#Ion-exchange Polymer Market

Explore tagged Tumblr posts

Text

Ion Exchange Resins Market: A Catalyst for Cleaner Solutions

The Ion exchange resins market is evolving rapidly, propelled by the increasing demand for cleaner processes across industries. From water purification to pharmaceutical applications, these resins are integral in maintaining purity and efficiency. But what exactly makes this market tick, and what challenges lie ahead? Here’s an in-depth look.

What Makes Ion Exchange Resins Essential?

Ion exchange resins are polymers designed to swap ions in a solution, effectively removing impurities like heavy metals, salts, and organic pollutants. Their dual functionality lies in cation exchange resins, which attract positively charged ions, and anion exchange resins, which bind to negatively charged ions. This adaptability makes them indispensable across industries where precision and purity are critical.

Ion Exchange Resins Market size is projected to grow from USD 2.13 billion in 2024 to USD 2.83 billion by 2030, registering a CAGR of 4.8% during the forecast period.

Why the Market is Booming

Global Water CrisisAs access to clean water becomes a mounting global challenge, ion exchange resins are emerging as a reliable solution for desalination, wastewater recycling, and demineralization. Their role in municipal water plants and industrial setups has grown significantly.

Industrial Needs EvolveIndustries such as power generation and chemical manufacturing rely heavily on purified water to maintain equipment and produce quality outputs. Ion exchange systems have become a cornerstone in ensuring process stability and safety.

Healthcare and PharmaceuticalsThe pharmaceutical sector leverages these resins to ensure active ingredients in medicines remain untainted. The rise in global healthcare needs directly impacts demand for high-performance resin solutions.

Environmental ConsciousnessWith stricter regulations on industrial discharge, companies are turning to ion exchange resins to meet compliance standards. Beyond that, the ability to regenerate and recycle makes these resins an eco-friendly choice.

Applications Across Industries

Water TreatmentThe largest application sector, water treatment uses these resins to soften water, remove heavy metals, and even desalinate seawater. These solutions are vital in both municipal and industrial systems.

Power PlantsBoiler feedwater in power plants must meet stringent purity levels. Resins help ensure these standards, preventing scaling and corrosion that could damage equipment.

Food and BeverageIn the food industry, resins are employed to refine sugars, purify beverages, and stabilize wine, ensuring the end product is of premium quality.

Chemical ManufacturingChemical industries use these resins to recover valuable by-products, neutralize effluents, and create ultrapure chemicals essential for production.

Geographical Highlights

North America & Europe: With advanced industrial infrastructure and rigorous environmental laws, these regions are leading the adoption of ion exchange technologies.

Asia-Pacific: Rapid industrial growth in countries like China and India, coupled with water scarcity, is driving significant demand for ion exchange systems.

Middle East & Africa: These regions hold untapped potential, especially in desalination projects addressing water shortages.

Future Prospects

The future of the ion exchange resins market looks bright. Innovations in bio-based and highly selective resins are addressing sustainability concerns, making them more attractive to industries. Additionally, advancements in IoT-enabled monitoring systems could revolutionize efficiency and integration in large-scale operations.

To know more Download PDF Brochure :��

Ion exchange resins are more than just purification tools—they’re enablers of sustainability and operational excellence across industries. As technology evolves and global challenges mount, these resins will play a central role in shaping processes that are both efficient and environmentally conscious. For industries aiming to stay ahead, investing in ion exchange resin technologies isn’t just an option—it’s a necessity for a cleaner, greener future

#IonExchangeResins#WaterTreatment#Sustainability#CleanTechnology#IndustrialSolutions#EnvironmentalInnovation#PharmaceuticalApplications

0 notes

Text

Chromatography Resins Market is driving Separation and Purification Processes

Chromatography resins help separate and purify biomolecules and are used extensively in pharmaceutical, food, and chemical separation processes. Chromatography resins are polymer beads that facilitate the separation, purification, and quantification of biomolecules like proteins, peptides, nucleic acids, and small molecules. The beads contain ligands that bind selectively to biomolecules based on their chemical or physical properties. Based on the ligand used, chromatography resins are available in different variants like ion-exchange resins, affinity resins, hydrophobic interaction resins, size-exclusion resins. When a sample mixture passes through the chromatography resin column, different biomolecules bind to the resin with varying affinity based on their characteristics and get separated. Pure components can then be collected by changing the conditions like pH or introducing an elution buffer. The Global Chromatography Resins Market is estimated to be valued at US$ 2.2 Billion in 2024 and is expected to exhibit a CAGR of 6.7% over the forecast period 2024-2027.

Rapid growth in the pharmaceutical and biotechnology industries and increasing research on drug discovery and large molecule biosimilars have boosted the demand for effective separation techniques. Chromatography resins have become integral to the purification of antibodies, vaccines, hormones, enzymes, and other therapeutic proteins. Key Takeaways Key players operating in the chromatography resins market are Thermo Fisher Scientific Inc., WR Grace & Co., Merck KGaA, Bio-Rad Laboratories Inc., Tosoh Corporation, and Purolite Corporation. The booming biopharmaceutical industry is driving consistent demand for chromatography resins for large-scale downstream processing applications. Monoclonal antibody production alone requires huge volumes of varied chromatography resins. Global players are expanding their production capacities across Asia Pacific and Latin America to meet the growing requirements of the pharmaceutical industry in emerging markets and benefit from low-cost manufacturing opportunities. Several new production plants for chromatography resins have come up over the past five years in China, India, Brazil, and Mexico. Market key trends One of the key trends gaining traction in the Chromatography Resins Market Demand is the rising popularity of pre-packed chromatography columns. These plug-and-play columns containing the resin reduce preparation time and improve reproducibility. They are well-suited for process development activities and process characterization runs involving short cycle-times. Major resin manufacturers are focusing on developing advanced pre-packed columns with better flow dynamics and higher binding capacities.

Porter’s Analysis Threat of new entrants: Low capital requirements and established value chain restrict threats of new entrants in chromatography resins market.

Bargaining power of buyers: Large number of buyers and availability of substitutes increases buyers bargaining power.

Bargaining power of suppliers: Established suppliers and intellectual property rights limit buyers bargaining power.

Threat of new substitutes: Emerging technologies pose threat of substitution to chromatography resins.

Competitive rivalry: Large number of players compete on cost and quality leading to high competitive rivalry. Geographical Regions North America accounts for the largest share in chromatography resins market in terms of value owing to increasing R&D investment and growth of pharmaceutical industry. Asia Pacific is anticipated to be the fastest growing region during the forecast period due to growing pharmaceutical industry, outsourcing trends and increasing research activities in countries like India and China.

Get more insights on Chromatography Resins Market

About Author:

Money Singh is a seasoned content writer with over four years of experience in the market research sector. Her expertise spans various industries, including food and beverages, biotechnology, chemical and materials, defense and aerospace, consumer goods, etc. (https://www.linkedin.com/in/money-singh-590844163)

#Coherent Market Insights#Chromatography Resins Market#Chromatography Resins#Purification Resins#Protein Purification#Ion Exchange Resins#Affinity Chromatography Resins#Gel Filtration Resins

0 notes

Text

Informative Report on Asia Pacific PEM Electrolyzer | Bis Research

A PEM Electrolyzer (Proton Exchange Membrane Electrolyzer) is a device that uses electrical energy to split water into hydrogen and oxygen through the process of electrolysis. It utilizes a solid polymer electrolyte (a proton exchange membrane) to conduct protons from the anode to the cathode, while separating the generated oxygen and hydrogen gasses.

