#Global Injection Moldings Market

Explore tagged Tumblr posts

Text

Injection Moldings Market to Hit $394.3 Billion by 2032

The global Injection Moldings Market was valued at USD 262.9 Billion in 2024 and it is estimated to garner USD 394.3 Billion by 2032 with a registered CAGR of 5.2% during the forecast period 2024 to 2032.

Global Injection Moldings Market Research Report 2024, Growth Rate, Market Segmentation, Injection Moldings Market. It affords qualitative and quantitative insights in phrases of market size, destiny trends, and nearby outlook Injection Moldings Market. Contemporary possibilities projected to influence the destiny capability of the market are analyzed in the report. Additionally, the document affords special insights into the opposition in particular industries and diverse businesses. This document in addition examines and evaluates the contemporary outlook for the ever-evolving commercial enterprise area and the prevailing and future outcomes of the market.

Get Sample Copy of Report @ https://www.vantagemarketresearch.com/injection-moldings-market-2356/request-sample

** Note: You Must Use A Corporate Email Address OR Business Details.

The Major Players Profiled in the Market Report are:-

C&J INDUSTRIES; All-Plastics; Biomerics; HTI Plastics; The Rodon Group; EVCO Plastics; Majors Plastics, Inc.; Proto Labs, Inc.; Tessy Plastics; Currier Plastics, Inc.

Injection Moldings Market 2024 covers powerful research on global industry size, share, and growth which will allow clients to view possible requirements and forecasts. Opportunities and drivers are assembled after in-depth research by the expertise of the construction robot market. The Injection Moldings Market report provides an analysis of future development strategies, key players, competitive potential, and key challenges in the industry.

Global Injection Moldings Market Report 2024 reveals all critical factors related to diverse boom factors inclusive of contemporary trends and traits withinside the worldwide enterprise. It affords a complete review of the top manufacturers, present-day enterprise status, boom sectors, and commercial enterprise improvement plans for the destiny scope.

The Injection Moldings Market document objectives to offer nearby improvement to the market using elements inclusive of income revenue, destiny market boom rate. It gives special observation and analysis of key aspects with quite a few studies strategies consisting of frenzy and pestle evaluation, highlighting present-day market conditions. to be. Additionally, the document affords insightful records approximately the destiny techniques and opportunities of worldwide players.

You Can Buy This Report From Here: https://www.vantagemarketresearch.com/buy-now/injection-moldings-market-2356/0

Global Injection Moldings Market, By Region

1) North America- (United States, Canada, Mexico, Cuba, Guatemala, Panama, Barbados, and many others)

2) Europe- (Germany, France, UK, Italy, Russia, Spain, Netherlands, Switzerland, Belgium, and many others)

3) the Asia Pacific- (China, Japan, Korea, India, Australia, Indonesia, Thailand, Philippines, Vietnam, and many others)

4) the Middle East & Africa- (Turkey, Saudi Arabia, United Arab Emirates, South Africa, Israel, Egypt, Nigeria, and many others)

5) Latin America- (Brazil, Argentina, Colombia, Chile, Peru, and many others)

This Injection Moldings Market Research/analysis Report Contains Answers to your following Questions

What trends, challenges, and barriers will impact the development and sizing of the global market?

What is the Injection Moldings Market growth accelerator during the forecast period?

SWOT Analysis of key players along with its profile and Porter’s five forces analysis to supplement the same.

How much is the Injection Moldings Market industry worth in 2019? and estimated size by 2024?

How large is the Injection Moldings Market? How long will it keep growing and at what rate?

Which section or location will force the market and why?

What is the important thing current tendencies witnessed in the Injection Moldings Market?

Who are the top players in the market?

What and How many patents are filed by the leading players?

What is our Offering for a bright industry future?

The Research Objectives of this Report are to:-

Company, key regions/countries, merchandise and applications, historical records from 2018 to 2022, and global Injection Moldings Market till 2032. Study and analyze the market length (cost and volume).

To recognize the structure of Injection Moldings Market via way of means of figuring out its numerous subsegments.

Injection Moldings Market on the subject of the primary regions (with every essential country). Predict the cost and length of submarkets.

To examine the Injection Moldings Markets with appreciation to person boom trends, destiny prospects, and their contribution to the general market.

To examine aggressive trends consisting of expansions, contracts, new product launches, and acquisitions withinside the market.

Strategic profiling of key gamers and complete evaluation of growth strategies.

Read Full Research Report with [TOC] @ https://www.vantagemarketresearch.com/industry-report/injection-moldings-market-2356

Reasons to Buy Market Report

The market record presents a qualitative and quantitative analysis of the market based on segmentation that includes each economic and non-economic element.

Injection Moldings Market through the region. The market evaluation highlights the consumption of products/services in areas and well-known shows elements influencing the market in every region.

Injection Moldings Market. It consists of an in-depth analysis of the market from specific views via Market Porter's Five Forces Analysis and provides insights into the market via the Value Chain.

The Injection Moldings Market file provides an outline of market fee (USD) information for every segment and sub-segment.

It consists of an in-depth analysis of the market from distinct views via a 5 forces analysis of the Injection Moldings Market and offers insights into the market through the fee chain.

