#Graphite Crucible

Explore tagged Tumblr posts

Text

Graphite Crucible Providers & Manufacturers

Features:

We provide graphite crucibles for a variety of applications.

In vacuum / high-density graphite crucibles are used

Furnaces with an inert atmosphere

The best crucibles for quality melting

Applications for Graphite Crucibles:

Graphite crucibles are excellent for use during the casting process because they are non-reactive.

Their superior heat performance speeds up metal melting, allowing for shorter production cycles.

The resistance of graphite crucibles to chemicals, corrosion, and the workshop environment is attributed to their durability and longevity.

There are two types of graphite:

natural and artificial. The differences in manufacturing methods can be attributed to the distinctive characteristics of each material. In order to leverage the refractory qualities of silica and carbon fibers to conduct heat while preserving structural strength, natural graphite crucibles are composed of clay graphite ceramics that have been fused or bonded with silica carbon bound graphite. To create synthetic graphite, carbon black, pitch, and petroleum must be treated. Pitch impregnation or densification, baking, shaping, graphitization, and powder preparation are some of the processes.

0 notes

Text

Mastering the Art of Graphite Crucibles: Unveiling Unrivaled Quality

Introduction

In metallurgy and material sciences, the graphite crucible is an indispensable tool, acting as the silent hero behind the scenes in various industrial processes. At Ants Lab, we are dedicated to unraveling the secrets of the graphite crucible, showcasing its unmatched capabilities and superior quality that set it apart from the rest.

Understanding the Essence of Graphite Crucibles

The Core Composition

Graphite crucibles are crafted from a unique combination of high-purity graphite, making them resistant to extreme temperatures and chemical reactions. This composition ensures durability and longevity, making them ideal for applications in metallurgical processes, foundries, and laboratories.

Unparalleled Thermal Stability

One of the distinguishing features of graphite crucibles is their exceptional thermal stability. These crucibles can withstand extreme temperatures without compromising their structural integrity. This quality is crucial for metal melting, casting, and alloy production industries.

Applications in Metallurgical Processes

Melting and Casting Metals

Graphite crucibles play a pivotal role in the melting and casting metals, providing a reliable and stable environment for these processes. Industries ranging from jewelry crafting to large-scale foundries benefit from graphite crucibles' consistent and controlled conditions.

Alloy Production

In the realm of alloy production, precision and consistency are paramount. Graphite crucibles ensure a homogeneous blend of metals, creating high-quality alloys with desirable properties. This makes them an indispensable tool for manufacturers aiming for excellence in their final products.

Advantages Over Traditional Crucibles

Longer Lifespan

Compared to traditional crucibles, graphite crucibles boast a significantly longer lifespan. Their ability to resist wear and tear, even under extreme conditions, translates to cost savings for industries, reducing the frequency of replacements and downtime.

Chemical Inertness

The chemical inertness of graphite crucibles prevents unwanted reactions with molten metals, preserving the purity of the processed materials. This is crucial for applications where the integrity of the final product is of utmost importance.

Choosing the Right Graphite Crucible

Size and Capacity Considerations

Selecting a graphite crucible's appropriate size and capacity is vital for efficient operations. Our experts at Ants Lab guide you through the process, ensuring you choose a crucible that aligns perfectly with your requirements.

Customization Options

To cater to the diverse needs of different industries, we offer customization options for graphite crucibles. Our team can tailor the crucible to your specifications, whether it's a specific shape, size, or special coating.

Maintenance and Care Tips

Cleaning Procedures

Maintaining the cleanliness of your graphite crucible is crucial for optimal performance. Regular cleaning, using recommended procedures, prevents the buildup of impurities and extends the crucible's lifespan.

Proper Storage Practices

Storing graphite crucibles in a controlled environment, away from extreme temperatures and corrosive substances, ensures their longevity. Our guidelines provide insights into best practices for storing these valuable tools.

Conclusion

In conclusion, graphite crucibles stand as an epitome of reliability and precision in metallurgical processes. Their unique composition, thermal stability, and numerous advantages over traditional crucibles make them an essential tool for industries aiming for excellence in their operations.

