts that providing performance you need to stay ahead in the competitive market.

Patel Plastic Machinery are equipped with advance technology that allow for precise control over the moulding machine which guarantees superior product quality in every time. We are focusing on durability and ease to operate. Our machine built quality are providing long term value and reducing downtime. . Trust Patel Plastic Machinery to elevate your production capabilities and achieve consistent, high-quality results with every run.

If you want to improve your production advance C-PVC injection moulding machine? Then visit our website pplastmach.com to explore our full range of products and how we can help you achieve reliable and efficient manufacturing. Click the link below to get started today!

#plastic injection moulding machine#micro injection moulding machine#micro injection moulding machine manufacturer#micro injection moulding machine supplier#micro injection moulding machine in ahmedabad#micro injection moulding machine in india#pet preform injection moulding machine#plastic injection moulding machine in india#thin wall container injection moulding machine#plastic injection moulding machine manufacturer

0 notes

Text

Plastic Injection Moulding Machine: The Secret Weapon Every Manufacturer Needs

1. Let's talk about Plastic Injection Moulding Machines!

Hey there, manufacturers! Looking for the secret weapon to boost your productivity and profits? Look no further than the plastic injection moulding machine. This amazing piece of technology has revolutionized the manufacturing industry, allowing for faster, more precise, and cost-effective production of plastic parts. Whether you're in the automotive, electronics, or consumer goods industry, a plastic injection moulding machine is your ticket to success. Don't believe us? Keep reading to discover the incredible benefits of this game-changing machine!

2. Why every manufacturer needs one!

Let's dive deeper into why every manufacturer needs a plastic injection moulding machine. Firstly, efficiency is the name of the game. With this machine, you can produce large quantities of plastic parts in a short period of time, eliminating the need for time-consuming manual labor. Not only does this save you time, but it also reduces costs and increases overall productivity.

Secondly, the precision of the plastic injection moulding machine cannot be underestimated. It ensures that every part produced is consistent in shape, size, and quality, resulting in satisfied customers and fewer product defects. This level of precision is crucial, especially in industries where accuracy is paramount, like the medical or aerospace sectors.

Lastly, purchasing a plastic injection moulding machine is a long-term investment that pays off in the long run. Not only does it offer a significant return on investment, but it also provides manufacturers with a competitive edge, enabling them to meet customer demands efficiently and stay ahead of the competition.

So, if you're a manufacturer looking to boost your productivity, lower costs, and enhance the quality of your products, a plastic injection moulding machine is your secret weapon! Say goodbye to traditional manufacturing methods and say hello to the future of production.

3. The benefits of a Plastic Injection Moulding Machine

The benefits of a plastic injection moulding machine are numerous and go beyond just efficiency and precision. Let's explore some of the additional advantages that make this machine a must-have for manufacturers.

One benefit is flexibility. Plastic injection moulding machines are highly versatile and can be used to produce a wide range of products in different shapes, sizes, and materials. This means that manufacturers can easily adapt to changing market demands and produce customized products to meet their customers' unique requirements.

Another advantage is waste reduction. With traditional manufacturing methods, there is often a significant amount of material waste. However, with a plastic injection moulding machine, the process is carefully controlled, and the amount of material used can be optimized, leading to minimal waste. This not only saves costs but also reduces the environmental impact of production.

Furthermore, the automated nature of the plastic injection moulding machine leads to consistent quality control. Each part produced is subjected to the same controlled process, ensuring that the final product meets the highest standards. This consistent quality builds customer trust and leads to improved brand reputation.

In the next section, we will delve into the different types of plastic injection moulding machines available in the market and how to choose the right one for your manufacturing needs. Stay tuned!

4. Where to find the best machines in town!

Now that we have established the advantages of a plastic injection moulding machine, the next step is to find the best machines in town. With numerous manufacturers and suppliers in the market, it can be overwhelming to make the right choice.

One option is to explore local suppliers who specialize in plastic injection moulding machines. These suppliers often have a wide range of machines available, catering to different production needs and budgets. You can visit their showrooms, discuss your requirements with their experts, and even witness a demonstration to get a better understanding of the machine's capabilities.

Another option is to research online suppliers. Many reputable companies offer plastic injection moulding machines on their websites. You can browse through their catalogue, compare different models, and read customer reviews to make an informed decision.

Additionally, attending industry trade shows and exhibitions can also provide valuable insights into the latest machines available in the market. You can network with experts, gather information, and even witness live demonstrations.

