#Injection molding production process parameters

Explore tagged Tumblr posts

Text

Injection molding production process parameters and precautions for polyamide (nylon) products

1. Process characteristics Polyamide (nylon) is a crystalline plastic with a high and obvious melting point, a narrow melting temperature range, but high melt fluidity; volume change of raw material before and after melting is large, melt has poor thermal stability and is easy to decompose; product shrinkage rate after injection molding is large, but it has good wear resistance, flexibility and…

View On WordPress

#injection molding#injection molding process parameters#Injection molding production process parameters#injection pressure#Mold temperature#plastic products#Plasticizing injection temperature#Polyamide injection molding

0 notes

Text

Achieving Precision and Efficiency with Custom Injection Molding Solutions

In today’s competitive manufacturing landscape, precision and customization are key factors in ensuring product quality and market success. Custom injection molding solutions have emerged as a game-changer, offering tailored manufacturing processes to meet the specific needs of industries ranging from automotive to medical devices. By leveraging advanced technologies and innovative design strategies, companies can produce high-quality components with superior accuracy, durability, and cost-effectiveness. One of the primary advantages of custom injection molding solutions is the ability to create complex geometries and intricate designs that would be difficult or impossible with traditional manufacturing methods. Whether you require lightweight components for aerospace applications or durable parts for industrial machinery, custom molds can be designed to meet precise specifications. This customization minimizes material waste, reduces production time, and enhances overall product performance.

Why Choose Custom Injection Molding Solutions for Your Manufacturing Needs?

Custom injection molding solutions offer a distinct advantage for manufacturers looking to produce high-quality, precision components. Unlike traditional molding methods, these solutions allow for complete customization, ensuring that each part meets exact specifications. This is particularly beneficial for industries such as automotive, aerospace, and medical devices, where precision and reliability are critical. By working with experienced mold designers, companies can create intricate designs, reduce material waste, and improve overall production efficiency. Additionally, the flexibility of custom injection molding allows businesses to adapt quickly to market demands, making it a smart choice for both prototyping and large-scale production.

Enhancing Product Quality with Custom Injection Molding Solutions

One of the primary benefits of custom injection molding solutions is the ability to enhance product quality. By tailoring the mold design and material selection to specific project requirements, manufacturers can achieve superior accuracy and consistency. This customization ensures that each component fits seamlessly within the final product, reducing the risk of defects and assembly issues. Custom injection molding solutions also allow for the use of advanced materials, such as high-performance plastics and composites, which offer improved strength, durability, and resistance to environmental factors. As a result, businesses can deliver products that not only meet but exceed customer expectations.

The Role of Material Selection in Custom Injection Molding Solutions

Material selection is a critical aspect of custom injection molding solutions, as it directly impacts the performance and durability of the final product. Different applications require different materials, ranging from lightweight thermoplastics to high-strength engineering resins. Custom injection molding solutions provide the flexibility to choose the best material for each project, ensuring optimal performance under specific operating conditions. Additionally, manufacturers can experiment with material blends and additives to achieve unique properties, such as enhanced UV resistance or electrical conductivity. By selecting the right material, businesses can create products that stand out in terms of quality and functionality.

How Custom Injection Molding Solutions Reduce Manufacturing Costs?

While custom injection molding solutions offer superior quality, they also contribute to cost savings in the manufacturing process. By optimizing mold designs and production parameters, manufacturers can reduce material waste and minimize cycle times. This efficiency translates into lower production costs and increased profitability. Additionally, custom molds can be designed for automated production, further reducing labor costs and improving output consistency. For businesses looking to maximize their return on investment, custom injection molding solutions provide a cost-effective way to achieve high-volume production without compromising quality or performance.

Scalability and Flexibility with Custom Injection Molding Solutions

Custom injection molding solutions offer unmatched scalability and flexibility, making them ideal for both small-scale prototypes and large-volume production runs. Businesses can start with a limited number of parts to test and refine their designs before ramping up to full-scale production. This approach minimizes risk and ensures that the final product meets all performance requirements. Additionally, custom molds can be easily modified to accommodate design changes or new product variants, providing the flexibility needed to adapt to evolving market demands. With custom injection molding solutions, manufacturers can scale their operations efficiently and stay competitive in a rapidly changing industry.

Sustainability and Eco-Friendly Options in Custom Injection Molding Solutions

Sustainability is a growing concern for manufacturers, and custom injection molding solutions offer eco-friendly options to reduce environmental impact. By optimizing mold designs and utilizing recyclable or biodegradable materials, companies can minimize waste and lower their carbon footprint. Custom injection molding also enables efficient use of raw materials, further enhancing sustainability. Additionally, some manufacturers offer energy-efficient molding processes and green manufacturing practices, which align with global sustainability goals. By choosing custom injection molding solutions, businesses can demonstrate their commitment to environmental responsibility while maintaining product quality and performance.

Applications of Custom Injection Molding Solutions in the Medical Industry

The medical industry requires precision, reliability, and compliance with strict regulatory standards, making custom injection molding solutions a perfect fit. These solutions allow for the production of complex medical components, such as surgical instruments, implants, and diagnostic devices, with high accuracy and consistency. Custom molds can be designed to meet specific requirements, such as biocompatibility and sterilization compatibility, ensuring patient safety and product efficacy. Additionally, the ability to produce intricate geometries and micro-sized components makes custom injection molding solutions essential for advancing medical technology and improving patient outcomes.

Conclusion

Custom injection molding solutions offer a powerful combination of precision, flexibility, and cost-efficiency, making them an essential tool for modern manufacturing. From creating complex geometries to enhancing product quality and reducing waste, these solutions provide significant advantages across a wide range of industries. Whether you're developing a prototype, scaling up production, or seeking sustainable manufacturing practices, custom injection molding can meet your unique needs with unmatched accuracy and reliability.

0 notes

Text

Precision in Production: The Critical Role of Moldflow in Manufacturing

In terms of industrial production, accuracy and efficiency dictate the pace of innovation and production. Advances in simulation technology, particularly through Moldflow And Casting Analysis and Mold Flow Analysis, have transformed the way manufacturers approach the design and creation of molds for plastic parts and metal castings. These technologies not only improve product quality but also significantly reduce the time and cost associated with development cycles.

The Impact of Mold Flow Analysis

Mold Flow Analysis is a necessary instrument for engineers and designers focused on optimizing the injection molding process. This sophisticated simulation software predicts how plastic flows within a mold, identifying potential issues like air traps, weld lines, and sink marks before a single piece is physically produced. By anticipating these problems, Mold Flow Analysis allows for adjustments in design or process parameters early in the development stages, thereby enhancing the structural integrity and aesthetic quality of final products.

Streamlining Design and Production

The ability to simulate and tweak designs digitally is a game-changer in manufacturing. It significantly shortens the product development timeline by minimizing the need for multiple physical prototypes. This not only saves material and labor costs but also speeds up the time to market for new products. Additionally, Mold Flow Analysis assists in selecting the most suitable materials and the most efficient design specifications, ensuring optimal performance and cost-effectiveness.

