#Hot melt plastic welding machine

Text

Fully automatic mask making machines

Fully automatic mask-making machines have revolutionized the production of masks in China, addressing the global demand for reliable and high-quality protective gear. These machines have improved efficiency, ensured consistent quality, reduced labor costs, and demonstrated technological advancements.

#catheter flaring machine#high frequency hot-melting machine#thermocouple welding machine#plastic pipe extruder#automatic brazing machine

0 notes

Text

Detailed List of popular Acrylic Bending Tools

Acrylic is a beautiful, versatile material. It can be used to make everything from jewelry to furniture to architectural models. There are several different methods of bending acrylic that has proven effective from time to time when working with this material:

Fabric steamer

Fabric steamers are handheld devices that use steam to soften acrylic. They can be used for a variety of things, including bending acrylic to make curved edges and corners, as well as forming plastic sheets into different shapes.

Heat gun

A heat gun is a tool that uses heat to bend acrylic. Heat guns are used in the construction industry, for example, to bend PVC pipes.

Hot air welder

A hot air welder is a tool that can be used to weld or glue acrylic together. It uses heated air to melt the pieces of acrylic into one piece of plastic. The process works by using high heat from an electric heating element in the nozzle of the tool and then sending that heat through tubes to a tip that melts both sides of the plastic together. The melted plastic becomes smooth, shiny, and clear again after cooling down.

Laser cutter

Laser cutters are machines that use a laser to cut materials. The process of laser cutting is called "laser engraving". A laser beam is focused on the material and the material heats up, melts, or vaporizes and the surface of it gets lifted away from surrounding areas creating a hole or an opening in the material. The process can be used to create objects from plastic, wood, and metal by removing parts of those materials with heat to create a design.

The oven method

If you are looking for a way for acrylic bending and bonding that is easy, then the oven method is your best option. This technique requires heat, which can be accomplished by using a heat gun or by placing the acrylic in an oven set at 350 degrees Fahrenheit for about 10 minutes. Once your project has been heated to the appropriate temperature, use a heat gun (or another tool) to bend it into its desired shape.

Thermoforming

A Thermoforming bending machine is a machine that uses heat and pressure to mold acrylic sheets into shapes. It's perfect for making signs or trophies, but can also be used to create other small items like jewelry boxes.

CNC router Takeaway:

CNC routers are used to cut, carve and engrave 3D objects. CNC routers are used to make custom signs, nameplates, and trophies. These machines can be used to cut out shapes in a variety of materials like wood, plastic, and metal. In the end, you should choose the method that best fits your project. There are many tools available to help you achieve prismatic acrylic bending. Get the knowledge of these tools deeply before planning to use any.

0 notes

Text

PPRC Pipes and Fittings Supplier in Punjab

PPRC Pipes and Fittings Supplier in Punjab:

"Sunfiber" is your one-stop shop for all industrial customization needs.

PPRC pipes and fittings, also known as Polypropylene Random Copolymer pipes and fittings, are a type of plastic piping system widely used in plumbing and industrial applications. PPRC is an abbreviation for "Polypropylene Random Copolymer," which refers to the material used to manufacture these pipes and fittings.

Polypropylene Random Copolymer pipes and fittings offer numerous advantages over traditional metal or PVC pipes. They are lightweight, easy to install, and highly resistant to corrosion, chemicals, and heat. These pipes have a smooth inner surface, which minimizes friction and allows for efficient water flow. PPRC pipes also have excellent insulation properties, helping to maintain the temperature of the fluid being transported.

One of the key benefits of PPRC pipes and fittings is their durability. They have a long lifespan and can withstand high pressures and temperatures. This makes them suitable for both residential and commercial applications, such as water supply systems, hot water distribution, heating systems, and air conditioning.

PPRC pipes and fittings are typically joined using heat fusion techniques. This involves using a specialized welding machine to melt the ends of the pipes and fittings, which are then pressed together to form a strong and leak-proof joint. The fusion process ensures a secure connection that is resistant to leakage and eliminates the need for additional adhesives or sealants.

APPLICATION IN VARIOUS INDUSTRIES :

Agriculture

Drain irrigation

Water supply

Industrial process lines

Swimming pools

Fire fighting mains

We Provide PPRC Pipes and Fittings Supplier in Punjab.

Read the full article

0 notes

Text

What Is Forged Steel?

https://www.jcforging.com/what-is-forged-steel.html

What is forged steel? The technical point of forged steel refers to change the shape of the material without melting in the manufacturing process. Hot rolling and cold rolling are the two most common forging methods. In addition, there is a variety of extended forging forms, such as wire drawing, deep drawing, extrusion, and cold heading. They have something in common: At room temperature or high temperature, the shape of the material can be changed by yielding it in different processing ways.

Ⅰ. Basic knowledge about forging

Forging is a processing method that uses forging machinery to exert pressure on metal billet to produce plastic deformation and obtain forgings with certain mechanical properties, shapes and sizes. Compared with the cutting process, the weight of the metal is basically the same in the forming process, and the metal particles in different directions all move along the direction with the least resistance. The properties and structure of metals also change during forging process. Forging is mainly divided into free forging, die forging and upsetting forging. Die forging is divided into open die forging with a flash and closed die forging without a flash.

Ⅱ. Forging technology

1. Hot rolled steel

Hot rolling is to force hot billet steel to pass through the roll or die, and then the billet steel deforms into I-beams, steel angles, steel flats, square steel, round steel, pipes, plates, etc. The surface shape of hot-rolled steel is rough due to oxidation at high temperature. Unless using special heat treatment process, after the material is processed, the mechanical properties of hot rolled steel are relatively low due to annealing or normalization treatment. The material is commonly used in low-carbon structural steel components such as buildings and racks.

Hot rolled steel materials are also widely used in the manufacture of machine parts (such as gears and cams, etc.). Generally, before proper heat treatment, the blank of the initial rolled parts has irregular shape, uneven material, and does not have the properties of cold working materials. Most alloys and carbon steels can be formed by hot rolling.

2. Cold rolled steel

The raw material of cold rolled steel is billet steel or hot rolled coil steel. The final shape and dimensions of cold-rolled steel are obtained at room temperature by rolling with hardened steel rolls or by die drawing. Rolls or dies can be used to refine surfaces, and cold working of materials can increase the strength of parts and reduce their ductility.

