#Parylene uses

Text

High-Quality Parylene Coating Services – Precision Protection from Dawntechsb.

DawnTechsb provides the Parylene Coating service in Malaysia. Our cutting-edge coating technology protects against moisture, chemicals, and mechanical wear, making it ideal for electronics, medical devices, and more. Parylene coatings create a thin, uniform layer that improves durability while maintaining lightweight properties—Trust DawnTechSB for reliable, precision-engineered solutions tailored to your specific needs. Visit our website today and how our Parylene Coating can elevate the performance and longevity of your products.

For more info visit us: https://dawntechsb.com/parylene-coating/

0 notes

Text

Parylene Market Insights and Global Outlook 2024-2030

Global Info Research announces the release of the report “Global Parylene Market 2024 by Manufacturers, Regions, Type and Application, Forecast to 2030” . This report provides a detailed overview of the market scenario, including a thorough analysis of the market size, sales quantity, average price, revenue, gross margin and market share.The report provides an in-depth analysis of the competitive landscape, manufacturer’s profiles,regional and national market dynamics, and the opportunities and challenge that the market may be exposed to in the near future. Global Parylene market research report is a comprehensive analysis of the current market trends, future prospects, and other pivotal factors that drive the market.

Parylene is a common generic name for a unique series of polymers based on paraxylene. It is a polymer created from a chemical compound known as dimer, which is actually a powder. The dimer is then vaporized, made to undergo pyrolysis, transformed into a gaseous state (now a monomer), cooled, and then introduced to a vacuum chamber where it polymerizes and becomes a film. It is the best protective coating in electronic, aerospace and medicinal fields.

According to our (Global Info Research) latest study, the global Parylene market size was valued at US$ 183 million in 2023 and is forecast to a readjusted size of USD 253 million by 2030 with a CAGR of 4.7% during review period.

The core global Parylene manufacturers include KISCO, Curtiss-Wright, Chireach Group, Penta Technology and Suzhou Paihua Coating, etc. The top three players hold a share about 59%. Asia-Pacific is the world's largest market, accounting for nearly 46% of the market share. In terms of product type, Parylene N is the largest segment, with a share of 39%. And in terms of application, Electronics has a share of 41%.

This report is a detailed and comprehensive analysis for global Parylene market. Both quantitative and qualitative analyses are presented by manufacturers, by region & country, by Type and by Application. As the market is constantly changing, this report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets. Company profiles and product examples of selected competitors, along with market share estimates of some of the selected leaders for the year 2024, are provided.

Market Segmentation

Parylene market is split by Type and by Application. For the period 2019-2029, the growth among segments provides accurate calculations and forecasts for consumption value by Type, and by Application in terms of volume and value.

Market segment by Type: Parylene N、Parylene C、Parylene D、Parylene F、Parylene HT、Others

Market segment by Application:Military and Aerospace、Electronics、Medical、Automotive、Others

Major players covered: KISCO、Curtiss-Wright、Chireach Group、Penta Technology、Suzhou Paihua Coating、Shanghai Parylene Biotechnology

The content of the study subjects, includes a total of 15 chapters:

Chapter 1, to describe Parylene product scope, market overview, market estimation caveats and base year.

Chapter 2, to profile the top manufacturers of Parylene, with price, sales, revenue and global market share of Parylene from 2019 to 2024.

Chapter 3, the Parylene competitive situation, sales quantity, revenue and global market share of top manufacturers are analyzed emphatically by landscape contrast.

Chapter 4, the Parylene breakdown data are shown at the regional level, to show the sales quantity, consumption value and growth by regions, from 2019 to 2030.

Chapter 5 and 6, to segment the sales by Type and application, with sales market share and growth rate by type, application, from 2019 to 2030.

Chapter 7, 8, 9, 10 and 11, to break the sales data at the country level, with sales quantity, consumption value and market share for key countries in the world, from 2017 to 2023.and Parylene market forecast, by regions, type and application, with sales and revenue, from 2025 to 2030.

Chapter 12, market dynamics, drivers, restraints, trends and Porters Five Forces analysis.

Chapter 13, the key raw materials and key suppliers, and industry chain of Parylene.

Chapter 14 and 15, to describe Parylene sales channel, distributors, customers, research findings and conclusion.

Our Market Research Advantages:

Global Perspective: Our research team has a strong understanding of the company in the global Parylene market.Which offers pragmatic data to the company.

Aim And Strategy: Accelerate your business integration, provide professional market strategic plans, and promote the rapid development of enterprises.

Innovative Analytics: We have the most comprehensive database of resources , provide the largest market segments and business information.

