#Electromechanical Manufacturer

Explore tagged Tumblr posts

Text

Buy Magnetic Float Level Switches in Jordan

Mastering & Innovation Est is one of the famous Electromechanical Manufacturer & Service provider. Magnetic Float Level Switches Manufacturer in Amman, Jordan

#manufactures#Magnetic Float Level Switches#buyMagnetic Float Level Switches#marketing#success#branding#products#Electromechanical Manufacturer

0 notes

Text

System Integration

Railway Signaling Systems

Power inverters

Controllers for industrial equipment

Medical devices and equipment

Fuel dispensing systems

Telematics modules

Camera and Vision Systems

Sensing and detection systems

#Complete Box Build#Life Cycle Management#Configuration Management#Cabinets#Enclosures#& Rack-Mount Systems#Functional Testing#Electromechanical Assemblies#electronics manufacturing services#electronic manufacturing services#electronic manufacturing services companies#electronics manufacturing services India#electronics manufacturing services chennai#top Ems companies in India#bestEmscompanies in India#EMS#System Integration

2 notes

·

View notes

Text

Exploring the World of Electromechanical Systems: A Fusion of Electronics and Mechanics

Introduction:

In the realm of facility management, the effective operation and maintenance of electromechanical systems play a vital role in ensuring the smooth functioning of buildings and infrastructure. The fusion of electronics and mechanics has given rise to sophisticated systems that require skilled professionals to handle their operations and maintenance.

Electromechanical systems are a fascinating field that combines the principles of electronics and mechanics. These systems involve the integration of electrical components and mechanical structures to create devices capable of performing a wide range of tasks. From simple household appliances to complex industrial machinery, electromechanical systems are an integral part of our daily lives.

Understanding Electromechanical Systems:

Electromechanical systems are integral to the functioning of modern facilities. These systems combine electrical and mechanical components, utilizing electronic controls to enhance efficiency and automation. Examples include HVAC (Heating, Ventilation, and Air Conditioning) systems, elevators, escalators, fire protection systems, security systems, and energy management systems.

Workforce Requirements:

To ensure the optimal performance of electromechanical systems, facility management teams require a diverse range of professionals with specialized skill sets. Key roles may include:

a. Engineers: Electrical and mechanical engineers are crucial for system design, installation, and troubleshooting. They possess the technical knowledge to handle complex electromechanical systems.

b. Technicians: Skilled technicians play a vital role in maintaining, inspecting, and repairing electromechanical systems. They are responsible for regular maintenance, diagnosing issues, and performing necessary repairs or replacements.

c. Operators: Operators are responsible for monitoring and controlling electromechanical systems, ensuring their proper functioning and responding to alarms or emergencies.

d. Facility Managers: These professionals oversee the operations and maintenance of electromechanical systems, ensuring compliance with regulations, managing budgets, and coordinating the work of the entire facility management team.

Recruitment Strategies:

To build a competent team for operations and maintenance in facility management, consider the following recruitment strategies:

a. Job Portals: Utilize online job portals that cater to the facility management industry to reach potential candidates with the desired skill sets.

b. Industry Networks: Engage with industry-specific networks, associations, and professional forums to connect with qualified professionals in the field of electromechanical systems.

c. Collaboration with Technical Institutes: Partner with technical institutes and vocational schools to tap into fresh talent. Establish internship programs or participate in job fairs to attract entry-level candidates.

d. Skill Assessment: Conduct thorough skill assessments during the recruitment process to evaluate candidates' proficiency in handling electromechanical systems and their related components.

Training and Professional Development:

Given the complexity and evolving nature of electromechanical systems, investing in training and professional development is crucial. Provide regular training sessions to enhance the skills of your workforce, keeping them up-to-date with the latest technologies and maintenance practices. Encourage employees to attend industry conferences, workshops, and certifications to expand their knowledge base.