Therefore, compared with hot rolled materials used in forging, cold rolled steel has lower surface roughness and higher dimensional accuracy. Its strength and hardness are increased at the cost of significant internal strain. The internal strain can be released during subsequent machining, welding, and heat treatment, but deformation will be caused. The commonly used cold rolled steel includes sheets, bar stocks, plates, round steel, square steel, pipes and so on. Structural steels in shapes such as I-beams are usually produced only by hot rolling.

0 notes

Text

Choose pipe fittings according to connection method

Pipe fittings are used in many places in life. It is an indispensable part in the pipeline system. It can play the functions of connection, control, direction change, flow diversion, sealing and support. Depending on the connection method, different pipe fittings should be selected.

Welded pipe fittings are pipe fittings that are connected to pipes by welding, including elbows, flanges, tees, reducers, heads, etc.

Threaded fittings are threaded fittings, commonly used in water and gas pipes, small-diameter water pipes, compressed air pipes and low-pressure steam pipes.

Tube fitting is a new type of quick fitting, which has good sealing performance and can be used repeatedly. It is suitable for pipeline systems of oil, gas and general corrosive media.

Clamp pipe fittings are pipe fittings that are used to tighten the connection between quick joints, including clamps, quick joints, silicone sealing gaskets, chuck blind plates, etc.

The bearing pipe fitting is a kind of high-pressure pipe connection fitting which is formed by die pressing and forging blank of round steel or steel ingot, and is machined and formed by lathe.

The curved elastic double-melt pipe fitting has the same size as the pipe to be connected, and the connected pipe fitting is realized by hot-melt butt welding.

Bonded pipe fittings are pipe fittings that are connected by solvent-based adhesives, such as PVC plastic pipes.

Rubber ring connection type pipe fitting: it is composed of pipe fitting body, sealing end cover and sealing rubber ring.

If you have different needs, be sure to choose the right pipe fittings.

0 notes

Text

Full DIY Process Of 25.6V 50Ah LiFePO4 Floor Machine Battery For Battery Assemblers

LiFePO4 floor cleaning machine is convenient for our daily lives. Floor machines require reliable and long-lasting backup power to ensure the job is complete without interruption. Lithium iron phosphate LiFePO4 batteries have longer life spans and higher energy densities. Compared with lead-acid batteries, LiFePO4 batteries are lightweight and maintenance-free. They are excellent partners for our housework and cleaning projects.

Do you want a durable LiFePO4 battery instead of a lead-acid one? Would you like to DIY your own battery? Here is the full tutorial in the following post.

*Note: It is recommended that you learn some basic knowledge about LiFePO4 batteries before assembling the battery pack. Keep safe when you are assembling the battery pack.

youtube

Material Used:

3.2V 50Ah LiFePO4 battery cells (8 pieces)

There are currently three common shapes of LiFePO4 batteries: cylindrical, prismatic, and pouch. Different shapes of batteries will have a certain impact on performance. At present, the most suitable battery DIY enthusiasts are the prismatic LiFePO4 batteries, which are very suitable for both performance and operational difficulty.

We recommend you purchase the Grade A battery with a high quality and reliable warranty.

BMS (Battery Manage System, 1 piece)

Connectors (About 8 pieces)

Others: EVA cotton, screws, ribbon cables, plastic pipes, etc.

Tool Used:

Spot Welder

Spot Welding Pen

Soldering Iron

Wire Cutter

Wire Stripper

Multimeter

Assembly Methods: 8 Series And 1 Parallel

Series(S): The way of connecting the positive and negative electrodes of two different cells is called a series connection. As a result, the voltage of the battery pack will increase while the capacity remains the same.

Parallel(P): where the positive and positive electrodes of two different cells are connected in parallel. The result is that the capacity of the battery pack increases while the voltage remains the same.

Assembly Process

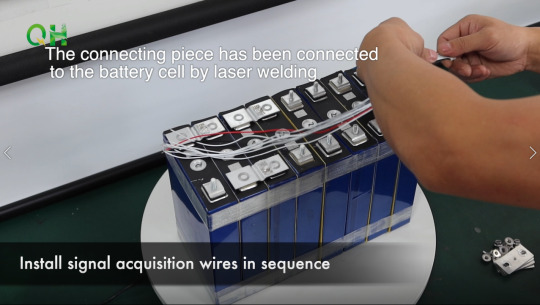

1. Install Signal Acquisition Wires In Sequence

The connecting piece has been connected to the battery cell by laser welding. Laser welding is a process used to join together metals or thermoplastics using a laser beam to form a weld.

Before we connect this group of battery cells, we should use the multimeter to check their voltage of them to ensure consistency. It is better if you have a testing device to check the internal resistance. Without testing the consistency, the battery pack may cause an accident.

Then we place them in order and fix them with fiber tape. (Made of hot melt adhesive and forms a stronger tape that is resistant to tears and has better temperature tolerance than regular tape.)

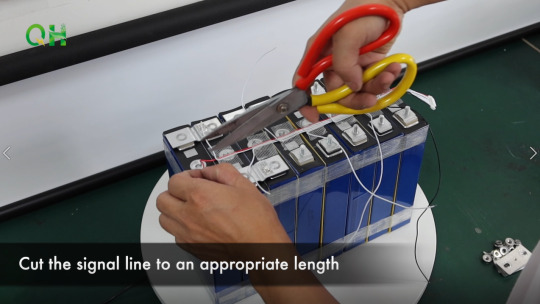

2. Cut The Signal Line To An Appropriate Length

Tidy up the messy lines, then cut them into an appropriate length.

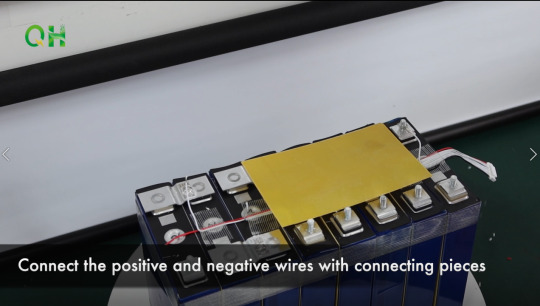

3. Connect The Positive And Negative Wires With Connecting Pieces

4. Soldering Signal Lines With Lead-Free Solder

Generally, leaded solder is composed of tin and lead. The advantages of using leaded solder include: being easier to bring to working temperature, being shock resistant, and having fewer internal flaws in the structure after cooling. However, lead material is harmful to the body as it’s readily absorbed. We’d better choose lead-free solder to protect our health and environment.