Check Out More Reports

Global Orthopaedic Shoes Market : Report Forecast by 2032

Global Battery Management System Market: Report Forecast by 2032

Global Vertical Farming Market: Report Forecast by 2032

Global Slickline Truck Service Market: Report Forecast by 2032

Global Dual Interface Payment Card Market: Report Forecast by 2032

#Injection Moldings Market#Injection Moldings Market 2024#Global Injection Moldings Market#Injection Moldings Market outlook#Injection Moldings Market Trend#Injection Moldings Market Size & Share#Injection Moldings Market Forecast#Injection Moldings Market Demand#Injection Moldings Market sales & price

0 notes

Text

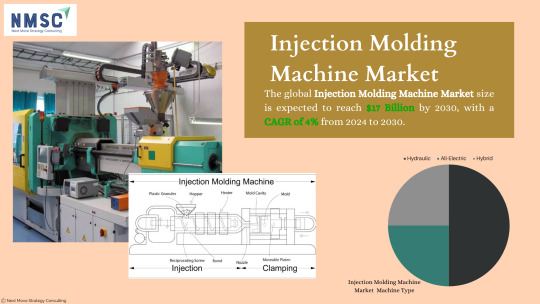

Asia-Pacific Leads, Rest of the World Grows: Insights into the Injection Molding Machine Market

Introduction

The injection molding machine market is a critical segment within the broader manufacturing industry, facilitating the production of a wide range of plastic products across various sectors. As per a study by Next Move Strategy Consulting, the global Injection Molding Machine Market is anticipated to reach a value of USD 17.22 billion by 2030, with a compound annual growth rate (CAGR) of 3.7%. This article aims to delve deeper into the dynamics of this market, with a particular focus on the contrasting trends observed in the Asia-Pacific region and the rest of the world (ROW).

Request for a sample PDF report: https://www.nextmsc.com/injection-molding-machine-market/request-sample

Asia-Pacific's Dominance in the Market

Asia-Pacific stands out as the undisputed leader in the injection molding machine market, boasting the largest market share globally. In 2022, the region commanded a market value of USD 7.12 billion, a testament to its robust manufacturing ecosystem and strategic initiatives undertaken by key players.

One of the primary factors driving Asia-Pacific's dominance is the expansion of manufacturing facilities by regional giants. For instance, Sumitomo (SHI) Demag China's announcement in February 2023 regarding the construction of a new 43,000 square-feet facility to double injection molding machine production in China underscores the commitment to meet escalating demand effectively.

Moreover, the automotive industry's expansion and diversification in the region further fuel the demand for injection molding solutions. Japan, with its reputation for automotive innovation and quality, serves as a prime example. As the world's third-largest automotive producer, Japan operates 78 factories across 22 prefectures, employing over 5.5 million individuals. This thriving automotive sector creates a sustained demand for high-quality injection molding machines, propelling market growth in the region.

Partnerships and collaborations also play a crucial role in driving the Asia-Pacific injection molding machine industry forward. SOLIZE India Technologies' partnership with Toray Engineering D Solutions in December 2022 to supply 3D injection molding machines for the Indian market exemplifies the collaborative efforts aimed at meeting regional demands efficiently.

ROW Market: Steady Growth Amidst Challenges

While Asia-Pacific leads the injection molding machine market, the rest of the world (ROW) presents a different landscape characterized by steady growth and unique challenges. Despite not matching the dominance of Asia-Pacific, ROW exhibits promising growth prospects driven by governmental initiatives and evolving manufacturing landscapes.

In September 2022, Argentina's government enacted tax and regulatory benefits for the automotive industry, offering incentives for investments in machinery and infrastructure. These initiatives aim to boost exports and attract investments, thereby driving demand for advanced machinery including injection molding machines.

Similarly, the United Arab Emirates (UAE) has emerged as a key player in various industries, including automotive, electronics, packaging, and consumer goods. The UAE's emphasis on industrial transformation towards smart manufacturing, as demonstrated by the Smart Manufacturing Incentive Program launched by the Abu Dhabi Department of Economic Development in June 2023, creates a conducive environment for the adoption of advanced injection molding solutions.

While ROW showcases steady growth, challenges such as regulatory complexities and geopolitical uncertainties persist. However, concerted efforts by governments and industry stakeholders are expected to mitigate these challenges and foster a conducive environment for market growth.

Inquire before buying: https://www.nextmsc.com/active-seat-belt-system-market/inquire-before-buying

Emerging Trends and Opportunities

In addition to regional dynamics, several emerging trends and opportunities are shaping the global injection molding machine market.

Customization and Personalization: Consumer preferences are increasingly favoring personalized products tailored to individual needs and tastes. Injection molding machines equipped with advanced software and automation capabilities enable manufacturers to efficiently produce customized components and products, catering to niche markets and enhancing customer satisfaction.

Medical and Healthcare Applications: The healthcare sector presents lucrative opportunities for the injection molding machine market, driven by the growing demand for medical devices, pharmaceutical packaging, and diagnostic equipment. With stringent quality standards and regulatory requirements, manufacturers are investing in state-of-the-art injection molding technologies to ensure precision, reliability, and compliance with medical industry standards.

Circular Economy Initiatives: Sustainability is a pressing concern for industries worldwide, prompting a shift towards circular economy models that prioritize resource efficiency, waste reduction, and recycling. Injection molding machines capable of processing recycled materials and biodegradable polymers are in high demand, aligning with corporate sustainability goals and regulatory mandates aimed at reducing environmental impact.