About Us:

Global Info Research is a company that digs deep into global industry information to support enterprises with market strategies and in-depth market development analysis reports. We provide market information consulting services in the global region to support enterprise strategic planning and official information reporting, and focuses on customized research, management consulting, IPO consulting, industry chain research, database and top industry services. At the same time, Global Info Research is also a report publisher, a customer and an interest-based suppliers, and is trusted by more than 30,000 companies around the world. We will always carry out all aspects of our business with excellent expertise and experience.

0 notes

Text

PTFE Coated O-Rings: Benefits, Applications, and Maintenance

O-rings are essential sealing components used in various applications to prevent leakage between two surfaces, however, they do have their limitations. Depending on the material, an O-ring could have higher than preferred friction, low chemical resistance, or confusing coloration. In situations like this, a specialty coating like Parylene or PTFE might be the right answer. In this blog, we will focus on PTFE-coated O-rings, their advantages, and their applications.

What are PTFE-Coated O-rings?

PTFE-coated O-rings are O-rings that are coated with a layer of PTFE material. PTFE, or polytetrafluoroethylene, is a type of fluoropolymer that is known for its non-stick properties, chemical resistance, and high-temperature resistance. When applied as a coating to O-rings, PTFE can provide an additional layer of protection, improving certain properties of the O-ring.

Most of our coating systems are applied using conventional compressed air driven spraying techniques. The coatings are supplied as liquids and are decanted into either gravity fed or pressure fed spraying equipment.

Powder systems such as PFA and FEP are applied electrostatically, where the coating material (powder) and the part receive opposing electrical charges so that the powder will be attracted to the part. This is particularly useful where complex shapes are involved. If you would like to learn more, see our PTFE Coatings page.

Advantages of PTFE-Coated O-rings

PTFE-coated O-rings offer several advantages over other types of O-rings. These include:

Color Identification: PTFE coatings can be produced in any color. This makes PTFE coated O-rings easy to identify.

Chemical Resistance: PTFE is highly resistant to chemicals, making the PTFE coating fully functional in applications involving harsh chemicals. However, PTFE coatings are porous, and wear off easily. They will not protect the O-ring from chemical contact.

High Temperature Resistance: PTFE can withstand high temperatures, making PTFE coatings suitable for applications where high temperatures are expected.

Low Friction: PTFE has a low coefficient of friction, making PTFE coatings an ideal, clean, dry lubrication for installation purposes.

Non-stick Properties: PTFE is known for its non-stick properties, which make PTFE-coated O-rings easy to remove and clean.

Thin Coat: PTFE coatings are extremely thin and typically have virtually no effect on the tolerances of the end part.

Limitations of PTFE-Coated O-rings

While PTFE coatings have their uses, their limitations can sometimes exclude their use from certain applications.

Poor Dynamic Wear Resistance: PTFE coatings can easily be rubbed off, meaning that they really only function as a one-time-use surface lubricant.

Flaking: Because PTFE coatings can easily flake off due to dynamic wear, pieces of the coating can sometimes contaminate clean systems.

Porous: PTFE coatings do not provide additional chemical resistance for the O-ring. Because of this, it is important to use an O-ring material that is resistant to the chemicals and temperatures used in the application.

Applications of PTFE-Coated O-rings

PTFE-coated O-rings are used in various industries, including:

Chemical Processing: PTFE-coated O-rings are used in chemical processing equipment, where they provide improved installation lubrication, reliable sealing properties, and chemical resistance.

Aerospace: PTFE-coated O-rings are used in aerospace applications, where they provide high-temperature resistance and easy colored identification.

Conclusion

PTFE-coated O-rings offer useful niche benefits and can be ideal for use in various industries depending on the use case. PTFE-coated O-rings provide an inexpensive dry surface lubricant and color identification system; however, the limitations of PTFE coatings can sometimes make them prohibitive for certain applications. If you are interested in the benefits of other coating types, see our blog about Parylene Coatings. Parylene coatings frequently fill the roles that PTFE coatings fail to. For more information, please visit our website: https://www.canyoncomponents.com/

0 notes

Text

Efficient PCB Conformal Coating Spray for Superior Protection

In the fast-paced world of electronics manufacturing, Printed Circuit Boards (PCBs) serve as the backbone of countless electronic devices, from smartphones to industrial machinery. Ensuring the longevity and reliability of these PCBs is paramount, especially in harsh or demanding environments. This is where conformal coatings come into play, offering a protective shield that guards against moisture, dust, chemicals, and other environmental factors. To achieve superior protection efficiently, PCB conformal coating spray has become an invaluable tool. In this comprehensive guide, we will delve into the world of PCB conformal coating, explore the importance of efficiency, and highlight key considerations when choosing the right spray method.

Understanding PCB Conformal Coating

PCB conformal coating is a protective layer applied to the surface of a printed circuit board to safeguard it against a variety of external threats. These threats include moisture, dust, dirt, chemicals, temperature fluctuations, and even physical damage. The primary purpose of conformal coating is to ensure the reliability and longevity of electronic devices.