In the next section, we will discuss the key factors to consider while choosing a plastic injection moulding machine. Stay tuned to discover how to make the best investment for your manufacturing needs!

5. Let's get started with Plastic Injection Moulding!

Now that you have found some options for purchasing a plastic injection moulding machine, it's time to dive into the process of actually using one. In this section, we will cover the basics of plastic injection moulding to get you started on your manufacturing journey.

Firstly, it's important to understand the core components of a plastic injection moulding machine. These include the hopper, barrel, screw, nozzle, mould, and clamping unit. Each component plays a crucial role in the injection moulding process, from melting and injecting the plastic material to shaping it within the mould.

Before you begin using the machine, it's essential to select the right material for your product. The choice of material will depend on factors such as the desired properties of the final product, its intended use, and the manufacturing cost. Common materials used in plastic injection moulding include polyethylene, polypropylene, polystyrene, and PVC.

Once you have selected the material, it's time to set up the machine. This involves adjusting the temperature and pressure settings to achieve the desired melt and injection conditions for the chosen material. It's important to follow the manufacturer's guidelines and refer to any technical documentation provided with the machine.

Now, you're ready to start the plastic injection moulding process. The machine will melt the plastic material in the barrel, then inject it into the mould under high pressure. The mould, which is designed to shape the final product, will then cool down and solidify the plastic.

Keep in mind that the success of the injection moulding process depends on several factors, such as the quality of the machine, the expertise of the operator, and the design of the mould. It may take some trial and error to achieve the desired results, but with practice and experience, you will be able to produce high-quality plastic products efficiently.

In the next section, we will delve deeper into troubleshooting common issues that may arise during plastic injection moulding. Stay tuned to learn how to overcome challenges and optimize your production process.

6. Wrap it up and start producing!

Now that you have a basic understanding of the plastic injection moulding process, it's time to wrap it up and start producing! With the right knowledge and equipment, you can now turn your ideas into reality.

Before you begin production, it's important to ensure that all the necessary safety precautions are in place. This includes wearing appropriate personal protective equipment (PPE) such as gloves and safety goggles. Remember, working with a plastic injection moulding machine involves high temperatures and pressures, so safety should always be a top priority.

Once you have taken the necessary safety measures, it's time to set up the mould and prepare for production. Ensure that the mould is properly secured in the clamping unit and that it is clean and free from any debris or contaminants. This will help to ensure that your final product is of high quality.

Next, it's time to load the chosen plastic material into the hopper. The material will then be fed into the barrel, where it will undergo the melting process. Make sure to monitor the temperature and pressure settings closely to maintain optimal conditions for the material.

Once the plastic material is melted, it will be injected into the mould under high pressure. The mould will then cool down and solidify the plastic, shaping it into the desired product. It's important to monitor the injection pressure and cycle time to ensure consistent and accurate results.

As you start producing, it's normal to encounter some challenges and issues along the way. This could include issues such as air bubbles, warping, or inconsistent dimensions. Don't be discouraged! Troubleshooting is a part of the learning process, and with time and experience, you will become more adept at identifying and resolving these issues.

Remember to keep good records of your production runs, including settings, materials used, and any troubleshooting steps taken. This will help you track your progress and make improvements over time.

So, with your plastic injection moulding machine ready and your skills honed, it's time to unleash your creativity and start manufacturing. Whether you're producing small components or large-scale products, the possibilities are endless. Embrace the challenges, learn from your mistakes, and enjoy the satisfaction of seeing your products come to life. Happy moulding!

7. Happy Manufacturing!

Now that you have all the necessary information and tools, it's time to get down to business and start manufacturing! With your plastic injection moulding machine at your disposal, the possibilities are endless. Whether you're producing small components or large-scale products, this is your chance to unleash your creativity and bring your ideas to life.

As you embark on this manufacturing journey, remember that challenges may arise along the way. From air bubbles to warping and inconsistent dimensions, troubleshooting is a normal part of the learning process. Don't be discouraged! With time and experience, you will become more adept at identifying and resolving these issues.

To keep track of your progress and make improvements over time, it's important to maintain good records. Keep a detailed log of your production runs, including settings, materials used, and any troubleshooting steps taken. This will help you understand your process better and make necessary adjustments.

So, roll up your sleeves, put on your gloves and safety goggles, and get ready to experience the satisfaction of seeing your products come to life. Happy manufacturing!