The Asia-Pacific PEM electrolyzer market is projected to reach $306.7 million by 2031 from $14.7 million in 2022, growing at a CAGR of 40.1% during the forecast period 2022-2031.

Asia Pacific PEM Electrolyzer Overview

A PEM Electrolyzer (Proton Exchange Membrane Electrolyzer) is a technology used for hydrogen production through water electrolysis. It operates by splitting water molecules (H₂O) into hydrogen (H₂) and oxygen (O₂) using electricity.

Download our Report to know more

Components for PEM Electrolyzer

Solid Polymer Electrolyte Membrane

Two Electrodes - Cathode and Anode

Functions of PEM Electrolyzer

Proton Conductor, allowing hydrogen ions to pass through while blocking electrons and gasses, ensuring the separation of hydrogen and oxygen.

Water Splitting- The primary function is to split water (H₂O) into hydrogen (H₂) and oxygen (O₂) using electrical energy.

Hydrogen Production - It generates pure hydrogen gas at the cathode for various industrial, energy, and fuel applications.

Advantages of PEM Electrolyzer

High Efficiency

Compact Design

High Purity Hydrogen

Fast Startup and Shutdown

Operates at high current density

High Pressure Hydrogen Production

Uses of PEM Electrolyzer

1 Conjunction with Solar or Wind Energy to produce Green Hydrogen, which can be stored, used as fuel, or for industrial purposes.

2 Hydrogen Production- PEM electrolyzers produce high-purity hydrogen, which is used in various industrial processes like refining, chemical production, and electronics manufacturing.

3 Renewable Energy- PEM electrolyzers are used to convert surplus electricity from renewable sources (solar, wind) into hydrogen, enabling energy storage and balancing the grid.

4 Fuel for Fuel Cell Vehicles -The hydrogen produced by PEM electrolyzers is used as fuel in hydrogen-powered fuel cell vehicles, providing a clean alternative to fossil fuels.

5 Power to Gas Systems - PEM electrolyzers are integrated into power-to-gas systems, converting electrical energy into hydrogen or synthetic natural gas for long-term energy storage.

6 Decarbonization of Industries- Green hydrogen from PEM electrolyzers helps decarbonize sectors such as steel, ammonia, and cement production by replacing fossil-based hydrogen.

Key Applications

Energy Storage

Fuel Cell Vehicles

Decarbonization of Industries reliant on Hydrogen

Visit our sample page click here !

Market Segmentation

1 By End Users

Refining Industry

Power and Energy Storage

Ammonia Production

Methanol Production

Transportation

Others

2 By Material Type

Iridium

Platinum

Others

3 By Country

Japan

India

South Korea

Australia

Rest of Asia Pacific

Key Players

Elchemtech Co., Ltd.

Hitachi Zosen Corporation

Beijing SinoHy Energy Co., Ltd

Ningbo VET Energy Technology Co., Ltd.

Conclusion

A Proton Exchange Membrane (PEM) electrolyzer is a key technology in the production of green hydrogen, offering several advantages such as high efficiency, compact design, and the ability to operate at high current densities. In conclusion, PEM electrolyzers represent a promising solution for sustainable energy storage and conversion, particularly in sectors aiming to reduce carbon emissions.

As renewable energy sources like solar and wind become more integrated into the energy grid, PEM electrolyzers are poised to play a pivotal role in decarbonizing industries and supporting a hydrogen-based energy economy.

0 notes

Text

Chromatography Resin Market Size, Trends, Revenue Share Analysis, Forecast, 2024–2030

The Chromatography Resin Market was valued at USD 2.6 billion in 2023-e and will surpass USD 4.4 billion by 2030; growing at a CAGR of 7.7% during 2024 - 2030. The report focuses on estimating the current market potential in terms of the total addressable market for all the segments, sub-segments, and regions. In the process, all the high-growth and upcoming technologies were identified and analyzed to measure their impact on the current and future market. The report also identifies the key stakeholders, their business gaps, and their purchasing behavior. This information is essential for developing effective marketing strategies and creating products or services that meet the needs of the target market.

Chromatography is a laboratory technique for the separation of a mixture into its components. Chromatography resin is a medium used in the column chromatography method, which includes ion exchange, affinity, and size exclusion chromatography. These resins are essential for purifying proteins, nucleic acids, and other biomolecules, making them indispensable in various industries.

Read More about Sample Report: https://intentmarketresearch.com/request-sample/chromatography-resin-market-3154.html

Key Drivers of Growth

Biopharmaceutical Boom: The rise in biopharmaceutical production, including monoclonal antibodies, vaccines, and recombinant proteins, has significantly boosted the demand for chromatography resins. These resins play a crucial role in the purification processes, ensuring the safety and efficacy of biopharmaceutical products.

Technological Advancements: Innovations in chromatography techniques and resin development have enhanced the efficiency and effectiveness of purification processes. Advances such as multi-modal resins, which combine different modes of interaction, have expanded the applications of chromatography.

Regulatory Compliance: Stringent regulatory requirements for drug approval and quality control in the pharmaceutical and food industries necessitate the use of reliable and efficient purification methods. Chromatography resins, known for their precision and reliability, are in high demand to meet these standards.

Environmental and Food Safety: The growing emphasis on environmental monitoring and food safety has increased the use of chromatography resins in testing and analysis. These resins help detect contaminants and ensure the quality of water, air, and food products.

Market Segmentation

The chromatography resin market can be segmented based on type, technique, application, and region.

By Type: Natural polymer, synthetic polymer, and inorganic media are the primary types of chromatography resins. Natural polymers, such as agarose and cellulose, dominate the market due to their biocompatibility and versatility.

By Technique: The market is segmented into ion exchange, affinity, size exclusion, hydrophobic interaction, and others. Ion exchange and affinity chromatography are the most widely used techniques, owing to their high selectivity and efficiency.

By Application: The applications of chromatography resins span across pharmaceuticals, biotechnology, food and beverage, water and environmental analysis, and others. The pharmaceutical and biotechnology sectors account for the largest share due to their extensive use in drug development and production.

By Region: North America holds the largest market share, followed by Europe and the Asia-Pacific region. The presence of major biopharmaceutical companies, advanced healthcare infrastructure, and significant R&D investments drive the market in these regions.

Ask for Customization Report: https://intentmarketresearch.com/ask-for-customization/chromatography-resin-market-3154.html

Future Prospects

The chromatography resin market is poised for continued growth, driven by several key trends:

Personalized Medicine: The shift towards personalized medicine and targeted therapies will increase the demand for chromatography resins in the purification of specific biomolecules tailored to individual patient needs.

Biosimilars and Biobetters: The rising development of biosimilars and biobetters will fuel the demand for efficient purification techniques, further driving the chromatography resin market.

Sustainability Initiatives: Increasing focus on sustainability and green chemistry will lead to the development of eco-friendly chromatography resins, reducing environmental impact and enhancing market growth.

Emerging Markets: Rapid industrialization and advancements in healthcare infrastructure in emerging markets, particularly in Asia-Pacific and Latin America, will provide significant growth opportunities for the chromatography resin market.