0 notes

Text

Latest document on Graphite Crucible!

Skytech Machine Tools provides an informative document on Graphite Crucible that describes a technical specification and various benefits about it. For more information, contact us!

#Graphite Crucible#Graphite Crucible manufacturer#Graphite Crucible supplier#Graphite Crucible exporter

0 notes

Text

Premium Graphite Crucibles for Faridabad's Industrial Applications:

Ensure efficient and precise melting processes with our premium graphite crucibles in Faridabad. We specialize in manufacturing high-quality crucibles that deliver outstanding performance, exceptional heat resistance, and excellent thermal conductivity. Our crucibles are designed to withstand extreme temperatures and provide optimal conditions for your melting applications. Reach out to us today to explore our range of graphite crucibles and elevate your industrial processes.

Contact Details:

Phone: +919958837764

E-mail: [email protected]

Website: https://www.faridabadgraphiteindia.com/

0 notes

Text

Pyrolytic Graphite Coated PBN Crucible for Electron Beam Evaporation

Pyrolytic graphite coated PBN (pyrolytic boron nitride) crucible refers to a crucible made of PBN material with a coating of pyrolytic graphite on its surface. The purity of Pyrolytic Graphite Coated Crucible is over 99.99% and the air tightness is good, which has high-temperature resistance, chemical stability, good thermal shock resistance, good thermal conductivity, low coefficient of thermal expansion, resistance to acid, alkali, salt, and organic reagent corrosion. In addition, it has a long service life.

By coating a PBN crucible with a layer of pyrolytic graphite, several advantages can be achieved: 1.Enhanced thermal conductivity: The pyrolytic graphite coating improves the thermal conductivity of the PBN crucible, allowing for efficient heat transfer during high-temperature processes. 2.Chemical resistance: The PBN material already exhibits exceptional chemical inertness, and the additional pyrolytic graphite coating further enhances its resistance to corrosive substances, ensuring greater durability and lifespan of the crucible. 3.Non-wetting properties: Pyrolytic graphite has a non-wetting surface, meaning it repels and does not absorb liquids. This property prevents molten materials from sticking to the crucible, facilitating easy removal and preventing contamination. 4.Electrically insulating: PBN itself is an excellent electrical insulator, and the pyrolytic graphite coating maintains the insulating properties of the crucible. This trait is valuable in electrical and electronic applications, where electrical isolation is necessary. 5.Reduced thermal stress: The combination of PBN and pyrolytic graphite helps reduce thermal stress caused by temperature variations, extending the crucible's lifespan. Pyrolytic graphite coated PBN crucibles are commonly used in high-temperature applications, such as semiconductor manufacturing, crystal growth, metallurgical processes, and materials research, where both high thermal stability and chemical resistance are critical. Read the full article

#PBNCrucible#PBNCrucibles#PyrolyticBoronNitrideCrucible#PyrolyticBoronNitrideCrucibles#Pyrolytic Graphite Coated Crucible

0 notes

Text

its been a while since i write abt terrafirmacraft... well its because i've been busy rebuilding the house. its a two story house with a wing dedicated for cooking and forging. the roof was burnt down twice until i replaced it with mudbricks instead of wood blocks. it also has a basement where i kept barrels of limewater, tallows, and preserved foods. limewater is useful for a lot of things, but right now im using it just for leather. tallows are candles. turns out whale hunting is a lot easier than i think. i crossed the ocean many times during my move, and some of them lingers and follow you on boat. candles are better light source than torches. you cant exactly hang it off the walls or ceiling, but it lasts longer. i'll be using candles until i finally get materials to make lamp glass.

as i get settled, i started farming. plants grow better here, and i can forage things from the forest, but they overheat fast so i need to provide crops with lots of fertilizers. i planted tomatoes, but i forgot they need a stick to prop them up. and then i find some animals, a cow, horse, and a llama i think? idk. i also got some chicken but it dies lol.