There are several common types of conformal coatings, each with its unique properties and advantages:

1. **Acrylic Coatings**: These coatings are easy to apply, dry quickly, and offer excellent moisture resistance. However, they may not provide the best protection against chemicals or extreme temperatures.

2. **Silicone Coatings**: Silicone coatings are known for their flexibility and resistance to high temperatures. They are often used in applications where thermal stability is crucial.

3. **Urethane Coatings**: Urethane coatings provide good protection against chemicals and abrasion. They are suitable for applications requiring durability and resistance to harsh environments.

4. **Parylene Coatings**: Parylene is a vapor-deposited conformal coating that offers exceptional protection against moisture, chemicals, and temperature extremes. It also has excellent dielectric properties, making it suitable for sensitive electronic components.

5. **Epoxy Coatings**: Epoxy coatings are known for their high dielectric strength and excellent adhesion properties. They provide robust protection against moisture and chemicals.

Selecting the right PCB conformal coating spray depends on the specific requirements of the PCB and the environment in which it will operate. Regardless of the type of coating chosen, the method of application plays a crucial role in determining the efficiency and effectiveness of the protective layer.

The Importance of Efficiency in Conformal Coating

Efficiency is a critical factor in the conformal coating process for several reasons:

1. Cost-Effectiveness:

Efficient conformal coating methods reduce material waste, saving costs in both material usage and labor. A precise application ensures that only the necessary amount of coating is used, preventing over-application.

2. Consistency:

Efficient coating methods provide a consistent and uniform coverage, reducing the risk of uneven protection. Inconsistent coating can leave vulnerable spots on the PCB, potentially leading to failure in critical applications.

3. Time Savings:

Efficiency in the coating process translates to faster production times. Reduced drying or curing times can significantly improve overall manufacturing throughput.

4. Environmental Impact:

Efficient coating methods contribute to a lower environmental impact by minimizing the use of chemicals and reducing waste. This aligns with sustainability goals and regulatory requirements.

5. Quality Assurance:

Efficient coating methods are more likely to produce high-quality results that meet or exceed industry standards. This is particularly crucial in applications where reliability is paramount, such as aerospace, automotive, and medical devices.

Choosing the Right Conformal Coating Spray Method

Selecting the appropriate PCB conformal coating spray method is essential to achieve efficiency and superior protection. There are several spray methods available, each with its advantages and limitations:

1. **Manual Spray**:

Advantages: Manual spraying allows for precise control over the coating application, making it suitable for small-scale production or prototyping.

Limitations: It can be time-consuming and labor-intensive, making it less efficient for high-volume manufacturing.

2. **Automated Spray**:

Advantages: Automated spray systems offer consistent and uniform coating application, making them ideal for high-volume production. They are efficient and can be customized for specific PCB designs.

Limitations: Initial setup costs can be high, and maintenance is required to ensure continuous performance.

3. **Selective Coating**:

Advantages: Selective coating systems target specific areas of the PCB, providing precise protection where it is needed most. This minimizes material usage and maximizes efficiency.

Limitations: These systems may not be suitable for fully coating complex PCBs with intricate designs.

4. **Aerosol Spray Cans**:

Advantages: Aerosol spray cans are convenient for small-scale projects or touch-up applications. They are readily available and require minimal equipment.

Limitations: They may not provide the same level of precision and consistency as automated systems. They are also less efficient for large-scale production.

5. **Parylene Vapor Deposition**:

Advantages: Parylene coating offers exceptional protection and dielectric properties. It is highly uniform and conformal, making it suitable for intricate PCB designs.

Limitations: The equipment required for parylene vapor deposition is specialized and costly. It is typically used for critical applications where the highest level of protection is necessary.

Factors to Consider When Selecting a Conformal Coating Spray Method

Choosing the right PCB conformal coating spray method involves considering various factors to ensure both efficiency and superior protection:

1. **PCB Design Complexity**:

Evaluate the complexity of your PCB design. For intricate designs, selective coating or parylene vapor deposition may be necessary to ensure uniform coverage.

2. **Production Volume**:

Determine your production volume. For high-volume manufacturing, automated spray systems are the most efficient choice. Manual methods or aerosol cans are suitable for smaller volumes.

3. **Coating Material**:

Consider the type of conformal coating material you intend to use. Some coating materials are better suited for specific spray methods.

4. **Budget**:

Assess your budget for both equipment and materials. Automated systems and parylene vapor deposition require a more significant initial investment compared to manual or aerosol methods.

5. **Environmental Regulations**:

Ensure that your chosen method complies with environmental regulations regarding emissions and waste disposal.

6. **Quality Requirements**:

Determine the level of quality and reliability required for your application. Critical applications may demand the use of parylene or automated systems for the highest level of protection.