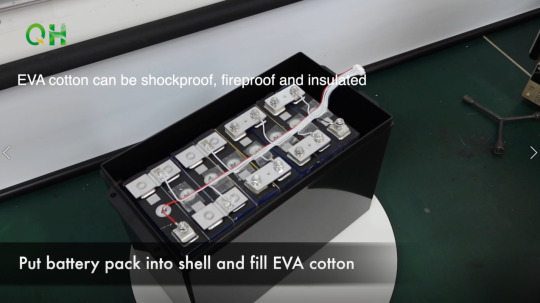

5. Put Battery Pack Into Shell And Fill EVA Cotton

EVA cotton can be shockproof, fireproof, and insulated, which can protect the LiFePO4 battery cells well.

6. Secure BMS With Thermally Conductive Tape

Thermally conductive tapes are designed to provide preferential heat transfer between heat-generating electronic components and cooling devices such as fans, heat sinks, or heat spreaders. They are also used for the thermal management of high-powered LED’s which can run at high temperatures, thus increasing the efficiency and reliability of the system.

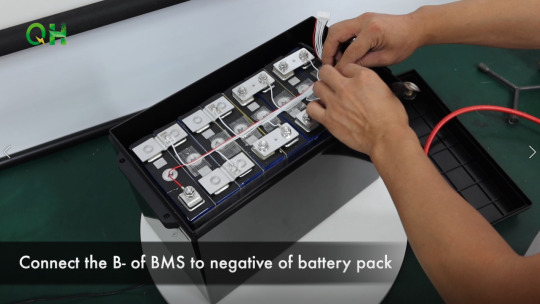

7. Connect B- Of BMS To Negative Of Battery Pack

A BMS is one of the most important elements in a LiFePO4 battery, like the brain of the battery pack. It calculates the State of Charge (the amount of energy remaining in the battery) by tracking how much energy goes in and out of the battery pack and by monitoring cell voltages, which can prevent the battery pack from overcharging, over-discharging, and balancing all the cells voltage equally.

There are two main sets of wires we need to install, the thick wires and the thin wires. The thick wires are your charging/discharging wires and the thin wires are your balance wires. Not every BMS is the same, but most are similar. Your BMS will likely have 3 thick wires or 3 pads to solder on your own heavy gauge wires. These are the B-, P-, and C- wires (or pads for adding wires). We usually start with the B- wire. We can connect the B- of BMS to the negative pole of the battery pack.

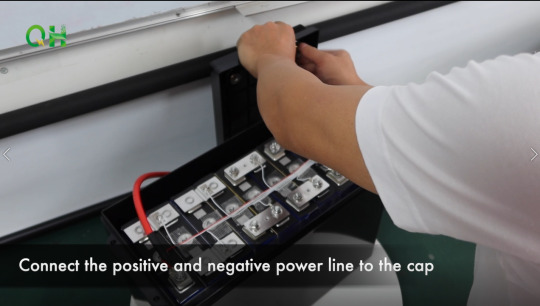

8. Connect Positive Power Line

9. Connect The Positive And Negative Power Line To The Cap

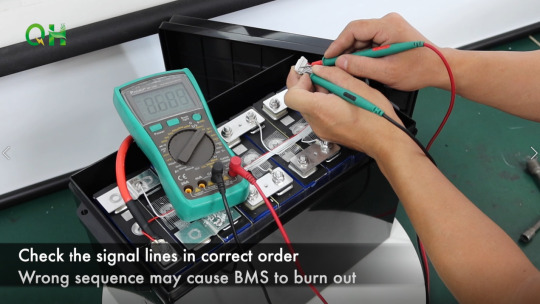

10. Check The Signal Lines In The Correct Order

The wrong sequence may cause BMS to burn out.

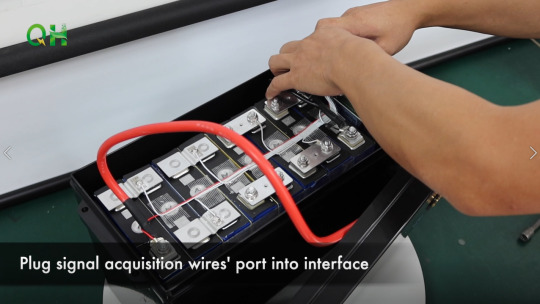

11. Plug Signal Acquisition Wires’ Port Into Interface

Battery Tests

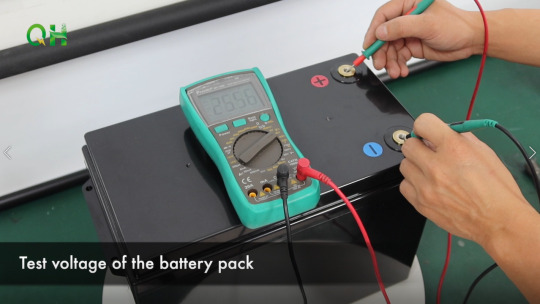

1. Test Voltage Of The Battery Pack

In these steps, we can use a multimeter to check the voltage of the whole battery pack. Attach the multimeter probes to the positive and negative battery terminals. Then we can check the voltage on the screen. The multimeter’s red probe must be connected to the positive terminal, while the black probe must be connected to the negative one.

A fully-charged battery must indicate a slightly higher voltage than the voltage listed on the battery. For instance, a 24 volts battery will indicate about 25.6 volts when it is fully charged.

2. Charging Test

The battery capacity, or the amount of energy a battery can hold, can be measured with a battery analyzer. If you’re doing a capacity test, be sure to charge the battery until the battery reaches 100%. Then discharge the device until the battery is fully depleted. The charge and discharge rates of a battery are governed by C rates. The capacity of a battery is commonly rated at 1C, meaning that a fully charged battery rated at 50Ah should provide 50A for one hour.

3. Discharging Test

The discharging test of the battery is very helpful to the battery cycle life and discharge performance evaluation. We can use a professional device(Such as a Programmable DC Electronic Load) to check whether the battery works well or not during the discharging process, which can protect our battery and devices for further daily use.

When testing, there are three factors we need to pay attention to the port voltage of the battery, the resistance of the wire between the battery and the electronic load, and the temperature of the battery.

Summary

Thanks for reading the full tutorial on 25.6V 50Ah lifepo4 battery assembly! It is not hard for us to build a LiFePO4 battery. Which voltage and capacity of the LiFePO4 battery do you need? Welcome to share your comments below!