the cow was probably the worst animal i had to drag back. theyre so stupid! i brought three, but only one survives because one of them escaped the leash and ran off while the other fell in a hole and gets bit to death by crocodiles. i hate crocodiles so much, theyre demons that trap you in swamps.

winter came, and i started preparing for a trek to find graphite. i found a bunch of coppers, cooked, don my leather armor, i vaguely remember that there was an exposed bit of rock that might contain graphite in one of the lakes near my super super first base. i spent at least one and a half prospective pick just to get graphite. its tedious, long, and arduous. i think it took me two weeks to get it. i play the game in 2 hour duration twice a week so yea im a casual. its super satisfying to hit a super large stack though and coming home with a bonus of pyrite and beets. also now i know how to mine deep underwater <3

my plan here is to make glass for lamps and jars. to do that i need tools like paddle, jacks, blowpipe, and gem saw. i need brass to make jacks. and for gem saw i would need gems like pyrite and brass rod. to make brass you need a tin and copper and a way to process said tin and copper to be brass. by that i mean i need a crucible. its made out of fire clay. fire clay is made out of kaolinite clay and graphite. i just need One Thing.

but of course finding kaolinite isnt as easy as it sounds. it took me a week before i start using cheats. i already live SOMEHWERE where kao is supposed to spawn. but all i see is sylvite and saltpeters. its drudget i use locate biome to see other places like highlands and old mountains that might give me what i need, but so far i found zero. im starting to think my world just doesnt have kao. so i just give up and type give tfc:kaolin_clay.

i gave myself just enough to make a crucible. i made my brass rods and once i got it, i have to weld and work said rods on the anvil to make my blowpipe.

i blew all my coal and brass ingots to zero results. i just suck, suck so bad at working the anvil. so i took a long break. i didnt touch tfc for quite a while. i focused on making gifsets and such. but i get bored with only dabbling with photoshop so i look up tips on anvil working on tfc. there's no way around it. the mod is meant to slow you down and make you learn and explore. some suggested i practiced working on an anvil using copper. some suggested i work on other shit before coming back to the anvil.

so, i went back, and realized how much i neglected my house. my animals still doesnt have a barn. i havent fixed the burned kitchen roof. my bookshelves are empty. my leather armor have been worn down to a nub. my inventory shelves are a mess. i havent restored the decorations that got burned down on the third (or was it fourth?) house fire. i went to work slowly fixing those things. i made copper armor again, a helmet and boots. to tell you the truth, i think i did metalworking better when im just going by vibes instead of overthinking the maths.

im gonna complete the armor i wear, but for now i think i want to make a proper barn first and a warehouse. as i was working, the chest near the forge caught fire. i realized then the space im working in is too small. i need to make a storage space and a building dedicating for forging.

2 notes

·

View notes

Text

What can Niobium be used for

Niobium is special because its high level of corrosion resistance is achieved at a relatively low weight. In the chemical industry, niobium is a high-quality acid and liquid metal corrosion resistant material that can be used in cooking machines heaters and coolers.

Based on its high transition temperature, niobium is the perfect material for superconducting cables and magnets.

Based on its high level of biocompatibility, niobium is also used as a material for implants.

We also use this material to manufacture coin of all colors, corrosion-resistant evaporation boats and dimensionally stable crucibles for diamond growth.

Niobium is used in the casting industry; it is mainly used to form a hard carbide and change of graphite morphology & size. They are used in the manufacture of automotive cylinder head, piston ring and brake etc.

Niobium can increase the transmittance of lenses, is also used in the manufacture of lenses in the optical industry.

Nb is also found in the lighting industry, such as Nb-1%Zr alloy can be used for producing precision support of high strength sodium vapor lamp, these small parts have excellent heat resistance to sodium vapor corrosion.

Another important application of Niobium is to use the material to make niobium rod. It is worked cold from ingot to final diameter. Forging, swaging, and drawing are used singularly or in combination to reach the desired size.