7. **Maintenance and Training**:

Consider the maintenance requirements of your chosen spray method and whether your team has the necessary training and expertise to operate it effectively.

Conclusion

Efficient PCB conformal coating spray is the key to achieving superior protection for electronic devices. By understanding the various conformal coating types and choosing the right spray method, manufacturers can ensure that their PCBs are safeguarded against environmental threats, while also optimizing cost, time, and quality aspects of the production process. Whether it's high-volume manufacturing with automated systems or precision protection with parylene vapor deposition, the choice of method should align with the specific needs of the application and the desired level of protection. In a world where electronics play an increasingly essential role in our daily lives, efficient conformal coating is a vital component of ensuring reliability and longevity in electronic devices.

#PCB Conformal coating spray#industrial parts#parts washing machines#contact cleaner spray#industrial component cleaning machine

0 notes

Text

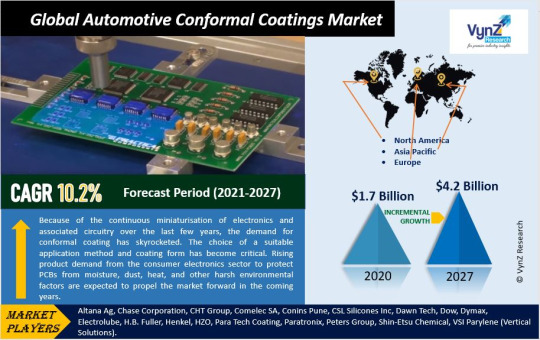

Global Automotive Conformal Coatings Market - Growth, Trends, COVID-19 Impact, and Forecasts (2021-2027)

The global automotive conformal coatings market is expected to reach USD 4.2 billion by 2027, from USD 1.7 billion in 2020. The market is growing at a CAGR of 10.2%, driven by the increasing adoption of electronics in vehicles and the development of new technology.

Market Overview

The global automotive conformal coatings market is segmented by material, component, vehicle type, application, and region.

By material: The market is segmented into acrylic, silicone, epoxy, polyurethane, and parylene. Acrylic is the most widely used material, followed by silicone.

By component: The market is segmented into ECU, PCB, sensor, battery casing, LED, and infotainment system. ECUs are the largest application segment, followed by PCBs and sensors.

By vehicle type: The market is segmented into passenger vehicles, light commercial vehicles, and heavy commercial vehicles. Passenger vehicles are the largest application segment, followed by light commercial vehicles and heavy commercial vehicles.

By application: The market is segmented into brush coating, dipping, spray coating, selective coating, and vapor deposition. Brush coating is the most widely used application method, followed by dipping and spray coating.

By region: The market is segmented into North America, Europe, Asia Pacific, Middle East & Africa, and South America. Asia Pacific is the largest market for automotive conformal coatings, followed by Europe and North America.

Get a free sample copy of the research report: https://www.vynzresearch.com/automotive-transportation/automotive-conformal-coatings-market/request-sample

Key Players

The key players in the global automotive conformal coatings market are:

• Altana Ag

• Chase Corporation

• CHT Group

• Comelec SA

• Conins Pune

• CSL Silicones Inc

• Dawn Tech

• Dow

• Dymax

• Electrolube

• H.B. Fuller

• Henkel

• HZO

• Para Tech Coating

• Paratronix

• Peters Group

• Shin-Etsu Chemical

• VSI Parylene (Vertical Solutions)

Trends and Opportunities

The global automotive conformal coatings market is expected to witness significant growth in the coming years. This growth will be driven by a number of factors, including:

The increasing adoption of electronics in vehicles

The development of new technology, such as self-driving cars and electric vehicles

The growing demand for conformal coatings in harsh environments

Challenges

The automotive conformal coatings market faces a number of challenges, including:

The high cost of conformal coatings

The complexity of the application process

The need for regular maintenance

Conclusion

The global automotive conformal coatings market is expected to grow significantly in the coming years. This growth will be driven by a number of factors, including the increasing adoption of electronics in vehicles, the development of new technology, and the growing demand for conformal coatings in harsh environments. The key players in the market are major suppliers of conformal coatings to OEMs and aftermarket distributors. The market faces a number of challenges, including the high cost of conformal coatings, the complexity of the application process, and the need for regular maintenance.

About Us:

VynZ Research is a global market research firm offering research, analytics, and consulting services on business strategies. We have a recognized trajectory record and our research database is used by many renowned companies and institutions in the world to strategize and revolutionize business opportunities.

Source: VynZ Research

0 notes

Text

FAQ

https://www.meank-magnet.com/service-support/faq.html

1

Why are neodymium magnets coated?

Neodymium magnet is mainly a composition of neodymium, iron, and boron. When the magnets are exposed to air, the iron in the magnet can rust and ruin the magnet, because iron is easy to be oxidized. Thus, to prevent the magnet from corrosion, the magnet have to be coated.