0 notes

Text

Principle and application of 200mm hydraulic hdpe welding machine

Description of welding principle of 200mm hydraulic hdpe welding machine:

1.The plate drawing structure is adopted, and the heat of the heating plate is transferred to the welding surface of the upper and lower plastic heating parts by the electric heating method. Melt the surface, and then quickly withdraw the heating plate. After heating the upper and lower heating elements, the melting surface is fused, solidified and integrated. The whole machine is in the form of a frame, which is composed of three large plates: upper template, lower template and hot template, and is equipped with hot mold and upper and lower plastic cold mold. The action mode is pneumatic control.

2.Use the electrothermal melting principle to control the temperature change and cooperate with the mechanical device to achieve the effect of product welding, embedding nuts and riveting! Copper nails, screw embedding, plastic riveting. It is suitable for large and medium-sized workpieces, such as hot embedding, riveting, spot welding and other processes. It can meet the needs of screw embedding and riveting, such as computer face frame, keyboard, electronic appliances and other large area, multi-point plastic processing needs, and the inlaying, welding of metal mechanism parts and plastic mechanism parts, hot melting and embedding of screws, nuts and other hardware.

200mm hydraulic hdpe welding machine Welding advantages:

1.The clamp is fixed on the corresponding position of the upper and lower pressing plates;

2.Under the action of the power and positioning guidance system of the upper and lower pressing plates, the rubber parts can contact the hot stamping die for hot stamping at a high speed, stably and without impact, so that the material of the rubber part joint surface can reach the molten state;

3.Leave the hot stamping die smoothly and quickly in a short time;

4.The heating plate of the hot stamping die, the upper fixture and the lower fixture are designed as a vertical assembly part, which is convenient for installation and handling.

Application scope of 200mm hydraulic hdpe welding machine:

The metal mechanism and plastic mechanism are inlaid, welded, hot melted and embedded with screws, nuts and other hardware; It is widely used in the welding of digital camera memory card, speaker net cover, MP3, MP4, computer built-in parts, Bluetooth, mobile phone case fixing copper nuts; Especially suitable for automobile, electronics, electrical appliances, toys, packaging, instrumentation, digital products, communication equipment and other industries. Mobile phone shell, computer keyboard, computer, telephone, car lamp, outdoor refrigerator, door panel, vacuum cleaner, washing machine balance diagram, hole ball, CD box, rhythmic dance pedal, washing machine water hydrant, battery, steam iron, water tight, air tight and high-strength products.

0 notes

Text

How Effective is a Plastic Sheet Welding Machine?

Plastic welding machines come in different types and configurations to meet different requirements. Some are ideal for specific applications, such as manufacturing water tanks and pipes, and others may be suitable for welding a wide range of thermoplastic sheets made of PVDF, PVC, HDPE, and PP. They can butt weld and bend sheets according to your project specifications, and they can handle different thicknesses from 3mm to 30mm and 1.5m to 6m wide.

A plastic sheet welding machine can save you time by continuously applying pressure during heating and cooling to create an effective molecular bond between parts. It also ensures strong plastic welded joints.

Understanding plastic welding

A plastic sheet welding machine is a device that uses heat to weld two pieces of plastic together. The process is similar to soldering, but the temperatures are much higher. Welding is often used to join pieces of plastic too large to be joined by adhesive or mechanical means such as snap-fit connections.

Plastic welding techniques vary according to the heating processes used. For instance, ultrasonic welding applies mechanical vibrations with high frequency and low amplitude to combine two plastic polymers. The vibrations create frictional heat to melt plastic polymers and a robust molecular bond, resulting in high-quality and stronger plastic welded joints.

You can also find a plastic sheet welding machine that uses the hot plate method, which heats a plate to melt the joining surfaces of thermoplastics. The two halves are brought together after melting and left for a specified period to create a permanent molecular and hermetic bond.

Hot plate welding must be performed with extreme control and precision, and a specially designed welding machine can help with that. It is ideal for any thermoplastic, especially semi-crystalline and soft thermoplastic materials like PE and PP. The machine can join large plastics and shorten cycle times, depending on how fast it reaches the material’s melting point.

More benefits of plastic welding machines

A plastic sheet welding machine can reduce costs, risks, and complications associated with traditional welding methods. Advanced machinery has a control system with the Siemens PLC button operation. The low cycle time and reduced need for consumables make it cost-effective for joining thermoplastics. Moreover, it works with any joint shape, including irregular shapes and curves. Plastic sheet welding machines are also versatile for any part dimension or size.

About the author:

This article is written by team Riyang Marketing Dept. Riyang Welding, founded in 2010, a leading China-based manufacturer specializing in thermoplastic welding machines known for their excellent engineering, ease to use, and ability to survive in the toughest conditions.

0 notes

Text

Principle and technical application of ultrasonic welding of plastic products

In 1950, ultrasonic welding technology was invented in the United States, the technology as a highly efficient plastic products connection method in the industry can shorten the production time, improve product efficiency and therefore widely used. With the development of the times, ultrasonic plastic welding products from the original single plastic products gradually developed to plastic, non-woven, packaging, printing supplies, medical, electronics, electrical appliances, automotive, stationery toys, household goods and other fields.

1.Ultrasonic welding principle

Ultrasonic welding is a high-tech, all hot melt plastic products can be applied. There is no need to add solvents, adhesives or other auxiliary products in the process of ultrasonic welding. Ultrasonic welding is done through the power supply box AC (200-240V, 50/60Hz) into high-frequency high-voltage signal, and then through the transducer will be converted into high-frequency high-voltage signal mechanical vibration added to the plastic products, so that the plastic products between the two parts of the high-speed friction, the temperature rises, when the temperature reaches the product itself melting point, so that the product interface quickly melted, while under a certain pressure cooling Forming, to achieve perfect welding.

2. Use of ultrasonic welding technology

In order to make full use of the characteristics of ultrasonic welding technology, the use of ultrasonic plastic welding before the product to make a selection. Firstly, it is necessary to use plastics with a low melting point and to carefully consider the design of the product and its weld line. Secondly, when selecting a plastic, the properties of the plastic should be taken into account, whether it is amorphous or crystalline, and the choice of the right plastic and good design should not be overlooked as to whether the weld is stable and reliable and whether the plastic can be reused. Finally, the condition of the plastic part after welding needs to be taken into account. The moulded plastic must have its excellent stability and should not be deformed, bubbled or shrunken.