Enhancing Sustainability in Manufacturing

Using Mold Flow Analysis also contributes to environmental sustainability. By optimizing the mold design and minimizing the material used, manufacturers can reduce waste and improve the energy efficiency of their production processes. This dedication to environmentally friendly methods is growingly crucial. in a world where consumers and regulatory bodies demand more environmentally friendly products and processes.

Expanding Capabilities with Moldflow And Casting Analysis

While mold flow analysis focuses on plastic injection molding, mold flow and casting analysis extend these capabilities to metal casting. This analysis includes simulations of mold filling, solidification, and cooling, as well as the prediction of defects that could occur during the casting process, such as porosity or thermal stresses. The insights gained from Moldflow And Casting Analysis enable foundries and manufacturers to refine their casting methods, enhance mold designs, and ultimately produce stronger, higher-quality metal components.

Conclusion

In conclusion, the integration of Moldflow Casting Analysis and Mold Flow Analysis into the manufacturing technique marks a major development in the manufacturing of both plastic and metal components. These technologies empower manufacturers to achieve greater precision, efficiency, and sustainability. For more information and expert guidance on incorporating these advanced simulation tools into your manufacturing operations, visit FEAmax.com. Embracing these modern techniques is crucial for any company aiming to lead in today’s competitive manufacturing industry, ensuring that each product not only meets but exceeds the rigorous standards of quality and performance.

Blog Source URL:

https://feamax1.blogspot.com/2024/11/precision-in-production-critical-role.html

0 notes

Text

Plastic parts manufacturing: 7 effective ways to reduce production costs

Cost control is a basic strategy for many companies to maintain competitiveness and profitability. Due to the special characteristics of plastic materials, they are manufactured into parts widely used in all kinds of products, for example, in the home appliance industry, the current use of plastic has reached 40% of the weight ratio, and many home appliance parts made of steel have been replaced by plastic parts, for example, the plastic parts of the refrigerator accounted for more than 70% of the overall parts and components, so cost reduction on plastic parts is one of the effective measures to reduce the cost of the entire product.

Optimize Design

The design stage is a key step in reducing costs. A simple and effective design can decrease material usage and lower production complexity.

1. Simplify Part Design: By reducing complex shapes and unnecessary features, you can significantly lower the difficulty and cost of mold making. A simpler design is also easier to produce, reducing errors and scrap rates during manufacturing.

2. Reduce Material Usage: Ensure the part is strong and functional while minimizing material thickness and weight. Tools like Finite Element Analysis (FEA) can help optimize the design to use materials more efficiently, cutting down on waste.

3. Standardize Design: Use standardized parts and components wherever possible. This reduces the need for custom molds and makes it easier to find suitable suppliers, lowering procurement costs.

Choose the Right Materials

Material selection has a big impact on cost. The right materials are affordable and meet the performance requirements of the part.

1. Cost-Effective Materials: Choose materials that are relatively inexpensive yet meet the necessary requirements. For example, polypropylene (PP) and polyethylene (PE) are often good choices because they are both affordable and have good mechanical properties.

2. Recycled Materials: Using recycled plastics can lower material costs and reduce environmental impact. This approach is both economical and eco-friendly, gaining popularity among manufacturers.

Optimize Mold Manufacturing

Molds are the key tools for producing plastic parts, and optimizing mold production can significantly cut costs.

1.Mold Design: A well-designed mold can improve production efficiency and reduce issues during manufacturing. Using multi-cavity molds to produce several parts at once can greatly increase efficiency and lower the cost per part.

2. Mold Maintenance: Regular maintenance ensures molds operate at peak efficiency, extending their lifespan and reducing downtime and repair costs.

Improve Production Processes

Enhancing production processes is an effective way to cut costs. Optimizing process parameters and introducing automation can boost efficiency and reduce labor costs.

1. Optimize Process Parameters: Experiment with and adjust injection molding parameters like temperature, pressure, and injection speed to improve efficiency and product quality. Proper temperature control, for example, can minimize material waste and ensure consistent products.

2. Automated Production: Introducing automated equipment and robots can significantly increase production efficiency and reduce labor costs. Automation not only speeds up production but also minimizes human errors, enhancing product quality.

3. Reduce Scrap Rates: Strengthen quality control and process monitoring to promptly identify and resolve issues, reducing the number of defective parts. High-quality products decrease waste and improve customer satisfaction.

Optimize Production Batches

Efficiently managing production batches can lower costs. Large batch production can spread fixed costs over more parts, boosting efficiency.

1.Large Batch Production: Producing parts in large batches spreads fixed costs like molds and equipment over more units, lowering the cost per part. For example, producing 1,000 parts costs less per unit than producing just 10.

2.Batch Management: Schedule production batches efficiently to avoid frequent mold and equipment changes, reducing adjustment time and scrap. Continuous production enhances efficiency and cuts downtime.

Supply Chain Management

Optimizing supply chain management can lower material and transportation costs, boosting production efficiency.

1. Procurement Optimization: Bulk purchasing can secure lower prices for materials and equipment. Working with multiple suppliers to find the best deals can effectively reduce procurement costs.

2. Logistics Management: Streamline logistics and storage to cut transportation and inventory costs. Efficient logistics reduce shipping time and expenses, enhancing production efficiency.

Save Energy

Energy costs are a significant part of plastic part manufacturing. Saving energy can noticeably reduce production costs.

1. Energy-Efficient Equipment: Use energy-efficient injection molding machines and auxiliary equipment to cut energy consumption. Modern machines often have energy recovery features, recycling waste heat generated during production.

2. Energy Recovery: Recycle waste heat during production to boost energy efficiency. For instance, waste heat from injection molding machines can be used to preheat materials, reducing energy use.

Summary

Reducing the manufacturing cost of plastic parts is crucial for many businesses. By employing reasonable methods and strategies, companies can significantly lower production costs while maintaining product quality. Key approaches include optimizing design by simplifying part features, reducing material usage, and standardizing components. Selecting cost-effective and recycled materials also plays a crucial role.

Optimizing mold manufacturing through effective design and regular maintenance can enhance efficiency and lower costs. Improving production processes by fine-tuning parameters, automating production, and minimizing scrap rates further reduces expenses. Efficient batch management and supply chain optimization, including bulk purchasing and streamlined logistics, help in cost reduction.

0 notes

Text

Designing Injection Molds: Key Considerations for Optimal Performance

Designing injection molds requires careful planning and consideration of various factors to ensure efficient production and high-quality parts. Here are some key aspects to keep in mind:

1. Part Design

Complexity:Minimize part complexity to reduce machining time and potential defects.

Draft Angles: Incorporate appropriate draft angles to facilitate part ejection and prevent sticking.

Undercuts:Avoid undercuts if possible, as they can complicate mold design and increase costs.

Wall Thickness:Maintain consistent wall thicknesses to prevent warping and ensure even cooling.

2. Mold Material

Strength and Durability:Select a mold material that can withstand the required loads and temperatures.

Corrosion Resistance: Consider the environment in which the mold will operate and choose a material that is resistant to corrosion.

Thermal Conductivity:Ensure the mold material has good thermal conductivity for efficient heat transfer.

3. Mold Cavity Design

Runner and Gate Design:Optimize runner and gate design to ensure proper material flow and prevent air entrapment.

Venting:Place vents strategically to allow air to escape and prevent part defects.