Safety and Compliance:

Operations and Maintenance in Facility Management must prioritize safety and compliance. Ensure that all staff members are well-versed in safety protocols, including electrical safety, lockout/tagout procedures, and handling hazardous materials. Familiarize your team with relevant regulations and standards, such as building codes, fire safety regulations, and environmental guidelines.

Team Collaboration and Communication:

Effective collaboration and communication within the facility management team are vital for seamless operations and maintenance. Foster a culture of teamwork, encourage knowledge sharing, and promote open lines of communication between different departments and roles. This collaborative approach can lead to efficient problem-solving and improved system performance.

Conclusion:

Electromechanical systems form the backbone of facility management, and staffing considerations for operations and maintenance are crucial to ensure their reliable and efficient functioning. By understanding the workforce requirements, implementing effective recruitment strategies, prioritizing training and professional development.

#Water Treatment Plant Manufacturers in India#Sewage Treatment Plant Manufacturers in India#Operation and Maintenance of Water Treatment#Operations and Maintenance in Facility Management#Water Treatment Plant Project#Sewage Treatment Plant Project#Effluent Treatment#Best Electromechanical Systems#Integrated Electronics and Mechanics

2 notes

·

View notes

Text

Distinguish a Top-Quality Surgical Implant Device Manufacturer

Surgical implant devices are a significant segment of the medical devices industry. These devices have a direct bearing on patients who undergo surgery. So, clinics should choose a competent surgical implant device manufacturer for the safety of their patients and efficiency in surgery.

A good idea for healthcare service providers is to learn about the fundamental attributes of a quality manufacturer. That way, they can choose a quality manufacturer, ensuring safe, reliable, and effective devices.

Advanced Technology

Technology is the primary aspect of consideration for a surgical implant device manufacturer. Usually, top-notch manufacturers use advanced technologies to create customized implants to suit different patient needs. Nowadays, factories deploy robots that help them to increase precision in implant production.

Implementation of advanced technologies can help in building improved products.

Quality Assurance

A reliable quality assurance system is essential for any manufacturer dealing in surgical implant devices. The company should ensure quality at every stage of production. In addition, the manufacturer should use quality raw materials.

Moreover, a high-quality testing process is essential to ensure the finished products meet quality standards. With high-quality devices, healthcare service providers can ensure reliability and patient safety.

Material Selection

Manufacturers should use high-quality materials in building their surgical implant products. The importance of good material quality arises from the fact that such devices remain inside the patient's body for a long time. As such, low-quality materials could hamper the patient.

Companies should use biocompatible materials to prevent adverse reactions, such as inflammation.

Ideally, the manufacturers should use Titanium and ceramic variants. These are biocompatible and durable. Their research & development professionals should be experts in material science. That can help them choose safe and high-quality materials to manufacture devices.

Moreover, the companies should use advanced techniques, such as electromechanical & fluidic assemblies.

Scalability

The manufacturer should scale up without compromising on the quality of the devices. The expertise becomes essential when the demand for their products increases.

In addition, scalability can help the company to adjust to changes in regulatory standards or shifts in market demands. It can also allow the company to stay agile and maintain competitiveness.

Research & Development Capabilities

Research & development capabilities are essential for a competitive surgical implant device manufacturer. The proficiency renders a manufacturer innovative. As such, such a company can improve its existing products and develop new products to cater to emerging needs.

Furthermore, research and development capabilities help the manufacturers to remain in sync with the latest industry trends. And they can cater to the evolving needs of the healthcare sector.

Proven Track Record

A proven track record of manufacturing quality products can help establish its credibility as a reliable manufacturer. Case studies, clinical trial data, and the history of the products should indicate reliability and safety. That also builds trust in patients.

Customer-Centricity

Such device manufacturers should have customer-centric policies. They should understand the evolving customer needs. Also, the companies should provide excellent customer service and technical support apart from quickly solving customer queries.

Such initiatives indicate that the companies care for their patients. Hence they offer good quality products.

Transparency

As the industry deals with sensitive implants, the companies should practice transparency. In addition, they should ensure ethical business practices and transparency to customers. As such, they should disclose their clinical trials and protect patient data.