Niobium acid is also an important catalyst.

https://www.edge-techind.com/category/Niobium-21-1.html

https://www.etimaterials.org/niobium/niobium-rod/

0 notes

Video

youtube

graphite crucible manufacturers

0 notes

Text

Maximizing Efficiency: How to Get the Most Out of Your Affordable Melting Furnace

Introduction

To get the best results from your affordable melting furnace, it’s important to use it efficiently. This post will share practical tips and techniques to help you maximize efficiency and save on costs.

1. Preheat Your Furnace

Why: Preheating reduces the time required to reach melting temperatures.

Tip: Start the furnace 10-15 minutes before you begin your melting process.

2. Use the Right Crucible

Why: Different metals require different crucibles for optimal heat distribution.

Tip: Graphite crucibles are excellent for even heat distribution, while ceramic crucibles are ideal for higher temperature processes.

3. Optimize Load Size

Why: Running the furnace with a full load is more energy-efficient.

Tip: Combine small batches into a single melt when possible to reduce energy consumption.

4. Maintain Proper Ventilation

Why: Proper ventilation prevents overheating and prolongs the furnace’s lifespan.

Tip: Ensure your workspace has adequate airflow and use exhaust systems if necessary.

5. Regular Maintenance

Why: Regular cleaning and maintenance keep the furnace running efficiently.

Tip: Clean the furnace interior after each use and inspect for any wear or damage.

6. Monitor Energy Usage

Why: Understanding your energy consumption helps identify areas for improvement.

Tip: Use energy monitors to track usage and adjust practices to reduce consumption.

7. Upgrade When Necessary

Why: Sometimes, investing in newer, more efficient models can save money in the long run.

Tip: Evaluate the cost vs. benefit of upgrading your furnace if it becomes outdated or inefficient.

Conclusion

By following these tips, you can maximize the efficiency of your affordable melting furnace, reducing costs and improving performance. Regular maintenance, proper usage, and smart upgrades can make a significant difference.

0 notes

Text

0 notes

Text

Graphite Market: An In-Depth Analysis

Graphite, a naturally occurring form of crystalline carbon, has long been a crucial material across various industries. With unique properties such as high thermal and electrical conductivity, resistance to chemical reactions, and lubricity, graphite's applications range from steel manufacturing to battery production. As global industries evolve, the graphite market is witnessing significant changes driven by technological advancements, environmental concerns, and economic shifts.

Current Market Dynamics

1. Demand Drivers

The demand for graphite market is primarily fueled by its extensive use in the steel industry, where it serves as a refractory material due to its ability to withstand high temperatures. Additionally, the burgeoning electric vehicle (EV) sector has dramatically increased the demand for battery-grade graphite. Lithium-ion batteries, which power EVs, require substantial amounts of high-purity graphite for their anodes, making this material indispensable for the green energy transition.

2. Supply Landscape

Graphite is sourced through both natural and synthetic means. Natural graphite is mined from geological deposits, whereas synthetic graphite is manufactured through high-temperature processing of carbon materials. China dominates the natural graphite market, accounting for a significant portion of global production. However, geopolitical factors and environmental regulations are prompting other regions, such as North America and Europe, to explore local graphite sources to reduce dependency on imports.

Market Segmentation

The graphite market is segmented based on type, application, and region.

1. By Type

Natural Graphite: Subdivided into flake, amorphous, and vein varieties, with flake graphite being the most sought-after due to its high carbon content and purity.

Synthetic Graphite: Primarily used in high-temperature applications, such as electric arc furnaces and battery anodes, owing to its superior consistency and quality.

2. By Application

Refractories: Graphite’s high thermal resistance makes it ideal for manufacturing refractory bricks and crucibles used in steelmaking.

Batteries: The exponential growth of the EV market has placed batteries as a critical application segment for graphite.

Lubricants: Graphite’s lubricating properties are exploited in various mechanical applications.

Foundries: Used in foundry facings to improve the quality of castings.

Others: Includes applications in pencils, coatings, and nuclear reactors.

Regional Insights

Asia-Pacific: Dominates the global graphite market, driven by substantial production and consumption in China. The region's growth is bolstered by increasing industrial activities and investments in EV production.

North America: Experiencing growth due to rising demand for locally sourced graphite for EV batteries and technological advancements in mining and processing.