Cooling Channels:Design efficient cooling channels to ensure rapid part solidification and prevent warping.

4. Molding Process Parameters

Injection Pressure: Adjust injection pressure to ensure complete cavity filling and prevent part defects.

Injection Speed:Control injection speed to avoid excessive turbulence and ensure proper material distribution.

Mold Temperature: Maintain appropriate mold temperatures to achieve desired part properties and prevent warping.

Cycle Time:Optimize cycle time by balancing part quality with production efficiency.

5. Mold Maintenance

Inspections:Conduct regular inspections to identify potential problems early on.

Cleaning:Clean molds regularly to remove contaminants and prevent corrosion.

Lubrication:Lubricate moving parts to reduce friction and wear.

Storage:Store molds in a clean, dry environment to prevent damage.

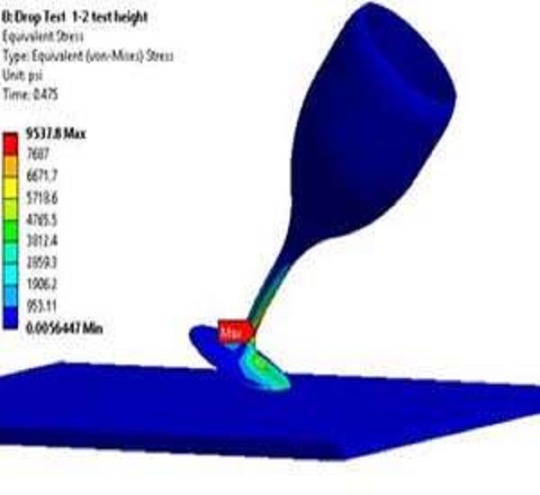

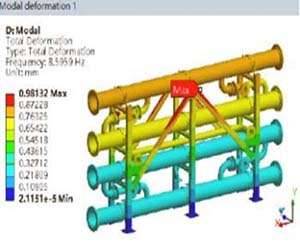

6. Simulation and Analysis

Mold Flow Analysis:Use simulation software to predict material flow, identify potential issues, and optimize mold design.

Thermal Analysis:Analyze heat transfer within the mold to ensure efficient cooling and prevent part distortion.

Stress Analysis:Evaluate stress distribution in the mold to identify potential weak points and optimize its design.

Conclusion:

By carefully considering the factors outlined in this guide, you can design injection molds that are efficient, produce high-quality parts, and minimize downtime. Remember to leverage simulation tools, conduct thorough analysis, and seek expert advice when necessary. With a well-designed injection mold, you can achieve optimal performance and maximize your manufacturing efficiency.

0 notes

Text

How to Improve the Quality of Plastic Injection Molds?

Do you want to make high-quality plastic parts with injection molding? Curious about how mold quality impacts the final product? What can you do to ensure your molds give the best results? Let's check out the factors to improve the quality of your plastic injection molds.

Plastic injection moulding is a key method used to manufacture everything from little plastic parts to significant components. High-quality moulds are important for achieving the greatest outcomes. The quality of the mould has a direct influence on the finished product, from its appearance to its strength and durability. Here are some practical methods you may take to boost the quality of plastic injection moulds.

1. Choose the Right Material

The quality of your mould begins with the material you employ to create it. The mould material should be strong and resistant to damage, especially if you're making a big number of pieces. Hardened steel, stainless steel, and aluminium are examples of commonly used materials. Steel is more costly, but it has more durability and can generate higher-quality parts over time.

2. Design with Precision

A well-designed mould is necessary to deliver high-quality results. Pay particular attention to design elements like wall thickness, cooling channels, and draft angles. Proper design ensures that the plastic flows smoothly throughout the mould, lowering the possibility of flaws such as warping or partial filling. Use modern CAD (Computer-Aided Design) equipment to generate accurate and detailed designs.

3. Use High-Quality Injection Machines

The quality of the injection moulding machine has an important impact on the overall quality of the mould. Ensure that your machines are properly maintained and calibrated. Machines with upgraded controls can deliver more constant pressure and temperature, which are critical for making high-quality moulds.

4. Implement Rigorous Quality Control

Quality control is essential at every stage of the injection molding process. Regularly inspect molds for wear and tear and check the finished products for any defects. Using tools like Coordinate Measuring Machines (CMM) can help in accurately measuring parts and ensuring they meet specifications.

5.Optimize the Cooling Process

Cooling is a critical phase in injection molding that affects the quality of the final product. Uneven or inadequate cooling can lead to defects such as warping or shrinkage. To optimize cooling, ensure that the cooling channels in the mold are well-designed and that the coolant flows efficiently throughout the mold. Using conformal cooling techniques, where cooling channels are designed to follow the shape of the part, can further enhance the cooling efficiency.

6. Use Proper Mold Maintenance

Regular maintenance of molds is key to extending their life and ensuring consistent quality. Clean the mold regularly to remove any residues or buildup. Also, inspect the mold components like ejector pins and slides to ensure they are functioning properly. Lubricate moving parts to prevent wear and replace any worn-out components promptly.

7. Control Injection Parameters

The parameters used during the injection process, such as temperature, pressure, and injection speed, significantly affect the quality of the molded parts. Fine-tuning these parameters can help reduce defects and improve overall product quality. Consider conducting trials to determine the optimal settings for your specific mold and material.

To improve the quality of plastic injection molds, use the right materials, design them accurately, use good machines, and maintain strict quality control. Regular maintenance and having skilled workers also help in making high-quality molds. By paying attention to these factors, you can produce parts that meet or exceed your quality expectations.

If you would like to discuss your requisites with one of our experts. You can submit you files here and our team will contact you as soon as possible.

0 notes

Text

Enhancing Production Efficiency of Plastic Industrial Tray Moulds Strategies and Innovations

In the realm of manufacturing, the Plastic Industrial Tray Mould stands as a critical component in the production of a wide array of plastic trays used across various industries. These molds are essential for creating durable, cost-effective, and uniform products that meet the demands of the market. However, the efficiency of these molds can significantly impact the overall production process. This article explores various strategies and innovations aimed at enhancing the production efficiency of Plastic Industrial Tray Moulds.

It is imperative to understand the factors that contribute to the efficiency of Plastic Industrial Tray Moulds. These include the quality of the mold material, the design of the mold, the maintenance routine, and the technology used in the molding process. By addressing these factors, manufacturers can optimize their production lines and reduce downtime.

The material of the Plastic Industrial Tray Mould plays a pivotal role in its durability and efficiency. High-quality steel, such as P20 or H13, is often used due to its good wear resistance and heat resistance. Investing in good materials can cause longer mold life, reducing the need for frequent replacements and reducing production interruptions.

The design of the Plastic Industrial Tray Mould is another critical aspect. A well-designed mold will have fewer parts, which simplifies the assembly and disassembly process, thus reducing the time required for maintenance and cleaning. Additionally, the design should facilitate easy ejection of the finished product, reducing the risk of product damage and reducing the time spent on post-molding operations.

Maintenance is a crucial yet often overlooked aspect of enhancing the efficiency of Plastic Industrial Tray Moulds. Regular cleaning and inspection can prevent the build-up of residue, which can cause poor product quality and reduced mold life. Implementing a preventive maintenance schedule can help identify and address potential issues before they escalate, thus avoiding costly production delays.