Conclusion

The main attributes of a quality surgical implant device manufacturer are advanced technological expertise, customer-centricity, transparency, and conformity with regulations.

A top-notch manufacturer demonstrates adherence to quality, innovation, and commitment to providing patients with the best devices.

This article will help distinguish a quality manufacturer.

0 notes

Text

International standards being what they are, the majority of consoles created in or imported to Japan, including those targeting uniquely domestic audiences, employ names or acronyms based on the English language. For the sixty odd years that Japan has been producing electromechanic and electronic game systems there is but a literal handful of systems named in the Japanese language that, I'd wager, even the most seasoned players know little or nothing about. Your curiosity may be rewarded if you continue reading.

1982 - Contrary to what you may have heard or read, Tomy was the first Japanese toy company to develop a computer. Styled after the Texas Instruments TI-99/4 and manufactured by Matsushita, the Pyūta was purposely designed to sit on toy store shelf space as hinted at by its name, a childish diminutive of the word Konpyūtā.

1983 - John Ross's Mini-Arcade project was sold world over under the sweet-sounding name Vectrex. The Japanese distributor, Bandai, was not so enamoured with it. Believing that a Japanese name would do better at retail, it was commercialized as Kōsoku-Sen - The Lightspeed Ship!

1988 - Bandai's history as a console maker is quite unlike any other. Terebikko is a VHS-based gaming system that uses the TV audio output to play sound via its phone receiver and quiz players with multiple response questions. The console produces a sound output that informs the player if the answer was correct or not. Tapes include animated films starring Mario, Anpanman and the characters from Dragon Ball, some even fetching quite the high price at auctions these days.

1990 - Sharp is seldom given due recognition for creating some of Nintendo's finest and durable consoles. The Sūpā Famikon Naizou Terebi SF1 TV perfectly mirrors the concept of their 1983 C1 NES TV, in spite of the technological leap. Its Japanese name describes its built-in console function. Nintendo fanboys would pounce on me were I to snub it.

1995 - Further proof of Bandai's unorthodox approach to console design is found in their unsuccessful Denshi Manga Juku - lit. Electronic Manga Tutor. The first ever stylus-based console - once again, contrary to what many may yet hold to be true - some of the games in its miniscule library allowed the player to design and animate characters or scenes; while others presented a blank canvas for the user to draw the game's protagonist.

1996 - A retail development kit, but a console all the same, Sony's Netto Yarōze was an ambitious project resulting in dozens of homebrewed independent titles. The name matches its vision: a network of creators coming together to realize their individual game design aspirations. Of all the systems in its restricted category, it was by far the most successful.

Unreleased - It's a beautiful fact that the first arcade game and globally successful console had a Japanese word stamped on them - Atari. Mirai, meaning Future, is a prototype found in the mid-1990s, about which nothing can be said authoritatively apart it from being a cartridge-based system. Given the more or less overt resemblances to the Atari XEGS, it is possible that it was designed by Ira Velinsky, in which case it could date from the late 1980s. Though not a made-in-Japan product, its borrowing of a Japanese word makes its presence in this list mandatory.

#consoles in japan#japanese-named consoles#videogame history#tomy#pyuta#bandai#Kōsoku-Sen#atari#mirai#sony#net yaroze#Denshi Manga Juku#terebikko#sha#sharp#Sūpā Famikon Naizou Terebi

30 notes

·

View notes

Text

Hardware proof-of-concept projects Magz found interesting, from "hack-a-day-prize 2023, 10th anniversary" event.

Contest where engineers and tech enthusiast, submit their hardware projects.

(Link to "Hack-a-day Prize 2023 event" page)

youtube

Video Title. "Open Book: 2023 #HackadayPrize Video" Project Description. "The Open Book: An open hardware reading device that's easy to build, easy to manufacture, and easy to make your own."