Europe: Focused on developing a sustainable supply chain for graphite, with increasing investments in battery manufacturing and recycling.

Challenges and Opportunities

1. Challenges

Environmental Impact: Graphite mining and processing can have significant environmental consequences, including habitat destruction and pollution. Stricter environmental regulations are compelling companies to adopt sustainable practices.

Market Volatility: Prices of graphite are subject to fluctuations due to changes in supply and demand dynamics, geopolitical tensions, and trade policies.

2. Opportunities

Technological Advancements: Innovations in graphite extraction and processing technologies are enhancing yield and quality, reducing costs, and minimizing environmental impact.

Recycling: The growing emphasis on circular economy principles is driving research into efficient graphite recycling methods, particularly from spent batteries, which could provide a significant secondary source of graphite.

Strategic Partnerships: Collaborations between mining companies, technology developers, and battery manufacturers are fostering integrated supply chains, enhancing market stability and growth prospects.

Request for a sample of the report browse through https://univdatos.com/get-a-free-sample-form-php/?product_id=25697

Future Outlook

The graphite market is poised for robust growth, driven by the accelerating adoption of electric vehicles and renewable energy technologies. Industry stakeholders are increasingly focusing on sustainable sourcing and processing methods to address environmental concerns and ensure long-term supply security. With advancements in recycling technologies and the development of new applications, graphite’s importance in the global economy is set to rise significantly.

In conclusion, the graphite market is navigating a transformative phase, marked by dynamic demand patterns and evolving supply chains. By embracing innovation and sustainability, the industry can unlock new opportunities and contribute to the global transition towards a greener and more resilient future.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

0 notes

Text

The Molten Marvels: Unveiling the Diverse World of Melt Furnaces

Melt furnaces are the industry's hidden heroes, silently shaping the world around us. From the towering steel structures to the delicate circuitry in our devices, these furnaces transform raw materials into usable forms like ingots and rods. This article dives into the captivating realm of melt furnaces, exploring their various types, distinctive characteristics, and key considerations for selecting the perfect fit for your needs.

A Menagerie of Melters: Exploring the Spectrum of Melt Furnace Types

The landscape of melt furnaces is far from homogenous. Each type boasts specific strengths and caters to distinct applications. Let's embark on a journey to discover some of the most common melt furnace varieties:

High-Calor Furnaces: Conquering extreme heat exceeding 1000°C, these powerhouses can tackle a vast array of materials, including metals, glass, and even ceramics. They reign supreme in aerospace, automotive, and electronics industries due to their ability to melt a wide range of materials and achieve rapid processing times. However, the scorching temperatures come at a cost – increased energy consumption and wear on the furnace, necessitating frequent maintenance and raising overall expenses.

Crucible Kings: A popular choice for various industries, crucible furnaces excel in handling high-temperature materials like metals. As the name suggests, loading occurs from the top into a crucible, a container made from heat-resistant materials like ceramic or graphite. These furnaces are user-friendly with minimal training required and are known for their energy efficiency. However, crucible furnaces can be expensive to maintain due to the crucibles being consumable items, and the loading/unloading process can be time-consuming, hindering productivity in fast-paced environments.

Front-Facing Furnaces: Offering convenient front access for material handling, these furnaces are ideal for smaller facilities due to their compact footprint. They excel in melting a variety of materials like metals, glass, and ceramics, making them well-suited for applications in aerospace, automotive, and electronics where precision is paramount. While these furnaces are easy to operate and maintain, their intricate design often translates to a higher price tag compared to other furnace types, and their capacity might be limited for large-scale operations.

Horizontal Travelers: True to their name, horizontal tube furnaces feature a horizontal tube crafted from high-temperature resistant materials like ceramics. This tube is heated using a heating element, offering versatility for melting various materials like metals, alloys, and even ceramics. They are relatively user-friendly and can be automated for efficient production. However, they might not be as energy-efficient as other options and may have slower heating rates.