Technology plays a significant role in improving the efficiency of Plastic Industrial Tray Moulds. The use of computer-aided design (CAD) and computer-aided manufacturing (CAM) can streamline the design and production process, reducing errors and improving the accuracy of the mold. Furthermore, the integration of automation and robotics can increase the speed of the molding process, causing higher output and reduced labor costs.

Another strategy to enhance the production efficiency of Plastic Industrial Tray Moulds is to optimize the injection molding process itself. This can be achieved by fine-tuning the injection parameters such as temperature, pressure, and speed. Each of these parameters can significantly impact the quality of the final product and the cycle time of the molding process.

In addition to the above strategies, continuous improvement, and innovation are key to enhancing the production efficiency of Plastic Industrial Tray Moulds. This can involve researching and implementing new materials, exploring advanced cooling techniques to reduce cycle times, and staying abreast of trends in mold design and technology.

Collaboration with suppliers and industry experts can also provide valuable insights into practices and emerging technologies that can be leveraged to improve the efficiency of Plastic Industrial Tray Moulds. Sharing knowledge and experiences can cause the development of more effective strategies and the adoption of innovative solutions.

Lastly, training and education of the workforce are essential. Employees who are well-versed in techniques and technologies will be better equipped to operate the machinery efficiently and troubleshoot any issues that may arise. Investing in the professional development of the team can produce a more skilled and efficient workforce.

In conclusion, enhancing the production efficiency of Plastic Industrial Tray Moulds is a multifaceted endeavor that requires a combination of high-quality materials, innovative design, diligent maintenance, advanced technology, process optimization, continuous improvement, collaboration, and workforce development. By focusing on these areas, manufacturers can ensure that their Plastic Industrial Tray Moulds operate efficiently, causing increased productivity and a competitive edge in the market.

0 notes

Text

The tabletop injection molding machine is a compact and efficient solution tailored for small-scale production, prototyping, and educational applications. These machines are especially popular among startups, educational institutions, and hobbyists looking to explore the world of plastic manufacturing without the need for large industrial equipment.

Design and Features

One of the standout features of tabletop injection molding machines is their compact design. They occupy significantly less space compared to traditional injection molding machines, making them ideal for workshops, labs, or even home use. Despite their small footprint, these machines are engineered to deliver high performance and precision, capable of producing intricate parts with fine details.

Typically, a tabletop injection molding machine includes a user-friendly interface that allows operators to easily set and adjust parameters such as injection speed, temperature, and pressure. Many models come equipped with digital displays that provide real-time feedback, enhancing the user experience and ensuring accurate monitoring of the molding process.

Versatility in Material Use

Tabletop machines are designed to work with a variety of thermoplastic materials, including ABS, PLA, and polycarbonate. This versatility allows users to experiment with different materials and applications, from creating prototypes for product designs to manufacturing small batches of functional parts. The ability to quickly switch between materials and molds also enhances their utility in a range of projects.

Safety Features

Safety is a key consideration in the design of tabletop injection molding machines. Most models include essential safety features, such as emergency stop buttons, safety guards, and temperature controls, to protect operators during the molding process. These features not only ensure a safer working environment but also help prevent damage to the machine itself.

Applications

The applications of tabletop injection molding machines are vast. In educational settings, they serve as valuable teaching tools, allowing students to learn about the principles of injection molding and materials science hands-on. For small manufacturers and startups, these machines provide a cost-effective way to produce small runs of products or test new designs without the substantial investment required for larger machines.

Cost-Effectiveness

One of the primary advantages of tabletop injection molding machines is their cost-effectiveness. They offer a more affordable entry point into plastic manufacturing, making it accessible for individuals and small businesses. Lower operational costs, combined with the ability to produce high-quality parts, make these machines a smart investment for those looking to explore or expand their manufacturing capabilities.

Conclusion

In summary, tabletop injection molding machines are an essential tool for anyone interested in plastic manufacturing. Their compact size, versatility, and safety features make them suitable for a wide range of applications, from education to small-scale production. As technology continues to advance, these machines are becoming increasingly efficient, enabling users to achieve professional-quality results without the need for large, expensive industrial equipment. Whether you are a hobbyist, educator, or entrepreneur, a tabletop injection molding machine can significantly enhance your ability to create and innovate in the field of plastic manufacturing.

0 notes

Text

Advances in 2K Tooling Technology: Improving Performance and Durability

The development of 2K mold technology represents a pivotal achievement in the manufacturing sector. With an increasing demand for greater precision and efficiency across various industries, 2K molds have emerged as a critical asset in meeting these standards. This piece delves into the latest strides in 2K mold technology, underscoring the enhancements in performance and longevity that these innovations bring to the table.

2K mold technology, alternatively termed two-component mold technology, encompasses the simultaneous molding of two distinct materials or components within a unified process. This groundbreaking method facilitates the fabrication of intricate parts with diverse characteristics in a single molding cycle. The key benefit of 2K molds lies in their capacity to merge dissimilar materials, resulting in a final product that capitalizes on the distinctive attributes of each constituent.

Recent advancements in 2K mold technology have significantly improved the performance and durability of molded products. One of the key developments is the integration of advanced materials and coatings. These materials are engineered to withstand higher temperatures and pressures, thereby extending the lifespan of the mold and enhancing the overall quality of the final product. By utilizing these advanced materials, manufacturers can reduce the frequency of mold replacements and improve production efficiency.

Another significant advancement in 2K mold technology is the refinement of mold design and manufacturing processes. Modern 2K molds are now equipped with sophisticated cooling systems that ensure more uniform temperature distribution during the molding process. This uniformity is crucial for less thermal stress and for preventing defects in the final product. Additionally, enhanced mold designs now include more precise gating systems that improve material flow and reduce cycle times.

Automation plays a crucial role in the advancements of 2K mold technology. Automated systems are increasingly being integrated into the molding process, allowing for greater precision and consistency. Automated handling systems can manage the complex movements required for 2K molding, including the precise alignment of the two components and the accurate injection of materials. This integration not only improves the consistency of the molding process but also reduces the potential for human error, and professional to higher-quality products.

The advancements in 2K mold technology are also evident in the development of new injection molding machines specifically designed for 2K processes. These machines feature advanced controls and software that enable manufacturers to fine-tune the molding parameters for good performance. The ability to precisely control factors such as injection speed, pressure, and temperature ensures that the final product meets stringent quality standards.

Moreover, the evolution of 2K mold technology has led to the development of more sustainable manufacturing practices. Modern 2K molds are designed with energy efficiency in mind, reducing the overall energy consumption during the molding process. This not only lowers operational costs but also contributes to environmental sustainability by less the carbon footprint of the manufacturing process.

In addition to performance and durability, advancements in 2K mold technology have also focused on improving the versatility of molded products. The ability to incorporate multiple materials in a single mold enables the production of parts with complex geometries and functional properties. For instance, a single 2K mold can produce a component with both rigid and flexible areas, catering to diverse application needs. This versatility is particularly beneficial in industries such as automotive and consumer electronics, where product requirements often demand a combination of different material properties.