(Link to "Open Book" Project page, on Hack-a-day website)

Note: Is open source hardware and firmware. However, "Open book" Reading device only support plain-text file for now. There are many feedback and suggestion to support ePub file and markdown format.

youtube

Video Title. "Electromechanical Refreshable Braille Module : HackadayPrize 2023" (thumbnail text. "Open-source refreshable braille") Project Description. "Lowering the cost of Refreshable Braille Cells by using Electromagnetic Cam Actuators & 3D Printing"

(Link to "Electromechanical Refreshable Braille Module" project page, on Hack-a-day website)

Note: $10 u.s. for the first braille cell production, but $1 u.s. per subsequent braille cell material. As opposed to the usual braille cell being $100 u.s. or more, with 40-cell displays costing $4k or more. The prototype have 100-200 millisecond refresh rate per dot, but will be improved with driver update in next prototype version, along with more durable material.

Other interesting project.

"Speak To Me: A Button Box" Project Page

Description: "A project to make life easier for my 91 year old father, who has hearing and eyesight loss as well as severe short term memory issues." ("Dad's 'Speak-to-me Button Box'" Showcase video, Youtube)

"OHMni-Stick" Project Page

Description: "Ultra Low Force and Displacement Assistive Tech Joystick." ("OHMni-Stick" entry video, youtube)

Long Range Weather Station (65€) Project Page

Description: "A cheap but precise Weather Station (Lora transmission)" ("Long Range Weather Station" entry video, youtube)

"Felini - Revolutionary Pocket-Sized Electronic Lab" Project Page

Description: "Extremely affordable pocket-friendly, designed to provide a wide range of hardware testing and debugging functions in a compact and low-cost" ("Pocker-size electronic lab" entry video, youtube)

"OMOTE - DIY Universal Remote" Project Page

Description: "Open-Source Infrared Remote Using ESP32 and LVGL"

"FindMyCat - The Open Source Pet Tracker" Project Page

Description: "The only pet tracker you will ever need. Months long battery life, works outdoors and indoors. It’s Purr-fectly Empowered." ("FindMyCat" Entry Video, Youtube)

"A 'smart' controller for a powered chair or bed" Project Page

Description: "Automates the powered recliner or bed. Ideal for the mobility-challenged." ("Power chair and bed 'smart' controller" entry video, youtube)

"mysoltrk - a solar tracker, reinvented" Project Page

Description: "A different approach for a solar tracker, alternative movements, to be installed on the outside, to optimize the efficiency of solar panels" ("solar tracker" entry video, youtube)

"Portable Sound Visualization AR Device" Project Page

Description: "A portable AR device that superimposes an image showing the location of a sound source on an image captured by a camera." ("Sound AR device" entry video, Youtube)

Can see more Projects At:

Prize 2023 (10th anniversary) Projects Submission Page, on "Hack-a-day" Site

Other Contests and Events, on "Hack-a-day" Site

#note: post include 'low cost braille for computer'. 'open source e-reader'. 'accessibility joy stick controller'. and more#text post#o post#accessibility#tech stuff#magz upload#Youtube#described

18 notes

·

View notes

Text

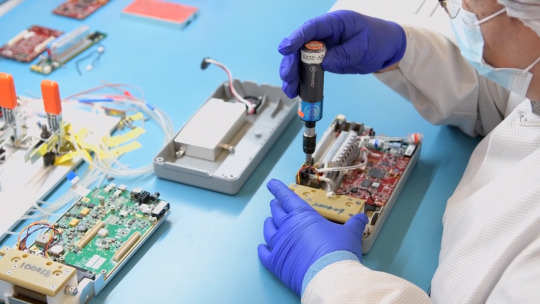

Circuit Board, PCB assembly & electronics manufacturing service provider from China (hitechcircuits.com)

What is a prototype PCB assembly?

PCB prototyping is the experimentation pilot stage of the product which is to be mass produced at a later stage. This is more of an experiment which is done after the initial discussions and the design. This offers a pre-production analysis of the boards that are to be manufactured, reducing the possible number of errors in the PCB design. PCB prototypes help the manufacturer analyze the strengths as well as weak areas of their proposed circuit boards. Prototypes also serve as a reference point for future versions of the same product. At Hitechpcba, we handle PCB prototype assembly in quantities from one to hundred printed circuit boards.