Conclusion

The chromatography resin market is on a trajectory of robust growth, driven by advancements in biotechnology, increasing biopharmaceutical production, and stringent regulatory requirements. With ongoing innovations and expanding applications, the future of the chromatography resin market looks promising. Stakeholders in the industry should stay abreast of these trends to capitalize on the growth opportunities and navigate the evolving landscape effectively.

#Chromatography Resin#Chromatography Resin Growth#Chromatography Resin Trends#Chromatography Resin Outlook

0 notes

Text

Proton Exchange Membrane Fuel Cell (PEMFC) Market overview by recent opportunities, growth size, regional analysis and forecast 2024-2033

“Global Insight Services company has recently revised its global market reports, now incorporating the most current data for 2024 along with projections extending up to 2033.

A Proton Exchange Membrane Fuel Cell (PEMFC) is a type of fuel cell that uses hydrogen and oxygen to produce electricity. PEMFCs are the most common type of fuel cell used in cars and other vehicles. PEMFCs work by passing hydrogen gas through a membrane. The hydrogen ions (protons) pass through the membrane and react with oxygen to produce water and electricity. The electrons produced by the reaction are used to power the vehicle.

View The Full Report Here –https://www.globalinsightservices.com/reports/proton-exchange-membrane-fuel-cell-pemfc-market

Key Trends

The Proton Exchange Membrane Fuel Cell (PEMFC) technology is a type of fuel cell that uses a proton-conducting membrane as the electrolyte. The PEMFC was first developed in the early 1900s, but it was not until the 1970s that it began to be used commercially.

PEMFCs are used in a variety of applications, including portable electronics, automotive, stationary power, and backup power. PEMFCs have a number of advantages over other types of fuel cells, including high power density, high efficiency, and low emissions.

PEMFCs are typically made with a thin film of proton-conducting polymer sandwiched between two electrodes. The electrodes are usually made of carbon, and the electrolyte is typically a thin film of proton-conducting polymer.

PEMFCs can operate at a wide range of temperatures, from -50°C to +100°C. They can also operate at a wide range of pressures, from atmospheric to 10 bar.

Key Drivers

The key drivers of the Proton Exchange Membrane Fuel Cell (PEMFC) market are the increasing demand for fuel cells, the need for clean energy, and government support for fuel cells.

Fuel cells are a clean and efficient way to generate electricity, and they are being increasingly used in a variety of applications, such as power generation, transportation, and portable electronics. Fuel cells offer many advantages over traditional combustion-based power generation technologies, including higher efficiency, lower emissions, and the ability to operate using a variety of fuels.

The demand for fuel cells is being driven by the need for clean energy, as fuel cells produce no emissions of pollutants or greenhouse gases. Fuel cells are also becoming increasingly cost-competitive with other power generation technologies, due to advancements in technology and manufacturing.

The government is also providing support for fuel cells, through policies and incentives, which is helping to drive the market for fuel cells.

#Proton Exchange Membrane Fuel Cell (PEMFC) Market#Proton Exchange Membrane Fuel Cell (PEMFC) Market Trends#Proton Exchange Membrane Fuel Cell (PEMFC) Market manufacturing#Proton Exchange Membrane Fuel Cell (PEMFC) Market industry#Proton Exchange Membrane Fuel Cell (PEMFC) Market Energy & Natural Resources

0 notes

Text

Itaconic Acid Market Analysis: Key Insights and Future Outlook

Introduction Methylenesuccinic acid is an organic dicarboxylic acid produced as an intermediate metabolite by certain fungi during glucose fermentation. With the chemical formula C5H6O4, methylenesuccinic acid has two carboxyl groups that make it highly reactive and versatile for chemical applications. Its production from renewable biomass via fermentation also makes methylenesuccinic acid attractive as a sustainable building block. Applications in Specialty Polymers One major use of itaconic acid is in the production of specialty polymers. Its two carboxyl groups allow it to act as a comonomer in polymerization reactions. When copolymerized with acrylic acid or other monomers, methylenesuccinic acid introduces desirable properties like hydrophilicity, permeability, and acidity into the final polymers. Such methylenesuccinic acid copolymers find widespread use as superabsorbents in hygiene products, thickeners in industrial applications, and biodegradable materials. They are also being explored for new applications in fuel cells, adhesives, coatings and ion-exchange resins. Intermediate for Synthetic RESINS Besides direct applications, methylenesuccinic acid also enables the production of many important intermediates and final products. It undergoes thermal decarboxylation to form styrene, a precursor to polystyrene plastics. Via acidolysis with polyols, methylenesuccinic acid can make reactive polyester resins used as binders, coatings or matrices. Dimerization to produce citraconic anhydride opens new routes for epoxy and alkyd resins essential to paints, varnishes and construction materials. With techniques like selective hydrogenation, methylenesuccinic acid can even yield substituted furan derivatives and other platform chemicals with wide scope in the agrochemical and pharmaceutical industries. Sustainable Chemical Building Block As industries transition towards renewable, sustainable bio-based options, itaconic acid displays immense potential. It serves as an ideal building block - with its versatile functional groups, biodegradability, and production from abundant biomass. Global production capacities are scaling up to serve diversifying applications. Meanwhile, metabolic engineering pushes yields and titers higher. Methylenesuccinic acid exemplifies how sustainable biomanufacturing and green chemistry principles can yield platform chemicals previously derived from petrochemicals. This opens up new pathways for more environmentally benign products meeting society's needs well into the future.

0 notes

Text

Exploring the Biomedical Applications of Itaconic Acid in Drug Delivery and Biomaterials

Itaconic Acid: A versatile platform chemical gaining significance Production and Applications of Methylenesuccinic Acid Itaconic acid is produced through fermentation of carbohydrates like glucose, sucrose or molasses by fungi species Aspergillus itaconicus or Ustilago maydis. The process involves fungi growth in aqueous medium containing nutrients and sugars followed by acidification to extract methylenesuccinic acid. The medium is then filtered and purified using ion-exchange or crystallization to achieve high purity methylenesuccinic acid. Some key players involved in commercial production of methylenesuccinic acid include Itaconix Corporation, Qingdao Kehai Biochemistry Co., Ltd. and Zhejiang Guoguang Biochemistry Co., Ltd. Current global production capacity of methylenesuccinic acid stands at over 50,000 tons per year. Uses in Polymers and Specialty Chemicals Manufacturing Being a dicarboxylic acid, methylenesuccinic acid serves as an important building block chemical for polymers and specialty chemicals. It finds significant usage in manufacturing of synthetic latex, superabsorbent polymers, chelating agents and copolymers for diverse applications. As a comonomer for acrylate or methacrylate polymers, methylenesuccinic acid improves water-absorbency and acid-base properties. Its copolymers with acrylates and styrene are used in paper coatings, adhesives, thickeners and dispersants. Methylenesuccinic acid also acts as a complexing agent for heavy metal ions and is used in industrial and agricultural chelating formulations. Potential in Novel Therapeutic Applications Novel applications of itaconic acid are being researched in the medical field as well. Some studies have revealed its anti-fungal, antibacterial and anti-viral properties. Research is in progress to develop itaconate derivatives with enhanced bioactivity against multi-drug resistant pathogens. Methylenesuccinic acid is also known regulate inflammatory responses in human body by inhibiting certain enzymes. This makes it a potential candidate for developing novel anti-inflammatory pharmaceuticals. Exploratory trials indicate it may assist in managing conditions like diabetes, neurodegeneration and cancer. Though in early stages, these therapeutic applications open up completely new frontiers for methylenesuccinic acid if successfully commercialized in future. To conclude, with its unique structural attributes and bio-based origin, methylenesuccinic acid has emerged as a very important specialty platform chemical with broad scope across industries. Backed by steady growth in end-use markets and rising sustainability emphasis, the methylenesuccinic acid industry is rightly positioned for significant expansion globally in the coming years. Ongoing R&D and commercial initiatives also point towards novel product concepts and applications further accentuating the industrial relevance of this multifaceted organic acid.