Furthermore, ongoing research and development in 2K mold technology continue to drive innovation. Engineers and scientists are constantly exploring new materials and processes that can further enhance the capabilities of 2K molds. These advancements aim to address emerging challenges and opportunities in manufacturing, ensuring that 2K mold technology remains at the forefront of industry progress.

In summary, advancements in 2K mold technology are transforming the landscape of manufacturing by improving the performance and durability of molded products. The integration of advanced materials, refined mold designs, automation, and energy-efficient practices contribute to the enhanced capabilities of 2K molds. As industries continue to evolve, the ongoing innovation in 2K mold technology will play a pivotal role in meeting the increasing demands for high-quality, versatile, and sustainable manufacturing solutions.

0 notes

Text

Teach you step by step how to adjust injection molding process parameters

Temperature Temperature measurement and control are very important in injection molding. Although these measurements are relatively simple, most injection molding machines do not have enough temperature sampling points or circuits.On most injection molding machines, temperature is sensed by thermocouples. A thermocouple is basically two different wires connected at the ends. If one end is hotter…

View On WordPress

#back pressure#Clamping pressure#Hold pressure#injection molded part#injection molding#injection molding machines#injection molding process parameters#injection pressure#injection speed#melt temperature#Mold exhaust#Mold temperature#plastic products#thermoplastic

0 notes

Text

Unlocking Efficiency in Manufacturing: The Power of Mold Flow Analysis

Imagine a world where every plastic part is flawless, embodying perfection in both form and function. Thanks to this vision, the reality is near. Advanced technologies like Mold Flow Analysis. This method not only enhances the quality of plastic parts but also optimizes the manufacturing process, resulting in major cost reductions and better product durability. The essence of Mold Flow Analysis lies in its ability to predict and solve injection molding challenges before they become costly problems.

Understanding Mold Flow Analysis

Mold Flow Analysis is a critical tool used in the injection molding industry to simulate the flow of plastic materials through a mold. This analysis helps manufacturers predict potential defects and determine the optimal mold design and processing parameters to guarantee the output's quality at last. By analyzing how the molten plastic flows, cools and solidifies within the mold, engineers can make informed decisions that enhance mold design, reduce waste, and improve the overall efficiency of production.

The Role of Moldflow in Modern Manufacturing

As sectors aim for higher accuracy and efficiency, software solutions like Moldflow become indispensable. Moldflow software provides detailed insights into the molding process, offering predictions on how the plastic will behave, which in turn allows for adjustments before committing to a full-scale production. This preemptive approach is vital in avoiding costly design errors and in ensuring that the products meet rigorous quality standards.

Advancing with Technology: Integration in Manufacturing

Integrating Moldflow Service into manufacturing processes represents a proactive approach to quality assurance. Utilizing Moldflow Service early in the design phase helps in identifying the ideal materials, the most effective mold design, and the optimal processing conditions. This integration results in a smoother production flow, minimal downtime, and a faster turnaround from design to final product, which is crucial in today's fast-paced market environments.

The Impact of Moldflow on Industry Standards

The influence of Moldflow Service extends beyond just enhancing individual products. It sets new industry standards for quality and efficiency, encouraging manufacturers to adopt more sophisticated and technologically advanced practices. This service not only aids in complying with industry regulations but also pushes the boundaries of what can be achieved in plastic manufacturing, ensuring that every product is not only high-quality but also manufactured in an environmentally responsible way.

Conclusion

In conclusion, the strategic implementation of technologies like Mold Flow Analysis and Moldflow Service is transforming the manufacturing landscape. These tools are pivotal in refining product design, enhancing quality, and optimizing production efficiency. For those interested in exploring these services, visiting the website FEAmax.com provides extensive resources and expert insights into how these analyses can be integrated into manufacturing processes. Embracing these advanced solutions equips manufacturers with the tools necessary to thrive in a competitive industry, making every production step more predictable, controlled, and efficient.

Blog Source Url:-

0 notes

Text

Understanding Weld Lines in Injection Moulding: Causes, Effects, and Solutions

Weld lines are a common issue in injection moulding, often presenting as visible lines or seams on the surface of moulded parts. These lines, also known as knit lines or meld lines, occur when two or more flow fronts of molten plastic meet and fail to fully bond during the moulding process. Although weld lines can sometimes be harmless, they can also compromise the structural integrity and aesthetic quality of the final product. In this article, we'll explore the causes, effects, and solutions for weldline in injection moulding.

Causes of Weld Lines

Weld lines form when the molten plastic injected into the mould cavity encounters obstacles such as cores, inserts, or holes, causing the flow to split into multiple streams. These streams must reunite to fill the mould completely. If the flow fronts are not at an optimal temperature or pressure when they meet, they may not fuse together properly, resulting in a visible weld line.

Several factors can contribute to the formation of weld lines:

Material Flow Properties: Different plastic materials have varying flow characteristics. Materials with lower flowability are more prone to forming weld lines because they may not flow smoothly around obstacles.

Mould Design: Complex mould designs with multiple gates, inserts, or varying wall thicknesses can create conditions where flow fronts are likely to separate and then meet, increasing the chances of weld lines.

Injection Moulding Parameters: The temperature, pressure, and speed of the injection molding cost process all play a crucial role in weld line formation. Insufficient mould temperature, low injection pressure, or slow injection speed can cause the material to cool down too quickly, leading to poor fusion at the weld line.

Cooling Rate: If the mould cools too quickly, the molten plastic can solidify before the flow fronts have a chance to fully merge, resulting in a weak bond.

Effects of Weld Lines

Weld lines can have several detrimental effects on the final moulded part:

Reduced Mechanical Strength: Weld lines can act as points of weakness in the part, leading to reduced tensile strength and an increased likelihood of cracking or breaking under stress.

Aesthetic Issues: Visible weld lines can detract from the appearance of the part, making it less visually appealing, which can be a critical concern for consumer-facing products.

Poor Surface Finish: Weld lines may create a rough or uneven surface finish, which can affect the functionality or feel of the part.

Quality Control Concerns: The presence of weld lines may signal underlying issues in the moulding process, leading to increased inspection and potential rejection of parts.

Solutions to Minimize Weld Lines

To reduce or eliminate weld lines in injection moulding, several strategies can be employed:

Optimizing Mould Design: Simplifying the mould design to minimize flow disruptions or adjusting gate locations can help reduce the chances of weld lines forming.

Adjusting Processing Parameters: Increasing mould temperature, injection pressure, and injection speed can help ensure that the flow fronts remain molten and merge properly.

Material Selection: Choosing materials with better flow properties or using additives that enhance flow can reduce the likelihood of weld lines.

Use of Venting: Improving the venting of the mould can help prevent air pockets and ensure that the material flows smoothly.

Post-Moulding Treatments: Surface treatments, such as painting or coating, can sometimes be used to mask weld lines and improve the appearance of the final part.

Conclusion

Weld lines are a significant concern in injection moulding, affecting both the structural integrity and appearance of moulded parts. By understanding the causes of weld lines and implementing appropriate solutions, manufacturers can minimize their impact and produce higher-quality products. Careful consideration of mould design, material selection, and processing parameters is essential to achieving a successful injection moulding process with minimal weld lines.