We have acquired capabilities that enable us to serve our clients better. All these years, we have worked on many complex prototype PCB assembly projects, and we believe the following capabilities have helped us serve our clients better.

Prototype PCB Assembly Services: We specialize in the following prototype printed circuit board assembly services.

SMT: We can provide single-sided and double-sided surface mount PCB assemblies in different specifications.

Plated Through Hole: We offer plated through hole assembly with selective soldering.

Mixed Assemblies: We often work on projects involving mixed assemblies – through-hole and SMT and electromechanical assemblies.

PCBA Testing: All the PCBA functional testing is performed in-house. Over the years, we have invested in various test fixtures and equipment, which helps us ensure the quality of PCBA. Currently, we provide the following types of PCBA testing services:

Flying probe testing for PCB

Functional testing including system and board-level testing

General PCB Assembly Capabilities: Our general PCB assembly capabilities are not limited to these:

RoHS, leaded or lead free, clean and no chemistries

PCB components including various types of QFNs, BGAs, 0105, 0201, 0804, and press fit components in small quantities.

What are the benefits of a prototype PCB assembly?

Prototype PCB assembly comes with several advantages. These benefits play a major role in the facilitation of your PCB manufacturing. Some of these benefits include:

Detection of Flaws Early

With prototype PCB, you will easily detect whatever flaws are present during the product’s development stages. This will allow you to solve the issues thereby saving you some money if you had gone ahead to make the production having the flaws in them.

If you go ahead to make changes during the production, there may be a need for more technicalities, and this may be expensive.

Testing of Each Component

With a prototype, you will be able to test all your system’s elements individually before you go ahead to set it up. You should do this because it is important especially for very complex projects composed of several parts that are PCB based.

When you validate each of these components, you will be able to identify those areas having issues that you should look into. This is the only way the project can function the right way.

Reduction in Total Costs

Utilizing the prototype bare PCB for any of your projects could go a long way in reducing what you’ll have spent in total for the project. With prototyping, you will be able to notice those errors in your project and then make corrections before you start the real production.

As soon as these flaws have been checked and rectified, then you may continue with the manufacturing of your Printed circuit boards in large quantities, thereby saving you unnecessary costs.

High-Quality PCBs

Why prototyping your PCB is important is to help you test if your project will function effectively. When we talk of testing, it involves the identification of errors present and then rectifying and making corrections to them.

Therefore, the eventual PCB after the prototyping will be of high quality that surely meets standards set internationally.

Less Turnaround Time

With prototype PCB assembly, you will be able to reduce the total time used in producing your printed circuit board. While making use of prototype printed circuit boards, you’ll be able to see the errors and then make corrections before you start the actual production.

Therefore, the eventual prototype will be free of defects. This implies that your PCBs will be produced quickly by your manufacturer.

What are the different types of prototype PCB assembly services you offer?

With years of market presence and experience, we specializes in the following prototype PCB assembly services.

Plated through-hole (PTH): We can provide the through-hole assembly with selective soldering.

Surface mount technology (SMT): We offer single-sided as well as double-sided SMT board assemblies in varied specifications.

Mixed Assemblies: Our experts often work on projects involving both PTH and SMT assemblies.

What are the types of testing Hitechpcba use for prototype PCB assembly?

Automated Optical Inspection (AOI): This is performed before and after the soldering to identify the component placement, presence, and solder quality.

X-ray Testing: In this type of testing, the operator relies on the X-ray images of the PCB to check the solder joints and lead-less components such as Quad Flat Packs and ball grid arrays, which are generally not visible to naked eyes.

In-Circuit Testing (ICT): This method is used to detect manufacturing defects by testing the electrical properties in the SMT Assembly.

These techniques help us ensure the reliability and accuracy of the circuit boards. In addition to this, it ensures a long operational life of equipment, minimal production losses, streamlined processes, and much more.