Industry 4.0 Integration: The integration of Industry 4.0 technologies, such as Internet of Things (IoT) sensors, data analytics, and predictive maintenance, is revolutionizing the injection molding process. Smart injection molding machines equipped with real-time monitoring and predictive analytics capabilities enable proactive maintenance, minimize downtime, and optimize production efficiency, thereby enhancing overall operational performance and competitiveness.

Reshoring and Nearshoring Trends: The ongoing geopolitical uncertainties and supply chain disruptions have prompted many manufacturers to reassess their sourcing strategies and consider reshoring or nearshoring production closer to their primary markets. This trend presents opportunities for injection molding machine suppliers to partner with local manufacturers and provide on-demand production solutions tailored to regional requirements, reducing lead times and transportation costs.

Advanced Materials Development: The injection molding machine market is witnessing a surge in demand for machines capable of processing advanced materials, including composites, bioplastics, and high-performance polymers. These materials offer superior mechanical properties, chemical resistance, and thermal stability, making them ideal for demanding applications in industries such as aerospace, automotive, and electronics. Injection molding machines equipped with specialized capabilities for handling these materials are poised to capitalize on this growing market segment.

Focus on Energy Efficiency: With increasing emphasis on sustainability and energy conservation, there is a growing demand for injection molding machines designed to minimize energy consumption and reduce carbon emissions. Manufacturers are investing in energy-efficient technologies such as servo-driven systems, variable frequency drives, and regenerative braking systems to optimize energy usage throughout the production process. Energy-efficient injection molding machines not only lower operational costs but also contribute to environmental preservation, aligning with corporate sustainability objectives and regulatory mandates.

Adoption of Hybrid and Electric Machines: The shift towards greener manufacturing practices and stricter emissions regulations is driving the adoption of hybrid and electric injection molding machines. These machines offer significant advantages over traditional hydraulic models, including higher energy efficiency, reduced noise levels, and lower maintenance requirements. As environmental awareness continues to grow, manufacturers are increasingly turning to hybrid and electric machines to enhance their sustainability credentials and gain a competitive edge in the market.

Digital Twin Technology: Digital twin technology is revolutionizing the injection molding process by enabling virtual simulations and predictive modeling of machine behavior. By creating digital replicas of physical injection molding machines, manufacturers can optimize process parameters, identify potential issues, and test new configurations in a risk-free virtual environment. Digital twin technology enhances operational efficiency, reduces time-to-market, and enables data-driven decision-making, ultimately improving overall productivity and profitability.

Focus on Worker Safety and Ergonomics: As occupational health and safety regulations become more stringent, there is a growing emphasis on designing injection molding machines with enhanced safety features and ergonomic design principles. Manufacturers are integrating advanced safety systems such as light curtains, safety interlocks, and automated guarding to protect operators from hazards and minimize the risk of workplace injuries. Additionally, ergonomic enhancements such as adjustable controls, intuitive interfaces, and ergonomic workstations improve operator comfort and productivity, leading to a safer and more efficient working environment.

These emerging trends and developments underscore the dynamic nature of the injection molding machine market and highlight the opportunities for innovation and growth. By staying abreast of these trends and investing in cutting-edge technologies, manufacturers can position themselves for success in an increasingly competitive landscape

Conclusion

In conclusion, the injection molding machine market is undergoing significant transformation, driven by regional dynamics, emerging trends, and technological advancements. While Asia-Pacific maintains its dominance, the rest of the world presents promising growth opportunities amidst challenges.

Sustainable practices, technological innovations, and digitalization are shaping the future of the industry, offering manufacturers new avenues for growth and differentiation. As stakeholders navigate this evolving landscape, collaboration, innovation, and adaptability will be key to unlocking the full potential of the injection molding machine market.

Also Browse:

0 notes

Text

The Growing Role of Automotive Plastics in Vehicle Design and Manufacturing

Automotive plastics are materials used for the construction of parts and components in automobiles, including the body, interior, and powertrain. These plastics are designed to be lightweight, durable, and cost-effective. Common types of automotive plastics include polypropylene, polyurethane, ABS, and polycarbonate. Automotive plastics are used in many areas of the vehicle, including interior…

View On WordPress

#automotive bioplastic market#automotive injection#automotive injection molding#automotive injection molding companies#automotive plastic additives market#automotive plastic injection molding companies#automotive plastic manufacturers#Automotive Plastics#Automotive Plastics Industry#automotive Plastics industry for Passenger Cars#Automotive Plastics Market#Automotive Plastics Market for Passenger Cars#automotive plastics market industry share#automotive plastics market industry size#automotive plastics suppliers#COVID 19 impact on Automotive Plastics Market#global automotive plastics market#injection molding in automotive industry#plastic car#plastic car part#plastics for electric vehicle market#polypropylene in cars#use of plastic in automobile

0 notes

Text

COVID-19 Pandemic Has Boosted Growth Of Medical Injection Molding Machine Market

The global medical injection molding machine market size is anticipated to reach USD 2.61 billion by 2030, according to a new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 4.7% from 2022 to 2030. The industry is primarily driven by the increased application of plastics in several healthcare products, and technological advancements in the medical industry.

The demand for testing kits witnessed exponential growth globally, as healthcare authorities attempted to track the spread of the COVID-19 pandemic. This resulted in various companies in the medical devices and pharmaceuticals sectors initiating the production of these kits and ramping up their production capacities to help alleviate testing shortages.