1 note

·

View note

Text

plastic injection moulding machine manufacturers in delhi

0 notes

Text

#Plastic Injection Machine#Plastic Injection Molding Machine#Plastic Injection Moulding Machine#Plastic Injection Molding Machine manufacturers

1 note

·

View note

Text

International Plastics and Rubber Industry Fair in October at Vietnam

Vietnam Plas 2024 will be held from 16th - 19th October 2024 at Saigon Exhibition and Convention Center - SECC in Ho Chi Minh City, Vietnam. VietnamPlas has consistently stood as the foremost industrial exhibition in Vietnam. Serving as the bridge connecting the global supply chain with the Vietnamese market, the exhibition has played a pivotal role in fostering collaboration and catalyzing the growth of the plastics industry to meet global demands. The fair covers a wide range of topics and sectors within the plastics and rubber industry. This includes plastic machinery, chemicals and raw materials, machinery auxiliary industry, heating and control devices, hydraulic and pneumatic technologies, recycling techniques, and other relevant products and services.

WHY SHOULD YOU ATTEND EXHIBITION?

VietnamPlas has brought together a diverse range of exhibition categories, including machinery equipment for plastics and rubber processing, manufacturing and distribution of injection moulding machines, film blowing machines, etc. VietnamPlas also bring the most promising businesses and exhibitors to participate, creating opportunities for the development of the plastics and rubber industry in Vietnam. VietnamPlas is not only an opportunity to access the latest technologies and products but also a chance to expand cooperation relations.

Visitors Profile:

Aerospace / Railway

Automobile / Auto Parts / Accessories

Building Materials

Chemicals & Raw Materials

Cosmetics / Daily Chemical Products

Environmental Protection / Recycling / Upcycling

Food & Beverages

Machinery & Testing Equipment

Moulds & Dies

Packaging / Printing

Pharmaceuticals / Medical Supplies & Equipment

Plastic Furniture / Lighting

Plastic Products & Parts

Plastics Recycling

Product / Industrial Design

Rubber Products & Parts

Exhibition Highlight

Exhibition Date: 16th To 19th Oct 2024

Time: 16 to 18 October 09.00 to 5.00 and 19 October 2024 09.00 to 3.00 PM.

Exhibition Location Address: 799 Nguyen Van Linh Parkway, Tan Phu Ward, District 7, Ho Chi Minh City, Vietnam

Hall No. – A1, A2 and B1, B2

Entry Fees – Free Ticket for Industry Professionals on advance booking.

Estimated Visitors: 60,000 Visitors

Estimated Exhibitors: 1000 Exhibitors

WHO SHOULD EXHIBIT?

The most promising exhibitors will showcase their latest cutting-edge products based on global trends at the VietnamPlas exhibition. Here, leading suppliers from many countries will meet all your needs in the supply chain of the plastics and rubber industry. A distinguishing feature of the exhibition is its close ties to the local plastics industry, positioning itself as an ideal platform for entry into the Vietnamese market and for the international showcase of products and services.

Organizer Information.

Organizer Name: Chan Chao International Co., Ltd

Organizer Address: 3F, No.185, Kangchien Road Nei-Hu Dist. Taipei, Taiwan

Organizer Phone No.: 886 2-26596000

Organizer Email Id: [email protected]

Stall Booking Number: +886-2-2659-6000

Website: https://www.chanchao.com.tw/en/

Registration Link: https://www.chanchao.com.tw/en/preReg/index.asp?id=FPLSHCM2024&c=

The event fosters collaboration and knowledge exchange, enabling participants to address key challenges such as environmental sustainability, product innovation, and supply chain optimization. As the industry moves forward, the insights and partnerships developed at this event will play a crucial role in shaping the future of plastics and rubber manufacturing in Vietnam and beyond.

0 notes

Text

How is a trigger sprayer assembled by an assembly machine?

A lot of small parts of the trigger sprayer are moulded by injection moulding machine and then assembled.

Piston Assembly Machine

The trigger sprayer piston and ball assembly machine uses a rotary dial mechanism to connect two pieces, namely the piston and the ball. Parts are conveyed through a vibrating bowl and a linear track (the stem track). The intelligent control system displays information about the production and running situation. The equipped lifting system and vibration feeding system further automate manufacturing.

Gasket and Chaplet Assembly Machine

The trigger sprayer chaplet and gasket assembly machine employs a rotating dial mechanism to connect two elements, the gasket and the chaplet, together. Parts are conveyed through a vibrating bowl and a linear track (the stem track). The intelligent control system displays information about the production and running situation. The equipped lifting system and vibration feeding system further automate manufacturing.