0 notes

Text

The Future of Production: How Advanced Manufacturing is Shaping the World

Tailoring Parts to Specific Needs

Custom component manufacturing on the other hand takes its roots in manufacturing parts to order as per demand in different fields. Thus it is possible to obtain parts with specific unique and accurate characteristics required for a specific area of application. Custom component manufacturing refers to processes such as CNC machining, injection moulding and 3D printing since the components are engineered specifically to the required parameters.

The Role of Injection Molding in Producing Synchronous Components

It is a very efficient technique of manufacturing products whereby a material in a molten state is forced into a mold to produce parts. The injection molding process is a necessary technology in manufacturing in which a solid material such as the plastic or metal is initially heated to a liquid state and then injected into a mold. This process consists of several stages.

Because of the capability to deliver parts with high dimensional accuracy and consistency, injection molding is a dependable process for large volume production.

It is particularly suitable for creating vast numbers of synchronous components with high accuracy.

Eliminating Fine Tuning with High-Tolerance CNC Machining

CNC machining is a modern technique of manufacturing parts using machines that are controlled by computers with high accuracy of the size of the parts to be produced. This process is very important for high accuracy application such as aerospace, auto mobile and medical devices. High accuracy achieved by the precision CNC helps in achieving a high quality in the performances of individual parts and in their reliability. Using precision CNC machining allows the manufacturers to produce products with high tolerances eliminating the need for subsequent fine tuning, hence improving production rates for lower cost.

High Tolerances and Small Runs with Custom CNC Machining

The use of Computer Numerical Control technology in the manufacturing of these parts is advantageous because it allows manufacture of small and specialized parts which may be required in specific uses. Custom CNC machining is particularly suitable for first piece machining applications and for small runs, and when high tolerances are called for. When choosing custom CNC machining, new products are evolved which may serve as a niche in areas of increased competition and the specific need of clients is met, starting from the type of material and finishing to the actual requirement for the part.

Reducing Costs and Time with Online CNC Services

Online CNC machining convenience includes ability of customers to order their custom parts through the internet where they provide their designs and specifications. online CNC machining makes accessing accurately manufactured bespoke parts possible for companies without initial face-to-face meetings. As a result of the options made available by online CNC machining, companies get to cut production time and costs while also being guaranteed of quality and reliability in their parts.

Saving Materials and Costs with Custom Sheet Metal Parts

Fabrication is convenient in that sheet metals can be cut, shaped and formed on-demand and this eliminates storage of large stocks of metal parts. This service will suit industries that produce small quantity or need quick turnaround on their products. In On demand sheet metal fabrication, the manufacturers are in a position to fabricate high-value, accurate and precise components that address all manufacturing specifications. On-demand fabrication of sheet metal is advantageous in saving materials, costs, and time to market for products.

Flexibility and Precision: Custom sheet metal parts have been developed planed for attractive on-demand that focuses on exact part needs for industries that require high turnaround time and small volume.

Cost Efficiency and Responsiveness: Through the on-demand sheet metal fabrication, enterprises can minimize waste and costs, and retain the ability to adjust the product offering to the customers’ demand without holding a ton of inventories.

Rapid Design-to-Market with Metal 3D Printing Services

The 3D metal direct part production services provide solutions to manufacturing through the fabrication of geometries of metal parts from STL files. There are benefits to using metal 3D printing services and these include the ability to design and get the products to the market much faster, minimal wastage of materials and parts that are stronger and more durable than those made from conventional methods.

Creating Complex Designs with Metal 3D Printing

Conventional metal 3D printing offers an opportunity to create required articles from metal with certain characteristics. This technology makes it possible to produce designs which are at least difficult to fashion through normally used techniques of production. The use of customized metal 3D printing is critical in case where accuracy and tailored solutions must be obtained. What the use of custom metal 3D printing has made it possible for manufacturers is the ability to create prototypes, limited-run parts and components with enhanced mechanical properties which are tailored to what is needed in the specific project.

Meeting Specific Needs with Custom Metal Parts Manufacturing

Custom metal parts manufacturing is a process of manufacturing metal parts particular to the requirement of a given project. Some of the activities involved in this process may comprise of; Computer Numerically Controlled Machining, Metal Casting, and 3D Printing. Custom metal parts manufacturing are crucial for sectors where firms require high quality and specific metal part that are difficult to obtain from regular sellers. Thus, when a company decides to go for a custom manufacturing of metal parts, it is guaranteed of quality and efficiency of the manufactured parts.

Reducing Lead Times and Costs with On-Demand CNC Machining

On-demand CNC machining enables organizations to get the manufacturing services that they desire, at the time that they want them, without having to purchase a lot of parts from the manufacturers that specialize in CNC machining. On demand CNC machining is an effective way of cutting on lead times and the costs of production while at the same time keeping high standards of quality necessary for a business.

High-Quality Enclosures and Brackets

Hardware manufacturing industries rely on sheet metal fabrication work so as to produce sturdy and high quality parts that may be incorporated in a number of products. This process entails machining of metal sheets to produce forms including enclosures brackets and fasteners through processes like cutting, bending and assembling.

Sheet metal fabrication for hardware manufacturing industry enables the creation of different parts such as enclosures, brackets, and fasteners, which are accurate needed.

Through using sheet metal fabrication in hardware manufacturing industries, industries can create quality parts to the increased performance details in the hardware industry.

Building Reliable Hardware with Component Manufacturing

Component manufacturing for hardware manufacturing industry means making small but compact parts used in the manufacturing of hardware product like screws, nuts bolts, holders, wrenches, etc. Component manufacturing for hardware manufacturing industry enables firms to develop and build efficient hardware products that conform to the industry standards.

High-Quality Hardware Manufacturing with Urethane Casting

Urethane casting in the manufacturing of hardware using urethane makes it possible for the manufacturing of high quality and hard wearing part especially in small to medium quantity. This process entails the construction of molds, and utilizing urethane to fabricate parts including, gasket and seals, housing among others. Urethane casting for hardware manufacturing industry allow for an additional degree of freedom in the design and material choice –the process is appropriate for prototyping and short series production.

Reliable and Sturdy Defense Equipment through Urethane Casting

Urethane casting for defense industry is crucial in manufacture of sturdy and long-lasting products to be used in defense. Urethane casting for defense industry provides an opportunity to shape components from aerospace materials with the necessary degree of hardness and elasticity. The use of urethane casting for defense industry brings the assurance to the producers that the end products can perform to the toughest requirements expected in the defense units, durability and efficiency in emergency use.

Versatile Urethane Casting in Energy Industry Manufacturing

Optimizing Robotic Systems with Urethane-Cast Grips and Enclosures

Urethane casting in robotics industry is vital in coming up with components with flexibility, durability, and accuracy in performing their functions. This process is well suited when it comes to manufacture of mainly parts like grips, bumpers and enclosures which are used in robotic systems. Urethane casting for robotics industry facilitates complex parts for the industry to be cast in a way that will directly address need of using robotics while at the same time guarantee efficiency and durability of the parts in use.