2

What type of coating can you supply?

We can supply the type of Nickel, Zinc, Epoxy, Gold, Silver, Sn, Parylene.

3

Which is the strongest type of magnet?

At present,the highest property magnets are rare earth magnets,NdFeB magnets are the strongest for rare earth magnets,but SmCo magnets are the strongest magnets for the environment over 200 degrees celsius.

4

What is monopole magnet?

All permanent magnets have two poles, but in some positions require mono pole magnet, so it is necessary to use a iron wrap one side of the magnet, the magnetism of the side that wrapped by iron is shielded, and refracted to the other side of the magnet through iron, the magnetic force of the other side is enhanced, so it called mono pole magnet or single pole magnet. There is no real single magnet!

5

What is Maximum Operating Temperature?

It is the temperature at which the magnet begin losing its ferromagnetic ability.

6

What is Curie Temperature?

It is the temperature at which the magnet will lose 100% of its ferromagnetic ability.

7

Will neodymium magnet lose their strength with time?

No, the magnet will keep the strength lifetime.

8

How is the strength of a magnet measured?

Gaussmeters are used to measure the magnetic field density at the surface of the magnet. This is referred to as the surface field and is measured in Gauss. Sometimes it measured in Tesla. Pull Force Testers are used to test the holding force of a magnet that is in contact with a flat steel plate.

0 notes

Text

0 notes

Text

How Medical Device Coatings can be Picked and Tested?

The coatings on medical devices can benefit to guarantee protection against corrosion, prurience, bone infiltration, and improved toughness. When choosing a precise coating, it’s imperative to select a solution offering the correct properties for the job, as this will make the most of the advantage to your device and guarantee ideal performance of the medical devices.

Though, selecting which kind of coating will be the best suited for an application is a pretty difficult task at hand. In these cases, having a reliable corporation conducting a laboratory coating assessment can be enormously treasured for defining the perfect solution for a definite job.

When looking for a coating assessment lab, one should take care to select a company offering a number of testing services, like corrosion testing, composition testing, morphology, metallurgical evaluation, and mechanical testing. Having several options up your sleeve will assist you to ensure that you find the coating complementing your parts and devices. It’s also indispensable to ply a squad of coating specialists using these up-to-the-minute tools and knowhows, providing clients with the most advanced, dependable solutions that are available in the medical device coating market.

Coating Assessments for the Medical Device Sector

The medical device sector, especially, can significantly take advantage from the usage of coatings. As innovative, pioneering technologies are available, the medical sector has begun to take part in many of them into trailblazing medical devices. But these coatings need cutting-edge features that guarantee optimal sturdiness, safety, sterility, and permanency. These precise necessities often require assessments to find coatings that will not just increase the lifespan of the medical device, but correspondingly make it biocompatible and corrosion resistant.

For medical devices, specifically, there are tests obtainable for a number of coatings like Parylene, beta-tri-calcium phosphate, hydroxyapatite, titanium and others to guarantee greater production control. These services support the R&D efforts, along with overflow testing.

Browse detailed report Medical Device Coating Industry Growth and Future Scope

What to Hunt for When Directing a Coating Assessment Process

Working with the appropriate coating solution aids guarantee the delivery of top-notch medical products, the ones that not just improves the eminence of life for patients, but also meet stringent standards of the industry, minimalize the probabilities of disappointment, and comply with applicable regulations. Proper evaluations will aid regulate the apt adhesion properties coating thickness, and chemical cleanliness required.

Concluding the Scene

Choosing the fitting medical device coating can really be a hard nut to crack in general, but if you can select the right company to do so, this can become a tad easier. With an increased demand for device coatings because of mass-scale development of healthcare infra and rise in the number of chronic diseases and healthcare-related infection, the device coating market will rise to a value of about $15,166 million in the years to come.

0 notes

Text

Medical Grade Coatings Market Size, Share, Demand and Trends by 2022-2031

As per a examine through future market Insights, the medical grade coatings market will enlarge at a CAGR of 6.7% in the course of the forecast length of 2021-2031. The growing demand for medical device and enlargement of the scientific devices zone in various regions had been creating possibilities for the increase of the clinical grade coatings marketplace. As according to the report, amongst materials used, the demand for polytetrafluoroethylene or PTFE is drastically high. PTFE substances have wider programs in coating and are utilized in hydrophobic, anti-microbial, and other coatings. It’s far anticipated to account for almost 33% of medical grade coatings synthetic in 2021 in phrases of fee.

Regionally, North the usa and Europe will stay key markets. Of these, North the united states is anticipated to remain dominant. The presence of a properly-developed healthcare infrastructure will maintain helping boom in those regions.