0 notes

Text

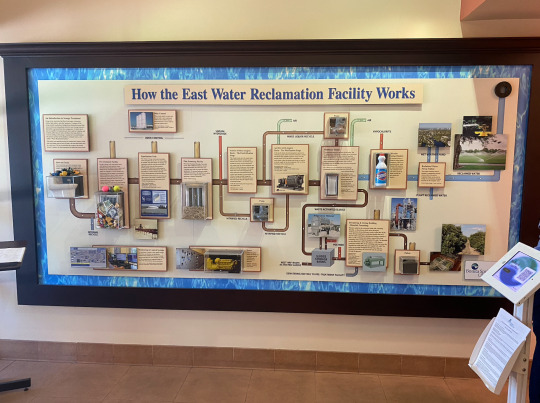

Bonita Springs Water Reclamation Facility

Photo taken by me.

The Bonita Springs East Water Reclamation Facility is a wastewater treatment plant that is leading its industry in sustainable practices. Up to 4 million gallons of sewage are processed at this facility every day, and the sewage is turned into new products that are sold to generate revenue for the plant. The process begins when water from drains all around the Bonita Springs area reaches the water reclamation facility through underground pipes. Large materials are removed from the water using a coarse drum screen before it reaches the equalization tank. The equalization tank serves the purpose of treating the sewage at a continuous rate as well as aerating the sewage to reduce malodors. The sewage is then moved through a finer drum screen to remove smaller solids, which are taken to a landfill. Next is the denitrification stage, which occurs inside the anoxic basin. The book “Sustainability Principles and Practice” explains that “some anaerobic bacteria can metabolize some kinds of contaminants that cannot be broken down by aerobic bacteria (Alexander 1999, 369). It is anaerobes who digest food in animal digestive tracts, sewage in wastewater treatment tanks, and buried matter in landfills” (Robertson, 2021, pp. 190-191). Indeed, anaerobic microorganisms are used at the wastewater treatment plant to consume any organic material in the sewage. From the anoxic basin, the water moves into the aerobic basin, where microorganisms use the oxygen in the basin for energy to convert ammonia in the sewage into nitrate and nitrite ions. Next, the water moves through Veolia membranes, which are long fibers with microscopic pores that filter all impurities out of the water. The next steps in the process turn the reclaimed water into products that are profitable for the facility.

Photo taken by me.

According to the textbook, “One industrial ecology strategy sets up closed-loop “food webs” among industries, where output from one industry is input for another and materials are reused. These networks of exchanges are sometimes referred to as industrial symbiosis or industrial metabolism. A complex of industrial facilities that applies these principles in an industrial ecosystem is referred to as an eco-industrial park” (Robertson, 2021, p. 344). The Bonita Springs East Water Reclamation Facility is a great example of a chain in one of these eco-industrial parks. After passing through the membrane basins, the remaining biosolids in the wastewater are mixed with polymers, thickened, and heated, evaporating the remaining water and turning the biosolids into small pellets. These pellets are marketed as fertilizer and make money for the wastewater treatment plant. The recovered water is disinfected using sodium hypochlorite and sent to a water pump station, where it is sold as irrigation water to businesses such as golf courses. Wastewater facilities like this one face many challenges, including excessive amounts of nutrients like nitrogen and phosphorus, limiting the energy used by the plant to run its operations, and limiting the release of endocrine disruptors into the environment. Despite these challenges, the Bonita Springs East Water Reclamation Facility has found a sustainable way to turn “waste” into profitable products that are in high demand by other industries.

Photo taken by me.

References:

Robertson, M. (2021). Sustainability Principles and Practice (3rd ed.). Taylor & Francis Group.

0 notes

Text

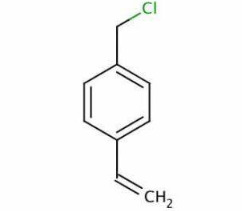

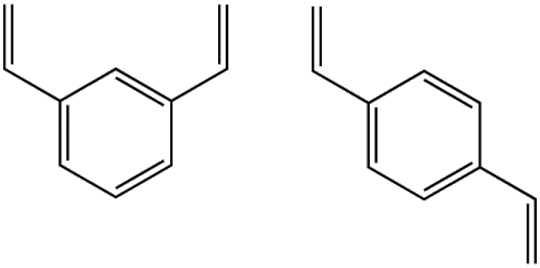

4-Vinylbenzyl Chloride, Global Market Size Forecast, Top 3 Players Rank and Market Share

4-Vinylbenzyl Chloride Market Summary

4-Vinylbenzyl Chloride is a colorless liquid that is typically stored with a stabilizer to suppress polymerization. In combination with styrene, vinylbenzyl chloride can be used as a comonomer in the production of chloromethylated polystyrene.

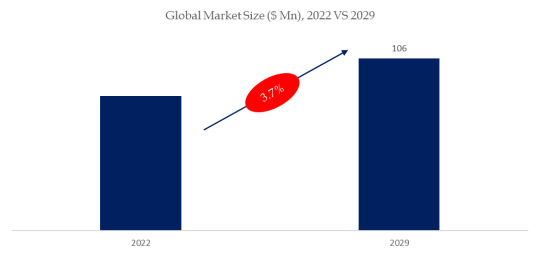

According to the new market research report “Global 4-Vinylbenzyl Chloride Market Report 2023-2029”, published by QYResearch, the global 4-Vinylbenzyl Chloride market size is projected to reach USD 106.1 million by 2029, at a CAGR of 3.7% during the forecast period.

Figure. Global 4-Vinylbenzyl Chloride Market Size (US$ Million), 2022-2029

Based on or includes research from QYResearch: Global 4-Vinylbenzyl Chloride Market Report 2023-2029.

Market Drivers:

Demand from anion ion exchange membrane market keep growing.

Hyperbranched polymers are used as polymeric additives in many linear commercial polymers as compatibilising agents, process and strength improvers. In recent years, the growing interest in Polyphenylene ether graft monomer has brought more attention to VBC.

Restraint:

4-Vinylbenzyl Chloride is produced through a batch reaction, and the production process is complicated, which means that it is difficult to supply this product in large quantities.

The transportation and storage of 4-Vinylbenzyl Chloride requires a low-temperature environment, which poses challenges to downstream enterprise applications.

Opportunity:

4-Vinylbenzyl Chloride is a niche market with limited suppliers. The demand mainly comes high molecular modifiers such as rubber and resin, photographic materials, coupling agents, and various other treatment agents. The market of 4-Vinylbenzyl Chloride would keep stable in the coming years.

4-Vinylbenzyl Chloride is a highly responsive monomer having vinyl and chloromethyl groups in molecules. Possibility of a new 4-Vinylbenzyl Chloride derivative is infinitely expanding in various fields.