Gain deeper insights on the market and receive your free copy with TOC now @: Medical Injection Molding Machine Market Report

The adoption of different raw materials used in the injection molding process, as well as the rising energy efficiency of injection molding machines, have replaced traditional molding machines. This, in turn, has boosted the demand for automated and energy-efficient injection molding equipment used in the medical industry. The key factors influencing the demand for medical products include availability, awareness, affordability, and adaptability. Increasing demand for better healthcare facilities and the ongoing COVID-19 pandemic has boosted the growth of medical devices manufactured by using injection molding machines.

Manufacturers are focusing on producing injection molding machines that can bring down production costs, provide flexibility in production, reduce scrap, are low maintenance, shorten production cycle times, and are efficient in every manner. This is increasing the demand for electric and hybrid medical injection molding machines.

#Medical Injection Molding Machine Market Size & Share#Global Medical Injection Molding Machine Market#Medical Injection Molding Machine Market Latest Trends#Medical Injection Molding Machine Market Growth Forecast#COVID-19 Impacts On Medical Injection Molding Machine Market#Medical Injection Molding Machine Market Revenue Value

1 note

·

View note

Text

I'm over the term "gender equality", and the way in which it is being used and advocated for by the mainstream, status-quo left.

"Men and women are equal" operates under the bias that men are the default standard of equality, which women are then sometimes required or expected to meet. Usually statements like "women are just as strong as men", "women are just as capable as men in sports" act as support.

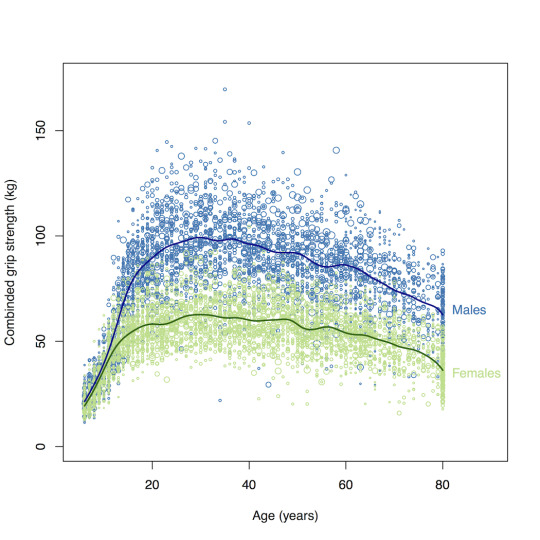

It intentionally is meant to be cheered on as liberating, but the reality is it's a derivative of "I don't see race I just see people", "no race but the human race", "not disabled just differently-abled", etc. It's a form of sexism that ignores sexism. It's "I am going to ignore biological differences based on sex" when the reality is being of the female sex shapes both my material and lived reality in extremely complex ways and can have dangerous consequences when ignored.

The average woman is not is strong as a man and it often takes a deliberate amount of persistence, training, and/or testosterone injections for us to come close to or meet the male default. "The muscle strength of women indeed, is typically reported in the range of 40 to 75% of that of men". The average man could easily kill and overpower me, and if I were an athlete a man who trained equally to me would defeat me in competition.

Women are 47% more likely than men to be injured in a car accident. Cars were designed for male drivers. In 2011 was when "female" crash dummies were introduced into measuring car safety in the US, however sometimes organizations in the US and UK just used "scaled down male dummies" to test car safety for women. As this article explains, we are not scaled-down men. We have different muscle mass distribution. We have lower bone density. There are differences in vertebrae spacing. Even our body sway is different. And these differences are all crucial when it comes to injury rates in car crashes. And what about pregnant women?

We have different needs and different experiences than males and the world around is us designed with males in mind - from housing to automobiles, to entire economic systems. 85% of women will eventually be mothers. When women take maternal leave to care for a newborn while the man continues to work (or returns shortly later), he effectively advances his career and over time earns more promotions and pay. His schedule is to focus on his career growth and then come home for a few hours in the evening to play with their child (or play videogames). Mothers pay a significant wage penalty for having children from being months out of the labor market.

This list could really go on.

"Gender equality" is utilized by men to distract women from focusing on only women's rights and needs to men's rights and needs. It's used to shoehorn in arguments of "men too" and sympathizing with men on "men's mental health" (while neglecting the fact that men are overwhelmingly and in shocking numbers responsible for violence done to both sexes - and are additionally unlikely to want to work on themselves mentally).

Reframing and enfolding "violence against women", "women's rights", "male violence", "female liberation", and "women's oppression" into the vague language of "gender equality" is a deliberate act of obfuscating the power dynamics between the sexes - in which men globally exploit and oppress women on the axis of sex.

And as vague language, carves a place for people to have the opportunity to shift the responsibility and blame onto women and girls for the suffering that men wield onto their own sex.

Women and girls do have advantages and strengths over men and boys due to our biological differences - yet this, too, goes ignored under the vague concept of "gender equality" and the cultural belief system it evokes, which treats man as the mold that women should fit.

#gender equality#gender#feminism#radical feminism#gender critical feminism#female liberation#women's rights#women's oppression#misogyny#intersectional feminism

284 notes

·

View notes

Text

According to Straits Research, the global injection molding machines market size was valued at USD 10724 Million in 2021. It is projected to reach from USD XX Million in 2022 to USD 16964 Million by 2030, growing at a CAGR of 5.9% during the forecast period (2022–2030).