Meeting Consumer Product Standards and Specifications

Parts employed in household articles and gadgets, ranging from electronic products to home use appliances. This process ensures that part have been manufactured to high accuracy so that they can meet the quality and performance of consumer products. In consumer products industry, the benefits of CNC machining include the ability to produce component parts for products that can be made to specific requirement of the design. When CNC machining for consumer products industry is emphasized, the manufacturers are able to produce the required products that are durable and create higher customer satisfaction.

CNC machining for consumer products industry facilitates part manufacturing for various consumer products, with high level of accuracy, for consumer products such as electronics and home appliances.

Adopting the CNC machining for consumer products industry allows the developers of products to use computer numerical control in order to develop high-value components and assemblies that meet the required standards and specifications in order to deliver efficient and innovate products that will meet consumer demand.

Durable and Flexible Parts for Electronics with Urethane Casting

Urethane casting to electronics manufacturing industry is crucial because many of the parts made need to be insulated, flexible, and extremely durable. This process is perfect for making parts such as connectors, enclosures and protective covers of electronic gadgets. Urethane casting for electronics manufacturing industry has one major advantage in the sense that it creates parts that are suitable for use in electronics in that they can easily be tailored to fit the particular demand of the application in use.

Streamlining Robotics Innovation Through Rapid Prototyping

Tailored Solutions for Consumer Products

Urethane casting for the consumer products industry is a suitable way of manufacturing a number of strong and high end parts that can be applied on different consumer products. This makes it possible to have elements such as grips, handles, and enclosures which must be rather flexible and capable of withstanding a certain pressure. Urethane casting for consumer products industry allows making custom parts in relatively small to average amounts; thus, it is most suitable for creating highly specific or short-run items.

Medical Components via Urethane Casting

Medical grade urethane casting is important because the medical industry demands high performances of the components that will be used. This process is useful when one needs to make part such as prosthetic limbs, medical device casings, or customized orthopedic appliances that must be flexible, hard-wearing, and biocompatible. Urethane casting for medical industry provides for the production of components which are bespoke to the medical application requirements and ensure durability.

Meeting Demands of Industrial Equipment

Urethane casting for industrial equipment Industry is particularly relevant for making parts that end users expect to work under heavy loads and in harsh conditions. Industrial equipment industry urethane casting provides the advantage to create individual part with properties that industrial purposes require, to provide durability and functionality. Specialization on urethane casting for industrial equipment industry allow creating the high-quality equipment needed for a variety of industries.

Sheet Metal in Energy Manufacturing

Energy manufacturing is a vital process as it involves fabrication of sheet metals which are used in making of energy products that in one way or the other are involved in energy production and distribution. It includes Sheet Metal Working, in which metal sheets are shaped into components such as enclosures, frames, and panels applied in energy systems. Sheet metal fabrication for energy industry involves the production of each individual part in its precise measure, the strength and quality needed is guaranteed.

Energy industries require various components and structures such as enclosures, frames and panels for energy equipment and systems and fabrication of sheet metal is vital in preparing these parts and guaranteeing they are of right characteristics of strength to endure certain conditions.

On using sheet metal fabrication for energy industry, manufacturers are able to have precise designs of energy systems that are durable and efficient for use in sustainable energy practices.

Micro Urethane Casting

Specialized Aerospace Components through Urethane Casting

Urethane casting for aerospace industry is very important since many parts required for the construction of planes and other flying equipment is subjected to high pressures and temperatures as well as being required to meet high safety requirements. This process is suitable for production of such parts as seals, gaskets and protective covers used in aircraft or spacecraft. Urethane casting for aerospace industry has the advantage of the ability to create components for aerospace that are specialized for the particular application and will perform with accuracy.

Key to Electronics Precision and Speed

CNC Machining plays a key role in the Electronics Manufacturing Industry. It uses machines controlled by computers to make exact parts that electronic devices need. This method ensures high precision and uniformity, which makes it perfect to create complex pieces like connectors, housings, and enclosures. In the world of electronics, cnc machining for electronics manufacturing industry allows quick production of intricate designs with strict tolerances.

The Power of Composite Materials

Composite material manufacturing for consumer products industry is essential for producing components that require a combination of strength, durability, and lightweight properties. This process involves the use of advanced materials like carbon fiber, fiberglass, and kevlar to create parts used in various consumer goods. Composite material manufacturing for consumer products industry offers the ability to produce custom components that meet the specific needs of consumer applications, ensuring reliable performance.

Quick Fixes for Energy Innovations

Rapid prototyping in the context of energy industry is a key in the build up of the energy systems. This process that enables designers and engineers to make and test designs and models in a short time permits the production of a product that meets certain standards. Rapid prototyping for energy industry favors fixes on this aspect to allow for changes on the designs before proceeding to mass production.

Conclusion

In conclusion, the current manufacturing has greatly evolved with the advancement of the new technologies including injection molding, precision CNC machining, and the custom metal 3D printing. They have therefore evolved as crucial processes in manufacture of high quality and durable parts and components in different sectors. This means that as manufacturers go for new innovations the capability to provide On-Demand Sheet Metal Fabrication and other specialized services offers them the opportunity to address all the request of the market. The advanced manufacturing does not only improve the production quality but also provides the custom and reliable solutions to improve the manufacturing possibilities.

FAQS

What industries benefit from on-demand sheet metal fabrication?

This service is popular in such spheres as automotive, aerospace, electronics, industrial equipment manufacturing, as well as other industries necessitating production of stably and accurately shaped metal parts.

What is the role of urethane casting in manufacturing?

Urethane casting is suitable for the making of superior prototype and closely limited production runs. It is versatile in its design and can produce near net shape and close tolerance parts with the appearance of injection molded parts with out having to invest in expensive tooling.

How does composite material manufacturing benefit the defense industry?

Manufacture of composite materials give lightweight but higher strength structures to the defense fraternity in areas like armors, aircrafts and UAVs.

0 notes

Text

The Wonders and Innovations of Injection Molds

Injection molds, as an important cornerstone of modern manufacturing, the development and innovation of their technologies are of crucial importance.

The design process of injection molds is extremely complex and precise. From the initial analysis of the product, including the shape, size, accuracy requirements, etc., to determining the parting surface, the number and arrangement of cavities, every link requires rigorous consideration. For example, when designing the injection mold for a mobile phone case, the position selection of the parting surface should fully consider the structural characteristics of the case to ensure that the mold can smoothly eject the product from the cavity when the mold is opened without affecting the appearance of the product.

The determination of the number of cavities needs to comprehensively consider factors such as the production batch of the product, the specifications of the injection molding machine, and the cost of the mold. If the production batch is large, in order to improve production efficiency, a multi-cavity mold structure may be selected, but this will also increase the manufacturing difficulty and cost of the mold.

The selection of the injection molding machine is also a key link. Different injection molding machines have different parameters such as injection pressure, clamping force, and injection volume. It is necessary to select the appropriate injection molding machine model according to the specific requirements of the mold and the product.

The design of the gating system is related to whether the plastic melt can fill the cavity smoothly and affects the quality of the product. The main runner, the runner, the gate, and the cold slug well all need to be carefully designed. For example, the selection of the location and form of the gate directly affects the appearance and internal quality of the product. For some products with high appearance requirements, a submarine gate may be used to avoid leaving obvious gate marks on the product surface.