Body Assembly Machine

The trigger sprayer body assembly assembly machine uses a rotary dial mechanism to assemble five parts: the body, closure, plastic spring, spinner, and nozzle. Parts are fed by a vibrating bowl and a linear track (the spinner track has an adjusting jaw to align the spinner hole with the plastic spring). The intelligent control system displays information about the production and running situation. The equipped lifting system and vibration feeding system further automate manufacturing.

Handle Assembly Machine

The trigger sprayer handle assembly assembly machine uses a rotating dial mechanism to assemble five parts: the body assembly, the Ss spring, the piston assembly, the chaplet assembly, and the trigger. Parts are fed by vibrating bowl and linear track. The intelligent control system displays information about the production and running situation. The equipped lifting system and vibration feeding system further automate manufacturing.

Trigger Sprayer Dip Tube Fitting Machine

The trigger sprayer dip tube fitting machine uses an internal fitting method to place the tube into the inside end of the lotion pump's housing. The intelligent control system simplifies tube length modification, and the lifting and vibration feeding systems further automate manufacturing.

#Trigger Sprayer Assembly Machine#Mist Sprayer Assembly Machine#Mini Trigger Assembly Machine#Lotion Pump Assembly Machine#Dropper Assembly Machine#Plastic Cap Assembly Machine#Sprayer Injection Mould#Mist Sprayer Injection Mould#Foam Pump Injection Mould#Lotion Pump Injection Mould#Cap Injection Mould

0 notes

Text

Because the plant extension, the mold factory chagnged the new name as: Rost mold! We will be your reliable partner in China!

#injectionmold #plastmold #plasticmould #injectionmould #injectionmoulding #imm #inyeccionmold #bucketmold #chairmold #petmold #householdmold #dailyusemold #electricmold #autopartsmold #doublecolormold #irrigationmold

#injection molding#plastic molding#plastic#injection moulding machine#injection manufacturing company#injection mold

0 notes

Text

Injection Moulding Machine Price | SHIPMI

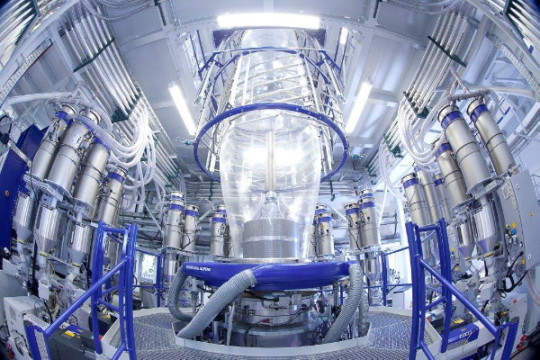

The Systec is a hydraulic injection moulding machine from the European product range of Sumitomo (SHI) Demag. It is characterized by sturdy and compact design, and offers much clearance for large moulding dies.

#Plastics machinery services India#Plastic injection moulding machine Gurgaon#Plastic moulding machine#All electric injection molding machine

0 notes

Text

The best plastic injection moulding machine manufacturers are known for their commitment to technological innovation. They invest heavily in research and development to create cutting-edge machines that offer high efficiency, precision, and reliability.

0 notes

Text

Used Plastic Injection Moulding Machine Sale in India

Discover high-quality used plastic injection moulding machines for sale at IndiaBizzness. We offer a wide range of reliable machines at competitive prices, ensuring cost-effectiveness for your business. Whether you're looking for small-scale or industrial-grade equipment, our diverse selection caters to various needs.

#used plastic injection moulding machines#second hand plastic injection moulding machines#Imported Plastic Processing Machines#Sell Second Hand Imported Plastic Processing Machines

0 notes

Text

Introduction to Mould Manufacturing 2024

Plastic mould manufacturing is the process of creating mould or tools for the production of plastic parts. The mould are designed to shape and form plastic materials into specific shapes and sizes, allowing for the production of identical parts at a rapid pace. This process is widely used in various industries, including automotive, medical, and consumer goods.

The fundamental principle behind plastic mould manufacturing is to create a negative impression of the desired product, which is then used to cast the final product. The mould are made from high-quality materials such as steel or aluminum, which are capable of withstanding high temperatures and pressure. The mould are designed to accommodate the specific properties of the plastic material, including its melting point, viscosity, and shrinkage rate.