#Injection Molding Machines Market Size#Injection Molding Machines Market Share#Injection Molding Machines Market Growth#Injection Molding Machines Market Trends#Injection Molding Machines Market Players

0 notes

Text

Composites Market Business Analysis, Share, Revenue & Sales Till 2030

The global composites market size is expected to reach USD 163.97 billion by 2030, registering a CAGR of 7.2% over the forecast period, according to a new report by Grand View Research, Inc. The demand for composites is expected to witness significant growth owing to the rising fuel prices and stringent government regulations have shifted automobile manufacturers focus on light-weighted components which would further propel the market demand over the forecast period.

Composite products play an essential role in the manufacturing of automotive and aircraft parts. The growing concerns regarding fuel consumption and CO2 emission levels have prompted the manufacturers to use carbon fiber composite materials as substitutes for metal components. Technological innovations to minimize the manufacturing cycle time is expected to propel the usage of composites in the automotive sector.

The high cost of composites has limited their application scope to premium segment cars. However, key players are conducting extensive R&D activities to develop low-cost composite grades with similar mechanical properties as that of the high-cost variants. This is expected to spur the demand for the product in the automotive industry over the forecast period.

Gather more insights about the market drivers, restrains and growth of the Global Composites Market

Composites Market Report Highlights

The glass fiber segment accounted for the largest market share in 2022 and is further expected to grow at a CAGR of 6.4% on account of increased penetration in pipe manufacturing applications owing to the strength and durability of these composites. Additionally, glass fiber comprises several thin that find application in building & construction, automotive, industrial, energy, and consumer goods

The layup process segment is forecasted to grow at a CAGR of 9.0% by 2030. The market is again forecast to grow due to easier technology applications and the requirement of less expensive machinery. The process involves placing multiple layers of composite fiber in a sequence by using a matrix of resin and hardener

The automotive & transportation segment dominated the composites market with a revenue share of USD 19.70 billion in 2022. This is attributed to its advantages such as fuel saving to the transportation sector as the components are significantly lighter in weight that allows ascending fuel efficiency

The demand for composites in Asia Pacific was the largest in the global market due to the increase in air passenger traffic, rise in automotive vehicle production, and ambitious electrical & electronics production capacity addition targets set by various governments in the Asia Pacific including China, India, Japan, and South Korea

Various initiatives such as technology innovations, research & development, partnerships, and merger & acquisitions to manufacture cost-effective and lightweight composite products have been undertaken by the key market players. Prominent players have patented technologies used for composites manufacturing

Browse through Grand View Research's Advanced Interior Materials Industry Research Reports.

Aluminum Composite Panels Market: The global aluminum composite panel market size was estimated at USD 6.47 billion in 2024 and is expected to grow at a CAGR of 7.0% from 2025 to 2030.

Centrifugal Pump Market: The global centrifugal pump market size was estimated at USD 39.80 billion in 2024 and is projected to grow at a CAGR of 4.2% from 2025 to 2030.

Composites Market Segmentation

Grand View Research has segmented the collated screws market on the basis of product, manufacturing process, end-use, and region:

Composites Product Outlook (Volume, Kilotons; Revenue, USD Billion, 2023 - 2030)

Carbon Fiber

Glass Fiber

Others

Composites Manufacturing Process Outlook (Volume, Kilotons; Revenue, USD Billion, 2023 - 2030)

Layup Process

Filament Winding Process

Injection Molding Process

Pultrusion Process

Compression Molding Process

Resin Transfer Molding Process

Others

Composites End-Use Outlook (Volume, Kilotons; Revenue, USD Million, 2023 - 2030)

Automotive & Transportation

Wind Energy

Electrical & Electronics

Construction and Infrastructure

Pipes & Tanks

Marine

Others

Composites Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2023 - 2030)

North America

US

Canada

Mexico

Europe

Germany

France

Italy

UK

Spain

Asia Pacific

China

India

Japan

South Korea

Central & South America

Brazil

Argentina

Middle East & Africa

Order a free sample PDF of the Composites Market Intelligence Study, published by Grand View Research.

0 notes

Text

Composites Market 2030 Overview, Regional Outlook, Growth Report

The global composites market size is expected to reach USD 163.97 billion by 2030, registering a CAGR of 7.2% over the forecast period, according to a new report by Grand View Research, Inc. The demand for composites is expected to witness significant growth owing to the rising fuel prices and stringent government regulations have shifted automobile manufacturers focus on light-weighted components which would further propel the market demand over the forecast period.

Composite products play an essential role in the manufacturing of automotive and aircraft parts. The growing concerns regarding fuel consumption and CO2 emission levels have prompted the manufacturers to use carbon fiber composite materials as substitutes for metal components. Technological innovations to minimize the manufacturing cycle time is expected to propel the usage of composites in the automotive sector.

The high cost of composites has limited their application scope to premium segment cars. However, key players are conducting extensive R&D activities to develop low-cost composite grades with similar mechanical properties as that of the high-cost variants. This is expected to spur the demand for the product in the automotive industry over the forecast period.