“Growing demand from medical sector is expected to drive the medical grade coatings sales. While developed countries will continue exhibiting demand, stagnancy in certain pockets will compel market players to explore options in emerging economies. Considering the presence of unmet medical needs and increasing focus on expansion of healthcare sector, medical grade coatings manufacturers will find conducive environment for growth in emerging nations,” says an FMI analyst.

Get Your 30% Discount Now! Request for Sample @ https://www.futuremarketinsights.com/reports/sample/rep-gb-8664

Key Takeaways of Global Medical Grade Coatings Market Study

Medical grade coatings market is expected to surpass US$ 6.68 Bn in 2021

The U.S. will emerge dominant, accounting for nearly 85% of sales in North America. Thanks to increasing focus on healthcare research, the U.S. will continue spearheading growth in the region

The U.K. will exhibit 5.4% y-o-y growth in 2021, driven by increasing healthcare spending

Germany and France will remain attractive pockets for sales within Europe

China will remain the leading market for medical grade coatings in East Asia, followed by Japan and South Korea.

The global medical grade coatings market is anticipated to grow substantially owing to the development in the medical as well as health-care sector and increasing investment in innovation and development of medical devices and equipment. Outbreak of COVID-19 has significantly impacted the global medical grade coatings market. The rising demand for various medical equipment and devices to offer efficient care to a mounting number of patients created prospects for medical grade coatings sales.

Who is Winning?

Key players are focusing on research and development activities to introduce new and innovative products, solutions, and technologies. The global medical grade coatings market can be considered as oligopolistic due to the presence of a considerable number of players across the globe, accounting for a considerable volume of share. There is increasing focus on collaboration and acquisitions to increase market presence.

The global medical grade coatings market has been identified as a significantly fragmented market. The Tier 1 manufacturers account for maximum share in the global market. Some of the leading players included in the report are DuPont, Koninklijke DSM NV, SurModics, Inc., Speciality Coating Systems Inc. Precision Coating Co. Inc., Biocoat Inc., Covalon Technologies Ltd., Harland Medical Systems Inc., Hydromer Inc., Medicoat, Inc. Aculon Inc., and AST Products Inc the manufacturers across the globe are anticipated to create tough competitive environment on the global level.

Medical Grade Coatings Market by category

Material

PTFE

PVDF

Silicone

Parylene

Metals

Others

Application

General Surgery

Cardiovascular

Orthopedics

Neurology

Gynecology

Dentistry

Others

Type

Hydrophilic

Hydrophobic

Anti-Microbial

Drug Eluting

Others

Formulation

Solvent Based

Water Based

Powder Coating

Table of Content

1. Executive Summary

1.1. Global Market Outlook

1.2. Demand Side Trends

1.3. Supply Side Trends

1.4. Technology Roadmap

1.5. Analysis and Recommendations

2. Market Overview

2.1. Market Coverage / Taxonomy

2.2. Market Definition / Scope / Limitations

3. Key Market Trends

3.1. Key Trends Impacting the Market

3.2. Innovation / Development Trends

4. Key Success Factors

To be continued…!

Browse Full Report: https://www.futuremarketinsights.com/reports/medical-grade-coatings-market

0 notes

Text

Conformal Coatings Market Size and Analysis, Trends, Recent Developments, and Forecast Till 2030

Conformal coating is a chemical or polymer coating type that helps protect the circuit board from any adverse or abrasive environment. The coating also aids in keeping the circuit away from any chemical contaminants. The global conformal coatings market, according to the recently published report by the team of Market Research Future (MRFR), is expected to grow with an impressive growth rate during the forecast period between 2021 and 2030. Furthermore, the valuation is forecasted to go beyond the previously reported market valuation by the end of the forecast period.

Conformal Coatings Market is projected to be worth USD 17.02 Billion by 2030, registering a CAGR of 5% during the forecast period (2021 - 2030).

The conformal coatings market is driven by the demand from the electronics industry. The market is expected to grow due to the increasing demand for gadgets from an expanding population. Increasing adoption of AI and IoT and proliferation of adoption are also key factors pushing the market growth further. The market is also gaining considerable traction from the aviation industry, which is, in turn, supporting the growth of the market.

Market Segmentation

The Global Conformal Coatings Market has been segmented into type, end-use industry, and region.

On the Basis of the Type, the market is divided into acrylics, epoxy, urethane, silicone, parylene and others.

Based on End-Use Industry, the market is segmented into electronics, automobile, aerospace, marine and others.

Geographically, the market is divided into five regions including North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa.

Key Players

The Dow Chemical Industry (U.S.)

Specialty Coatings System Inc.

Global Manufacturing Services Inc (U.S.)

HemiSeal (U.S.)

Henkel AG & Co. kgaA (Germany)

Chemtronics (India)

H.B.Fuller Company (U.S.)