There are two primary types of plastic mould manufacturing: injection moulding and compression moulding. Injection moulding involves injecting molten plastic material into a mould cavity, which is then cooled and solidified to create the final product. This process is highly efficient and produces high-quality parts at a rapid pace. Compression moulding involves heating plastic pellets and then placing them into a heated mould cavity, which is then compressed to form the final product. This technique is used for larger parts or when the part requires greater strength and durability.

Plastic mould manufacturing has a wide range of applications, from the production of small plastic components to large automotive parts. The process allows for the creation of complex parts with intricate shapes and sizes. The ability to create identical parts at a rapid pace makes it an essential process in modern manufacturing.

In conclusion, plastic mould manufacturing is a crucial process in the manufacturing industry. It allows for the production of high-quality plastic parts at a rapid pace, making it a highly efficient and cost-effective process. The use of advanced technology and high-quality materials has made plastic mould manufacturing an essential process in various industries, including automotive, medical, and consumer goods.

Mould Manufacturing Process

The process of manufacturing a mould is a complex one, and it's important to note that not all plastic mould manufacturers use the same methods.

The most common method used by manufacturers is CNC machining, which involves using computer-controlled machines to carve out the shape of your product in thin layers. This technique has been around for decades and allows for greater precision than other methods like EDM (electrical discharge machining) or grinding.

Plastic mould manufacturing is a complex process that involves several steps to create high-quality mould for various industries. The process begins with designing the mould using computer-aided design (CAD) software. This software allows engineers to create a detailed 3D model of the mould, including all the intricate details required for the final product.

Once the design is complete, it's time to move onto the manufacturing stage. The first step in manufacturing is to create a mould base using steel or aluminum. This base is what will hold all the various components of the mould together. The base must be designed to withstand the high pressure and temperature required for the moulding process.

Next, the mould is assembled, which involves attaching various components such as the ejector pins, the sprue bushing, and the runner system. These components are essential for the mould to function correctly during the moulding process.

The next step is to machine the mould. This involves using specialized equipment to create the cavities and cores required for the final product. This process involves a high level of precision, and any errors or imperfections can result in a faulty mould.

Once the mould is machined, it's time to test it. This involves running a trial batch of plastic through the mould to ensure that it produces the desired product. Any issues with the mould or the moulding process can be addressed in this stage.

Finally, after the mould is tested and approved, it's ready for production. The mould is attached to an injection moulding machine, and plastic is injected into the cavities to create the final product. This process can be repeated thousands of times to create a large number of identical products.

Overall, plastic mould manufacturing is a complex and intricate process that requires a high level of skill and expertise. From designing the mould to running production, every step of the process must be executed with precision to ensure a high-quality final product.

1. Introduction

Mould manufacturing is an essential process in the production of various products, including automotive parts, consumer goods, and medical devices. Identifying different types of mould is crucial to ensure that the correct type is used for each product. In this guide, we will discuss the different types of mould prevalent in the mould manufacturing industry, their unique characteristics, materials they are best suited for, and the benefits and drawbacks of each type.

2. Types of Mould

Plastic Injection Mould:

Thermoset Compression Mould:

Blow Mould:

Rotational Mold:

3. Precautions and Safety Measures

Different types of mould have different safety considerations, but in general, it is important to wear appropriate personal protective equipment (PPE) when working with mould, such as gloves, goggles, and respirators. It is also important to follow proper handling and storage procedures to prevent mould contamination and ensure optimal mold performance.

Conclusion

Identifying different types of mould and understanding their unique characteristics, materials they are best suited for, and the benefits and drawbacks of each type is crucial to ensure that the correct type is used for each product. Proper maintenance and cleaning of mould are also essential to prevent mould contamination and ensure optimal mould performance. By implementing the knowledge gained in this guide, manufacturers can improve their mould manufacturing processes and produce high-quality products with greater efficiency and consistency.

#mold manufacturing#mould manufacturing#plastic molding#thermoset compression mould#cnc machining#injection molding#3d printing#manufacturing#compression molding#mumbai#india#blow mould#rotational molding

1 note

·

View note

Text

Buy Advanced Thin Wall Container Injection Moulding Machine

Patel Plastics Machinery is specializes in high performance injection molding machines that design for thin wall container production. those machines are manufactured to compete demand and modern manufacturing. they providing rapid cycle times and exceptional precision to make sure that consistent quality in thin wall container production. Patel Plastics Machinery specialized in this field to their innovative design and optimal efficiency or reduce material wastege their machines is high volume production environment.