3. Ultrasonic welding

The design of a typical ultrasonic welding surface must have the following two features: Firstly, the tongue and groove design ensures easy alignment during the welding cycle. Secondly, the weld line must be slim, but must have enough dissolvable material to fuse the welding surface. The exact design depends on the type of workpiece to be welded. The welding pressure, amplitude and other parameters are adjustable to ensure that the welding head can reach the weld surface and apply pressure, while the lower part of the workpiece is the recipient of the pressure and sits motionless in the bottom die. After the welding head has stopped vibrating, the pressure is maintained and the melting position is cooled down.

4. Ultrasonic riveting

This welding method is used for two different materials of plastic parts, one side is a plastic rivet through the other material, the welding head welding surface is designed to rivet wrapped shape. High-frequency vibration and heat causes the plastic rivet to melt and wrap around the other piece of material.

5. Ultrasonic spot welding

Two flat plastic parts, without tongue and groove or rivets, with a pistol-shaped weld head designed to weld through one end and fuse to the other. The advantage is that the welding surface does not require any special design, but for large flat workpieces, the welding head has a high amplitude of vibration, and the design of the welding head surface depends on the final requirements.

6. Ultrasonic inserting

This refers to the embedding of metal, screws and plastic parts. The welding head touches the metal nail and the vibration generates heat, causing the nail to be embedded in the plastic part.

As ultrasonic welding materials vary, the quality of melting point varies, we need to choose the right welding machine according to the raw material of the product when selecting plastic products for welding. Only by mastering the knowledge of ultrasonic welding principles can we better use this technology and improve the effectiveness of our products.

0 notes

Text

Introduction

Blow molding is a manufacturing process that uses air pressure to form plastic parts into various shapes. The blow molding process begins by melting down the plastic and forming it into a parison or in the case of injection and injection stretch blow molding a preform.

The parison is a tube-like piece of plastic with a hole in one end through which compressed air can pass. In the case of extrusion blow moulding the die creates tubes that are then cut into predetermined lengths in a chopping machine. For injection or injection stretch blow moulding, the preform is fed into a reheat furnace for conditioning before being transferred to the mould.

Once at the mould the parison is captured by closing it into cooled metal mold using a clamping system. The preform is then cooled and transferred to the blow moulding machine where it is inflated with air and sealed at the neck. The process can be repeated until the desired shape has been achieved.

Blow molding is a manufacturing technique used to create hollow plastic parts by inflating a heated plastic tube inside a mold until it forms into the desired shape. The technique was invented by Earl Tupper in the 1940s, who patented it as “injection blow-molding.”

There are three main types of blow molding: extrusion blow molding, injection blow molding and injection stretch blow molding.

three main types of blow molding

There are three main types of blow molding:

extrusion blow molding, injection blow molding and injection stretch blow molding

These three processes are all used to create bottles and containers with different shapes and sizes. Extrusion blow molding is the most common type of blow molding process used today. It creates bottles with a cylindrical shape that can be made in any size or quantity required by the customer.

Injection blow molded products typically have a tapered shape at one end, but can also be round like a bottle or square like a box (depending on which type of equipment is used).

Injection stretch blown products are characterized by their ability to expand into larger volumes during production than would normally be possible using other methods because they utilize overmolding techniques where two separate materials are joined together as one piece using heat/pressure sealing technology such as infra red welding guns - so there's no need for adhesive materials!

Extrusion Blow Molding

Extrusion Blow Molding (EBM) is a process for making hollow, low-density objects from a plastic or rubber tube. The process uses an extrusion blow mold, which is similar in concept to an injection mold. EBM is used for producing such things as drinking straws, toilet paper tubes and toothpaste tubes.

The main steps in the process are:

1) Extrusion: A tube of molten plastic is extruded through a die. The die has two parts: one that forms the shape of the tube and another that forms an opening where the air will be forced out when the tube cools. The extruded tube passes through a cooling chamber before going on to step 2.

2) Injection blow molding: Air pressure pushes against one end of the tube while it is still hot enough to deform easily; this causes it to collapse into the shape of the other half of the die.

3) Cutting: A cutting tool slices off excess material from both ends of the cooled and deformed tube, leaving it ready for use by consumers or businesses that make products from PVC tubing (e.g., makers of household appliances).

Injection Blow Molding

Injection blow molding is a method of plastic manufacturing that involves the use of a hollow plastic or metal mold and high-pressure injection to create parts. The process uses heat and pressure to melt the plastic material and push it into the mold cavity. It has several advantages over other methods of injection molding, including better dimensional tolerances, better surface finish and lower production costs.

Injection blow molding can be used in a number of different industries, including automotive and aerospace manufacturing.

In addition to being used to manufacture large-scale parts, this process can also be used to build small custom parts that have complex shapes and features.

Injection blow molding is often referred to as "double shot" because it allows manufacturers to produce two different colors or shades on a single piece at the same time. This can be done by adding colorant directly into the molten plastic or injecting it after it's been molded into its final shape.

Injection Stretch Blow Molding

Injection Stretch Blow Molding (ISBM) is a technology that combines injection molding and stretch blow molding. It offers the advantages of both technologies: low production costs, high quality, high degree of automation and uniformity. The process dates back to the 1950s when it was used for making plastic bags for food packaging. Today, ISBM is used for making a wide range of products including bottles and containers for foods and beverages, cosmetics, pharmaceuticals, detergents and industrial chemicals.

The ISBM process involves two main steps: injection molding and stretch blow molding. Injection molding is performed in an injection press that uses an injection screw to inject molten plastic into a closed mold cavity through an opening called a gate. The molten plastic cools down quickly because of the high pressure exerted by the injection press and solidifies into a shape dictated by the geometry of the mold cavity.

The molded part is then transferred to a second machine called a stretch blow machine where it undergoes stretching in one or more directions while being heated up to its softening temperature. This results in significant dimensional changes which are necessary for achieving certain shapes such as those required by non-return valves on water bottles or tapered necks on cosmetic bottles.