Gather more insights about the market drivers, restrains and growth of the Global Composites Market

Composites Market Report Highlights

The glass fiber segment accounted for the largest market share in 2022 and is further expected to grow at a CAGR of 6.4% on account of increased penetration in pipe manufacturing applications owing to the strength and durability of these composites. Additionally, glass fiber comprises several thin that find application in building & construction, automotive, industrial, energy, and consumer goods

The layup process segment is forecasted to grow at a CAGR of 9.0% by 2030. The market is again forecast to grow due to easier technology applications and the requirement of less expensive machinery. The process involves placing multiple layers of composite fiber in a sequence by using a matrix of resin and hardener

The automotive & transportation segment dominated the composites market with a revenue share of USD 19.70 billion in 2022. This is attributed to its advantages such as fuel saving to the transportation sector as the components are significantly lighter in weight that allows ascending fuel efficiency

The demand for composites in Asia Pacific was the largest in the global market due to the increase in air passenger traffic, rise in automotive vehicle production, and ambitious electrical & electronics production capacity addition targets set by various governments in the Asia Pacific including China, India, Japan, and South Korea

Various initiatives such as technology innovations, research & development, partnerships, and merger & acquisitions to manufacture cost-effective and lightweight composite products have been undertaken by the key market players. Prominent players have patented technologies used for composites manufacturing

Browse through Grand View Research's Advanced Interior Materials Industry Research Reports.

Aluminum Composite Panels Market: The global aluminum composite panel market size was estimated at USD 6.47 billion in 2024 and is expected to grow at a CAGR of 7.0% from 2025 to 2030.

Centrifugal Pump Market: The global centrifugal pump market size was estimated at USD 39.80 billion in 2024 and is projected to grow at a CAGR of 4.2% from 2025 to 2030.

Composites Market Segmentation

Grand View Research has segmented the collated screws market on the basis of product, manufacturing process, end-use, and region:

Composites Product Outlook (Volume, Kilotons; Revenue, USD Billion, 2023 - 2030)

Carbon Fiber

Glass Fiber

Others

Composites Manufacturing Process Outlook (Volume, Kilotons; Revenue, USD Billion, 2023 - 2030)

Layup Process

Filament Winding Process

Injection Molding Process

Pultrusion Process

Compression Molding Process

Resin Transfer Molding Process

Others

Composites End-Use Outlook (Volume, Kilotons; Revenue, USD Million, 2023 - 2030)

Automotive & Transportation

Wind Energy

Electrical & Electronics

Construction and Infrastructure

Pipes & Tanks

Marine

Others

Composites Regional Outlook (Volume, Kilotons; Revenue, USD Million, 2023 - 2030)

North America

US

Canada

Mexico

Europe

Germany

France

Italy

UK

Spain

Asia Pacific

China

India

Japan

South Korea

Central & South America

Brazil

Argentina

Middle East & Africa

Order a free sample PDF of the Composites Market Intelligence Study, published by Grand View Research.

0 notes

Text

Key Trends Shaping the Medical Plastics Market in 2024 and Beyond

Medical Plastics Industry Overview

The global medical plastics market size is expected to reach USD 87.58 billion by 2030, registering a CAGR of 7.4% from 2024 to 2030, according to a new report by Grand View Research, Inc. The demand for medical device packaging is likely due to the increased need for in-house and advanced medical devices. Plastics including polyethylene, polypropylene, and polycarbonate are increasingly being utilized in the medical device manufacturing The growth of the home healthcare sector on account of the low costs involved as compared to hospital care and intensive care contributes to a rise in the demand for medical devices and multiple hospital associated tests as well.

The growth of the home healthcare sector on account of the low costs involved as compared to hospital care and intensive care has resulted in a rise in the demand for medical devices. The increasing demand for medical devices can also be attributed to the various types of medical tests conducted by hospitals for diagnostic purposes.

Gather more insights about the market drivers, restrains and growth of the Medical Plastics Market

Healthcare spending in the country is likely to accelerate in the near future owing to the growing awareness about healthcare. The rise in demand is driven by the aging population (65 years of age or above), growing prevalence of chronic diseases, infrastructure enhancements and technological advancements in medical plastics market.

The strengthening of the Western European economies is expected to result in an increased provision of healthcare expenditure in the annual budgetary proposals. Moreover, Northern European economies such as Germany, the UK, and Sweden are projected to exhibit an increase in healthcare expenditure, thereby leading to a growth in the production of medical devices. However, the growth is expected to be supported by political unrest in Europe’s transition economies such as Russia and Ukraine.

Browse through Grand View Research's Plastics, Polymers & Resins Industry Research Reports.

The global poly alpha olefin market size was valued at USD 1.48 billion in 2023 and is projected to grow at a CAGR of 2.8% from 2024 to 2030.

The global cross-linked polyethylene market size was valued at USD 8.0 billion in 2023 and is projected to grow at a CAGR of 6.9% from 2024 to 2030.

Medical Plastic Market Segmentation

Grand View Research has segmented the global medical plastic market based on product, application, and region:

Medical Plastics Product Outlook (Volume, Kilotons & Revenue, USD Million, 2018 - 2030)

Polyethylene (PE)

Polypropylene (PP)

Polycarbonate (PC)

Liquid Crystal Polymer (LCP)

Polyphenylsulfone (PPSU)

Polyethersulfone (PES)

Polyethylenimine (PEI)

Polymethyl Methacrylate (PMMA)

Others

Medical Plastics Process Technology Outlook (Volume, Kilotons; Revenue, USD Million, 2018 - 2030)

Extrusion

Injection Molding

Blow Molding

Other

Medical Plastics Application Outlook (Volume, Kilotons & Revenue, USD Million, 2018 - 2030)

Medical Device Packaging

Medical Components

Orthopedic Implant Packaging

Orthopedic Soft Goods

Wound Care

Cleanroom Supplies

BioPharm Devices

Mobility Aids

Sterilization and Infection Prevention

Tooth Implants

Denture Base Material

Other Implants

Others

Medical Plastics Region Outlook (Volume, Kilotons & Revenue, USD Million, 2018 - 2030)

North America

US

Canada

Mexico

Europe

Germany

UK

France

Italy

Netherland

Asia Pacific

China

India

Japan

Central & South America

Brazil

Argentina

Middle East & Africa

Saudi Arabia

UAE

Key Companies profiled:

Röchling SE & Co. KG

Nolato AB

Saint-Gobain S.A.