Electrolube (UK)

Europlasma NV (Belgium)

Shin-Etsu Chemical Co. Ltd (Japan).

Regional Analysis

North America was the dominant region in the Global Conformal Coatings Market due to its increasing use in the electronic devices mainly in automobile and aerospace industry. Additionally, increasing expenditure on consumer electronics mainly in home appliances, smart watches, and wireless devices.

Europe is expected to drive the market growth due to the introduction of high quality and technically advanced products. Increasing expenditure on research and development in electronics by Germany is likely to fuel the product demand in this region.

Asia Pacific region is growing substantially due to rapid urbanization and digitalization in the developing economies such as India and China. Moreover, implementation of various initiatives such as Smart City and Startup in India is encouraging the Indian companies to focus on product innovation and R&D.

Get Complete Report @ https://www.marketresearchfuture.com/reports/conformal-coatings-market-5786

Contact us:

Market Research Future (part of Wantstats Research and Media Private Limited),

99 Hudson Street, 5Th Floor,

New York, New York 10013

United States of America

+1 628 258 0071

Email: [email protected]

0 notes

Text

Parylene Coating Solutions from DawnTechsb

DawnTechsb provides premium Parylene Coating Services in Singapore and Malaysia. Our service is cutting-edge technology that ensures superior protection for your components. Ideal for applications requiring moisture, chemical, and abrasion resistance, our coatings provide unmatched durability. Whether you're in electronics devices or aerospace, DawnTechSB delivers precision and reliability. Visit DawnTechsb to learn more about our Parylene coating services.

For more info visit us: https://dawntechsb.com/parylene-coating-process/

#parylene coating#nano ceramic coating#conventional coating suppliers#nano ceramic coatings manufacturer

0 notes

Text

Freespace 13

#Freespace 13 free#

5 Experimentally, significant improvements of sensitivity by mode-filtering were shown with the use of a single-mode fiber-coupled detector (FCD). This effect can be explained using different frameworks, either as rejecting more divergent components of the beam which carry lower contrast interference fringes 4 or removing higher-order spatial modes of the beam which carry spectrally shifted interference fringes which lower the contrast (and hence sensitivity) of the ITF. 8 An alternative method of aberration correction is based on spatial-mode-filtering 4, 5, 9 where a single-mode fiber 5, 9 or an optical pinhole 4 is used to reject part of the interrogation light to improve the measurement sensitivity. 4 It was previously shown that both beam and cavity aberrations, 5 surface roughness 6 as well as mirror non-parallelism 4, 7 can lead to severe deterioration of the optical sensitivity of the FPI and that this loss can be partially recovered by the use of aberration correction techniques including adaptive optics. Among different types of optical sensors, FP cavities are especially sensitive to aberrations as their sensing principle is dependent on the high spatial uniformity of the light beam to facilitate efficient interference. 2, 3Īs optical devices, FPIs are sensitive to light beam aberrations, which can have detrimental effects on their performance under certain conditions. In practice, this approach has allowed acoustic sensing in the range of 100 to 10 6 Pa with a very broadband frequency response (bandwidth ∼ 0.1 to 40 MHz). The sensor is then interrogated by tuning the laser wavelength to the point of maximum slope on the ITF (so-called bias wavelength) which translates the acoustic (pressure) waves into a modulation of an optical (interference) signal. This optical resonator has then the ability to elastically deform under pressure, modulating the FP interferometer’s transfer function (ITF), which is a function of the cavity thickness. For this application, a pressure-sensitive FP device is formed by sandwiching a thin layer (10 to 100 μ m) of elastomer (e.g., Parylene C) between two dichroic mirrors. Among them, Fabry–Pérot interferometer (FPI) sensors are particularly promising, as they combine the ability to measure acoustic waves with high spatial resolution and pressure sensitivity. 1 Multiple optical detector types and geometries are constantly being developed and improved with the overarching aim of matching the detection sensitivity of piezoelectric systems. Results: We found that fiber-coupled detectors are superior in terms of both signal level and image quality in realistic all-optical PA tomography settings.Ĭonclusions: Our study has important practical implications in the field of PA imaging, as for most applications and implementations fiber-coupled detectors are relatively easy to employ since they do not require modifications to the core of the system but only to the peripherally located detector.Īll-optical photoacoustic (PA) tomography is an emerging alternative to classical piezoelectric approaches.

#Freespace 13 free#

While spatial mode-filtering has been proposed to alleviate these problems in Fabry–Pérot-based pressure sensors, their real functional advantage has never been properly investigated.Īim: We rigorously and quantitatively compare the performance of free-space and fiber-coupled detectors for Fabry–Pérot-based pressure sensors.Īpproach: We develop and characterize a quantitative correlative setup capable of simultaneous PA imaging using a free space and a fiber-coupled detector. However, free-space optical detectors are prone to optical aberrations, which can degrade the pressure sensitivity and result in deteriorated image quality. Significance: Highly sensitive detection is crucial for all-optical photoacoustic (PA) imaging.