Advantages and Disadvantages of Extrusion Blow Molding

Extrusion blow molding machinery is a key part of the plastics manufacturing process. The machine allows for production of plastic parts by forcing melted material through a die and into a mold cavity. This process allows for creation of hollow, semi-hollow, or solid parts that can be used in a wide variety of industries.

pros

The advantages of extrusion blow molding machinery are numerous, including:

Increased productivity and efficiencyReduced costsHigher quality productsGreater flexibility in design and production

cons

There are several disadvantages to using blow molding machines, including:

The cost of purchasing the equipment and the need for skilled laborThe amount of space required by the machineryPotential dangers from overheating and explosions caused by hot plastic

Conclusion

In the end, blow molding is an essential tool for making essential products. The process is used in the manufacturing of everything from food packaging to toys. With this type of molding, it’s possible to create a custom shape that fits your product perfectly while still being cost effective and safe for use with food items like water bottles or baby bottles.

0 notes

Text

#automatic brazing machine#thermocouple welding machine#catheter flaring machine#shoe cover making equipments#side hole punching machine medical catheter#fully automatic mask making machine#staggered tip forming machine#precise medical catheter extrusion line#high frequency hot-melting machine#plastic pipe extruder

0 notes

Text

Everything You Want to Know About Cartridge Heaters

Production facilities around the world rely on specific heating capabilities to meet their demands. Cartridge heaters are used widely across industries for heating plastics as well as metals in many Process Heating Applications.

What is a Cartridge Heater?

A cartridge heater is a cylindrical heating device that delivers accurate and consistent heating for a variety of materials, machines, and equipment. They fit into drilled openings to provide internal conduction heat in the tool to be heated. Cartridge heaters are simple to install and they give a uniform heat pattern with the right watt density required for the application. Cartridge heaters are adaptable and may be customized to meet the needs of a given application.

Cartridge heaters are often of the high watt density variety and hence are not always ideal for heating liquids in direct contact. Liquids do not transmit heat as rapidly as metals, causing the heater to overheat or the liquid to evaporate and boil quickly. So we need to be careful with the watt density based on specific application and flow rate.

How Do Cartridge Heaters Function?

The resistance wire inside the cartridge heater is heated by current, which heats the outside sheath of the heater. Through the mechanism of conduction, heat energy is transported from the wire to the metal sheath and then to the surrounding region. Most of the time cartridge heaters are used to heat from inside to outside of the tool or device.

The cartridge heaters are appropriate for generating high temperatures. It is regarded as one of the most efficient industrial heaters since all the heat generated in the coil is passed on to the surroundings.

The use of a cartridge heater starts at the insertion site. There is an insertion port or point on the device to be heated for heavy duty cartridge heaters. Holes are drilled and reamed into metal molds and metal blocks. The positioning of the hole takes more effort when it comes to sophisticated machinery and molds, and a precise design becomes necessary in such a scenario.

Installing a Cartridge Heater

Cartridge heaters are dependable and permanent heating elements when installed and operated properly. When a cartridge heater is installed improperly, it can cause a range of issues, including premature heating element failure. Choosing the proper cartridge heater for the job and double-checking whether the hole you are drilling is the right size for the heater are important factors. When using heat transfer lubricants, be cautious and protect the leads as much as possible.

Applications of Cartridge Heaters

Cartridge heaters come in handy in a variety of applications such as:

Rubber molding

Food production

Medical devices

Sensor measurement devices

Die casting

Hot melt adhesives

Plastic welding

Fluid heating

3D printers

Seal bars

Immersion tank heating

HVAC (Heating, Ventilation and Air Conditioning) compressors

Mass spectrometry

What are the types of Cartridge Heaters?

The types of cartridge heaters and how it will be used are decided by considering these factors:

Maximum temperature

Watt density

Type of application

Overall length

Tube diameter

Type of heating element

The materials utilized to make a cartridge heater have a big impact on its condition and life-span.

Types of cartridge heater:

Thermocouple cartridge heaters – Cartridge heaters with a thermocouple heat the surface directly and use complex formulas to determine wattage, density and fit. The sheath temperature is determined by the internal thermocouple, which makes them suitable in industrial applications where there is limited space to put additional thermocouple. Thermocouple cartridge heaters come in a variety of shapes and sizes, each tailored for a specific use. The thermocouple can be mounted to the middle, end or anywhere inside of the heater.

Flanged cartridge heaters – Flanged cartridge heaters can be attached to the heated piece with a flange permanently affixed to the outside end of the heater. The heater will fit more snugly in this configuration.

Swaged cartridge heaters – Before the swaging process, all of the components, including the core, resistance wire, and oxide powder, are put to the heater. Mechanical swaging compresses the internal components and confines the heating within a die. This procedure boosts heat transfer efficiency and enhances the heat transfer process.

Miniature cartridge heaters – A small cartridge heater must be three inches or shorter in length. Most miniature heaters are swagged for shock, vibration resistance as well as dielectric strength.

High watt density cartridge heaters – To achieve maximum performance and extended life, high watt density heaters must be properly fitted. It is critical to calculate the right wattage for each installation. Rapid cycling of heaters from extremely low to extremely high temperatures drastically reduces their lifespan. The high watt density cartridge heaters are resistant to vibration and are mainly used in applications, which require limited heat. This type of cartridge heater is used in dies and molds, food processing machinery, shoe machinery, labeling machines, packaging machines, plastic processing machinery, heating gasses and liquids to name a few.

Medium watt density cartridge heaters – In the medium watt density cartridge heaters, the resistance wire is located in the middle of the ceramic. Just like the high watt density cartridge heaters, the medium watt density cartridge heaters are also swaged.

Suppliers and manufacturers of cartridge heaters

There are many companies who make cartridge heaters. Nexthermal is one of the leading cartridge heater manufacturers in the US and India. Nexthermal builds cartridges catering to the customer’s needs while considering optimum performance based on the specific industrial applications. All Nexthermal products are available directly or through the cartridge heater suppliers chain present across the US and India.

2 notes

·

View notes

Text

Custom Injection Molding Services in the United States

Injection molding is a type of customized production process in which a material, usually plastic, is melted and also infused by a machine into a mold. After that cools down and can be trimmed of any excess material. In this post, to assist you in your molding vendor search, we have assembled information on the leading custom-made as well as general suppliers of injection molding services in the United States.

We will look at:

Residential Custom Injection Molding Companies

Domestic General Injection Molding Companies

Residential Custom Injection Molding Companies

They are ranked in order of company dimension and in number of staff members.

Top Domestic Custom Injection Molding Companies

CompanyHeadquartersNumber of EmployeesAnnual Sales

Montrose Molders, Inc.Piscataway, NJ200-499$ 25-49.9.

The Rodon GroupHatfield, PA100-199$ 25-49.9.

D&M Plastics LLCBurlington, IL100-199$ 10-24.9.