Vertical Victors: When extremely high temperatures are demanded, vertical tube furnaces enter the arena. Their vertically arranged heating element allows them to reach scorching temperatures, making them perfect for melting challenging materials like ceramics and certain high-melting-point metals. They boast energy efficiency and cater to diverse applications, including research and development, material testing, and production processes. Nevertheless, their high cost and demanding maintenance requirements can be a significant hurdle.

Choosing Your Molten Match: Considerations for Selecting the Perfect Furnace

Selecting the most suitable melt furnace hinges on several factors specific to your operation. Here are some key considerations to guide your decision:

Material Matters: The type of material you intend to melt is the primary factor. Different furnaces excel at handling specific materials based on their temperature tolerance.

Temperature Needs: Consider the melting point of your chosen material and choose a furnace that can achieve and maintain the necessary temperature for efficient melting.

Capacity Counts: Think about the volume of material you intend to melt per cycle. Furnaces come in various capacities, so ensure yours aligns with your production needs.

Energy Efficiency Matters: Evaluate the furnace's energy consumption to optimize operational costs in the long run.

Budgeting for Success: Melt furnaces come with varying price tags. Consider your budget alongside the features and benefits offered by each type.

By carefully considering these factors and understanding the unique strengths of each melt furnace type, you can make an informed decision that empowers your operations and fuels your success in the world of molten materials.

0 notes

Text

Graphite Crucible

Introducing the Conical Graphite Crucible by AntsLab – a pinnacle of craftsmanship for your melting needs. Engineered with precision and designed for durability, this crucible sets the standard for excellence in metallurgy. Upgrade your melting game with the Conical Graphite Crucible from AntsLab. Elevate your craftsmanship, achieve precise results, and enjoy the durability that only top-notch materials can provide. Order now and witness the transformation of your melting endeavors with this exceptional graphite crucible. Your next masterpiece awaits – seize the opportunity today!