Patel Plastics Machinery their thin wall container injection molding machines are equipped advance features,high sped injection, pricise system and robust construction to continous operation. Those machine are manufacturing thin wall containers with thin and uniform wall or these container are significant weight reduce with maintaining strength and durability. Patel Plastics Machinery commitment to technological advancement and customer satisfaction and make sure that their injection molding machine are not only compete industry standard they make first choice of reliable and efficient solution for thin wall container production challenges.

if you seeking high performance injection molding machines designed for thin wall container production then visit our website PPLastMach.com . discover the advance features high speed injection molding machine that was precise, robust, efficient and reliable or manufacturing with reduce waste material then Patel Plastics Machinery compete your requiredment.

#micro injection moulding machine in ahmedabad#plastic injection moulding machine#micro injection moulding machine#pet preform injection moulding machine#thin wall container injection moulding machine#plastic injection moulding machine in india#micro injection moulding machine supplier#micro injection moulding machine in india#micro injection moulding machine manufacturer#plastic injection moulding machine manufacturer

0 notes

Text

Plastic Injection Moulding Machine Delhi

KARAN HI-TECH MACHINERY INDIA PVT LTD.

Plastic Injection Moulding Machine Manufacturers in India

#plastic injection moulding machine price#plastic injection moulding machine#Plastic Injection Machine

0 notes

Text

#Plastic Injection Machine#Plastic Injection Molding Machine#Plastic Injection Moulding Machine#Plastic Injection Molding Machine manufacturers

0 notes

Text

Fakuma 2024 Global Event for Plastics Industry at Frickenhausen

The FAKUMA 2024 trade show is considered the prime global event dedicated to the industrial plastic processing sector. This event is scheduled to take place from 15th to 19th October 2024, in Friedrichshafen, Germany. Fakuma international trade fair for plastics processing has become a prominent meeting place for the industry, with international charisma. It holds second place in the overall ranking of international trade fairs for plastics. However, because of the organization cycle, it is the principal event for the Plastic industry.

WHY SHOULD YOU ATTEND EXHIBITION?

Fakuma 2024 is one of the most important events in the plastics processing industry, attracting experts, manufacturer, supplier, Managing Director, Board member, Supervisor, Group leader, engineer. This exhibition offers numerous opportunities to learn, innovate, and connect with the global plastics community. The Exhibition also welcomes regulatory representatives, higher education institutions, and R&D institutes. This broad attendance underscores Fakuma 2024's importance as a global meeting point for the plastic Industry.

Exhibition Highlight

Exhibition Date – 15th to 19th October 2024

Time – Thursday to Friday: 9.00 am to 5.00 pm and Saturday 9.00 am to 3.00 pm

Expo Location Address – P. E. Schall GmbH & Co. KG Gustav-Werner- Strasse 6 D Frickenhausen, Germany.

Entry Fees – Free Ticket for Industry Professionals on advance booking. + Admission for one person on one day of the fair: €30

Estimated Visitors – 1636 from 40 Countries

Estimated Exhibitors – 39,343 visitors from 89 Countries

Hall No.: A1 to A7 and B1 to B5

Estimate area: 85,000 square meters

WHO SHOULD EXHIBIT?

Fakuma stands as a premier global event for industry professionals, offering unmatched opportunities for networking, innovation, and business growth. Renowned for its international reach, Fakuma provides a platform to showcase advancements, engage with thought leaders, and explore cutting-edge technologies. The exhibition will showcase the latest advancements in Injection moulding machine, extrusion, thermoforming, and 3D printing machine. It serves as a catalyst for innovation and a hub for professional connections, making it an essential event in the plastics processing.

Organizer Information:

Organizer Name: P. E. Schall GmbH & Co.KG

Organizer Address: Gustav-Werner-Strasse 6, D Frickenhausen, Germany

Organizer Phone No.: 49-7025-9206-650

Organizer Email Id: [email protected]

Website: www.schall-messen.de

Registration Link: https://obs.schall-messen.de/Members/Login.aspx

Fakuma 2024 underscored the industry's commitment to innovation in sustainable plastics, showcasing a range of new materials, advanced manufacturing techniques, and comprehensive services aimed at reducing the environmental footprint of plastic Industry.

#plastic industry#plastic exhibition#plastic expo#plastic packaging industry#plastic product#plastic industry raw materials#injection moulding#plastic and packaging#3d printing#3d printing machine#raw materials#injection moulding machine#P4t

0 notes