What are the capabilities Hitechpcba offer for prototype PCB assemblies?

We specialize in offering IPC compliant, and quick turn PCB assemblies. We are very particular about our scheduled deliveries and timelines, and we deliver without compromising the quality. Our PCBA capabilities are not limited to these. Here are some capabilities we offer through prototype PCB assemblies.

RoHS compliance

Stringent testing procedures

Device encapsulation

Full turnkey, partial turnkey, and kitted/consigned services

Assemblies using Surface Mount (SMT), Thru-hole, Mixed Technology (SMT/Thru-hole), Single and double-sided SMT/PTH, Large parts on both sides, BGA on both sides.

Do you perform a component analysis for prototype PCB assemblies?

Yes, we check the quality and performance of components before mounting them on the circuit boards. This is because a malfunctioning component can affect the performance of the entire circuit board assembly and also pose risks.

What is your standard turnaround time for a prototype PCB assembly?

Our turnaround time for standard applications is two weeks. This timeframe varies depending on the complexity of the applications. However, we are committed to offering quick turnaround times without compromising on quality, functionality, and accuracy, which offers our client a competitive advantage and reduced time to market. You can also request any emergency assistance or queries related to any type of PCB assembly. Our experts will assist you in all possible ways.

How is the cost of prototype PCB assembly estimated?

PCBA costing varies based on the different factors, such as PCBA parts, type of materials to be used, order quantity, and much more. We can also offer quotes and customization options once you share the detailed requirement with us.

We focus on quality and customer satisfaction over anything else. This has helped us build a long list of happy and satisfied customers. So, if you wish to partner with a manufacturer of prototype PCB assembly in China, then don’t hesitate to reach us. Our experts will assist you through all the phases of the prototype PCB assembly process. We look forward to making your experience with us better and memorable.

How to choose prototype pcb assembly manufacturer?

Our pcb prototype assembly service includes the sourcing of components. This allows you to concentrate on what you do best: layout design. We have a dedicated sourcing staff that coordinates with multiple suppliers and distributors to purchase electronic parts as per client requirements, and our staff completes these purchasing particulars in a most efficient manner. We have advanced processes for optimal selection of packaging (cut tape, tube, bulk, etc.) to reduce the total cost. Furthermore, we are capable of cross-referencing parts and even locating hard-to-find and obsolete parts. Customers can be rest assured that when Hitech Circuits substitutes components that they are high quality: we only use the electronic component numbers and manufacturers specified in the BOM. We will not modify your original layout design. Part substitutions take place only with your permission.

The final pcb prototype assembly service cost includes assembly labor charges, bare circuit board rates, and part costs. We understand the importance of prompt delivery. The sooner the components are sourced, the sooner we can begin circuit board fabrication. We thoroughly evaluate engineering inquiries and concerns related to the related parts with our clients before commencing circuit board assembly. The average time taken for pcb manufacturing assembly is about two weeks, which can be further reduced if there are no hard-to-locate components or documentation mistakes.

We have specialized experts to deliver fast turnarounds for prototype circuit board assembly with surface-mount (SMT), through-hole (THT) and mixed-technology components.

Anyone interested in electronics and electronic circuit boards needs to understand the various stages of developing and producing a printed circuit board. It can come in handy when you are seeking a top prototype smt assembly provider. The various production stages of printed circuit boards entail design, prototyping (prototype PCB development and rapid prototyping pcb assembly), and PCB high volume production. Different entities will always seek part of the whole production process depending on their electronic circuit board needs.

However, this article seeks to help you understand everything about prototype PCB assembly, a fundamental aspect of the PCB production process.

Rapid prototyping pcb assembly represents a fundamental phase of the printed circuit production process. It is also inferred as PCBA prototype assembly, SMT or surface-mount technology PCB prototype, PCB sample assembly, etc. From these alternative names, the meaning of prototype assembly regarding printed circuit boards becomes apparent. So what is assembly prototype?