0 notes

Text

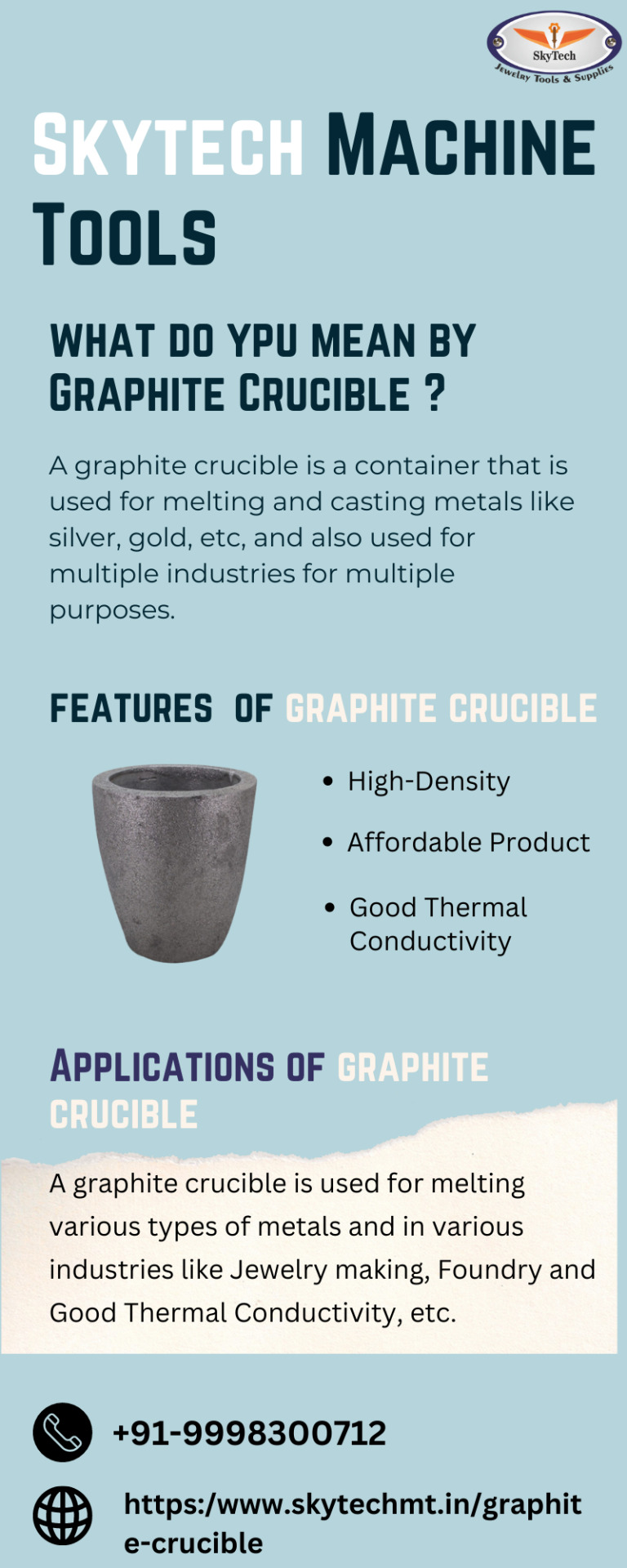

Check the new infographics on graphite crucible

Skytech machine tools upload the latest infographics in the top high-quality graphite crucible that is a container used for various industries. For more information contact us.

0 notes

Text

https://www.custommarketinsights.com/report/graphite-crucible-market/

0 notes

Text

Choosing the right solar panel: Why 10w Polycrystalline Panels Might be the Perfect Fit

As all know Solar panel is the most increasing source of renewable energy. Popularity has come due to the eco-friendliness and cost-effectiveness of powering a house. And Polycrystalline solar panel 10W is the choice when it comes to solar panels available.

Polycrystalline solar panels also referred to as multicrystalline panels composed of multiple silicon fragmented crystals. This silicon is melted and cooled to fragments and then molded before cutting into panels. Although they are less efficient and, they are slightly less expensive. They still have a serviceable life of well over 20 years.

Let’s see in detail what makes Polycrystalline solar panel 10W stand outstanding than others:-

Appearance

Polycrystalline panels are more noticeable and have a blue appearance. While there are variations in the actual cell shape, colour is likely to catch the attention more than other factors in residential solar panels.

Effective Energy Production

The Polycrystalline solar panel 10W effectively captures sunlight to provide clean, sustainable electricity. These panels efficiently convert sunlight into energy thanks to high-efficiency polycrystalline silicon cells, providing a dependable power source for industrial, commercial, and domestic applications.

Cost Effective

The method used to make silicon is what makes polycrystalline solar panels of Novasys Green less costly. Essentially, rather than being formed into a single crystal, the molten silicon is poured into a cast.

By utilizing a seed crystal with the appropriate crystal structure, liquid silicon may be allowed to cool to create this material with ease. In addition, there are further techniques, such as high-temperature chemical vapour deposition, for crystallizing amorphous silicon to create polysilicon.

In the casting process, silicon fragments are melted in a ceramic crucible and subsequently shaped into an ingot using a graphite mould. To aid in formation, a seed crystal with the intended crystal structure is added while the molten silicon cools.

Small and Condense Design

A notable feature of the polycrystalline solar panel 10W is their small size and space-saving construction, which makes them perfect for installations with limited space. These panels maximise energy output while taking up the least amount of area, whether they are installed on ground-mounted buildings, roofs, or facades.

Environmental Enhancement

Some producers of polycrystalline solar panels like Novasyas Green go above and beyond by developing new technologies that eliminate costly soldering, which also contains lead, making these panels even more environmentally friendly. This is in addition to the fact that solar panels can generate energy from the sun and thereby help reduce greenhouse gases and related environmental problems of extracting fossil fuels.

Conclusion

Energy prices may be reduced, carbon footprints can be reduced, and a more resilient and environmentally friendly future can be achieved by people and organisations investing in solar technology. Polycrystalline solar panel 10W is popular among house owners looking to install budget friendly residential solar panels.

Also Read:

Evaluating the Environmental Impact of Industrial Solar Panel Installation

The Benefits of Choosing 335W Polycrystalline Solar Panels for Residential Use

Originally published at https://novasysgreenergy.blogspot.com

0 notes