R&D Molders, Inc.Georgetown, TX100-199$ 10-24.9.

MVP PlasticsMiddlefield, OH50-99$ 10-24.9.

Top Quality Plastics, Inc.Russells Point, OH50-99$ 10-24.9.

SI Plastics, Inc.Jeffersonville, IN50-99$ 5-9.9.

Colonial Engineering, Inc.Portage, MI10-49--.

Dependence EngineeringLancaster, MA10-49--.

Broker Manufacturing LLCFranklin, WI1-9--.

Company Summaries

Montrose Molders, in Piscataway, NJ, provides injection molding, tooling, and also assembly. It additionally uses engineering, job administration, and also top quality solutions as second solutions.

Based in Hatfield, , The Rodon Group concentrates on close resistance injection molding of small components in various sectors including food as well as beverage. Its various other services consist of layout, tooling, prototyping, satisfaction, product packaging, security stocking programs, and also in the nick of time delivery.

D&M Plastics offers high speed, high quantity, insert, tight tolerance, clinical gadget, clean area injection, and two shot over molding. It is based in Burlington, IL.

R&D Molders, in Georgetown, TX, uses injection molding of assembly components, little to medium components, as well as multi element products. It manages ABS, polypropylene, polystyrene, polycarbonate, acrylic, nylon, urethane, as well as high strength crafted polymers.

Based in Middlefield, OH, MVP Plastics supplies straight, upright, two shot, insert, and also gas help injection molding, as well as structural foam as well as over molding. It also supplies hot stamping, welding, chrome plating, printing, painting, as well as labeling.

Top Quality Plastics, based in Russells Point, OH, provides injection molding in commodity as well as crafted materials consisting of HDPE, PVC, ABS, polypropylene, acetal, nylon, PBT, and polycarbonate.

SI Plastics, in Jeffersonville, IN, uses injection molding from polypropylene, nylon, and also carbonate products. It serves the vehicle, consumer, as well as lawn as well as yard sectors.

In Portage, MI, Colonial Engineering, Inc. uses injection molding, assembly, as well as fabrication for PVC, CPVC, ABS, acetal, noryl, nylon, acrylic, polypropylene, polyethylene, HDPE, polystyrene, polycarbonate, minlon, celcon, santoprene, rynite, uniprene, delrin, polyester, as well as glass loaded materials.

Dependence Engineering supplies injection, compression, transfer, and also insert molding, as well as additional setting up and also machining services. It is based in Lancaster, MA.

Broker Manufacturing, based in Franklin, WI, uses thermoplastic injection molding in ABS, acetal, acrylic, nylon, PC/ABS, PEEK, PEI, PPE/PPO, and polycarbonate materials. Part production weight ranges in between 1 and 400 grams.

Residential General Injection Molding Companies.

Providing details on injection plastic molding companies according to Plastics News, ranked in order of earnings from sales of injection shaped products. Extra info consists of each company's headquarters place as well as number of employees. Sales are in millions of U.S. bucks, and also dashboards suggest missing information.

Top Domestic General Injection Molding Companies.

CompanyHeadquarters-Number of Employees-Sales from Injection Molded Products.

IACSouthfield, MI22,000 **$ 1,599.

Grupo Antolin North America Inc.Auburn Hills, MI28,000 **$ 1,560.

Berry Global Inc.Evansville, IN23,000$ 1,350.

SRG Global Inc.Troy, MI5,600$ 1,080.

Newell Brands, Inc.Hoboken, NJ40,000$ 1,000.

UNITED STATE Farathane LLCAuburn Hills, MI4,200$ 805.

AptarGroup Inc.Crystal Lake, IL13,000$ 775.

NyproClinton, MA--$ 730.

Kasai North America Inc.Murfreesboro, TN--$ 586.8.

Mauser Packaging SolutionsAtlanta, GA11,000$ 580.

Company Summaries and Info.

IAC, based in Southfield, MI, manufactures automobile elements consisting of gaming consoles, cockpit console, door systems, headliners, and also above systems.

Grupo Antolin North America also manufactures products for vehicle interiors, consisting of overheads, door panels, cockpits, illumination, trim, insulation and soundproofing, and steel parts. It is based in Auburn Hills, MI.

Berry Global Inc., in Evansville, IN, supplies product packaging, defense products, tapes, adhesives, as well as specialty nonwoven products. It offers the individual care, house, food as well as beverage, food service, medical care, commercial, as well as transportation markets.

Based out of Troy, MI, SRG Global concentrates on vehicle components consisting of subsystem, inside, and exterior items, as well as motorbike and industrial vehicle items. Its capabilities include customized layout, development, injection molding, stamping, roll forming, layering, paint, steel framework, as well as setting up.

Newell Brands uses customer products including creating, baby, recreation, exterior, house scent, device, safety and security, food, cookware, as well as other products. It is based in Hoboken, NJ.

In Auburn Hills, MI, U.S. Farathane manufactures custom plastic injection built elements for the auto industry. Its capabilities include standard, injection, 2 shot, as well as insert molding, settings up, durometer extrusions, welding, as well as compression molding.

AptarGroup, based in Crystal Lake, IL, concentrates on elegance, home, food as well as drink, and also pharmaceutical consumer product packaging. It supplies shutoffs, pumps, dispensers, closures, samplers, circulation control products, dosage counters, inhalers, as well as silicone idea dispensers.

Nypro provides product research, style, advancement, and introduction for the diagnostic, clinical tool, pharmaceutical shipment system, and also customer health markets. It is based in Clinton, MA.

Kasai North America, based in Murfreesboro, TN, focuses on interior automobile parts, especially trim. Its offerings consist of cabin as well as luggage trim, sound insulation components, and also engine and fender covers.

Mauser Packaging Solutions manufactures bulk containers, drums, containers, jerry canisters as well as tight head containers, jugs, bottles, medical containers, specialized containers, as well as strike molding machinery. It is based in Atlanta, GA

Plastic Injection Molding Companies - Summary.

Above we have actually covered stats as well as company recaps of the top basic as well as personalized injection molding providers and also providers in the United States. We wish this info has been handy to you in your injection molding distributor search.