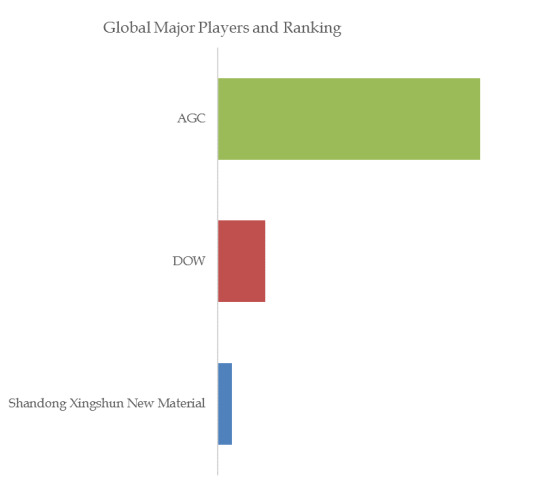

Figure. 4-Vinylbenzyl Chloride, Global Market Size, The Top 3 Players Hold 95% of Overall Market

Based on or includes research from QYResearch: Global 4-Vinylbenzyl Chloride Market Report 2023-2029.

This report profiles key players of 4-Vinylbenzyl Chloride such as AGC, DOW, Shandong Xingshun New Material. In 2022, the global top 3 4-Vinylbenzyl Chloride players account for 95% of market share in terms of revenue. Above figure shows the key players ranked by revenue in 4-Vinylbenzyl Chloride.

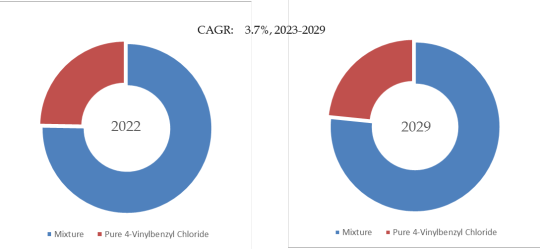

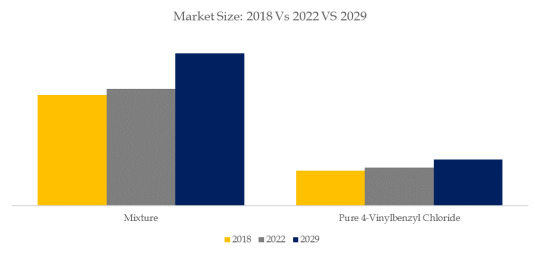

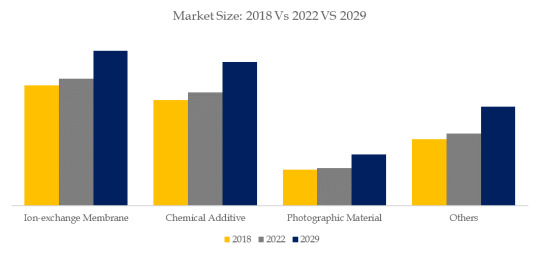

Figure. 4-Vinylbenzyl Chloride, Global Market Size, Split by Product Segment

Based on or includes research from QYResearch: Global 4-Vinylbenzyl Chloride Market Report 2023-2029.

In terms of product type, Mixture is the largest segment, hold a share of 75.3%.

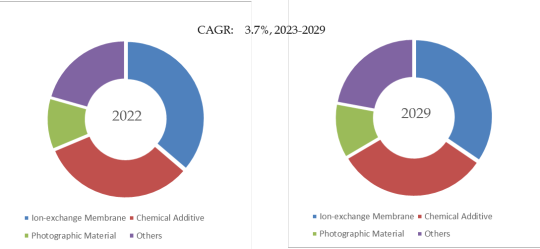

Figure. 4-Vinylbenzyl Chloride, Global Market Size, Split by Application Segment

Based on or includes research from QYResearch: Global 4-Vinylbenzyl Chloride Market Report 2023-2029.

In terms of product application, Ion-exchange Membrane is the largest application, hold a share of 36.2%.

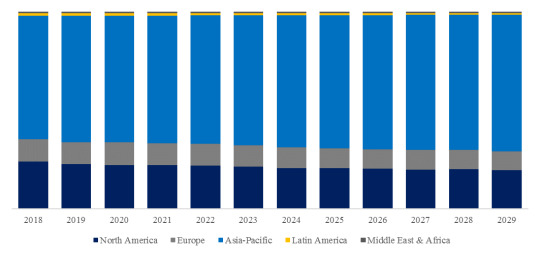

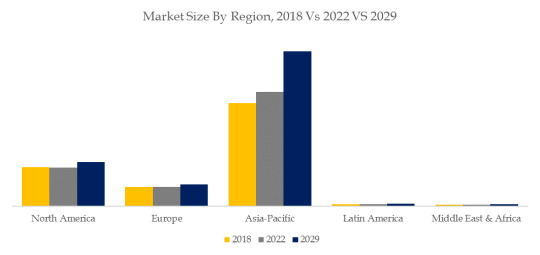

Figure. 4-Vinylbenzyl Chloride, Global Market Size, Split by Region

Based on or includes research from QYResearch: Global 4-Vinylbenzyl Chloride Market Report 2023-2029.

About The Authors

Lu Jing - Lead Author

Email: [email protected]

Lu Jing is a technology & market senior analyst specializing in chemical, advanced material, and component. Lu has 9 years’ experience in chemical and focuses on catalyst and additive, metal and plastic materials, waste recycling, daily chemicals. She is engaged in the development of technology and market reports and is also involved in custom projects.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

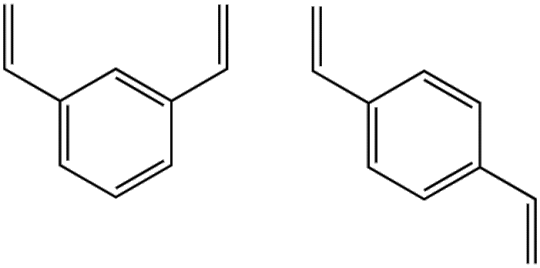

DVB: Deciphering the Chemistry Behind a $110 Million Market

Welcome, dear readers, to the not-so-secret world of divinylbenzene (DVB) — the unsung hero of cross-linked polymers, ion-exchange resins, and the booming market valued at a cool $110 million by 2031. But hey, no need for a secret handshake or a chemistry degree; we’ve got you covered with the lowdown on this chemical compound that’s making waves.

DVB Unveiled: More Than Just a Tongue-Twister

So, what’s the deal with DVB? It’s not the latest dance craze, nor is it a secret society code. Divinylbenzene, or DVB for short, is a chemical wizard that sprinkles its magic in the manufacturing of ion-exchange resins and chromatography resins. Hold your excitement; we’re talking about water treatment, pharmaceuticals, petrochemicals, and electronics — the real A-listers of industry.

The Billion-Dollar Play: DVB in the Limelight

Picture this: from a modest $76 million in 2022, the DVB market is strutting towards a glamorous $110 million by 2031, growing at a sassy 4.2% CAGR. What’s fueling this dazzling rise, you ask? Well, the demand for high-performance resins in water treatment is turning DVB into the Beyoncé of the chemical world. It’s eliminating heavy metals and impurities like a superhero — move over, Iron Man.