The design of the demolding mechanism must ensure that the product can be smoothly ejected from the mold after molding without causing damage to the product. Common demolding mechanisms include ejector pin demolding and ejector plate demolding. The design of its structure and quantity needs to be determined according to the shape and size of the product.

The cooling system plays an important role in controlling the molding cycle and quality of the product. By reasonably arranging the cooling water channels, the mold temperature can be effectively reduced, so that the plastic melt can be quickly cooled and solidified in the cavity, improving production efficiency and product quality.

In short, the design and manufacturing of injection molds is a comprehensive project that requires knowledge and technologies in multiple fields. Continuous innovation and optimization are the keys to promoting the development of the injection mold industry.

0 notes

Text

Advances in Cap Mold Technology: Key Developments and Trends

The evolution of bottle cap mold technology has significantly influenced the packaging industry, bringing about substantial improvements in efficiency, precision, and sustainability. As the demand for more advanced and reliable packaging solutions continues to rise, the development of bottle cap mold technology has been at the forefront of these changes.

One of the key advancements in bottle cap mold technology is the integration of more sophisticated materials. Traditional bottle cap molds were predominantly made from metal alloys that could endure high pressure and temperature. However, recent developments have introduced new composite materials that offer enhanced durability and reduced weight. These modern materials contribute to the longevity of bottle cap molds and the efficiency of the production process.

Another notable trend in bottle cap mold technology is the advancement in computer-aided design (CAD) and manufacturing (CAM) techniques. The use of CAD allows for the creation of highly detailed and precise bottle cap mold designs, which can be tested and modified virtually before actual production begins. CAM technology further streamlines the manufacturing process by automating the production of bottle cap molds with high accuracy. This integration of CAD and CAM not only improves the precision of bottle cap molds but also reduces production times and costs.

The focus on sustainability has also driven significant changes in bottle cap mold technology. Manufacturers are increasingly adopting eco-friendly practices, such as using recyclable materials and reducing waste. Modern bottle cap molds are designed with features that lessen the amount of scrap material generated during production. Additionally, advancements in injection molding technology have led to more efficient use of resources, thereby supporting environmental sustainability.

Furthermore, advancements in bottle cap mold technology have led to the development of multi-cavity molds. These molds are designed to produce multiple bottle caps in a single cycle, greatly enhancing production efficiency. Multi-cavity bottle cap molds are particularly advantageous for high-volume manufacturing, as they help to meet the growing demands of the market while maintaining consistent quality.

Automation and robotics have also made a significant impact on bottle cap mold technology. The incorporation of robotic systems in the production process has improved the precision and speed of mold operations. Robots can handle complex tasks such as mold changes and quality inspections with greater accuracy than manual methods. This automation not only increases production capacity but also reduces the likelihood of human error, resulting in higher-quality bottle caps.

The trend towards smart manufacturing is another development shaping bottle cap mold technology. Smart molds equipped with sensors and data analytics capabilities provide real-time monitoring and feedback on the production process. These smart bottle cap molds can detect anomalies, adjust parameters automatically, and provide valuable insights into the performance of the molds. This technology enhances the overall efficiency and reliability of bottle cap production.

Moreover, the introduction of advanced cooling systems in bottle cap molds has further improved production processes. Effective cooling is crucial for maintaining the quality and consistency of bottle caps. Modern cooling systems are designed to optimize the temperature control during molding, ensuring that the bottle caps are produced with small defects.

In conclusion, advancements in bottle cap mold technology are transforming the packaging industry by enhancing efficiency, precision, and sustainability. The integration of sophisticated materials, CAD and CAM techniques, eco-friendly practices, multi-cavity molds, automation, smart manufacturing, and advanced cooling systems all contribute to the ongoing improvements in bottle cap mold technology. As the industry continues to evolve, these developments will play a crucial role in meeting the demands for higher-quality and more sustainable packaging solutions. The future of bottle cap mold technology promises even greater innovations, further advancing the capabilities and performance of these essential tools in the manufacturing process.

0 notes

Text

Advancing Automation in the Production of Plastic Industrial Box Moulds

The manufacturing sector is undergoing a transformative shift towards automation, driven by the need for increased efficiency, precision, and cost-effectiveness. Plastic Industrial Box Mould, integral to the packaging and storage industry, is no exception to this trend. The integration of automation in the production process of Plastic Industrial Box Moulds is a complex yet rewarding endeavor that can significantly enhance manufacturing outcomes. This article explores the various strategies and implementations that can be adopted to automate the production of Plastic Industrial Box Moulds.

The journey towards automation in the production of Plastic Industrial Box Moulds begins with the design phase. Utilizing Computer-Aided Design (CAD) software allows for the creation of precise digital models that can be seamlessly transferred to Computer-Aided Manufacturing (CAM) systems. These systems are capable of interpreting the design data and programming the necessary machine movements to produce the molds with high accuracy, eliminating the need for manual intervention in this stage.

Once the design is finalized, the next step is the selection of appropriate materials for the Plastic Industrial Box Moulds. Automation in material handling can be achieved through the use of robotic arms and conveyor systems that transport raw materials to the production line. These systems can be programmed to recognize different types of materials and deliver them to the correct stations, reducing the risk of human error and improving workflow efficiency.

The actual production of Plastic Industrial Box Moulds can be automated using various techniques such as injection molding machines. These machines are designed to heat and inject plastic material into the mold cavity, where it cools and solidifies into the desired shape. Advanced injection molding machines can be equipped with sensors and feedback systems that monitor the process in real-time, adjusting parameters such as temperature and pressure to ensure consistent quality across all molds produced.

Post-production processes, such as the removal of excess material and the inspection of the finished Plastic Industrial Box Moulds, can also be automated. Robotic arms can be programmed to perform these tasks with a level of precision that surpasses human capabilities. Automated inspection systems, using high-resolution cameras and image recognition software, can detect even small defects, ensuring that only high-quality molds are approved for use.

Another critical aspect of automating the production of Plastic Industrial Box Moulds is the implementation of an integrated production management system. This system can oversee the entire production process, from the initial design to the final inspection, and provide real-time data on the status of each stage. This data can be used to identify bottlenecks, optimize production schedules, and improve overall efficiency.

The integration of automation in the production of Plastic Industrial Box Moulds also extends to quality control. Automated testing equipment can perform a range of tests, such as tensile strength, impact resistance, and dimensional accuracy, to ensure that the molds meet the required standards. This not only reduces the reliance on manual testing but also ensures a more consistent and reliable assessment of product quality.

Moreover, the adoption of Industry 4.0 technologies, such as the Internet of Things (IoT), can further enhance the automation of Plastic Industrial Box Mould production. IoT devices can collect data from various points in the production line, allowing for real-time monitoring and analysis. This data can be used to make informed decisions about production adjustments, predictive maintenance, and resource allocation.

In conclusion, the automation of the production process for Plastic Industrial Box Moulds is a multifaceted approach that encompasses design, material handling, manufacturing, post-production processes, and quality control. By leveraging advanced technologies and systems, manufacturers can achieve higher levels of efficiency, precision, and product quality. The journey towards full automation is ongoing, with continuous advancements in technology offering new opportunities for improvement and innovation in the production of Plastic Industrial Box Moulds.

0 notes