SABIC

Orthoplastics Ltd

Eastman Chemical Company

Celanese Corporation

Dow, Inc.

Tekni-Plex, Inc.

Solvay S.A.

HMC Polymers Company Limited

ARAN BIOMEDICAL TEORANTA

Trelleborg Group

Avantor, Inc.

Trinseo

Evonik Industries AG

Key Medical Plastics Company Insights

Some key market players include BASF SE; Celanese Corporation; Evonik Industries AG; SABIC; Dow, Inc.; Solvay S.A.; Trinseo S.A.; and Eastman Chemical Company.

In November 2022, Celanese Corporation announced the acquisition of DuPont's Mobility & Material (M&M) business for USD 11 billion. This strategic move enables Celanese to expand its global reach and enhance its offerings in the environmental sector, particularly in sustainable transportation.

Recent Developments

Some key players operating in market include BASF SE; Celanese Corporation; Evonik Industries AG; SABIC; Dow, Inc.; Solvay S.A.; Trinseo S.A.; Eastman Chemical Company among others.

In February 2023, Cleanse Corporation announced the acquisition of DUPONT's mobility and mobility business for USD 11.00 billion. This strategic move enables Cleanse to expand its global reach and enhance its offerings in the environmental sector, particularly in sustainable transportation.

In June 2023, SABIC acquired Clariant's 50% stake in Scientific Design, a renowned catalysis leader. This acquisition bolstered the non-cyclical, technology-driven business and brought it closer to becoming a leading global specialist.

Order a free sample PDF of the Medical Plastics Market Intelligence Study, published by Grand View Research.

0 notes

Text

Rapid tooling technologies have contributed to significant advancements in the manufacturing industry, transforming the way products are developed and marketed. Plastic mold manufacturing, in particular, has seen major changes with the development of sophisticated tooling methods. These developments have improved the speed, accuracy, and cost-effectiveness of conventional plastic injection molding procedures. The rapid tooling environment continues to grow with significant advancements as major global manufacturing hubs like China continue to invest in state-of-the-art technologies.

0 notes

Text

0 notes

Text

Exploring Tool Steel: A Comprehensive Guide for Professionals

Introduction to Tool Steel

Definition and Composition of Tool Steel

Special steel known for its toughness and wear resistance is referred to as tool steel because of its hardness levels.It usually consists of quantities of carbon and additives such, as chromium,vanadium,molybdenum and tungsten.These elements improve the steels characteristics making it ideal, for producing cutting tools dies and molds.

Historical Development of Tool Steel

Tool steels evolution can be traced back, to the 1800s, marked by advancements in heat treatment methods and alloy blending techniques that propelled the industry forward significantly. In a move in 1898 high speed steel emerged, transforming the sector as it enabled tools to retain their hardness, in elevated temperatures.

Applications and Uses in Various Industries

Steel tools are commonly utilized across sectors, like aerospace industries as well as construction and manufacturing fields for a range of purposes such as crafting drilling equipment and saw blades along with creating molds for plastic injection and metal forging as well, as manufacturing precision measuring devices.

Properties of Tool Steel

Mechanical Properties

Tool steel exhibits high hardness and excellent wear resistance. It can achieve a hardness level above HRC 60 when properly heat-treated. This makes it ideal for applications requiring durability under mechanical stress.

Thermal Properties

Some types of tool steel exhibit stability, with high speed steel maintaining its cutting performance even at high temperatures thanks to its red hardness characteristic while hot work tool steels are engineered to endure thermal fatigue in heat intensive processes.

Chemical Properties

Tool steels are designed with added elements that help boost their ability, to hardening and resistance to corrosion such as chromium, for corrosion protection and tungsten for increased durability and resistance to wear and tear.

Types of Tool Steel

Water-Hardening Tool Steels (W-Grades)

Water hardening grades are considered tool steels that achieve hardness through the cooling process, in water providing wear resistance while being slightly less durable than alternative grades available, in the market.

Cold-Work Tool Steels (O, A, D Grades)

These types of steels are commonly utilized in tools that function under temperatures, for striking a mix of durability and resistance to wear and tear. Ideal for applications, like stamping dies and cold extrusion tools.

Shock-Resisting Tool Steels (S-Grades)

Grades of steel known as S grades are specifically crafted to endure impact without breaking making them ideal, for tools, like chisels and punches that require resistance to forceful impacts.

Hot-Work Tool Steels (H-Grades)

High strength grades maintain their durability, in temperatures making them ideal for applications in die casting molds and extrusion dies that require excellent resistance, to thermal fatigue.

High-Speed Tool Steels (T, M Grades)

High speed steels retain their hardness when operating at high cutting speeds making them ideal, for cutting tools that need to perform well in intense heat conditions.

Selecting the Right Tool Steel for Your Needs

Factors to Consider in Selection

When choosing tool steel for a job or project it's important to take into account factors such, as the temperature at which it will operate the level of toughness needed its resistance to wear and how easy it is to machine. Ultimately the decision hinges on finding the balance, between these characteristics to ensure that the steel meets the performance standards required for the application.