Behind the Curtain: Market Dynamics and Segmentation Extravaganza

Let’s take a peek behind the chemical curtain. The divinylbenzene market isn’t a monolith; it’s a star-studded show with headliners like DVB 80 and the fast-rising DVB 50. The real drama unfolds in the application segment — ion exchange resins taking center stage while chromatographic resins make a flashy entrance, demanding attention.

Asia-Pacific: The Diva of DVB Domination

Hold on to your chemical equations; Asia-Pacific is stealing the spotlight in the divinylbenzene saga. Countries like China, India, and South Korea are hosting the biggest chemical galas, driving the demand for DVB. The industrial growth in APAC is the real MVP, cementing its dominance in the DVB market — move over, Hollywood!

Market Dynamics: The Good, the Bad, and the Ugly Side of DVB

But like any blockbuster, there’s a plot twist. The divinylbenzene journey isn’t all glamour; it’s got its share of challenges. Environmental regulations are throwing shade, demanding eco-friendly purification methods. Raw material prices are the villain, causing price fluctuations that could rival a rollercoaster.

Competitive Landscape: Where Chemical Titans Collide

In this chemical arena, titans like Dow Chemical Company, Mitsubishi Chemical Corporation, and Merck KGaA are battling it out. It’s not just about chemical formulas; it’s about innovation, partnerships, and global expansion. These chemical gladiators are investing big, not just in products but in sustainable solutions — saving the world, one resin at a time.

For More Information: https://www.skyquestt.com/report/divinylbenzene-market

Global Divinylbenzene Trends: The Eco-Friendly Evolution

Hold the front page! There’s a shift towards sustainable and bio-based alternatives in the chemical industry. DVB is no exception; the market is singing the eco-friendly anthem. Green bio-based options are the new black, and researchers are on a mission to make DVB production as sustainable as a reusable shopping bag.

The Final Act: Divinylbenzene in the Limelight

As the curtains fall on this chemical extravaganza, divinylbenzene stands tall, the unsung hero of polymers, resins, and water treatment solutions. It’s not just a chemical; it’s a billion-dollar play with twists, turns, and a dash of eco-friendly glamour. So, the next time someone mentions DVB, give them a nod of approval; it’s more than just a tongue-twister — it’s a chemical superstar.

In a world filled with decoding and navigating, DVB keeps it real, chemical, and fabulous. Cheers to the unsung hero!

About Us-

SkyQuest Technology Group is a Global Market Intelligence, Innovation Management & Commercialization organization that connects innovation to new markets, networks & collaborators for achieving Sustainable Development Goals.

Contact Us-

SkyQuest Technology Consulting Pvt. Ltd.

1 Apache Way,

Westford,

Massachusetts 01886

USA (+1) 617–230–0741

Email- [email protected]

Website: https://www.skyquestt.com

0 notes

Text

DVB: Deciphering the Chemistry Behind a $110 Million Market

Welcome, dear readers, to the not-so-secret world of divinylbenzene (DVB) — the unsung hero of cross-linked polymers, ion-exchange resins, and the booming market valued at a cool $110 million by 2031. But hey, no need for a secret handshake or a chemistry degree; we’ve got you covered with the lowdown on this chemical compound that’s making waves.

DVB Unveiled: More Than Just a Tongue-Twister

So, what’s the deal with DVB? It’s not the latest dance craze, nor is it a secret society code. Divinylbenzene, or DVB for short, is a chemical wizard that sprinkles its magic in the manufacturing of ion-exchange resins and chromatography resins. Hold your excitement; we’re talking about water treatment, pharmaceuticals, petrochemicals, and electronics — the real A-listers of industry.

The Billion-Dollar Play: DVB in the Limelight

Picture this: from a modest $76 million in 2022, the DVB market is strutting towards a glamorous $110 million by 2031, growing at a sassy 4.2% CAGR. What’s fueling this dazzling rise, you ask? Well, the demand for high-performance resins in water treatment is turning DVB into the Beyoncé of the chemical world. It’s eliminating heavy metals and impurities like a superhero — move over, Iron Man.

Behind the Curtain: Market Dynamics and Segmentation Extravaganza

Let’s take a peek behind the chemical curtain. The divinylbenzene market isn’t a monolith; it’s a star-studded show with headliners like DVB 80 and the fast-rising DVB 50. The real drama unfolds in the application segment — ion exchange resins taking center stage while chromatographic resins make a flashy entrance, demanding attention.

Asia-Pacific: The Diva of DVB Domination

Hold on to your chemical equations; Asia-Pacific is stealing the spotlight in the divinylbenzene saga. Countries like China, India, and South Korea are hosting the biggest chemical galas, driving the demand for DVB. The industrial growth in APAC is the real MVP, cementing its dominance in the DVB market — move over, Hollywood!

Market Dynamics: The Good, the Bad, and the Ugly Side of DVB

But like any blockbuster, there’s a plot twist. The divinylbenzene journey isn’t all glamour; it’s got its share of challenges. Environmental regulations are throwing shade, demanding eco-friendly purification methods. Raw material prices are the villain, causing price fluctuations that could rival a rollercoaster.

Competitive Landscape: Where Chemical Titans Collide

In this chemical arena, titans like Dow Chemical Company, Mitsubishi Chemical Corporation, and Merck KGaA are battling it out. It’s not just about chemical formulas; it’s about innovation, partnerships, and global expansion. These chemical gladiators are investing big, not just in products but in sustainable solutions — saving the world, one resin at a time.

For More Information: https://www.skyquestt.com/report/divinylbenzene-market

Global Divinylbenzene Trends: The Eco-Friendly Evolution

Hold the front page! There’s a shift towards sustainable and bio-based alternatives in the chemical industry. DVB is no exception; the market is singing the eco-friendly anthem. Green bio-based options are the new black, and researchers are on a mission to make DVB production as sustainable as a reusable shopping bag.

The Final Act: Divinylbenzene in the Limelight

As the curtains fall on this chemical extravaganza, divinylbenzene stands tall, the unsung hero of polymers, resins, and water treatment solutions. It’s not just a chemical; it’s a billion-dollar play with twists, turns, and a dash of eco-friendly glamour. So, the next time someone mentions DVB, give them a nod of approval; it’s more than just a tongue-twister — it’s a chemical superstar.

In a world filled with decoding and navigating, DVB keeps it real, chemical, and fabulous. Cheers to the unsung hero!

About Us-

SkyQuest Technology Group is a Global Market Intelligence, Innovation Management & Commercialization organization that connects innovation to new markets, networks & collaborators for achieving Sustainable Development Goals.

Contact Us-

SkyQuest Technology Consulting Pvt. Ltd.

1 Apache Way,

Westford,

Massachusetts 01886

USA (+1) 617–230–0741

Email- [email protected]

Website: https://www.skyquestt.com

0 notes

Text

What Is an Ion Exchange Water Filter?

Whether you use water for your home or commercial purposes, getting access to safe water, which is free from contaminants, has become crucial. In most parts of the country, the water which is available through civic sources, is unfit for consumption and basic needs.

Due to the indiscriminate use of chemicals and pesticides, the water has become heavily contaminated and contains a plethora of pathogens like bacteria and viruses, along with traces of heavy metals like arsenic, lead, etc. This, if consumed, can cause a host of illnesses in the long term.