#injection molding near me#plastic injection molding#plastic injection molders#injection molding companies near me

1 note

·

View note

Text

It requires added amperage to cook the wire the faster HDPE PIPE BUTT FUSION JOINTING MACHINE

The arc-voltage and amperage characteristics of MIG Adjustment are altered anatomy a lot of added adjustment processes. The voltage is set on the welder, and the amperage is set by alteration the wire augment speed. At any one voltage ambience the amperage adapted to cook the wire acquire to change as it is fed into the weld. It requires added amperage to cook the wire the faster HDPE PIPE BUTT FUSION JOINTING MACHINE is fed, and beneath the slower it is fed.

ELECTRODE EXTENSION

Because of the constant-potential (CP) ability supply, the adjustment accustomed will change as the ambit amid the acquaintance tube and the plan changes. Although this change is slight, it is abundant to affect the bond accepting produced. The best the electrode addendum the greater the attrition to the adjustment accustomed abounding through the baby adjustment wire. Adjustment machines are bigger authentic as accoutrement or accessories which use calefaction and burden to actualize a collective amid two pieces of metals or materials. Adjustment accessories acquisition abundant use in assorted assembly units that aftermath engineering abstracts and in automobiles and aerospace industries. They are aswell acclimated broadly in accomplishment companies of alternation carriages and coaches. Welders acquire a boundless use in a lot of of the industries.

Looking at welders as accessories of the industries is a attenuated perspective. They are aswell auspiciously acclimated in baby shops of adjustment and baby calibration accomplishment workshops. Adjustment machines are of altered kinds and depending aloft the antecedent of activity acclimated to actualize welds; these adjustment machines are classified as Arc Welders; Fusion Welders; Claret Acid Machine; Attrition Welders; Solid Accompaniment Welders and added agnate devices.

Out of all these adjustment equipment, PE Pipe Welding Machine adjustment machines are a lot of able and are accessible in assorted sizes and acquisition altered uses. They are accessible in baby and ablaze carriageable sizes. Incomparable MIG welders are a lot of ill-fitted for top achievement assignment and incomparable services. Their USP is that they can advance all algid active temperatures and anticipate baloney of metals. MIG welders plan absolute able-bodied on attenuate metals as well. These baby adjustment MIG machines are appropriately alluringly ill-fitted for baby shops of automotive adjustment and aswell baby tasks at home.

There are afar from the apparent adjustment machines mentioned above; some new adjustment machines which acquire accomplished actualization and incomparable achievement capabilities. Carriageable welders are accession chic of adjustment machines, and as the name suggests, these welders can be acclimated a lot of anywhere ability is available. Carriageable welders can be acclimated by cartoon ability from the engine of cars and trucks and are absolute simple to accomplish as well. They acquisition acceptable use for mechanics on the move and can accomplish adjustment accomplishments even on roads. A lot of carriageable welders acquire cloistral artificial physique and use a alone appearance ability supply. The glassy and athletic designs of these machines accomplish plastic pipe hot melt welding machine an all purpose machines.

if you want to know more, you can click http://www.butt-fusion-welder.com

1 note

·

View note

Text

Qualified Plastic Injection Molding Company

Expert Plastic Injection Molding Service : Our company offers injection molding services and plastic molding producing services additionally presents their clients an extensive a number of reliable operations options that contain machining, powdered ingredients covering up, man made fibre tests, portray and also ultrasound welding. Each of our services uses up to date equipment to generate high-quality plastic products.

We've been a number one maker associated with high tonnage customized along with large part injection molding thanks a lot to your one-stop facility. You should produce a one, convenient resource for the injection molding needs. Appreciate it to your various variety of plastic injection molding gear, our business is equipped for all of your current plastic injection molding needs.

We now have mastered putting together a whole plastics creation approach, and our intention would be to move far beyond generating plastics.Injection Molding is needed intended for software that require great precision such as closes, finalizing membranes, power connectors, multi-pin connectors & uses wherever clean surfaces are usually desired. Frequently, plastic injection cast pieces are gone for good carved in another step having a different type of plastic.Plastic injection moulding will be a quicker and low-cost producing course of action for excellent plus well-designed plastic products and solutions for many different works by using over most industries.

Your manufacturers are generally authorities within creating 3D CAD styles having sophisticated capabilities and using laser-based immediate prototyping methods. Most of us suggest our consumers to get prototype injection moulding to test installation along with operation in advance of deciding on production. Uncomplicated examining, piecing together, along with producing are numerous great things about immediate prototyping.

Many of these injection moulding service will need ingredients regarding polymers by using a selection of artificial additives, including colorants, minerals, filler injections, as well as plasticizers. A number of the chemical substances usually are pre-prepared simply by hot-melt extrusion, pelletized, and the pellets given on the injection molder so that you can constitute the part. Please note that must be tough to estimate the actual get smaller with this resin. It's responsive to wall structure width, piece design and style, molding procedure variables in addition to lot-to-lot variation. Go to your web site to talk about should you have questions.

1 note

·

View note

Text

The operation process of electrofusion welding machine for hot melt butt welding

Many people who are new to PE construction often ask questions about the operation of electrofusion welding machine.Although there are very detailed instructions in the instruction manual, there are still many users who cannot master it. The connection interface of electrofusion welding machine for hot-melt butt joint is flat. The method is to heat two identical connection interfaces to a viscous flow state with a hot plate, remove the hot plate, and then apply a certain pressure to the connection interface, and in this pressure state Cool down and solidify to form a strong connection.

Before heating the pair, it is necessary to mill the two ports of the pipeline to be welded, so as to make the welding surface smoother, and to remove the plastic oxide layer on the surface of the port to make the same molecule melt more thoroughly. The main processes of the whole welding process are adjustment, heating, switching, joint pressurization and cooling.

The material in the viscous flow state on the interface during butt joints flows and diffuses. Too much flow is not conducive to diffusion and entanglement. Therefore, the flow should be limited to a certain range to achieve "post-melt welding" in a limited flow. Therefore, the key to the docking process is to adjust the three parameters of temperature, time and pressure during the docking process, and to consider factors such as the performance, stress state, geometry and environmental conditions of the connection interface material, in order to achieve reliable fusion welding.

According to the general rules and the characteristics of the respective materials used, the test should be carried out to evaluate the welding quality. After reaching the system standard, the process specification of each variety and specification should be determined.

In electrofusion welding machine, whether it is manual type or hydraulic type, heating plate and milling cutter are necessary. The difference is that the former relies on manual control, while the latter is powered by hydraulic system to realize semi-automatic control, especially for pipes with larger diameters. Milling, heating and cooling all require a lot of pressure, which is generally difficult to do manually.

0 notes