Common Challenges in Selection

One of the challenges is figuring out the heat treatment method to get the desired properties without affecting the materials strength or causing size changes while processing it.

Promisteel: Elevating Chinese Steel Brands Globally

Commitment to Quality and Innovation

Promisteel is committed to creating high quality tool steel items through a combination of cutting edge manufacturing methods and strict quality assurance processes guaranteeing performance in a range of uses.

Promispecial Brand: Integration of Resources

The Promispecial brand emphasizes utilizing resources to deliver solutions designed for specific industrial demands, which involves providing a diverse selection of tool steels to meet both general and unique needs.

Customized Solutions for Special Steel Needs

Promisteel provides tailored solutions by comprehending the requirements of clients and supplying tool steels that adhere to exact specifications thereby improving manufacturing processes through the provision of materials that comply with industry norms.

0 notes

Text

LDPE quotes lower in Chennai market

A decline in LDPE (24FS040) prices within the Chennai domestic petrochemical market was recorded today. On November 13, 2024, the commodity's price dropped from Rs.124/Kg to Rs.123/Kg, marking a Re.1/Kg decrease. Based on general knowledge of Indian LDPE production, companies such as Reliance Industries, Indian Oil Corporation (IOCL), and Hindustan Petroleum Corporation Limited (HPCL) are major producers of LDPE in India. These manufacturers produce various grades of LDPE for applications like: Film extrusion (used for packaging films, stretch wraps, and agricultural )Injection molding (for containers, caps, etc.) Blown films (used in flexible packaging and food packaging) LDPE is one of the most commonly used types of polyethylene, and its global production is dominated by a few major chemical producers. Some of the key players in the global production of LDPE include: 1. ExxonMobil Chemical, 2. Dow Chemical, 3. LyondellBasell, 4. SABIC (Saudi Basic Industries Corporation) and 5. Reliance Industries (Industries). Indian LDPE Prices, LDPE Prices In India, Indian Prices LDPE, Indianpetrochem.

0 notes

Text

Medical Injection Molding Market Projected To Advance At CAGR Of 5.7% From 2022 To 2030

The global medical injection molding market size is anticipated to reach USD 33.28 billion by 2030, according to a new report by Grand View Research, Inc. The market is projected to advance at a CAGR of 5.7% from 2022 to 2030. The global industry is primarily driven by the increased adoption of plastics in several healthcare products, coupled with rapid technological advancements in the medical sector.

With the advent of the COVID-19 pandemic, the injection molding industry has witnessed an uptick, particularly in the medical field, where it can provide accuracy, a wide range of operations, repeatability, and cleanliness. In addition, it provides cost-effective and efficient ways for producing high-volume parts and products.

Gain deeper insights on the market and receive your free copy with TOC now @: Medical Injection Molding Market Report

In recent years, the industry for medical injection molding has seen a boom with regard to the manufacturing processes of complicated healthcare products. Players are incorporating Industry 4.0 into their processes to optimize their raw material requirements, reduce costs, and increase automation, flexibility, & efficiency, among other things.

The key factors influencing the demand for medical products include availability, awareness, affordability, and adaptability. Increasing demand for better healthcare facilities coupled with the ongoing COVID-19 pandemic has boosted the growth of medical devices manufactured with the help of injection molding machines, thereby augmenting industry growth. Medical injection molding has seen a growth in popularity in the last few years as a manufacturing process for generating complex net form medical devices. It lowers the cost of production and repetition, reducing the number of raw materials needed to develop medical items.

Companies that provide injection molding services are working to acquire the most up-to-date technologies, in order to fulfill the changing demands of the medical industry and expand their manufacturing capacity. For example, in March 2022, Beacon MedTech Solutions increased its medial injection molding capacity with the installation of the SE-EV-A series Sumitomo (SHI) Demag machines.

#Medical Injection Molding Market Size & Share#Medical Injection Molding Market Latest Trends#Medical Injection Molding Market Growth Forecast#COVID-19 Impacts On Medical Injection Molding Market#Medical Injection Molding Market Revenue Value#Global Medical Injection Molding Market

0 notes

Text

CF & CFRP Market worth $60.3 billion by 2028

The report "CF & CFRP Market by Source (Virgin, Recycled), Precursor, Resin Type, Manufacturing Process (Lay-up,Compression Molding, Resin Transfer Molding, Filament Winding, Pultrusion, Injection Molding), End-Use Industry, and Region - Global Forecasts to 2028", is estimated at USD 29.7 billion in 2022 and is projected to reach USD 60.3 billion by 2028, at a CAGR of 12.7% from 2023 to 2028. The increasing adoption of electric vehicles and the need for lightweight materials to improve their range and efficiency has further boosted the demand for CF & CFRP in the automotive industry. Additionally, the growing trend of sustainability and eco-friendliness has led to the increasing use of CF & CFRP in green energy applications such as wind turbines.

#CF & CFRP Market#CF & CFRP Market Size#CF & CFRP Market Share#CF & CFRP Market Analysis#CF & CFRP Market Trends#CF & CFRP Market Report#CF & CFRP Market Research#CF & CFRP Industry#CF & CFRP Industry Report

1 note

·

View note

Text

The global medical injection molded plastics market size was valued at USD 24.61 billion in 2022. It is estimated to reach USD 36.57 billion by 2031, growing at a CAGR of 4.5% during the forecast period (2023–2031).

0 notes