To combat this, the market today is filled with a wide variety of purifiers, filters, softeners, etc. which make the source water pure and free of contaminants. One such method of water treatment is an ion exchange water filter, which softens water.

In this blog, we discuss how ion exchange filters work, the types of ion exchange filters, and their advantages and disadvantages. Let’s dive in!

Related Reading: Common Water Contaminants and How Purifiers Remove them

What do you mean by an ion exchange water filter?

The impurities found in water affect its taste and smell while making it unsafe for consumption. Currently, there are many ways in which water quality can be improved and one such method is an ion exchange water filter. It involves a chemical process that removes certain impurities and minerals from the water, thereby softening it.

A quick chemistry refresher will throw more light on the concept of ion water filters. Atoms are made up of electrons, protons, and neutrons which have positive, negative, and neutral charges respectively. Many atoms link together to form molecules or compounds through electronic bonding. An atom or molecule that has an unequal number of protons or electrons, resulting in a positive or negative charge is known as an ion.

Minerals such as calcium, magnesium potassium, etc. become ions when they get dissolved in water. Their presence affects the taste, odor, and hardness of water.

GET 7-DAYS RISK-FREE TRIAL

How does an ion exchange water filter work?

Softens water

An ion exchange water filter softens your source water, it does not filter or purify it. Electrically charged solids are used to remove contaminant ions from the water. This works even if the contaminants are in liquid form.

Removes calcium and magnesium

Hard water which is caused by the presence of calcium and magnesium, causes a host of skin and hair problems as well as limescale build up on appliances and inability to lather soap.

Ion exchange water treatment gets rid of this calcium and magnesium, by using resins, a small porous bead-like material made of synthetic or natural polymers. This is fortified with specific chemical groups which exchange or draw certain ions, based on their charge.

Use of resins

Ion exchange systems use three types of resins. Cationic resins can be of weak acid cation or strong acid cation. They can remove contaminants like iron, calcium, chromium, magnesium, sodium, etc. They are mostly useful in water softening, demineralization, and alkalization.

The systems that use anionic resins can contain either a strong base anion, which can be useful for demineralization, or a weak base anion which can help with acid absorption applications. Anionic resins can remove arsenic, uranium, carbonates, cyanide chlorides, etc. The third type, which is specialty resins, is mostly used in industrial applications. They are generally more expensive.

Recharging of resins

Resins need to be recharged periodically. When the ion exchange process is not functioning properly, resins need to be recharged with sulphuric acid, sodium chloride, sodium hydroxide, or hydrochloric acid.

What are the different types of ion exchange filters?

There are different types of ion exchange water filters, each designed for a specific need or application and to suit different environments.

Countertop filters

As the name suggests, they sit snugly on your countertop. They are best suited for small apartments or families and especially rental houses as they do not require any drilling or plumbing.

Under sink filters

These filters are installed under your sink area and connected to your taps. They filter larger quantities of water and free up your countertop space.

Stand-alone filters

They are designed for larger households or for commercial purposes. They are most often used in tandem with other water treatments.

Inline filters

These filters are connected directly to your plumbing system and can be used for whole-house filtration and even for special uses like connecting to your fridge or ice maker.

Like with most systems, ion exchange water treatments also come with their own set of advantages and disadvantages.

Advantages of Ion exchange water treatment

1. Easy to set up

Ion exchange water filters are relatively easy to install and fits in your budget too.

2. Improves taste

It improves the taste and odor of water, which is a bonus.

3. Reduces hardness of water

Ion exchange water filters remove the hardness of water and dissolve heavy metals from water.

4. Easy installation

The installation process is simple for these ion exchange water filters, and it is relatively easy to maintain them as well.

GET 7-DAYS RISK-FREE TRIAL

Disadvantages of Ion exchange water treatment

1. Does not remove microorganisms

Ion exchange water filters cannot remove pathogens like viruses or bacteria particles etc.

2. Expensive

Ion exchange water filters mostly have long-term operating costs which can prove to be detrimental.

3. Use of chemicals

These filters need to use chemicals like salt for water softening.

4. Wastewater generation

Ion exchange water filters may generate a lot of waste water which requires disposal.

5. Additional add-ons required

These filters require a lot of extra add-ons, for proper functioning. A discharge line, to rinse off the calcium and magnesium from the resin beads, an electrical source to provide power for the regeneration process, and periodic refilling of the brine solution, to ensure that the water softener functions well.

Conclusion

So, is water from an ion exchange water filter completely safe for you to drink? Ion exchange water filters are used to produce bottled water and home-based water treatment solutions. It is important for you to understand that ion exchange water filters work primarily as a water softener and may not completely remove pathogens such as bacteria viruses etc.

It is for this reason that ion exchange water filters are coupled with other water filtration systems, to ensure that the water that you get is pure and safe for your consumption. It is essential that you get your source water tested, to get an idea of the contaminants that you are dealing with, before zeroing in on a water filtration and purification system.

Source: What Is an Ion Exchange Water Filter?

0 notes

Text

Sodium Lignosulfonate Market Insight, Outlook, Forecast 2022-2029

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated the global sodium lignosulfonate market size at USD 1.19 billion in 2022. During the forecast period between 2023 and 2029, BlueWeave expects the global sodium lignosulfonate market size to grow at a significant CAGR of 3.78% reaching a value of USD 1.49 billion by 2029. Major growth drivers for the global sodium lignosulfonate market include a surging number of residential and non-residential construction projects, coupled with the rising demand for concrete admixtures in the construction sector, as well as the need for lignosulfonates as oil additives in the oil and gas industry. Sodium lignosulfonate is widely used as a water-reducing and dispersing agent in concrete admixtures. The growing construction industry worldwide, especially in emerging economies, has led to an increased demand for sodium lignosulfonate to enhance concrete performance, improve workability, and reduce water usage. Another notable factor, sodium lignosulfonate is used as a dispersing agent and binder in agriculture, primarily in fertilizers and animal feed. The growth of the agricultural sector, driven by the increasing need for food production, has contributed to the demand for sodium lignosulfonate in this domain. Also, sodium lignosulfonate finds applications in oil drilling as a deflocculant and water-reducing agent. The expansion of oil and gas exploration and drilling activities has resulted in increased demand for sodium lignosulfonate in the oilfield chemicals sector. However, price volatility of raw materials and limited awareness and adoption in a few regions are anticipated to restrain the overall market growth during the period in analysis.

Global Sodium Lignosulfonate Market – Overview

Sodium Lignosulfonate, a water-reducing additive in concrete mixtures, is a water-soluble and versatile polymer electrolyte with the chemical formula C₂₀H₂₄Na₂O₁₀S₂. Its unique properties enable the efficient dispersion of biological slime, oxidizing phosphate scale, and iron (Fe) scale, while also forming stable complexes with zinc and calcium ions. Production methods involve ion exchange and pulping with sodium carbonate or sodium hydroxide. With low air content and high water-reducing rates, this chemical exhibit adaptability to various cement types, making it an ideal choice for construction projects, including dams, buildings, and highways. It finds extensive application in the construction sector for residential and non-residential structures. Additionally, it serves as a plasticizer, dust suppressant, gypsum plasterboard, animal feed binder, and oil well additive. Sodium Lignosulfonate stands as a multifunctional solution catering to diverse industries.