0 notes

Photo

A new solution to cool electronic devices and prevent them from overheating

Electronic devices, including smartphones and tablet portable computers, are becoming increasingly advanced and compact. As their performance increases and their size decreases, these devices generate more heat, which can reduce their safety and cause them to break.

In recent years, engineers have thus been trying to develop strategies that could prevent electronics from overheating. One proposed solution entails the use of heat spreaders, layers that promote the spread and dissipation of heat inside devices.

Researchers at University of Illinois at Urbana-Champaign and University of California, Berkeley (UC Berkeley) have recently devised an alternative strategy that could cool electronics more efficiently than other existing solutions. Their strategy, introduced in a paper published in Nature Electronics, is based on the use of heat spreaders comprised of an electrical insulating layer of poly (2-chloro-p-xylylene) (Parylene C) and a coating of copper.

Read more.

30 notes

·

View notes

Video

youtube

Electronics are an essential part of today’s world; they are built to resist many things and endure the daily life of any individual. The resistance is paramount for any electronic product today, but not all of them are built to withstand a fight against the most basic element: water. Fortunately, some companies specialize in developing solutions for this inconvenience. Electronics, after all, tend to be expensive, and taking care of them should be a priority for any owner. HZO is a company that genuinely believes that when it comes to waterproof, they can provide the most reliable solution for your equipment. They use protection that range from nanocoatings to parylene barrier coatings to give the security you are precisely looking. If you are looking for true environment-proofing and waterproofing coating technologies; then HZO is the right company to contact. Their technology and coatings prevents corrosive liquids from damaging your electronics. Check their website to find out more about HZO and their incredible waterproof abilities: https://hzo.com. You can visit their office at 13894 S. Bangerter Pkwy. Suite 200, Draper, UT. What are you waiting for your gadget to enter the new generation of endurance? Contact HZO and make your product waterproof so it is one of the most resistant on the market!

1 note

·

View note

Photo

Parylene Market Research for 2017 Examined in New Report Summary Parylene is a common generic name for a unique series of polymers based on paraxylene. It is a polymer created from a chemical compound known as dimer, which is actually a powder.

#Parylene#parylene coating process#parylene coating services in india#parylene deposition system#Parylene forecast#Parylene growth#Parylene Market#Parylene price#Parylene share#Parylene size#Parylene trends#Parylene uses

0 notes

Text

Corrosion-Proofing Your Devices

Corrosion refers to the oxidation reaction that takes place when metals react with oxygen and water to form a metal oxide. It is a chemical reaction that affects most metals in the world. Let’s have a look at how a steel metal gets corroded. When metal steel is exposed to air, the iron reacts with oxygen to form tri-iron tetraoxide, which is a brown coat, mostly known as rust. Rust gradually destroys the material, thus reducing its lifetime. Exposure of the metal material to the environment and water is the most significant cause of rust and breakdown. It is, therefore, essential to prevent breakdown of the metals one uses. How can one help make devices corrosion proof?

Not only are the construction arterials at risk of getting corroded but also electronic devices and devices such as cell phones, refrigerators, electric gas cookers, among many others. The next electronic equipment that one will buy should be corrosion proof. Why? Because of the following reasons:

To make them last longer. Devices that are rusted tends to experience some malfunctioning. It is, therefore, essential to make them corrosion proof so that one can use them for a more extended period.

To improve their efficiency. Devices will operate better if they are free from all the causes of damage. Make sure they are corrosion-proof so that they can work effectively.

To help in minimizing cost. As stated earlier that electric gadgets and machines that are not made of corrosion-proof material tend to work ineffectively, it means that they are prone to breakages and malfunctioning.

How to Reduce Metal Breakdown:

1. By Using Special Metals

This is the simplest way of making thing corrosion proof, where one uses metal resistant metals such as stainless steel or aluminum. Go for electric appliances that are made of aluminum or stainless steel.

2. Use Of Protective Coatings

Choose electronics and devices that apply parylene or nanocoatings to the intricate metal interior. These kind of devices are submersion, high humidity, and splash proof.

3. Sacrificial coating

This involves coating the equipment material with a more reactive metal that will corrode first before the primary material. Sacrificial protection uses two major techniques.

4. Use Of Damage Inhibitors

These are chemicals that react with gases surrounding the material or the surface of the material to suppress the chemical reaction leading to metal rusting and decay. They are applied at the surface of the metal and form a protective layer. They can be used as coatings or as solutions.

5. Design Modification

This involves using technology to modify the designs of material used to manufacture the electronic tools and equipment. They should be designed in a way that they trap dust and water as well as the encouraging movement of air. This will improve the longevity of the equipment.

1 note

·

View note