Sample Request @ https://www.blueweaveconsulting.com/report/sodium-lignosulfonate-market/report-sample

Impact of COVID-19 on Global Sodium Lignosulfonate Market

COVID-19 pandemic had a mixed impact on the global sodium lignosulfonate market. During the initial phases, lockdowns and restrictions on construction activities led to a temporary decline in demand from the construction sector. However, the market found some resilience due to its applications in essential sectors like agriculture and animal feed. The increasing demand for disinfectants during the pandemic also boosted sodium lignosulfonate usage in the production of cleaning agents. Overall, while certain segments faced challenges, the market's diverse applications and adaptability to changing demands helped mitigate the adverse effects, enabling a gradual recovery as economic activities resumed.

Global Sodium Lignosulfonate Market – By Application

By application, the global sodium lignosulfonate market is divided into Animal Feed Binder, Concrete Admixture, Oil Well Additives, Agricultural Chemicals, and Lead Batteries segments. The concrete admixture segment is expected to hold the highest market share during the forecast period by application. Concrete admixtures play a vital role in the construction industry, enhancing concrete performance and workability. Sodium lignosulfonate's effectiveness as a water-reducing agent makes it sought-after in construction projects worldwide. With a growing construction industry and infrastructure development, the demand for concrete admixtures, including sodium lignosulfonate, is on the rise. Its versatility allows for use in various concrete formulations, compatible with different cement types. Also, sodium lignosulfonate's cost-effectiveness makes it an appealing choice for construction companies aiming to enhance concrete quality while optimizing costs. As a result, it remains a significant contributor to the global sodium lignosulfonate market.

Competitive Landscape

Major players operating in the global sodium lignosulfonate market include Material Technology, Abelin Polymers, Sappi, Nippon Paper Industries Co. Ltd., Borregaard LignoTech, Cardinal Chemicals, Liaocheng Jinhui Chemical, Domsjo Fabriker, Tembec, Burgo Group, and Shenyang Xingzhenghe Chemical. To further enhance their market share, these companies employ various strategies, including mergers and acquisitions, partnerships, joint ventures, license agreements, and new product launches.

Contact Us:

BlueWeave Consulting & Research Pvt. Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Text

0 notes

Text

Battery technology advancements and innovations

In recent years, battery technology has made enormous strides and breakthroughs, revolutionized several industries and become essential to the move toward a sustainable future.

This article examines the major improvements in battery technology, emphasizing the most recent developments and inventions that could revolutionize transportation, energy storage, and other industries.

1. Lithium-ion Batteries

Due to its high energy density and long cycle life, lithium-ion batteries have dominated the energy storage market. However, scientists have been working to make them even more effective.

The energy density and charging rates of lithium-ion batteries have grown thanks to the development of silicon anodes, solid-state electrolytes, and improvements in electrode design.

Additionally, the use of nanotechnology and nanomaterial has increased their overall efficiency, stability, and safety.

2. Solid-State Batteries

Solid-state batteries are a promising development in the field of energy storage. By swapping the liquid electrolyte in conventional batteries with a solid-state substitute, these batteries have various benefits, such as better energy density, improved safety, and longer lifespan.

With the use of improved electrode materials like lithium metal and ceramic or polymer electrolytes, solid-state batteries may be able to store even more energy and charge batteries more quickly.

Additionally, solid-state batteries can be incorporated into flexible and thin-film form factors, allowing them to be used in electric vehicles (EVs), wearable technology, and Internet of Things (IoT) devices.

3. Flow Batteries

Flow batteries have attracted interest as a potential large-scale energy storage option. The power stored in these batteries is using ion exchange membranes, liquid electrolytes housed in external tanks generate electricity.

The introduction of novel materials including organic compounds and metal complexes as redox partners in flow battery technology has recently advanced its energy efficiency, longevity, and cost-effectiveness.

Applications such as grid-scale storage, load balancing, and the integration of renewable energy are particularly well suited for flow batteries.

Other than Lithium-ion

Although lithium-ion batteries have dominated the field of energy storage, scientists are looking at other chemistries to get around these batteries' drawbacks. The creation of sodium-ion, magnesium-ion, and zinc-ion batteries is one important development.

These alternative chemistries make use of readily available and inexpensive materials, providing the possibility for affordable and eco-friendly energy storage solutions.

Moreover, studies into novel battery technologies such as lithium-Sulphur Increasing energy density and extending battery life are goals for lithium-ion and lithium-air batteries.

Certainly! Here are some further battery technology developments:

Other than Lithium-ion

Researchers are looking into alternative chemistries to lithium-ion batteries, which have dominated the energy storage market, in order to get around some of their drawbacks and develop battery technology.

1. Sodium-ion Batteries:

These batteries are gaining popularity as lithium-ion battery substitutes. Sodium-ion batteries are a cost-effective alternative since sodium is more accessible and less expensive than lithium.

To increase the energy density, cycle life, and general performance of sodium-ion batteries, Researchers are investigating new electrode materials and formulas to increase the energy density, cycle life, and general performance of sodium-ion batteries.

2. Magnesium-ion Batteries:

Compared to lithium-ion batteries, magnesium-ion batteries have the potential to provide better energy densities. Magnesium can store more energy than lithium since it is more common and has a higher charge density.

However, the growth of a Lack of acceptable electrolytes and electrode materials is a problem for magnesium-ion batteries. Researchers are actively attempting to overcome these obstacles to fully realize the potential of magnesium-ion batteries.

3. Zinc-ion Batteries:

Zinc-ion batteries are an additional lithium-ion battery substitute with a high energy density and low price. Zinc is a common metal with great electrochemical qualities. In an effort to increase the efficiency, stability, and cycling capacities of zinc-ion batteries, researchers are investigating alternative electrode materials and electrolytes. These batteries show potential for use in portable devices and grid storage.

Since lithium-Sulphur (Li-S) batteries have a high theoretical energy density, they have received a lot of interest. Sulphur is widely available, reasonably priced, and eco-friendly. Li-S batteries, however, encounter difficulties because of the insulating properties of Sulphur and the lithium polysulfide dissolve with cycling.

Researchers are working on creating novel electrode designs, Sulphur hosts, and electrolyte formulations to address these obstacles and improve the performance and lifespan of Li-S batteries.

Lithium-Air Batteries:

Compared to lithium-ion batteries, lithium-air (Li-Air) batteries have the potential to provide even better energy densities. Li-Air batteries drastically lower the weight of the battery by using oxygen from the air as the cathode.

Li-Air batteries do, however, encounter issues with the electrolyte's stability and the production of undesirable by-products during cycling. Researchers are looking into new materials and methods to increase the effectiveness, cyclability, and general performance of Li-Air batteries.

Conclusion

By enabling the integration of renewable energy, electric transportation, and effective energy storage solutions, battery technology breakthroughs and innovations are accelerating the transition to a sustainable future.

Lithium-ion batteries, solid-state batteries, flow batteries, and the investigation of alternative chemistries have all shown ongoing improvements, suggesting that future developments could be even more significant.

These developments will help clean energy sources be used more widely, reduce greenhouse gas emissions, and build more durable and sustainable energy infrastructure.

In order to speed the world's shift towards renewable energy sources, it is critical to encourage and invest in these advancements as research and development efforts continue to push the limits of battery technology. a more sustainable and clean future.

#Battery technology#revolutionize transportation#lithium-ion batteries#nanotechnology#and nanomaterial#electric transportation

0 notes