PCB prototype assembly service is a fast prototype printed circuit board assembly primarily used to test fresh or new electronic designs. Consequently, it assists with checking and ensuring quality assurance of the PCB. For instance, it verifies that no bug exists in the test PCB, updates the design, and finds bugs. In most instances, prototype assembly of an electronic project will require two or three iterations to ensure everything is perfect.

Why Choose Hitech Circuits PCB Assembly for Your Prototype PCB Assembly Projects?

There are several PCB manufacturers specializing in prototype PCB assembly services. However, Hitech Circuits stands out owing to the following:

1.Strong Supply Chain: Over the years, we have built strong supply chain relationships in the industry, which helps us fulfill the requirements of turnkey prototype assembly services easily.

2.Fastest Turnaround Times: Our engineering expertise coupled with our understanding of industry requirements and a well-equipped facility enables us to assure the fastest turnaround times of 24-48 hours.

3.Reliability: All the printed circuit boards that we produce are IPC compliant, which helps us assure reliability.

4.Competitive Pricing and Quick Quote: Our supply chain relationships enable us to assure competitive prices. The cost of the PCB prototype assembly will be made available within 24-48 hours.

2 notes

·

View notes

Text

Achieve Precision Motion Control with Robust Piezoelectric Bimorphs

A piezoelectric bimorph is a specialized bending actuator or sensor comprised of two bonded piezoelectric ceramic layers separated by an inner passive layer. When subjected to an electric field, one ceramic layer expands while the other contracts due to the converse piezoelectric effect, causing the composite to bend. This bending motion can be harnessed for precision actuation and vibration control applications.

The central passive layer, typically made of a metal or polymer, provides mechanical support and prevents electrical shorting between the two active piezo layers. The ceramic layers are poled during manufacturing to align their electric dipole moments in opposite axial directions. When an electric field is applied across the bimorph’s thickness, one layer expands longitudinally while the other contracts, resulting in a net bending displacement perpendicular to the field direction.

For More Information Please visit, pzt bimorph

Bimorphs exhibit higher generative force compared to unimorphs, but slightly lower displacement range. The three-layer symmetric configuration also provides enhanced thermal stability. Bimorphs are engineered to resonance in desired frequency ranges from ~5 Hz up to hundreds of kHz depending on the materials and construction.

Key bimorph advantages:

Large bidirectional bending motions possible up to ±1 mm range.

Fast response times in milliseconds or less.

Generative force up to 100s of newtons.

Low operating voltages, often less than 30V.

Tailorable dynamics via materials selection and dimensions.

Compact, simple construction suitable for arrays.

Lower cost compared to stacks.

Consistent performance over billions of cycles.

Bimorph applications include:

Precision positioning stages and manipulators.

Piezoelectric motors and pumps.

Speakers and headphones due to good audio range response.

Vibration suppression and shock absorption.

Energy harvesting from vibrations and motion.

Overall, the bimorph configuration offers a balanced set of advantages for electromechanical transduction compared to other multilayer piezo options. With thoughtful design, bimorphs enable highly adaptable and robust motion control, acoustic, and sensor solutions.

2 notes

·

View notes

Text

Step-by-Step Guide: How to Use Your First Electric Valve Actuator

If you're looking for a quick and easy guide on how to use your first electric valve actuator, you've come to the right place. In this blog post, we'll cover everything you need to know, from what an electric valve actuator is to the different types available, to how to choose the right one for your application. So let's get started!

What is an electric valve actuator?

An electric valve actuator is a device that is used to control the flow of liquids or gases. It consists of a motor and a valve, and is operated by an electrical signal. The motor turns the valve to open or close it, depending on the desired flow. Electric valve actuators are used in many industries, such as oil and gas, water treatment, and manufacturing.

The different types of electric valve actuators

Electric valve actuators are devices that use electromechanical or electrohydraulic means to control the movement of a valve. There are three main types of electric valve actuators: linear, rotary, and scotch yoke.

Linear actuators use a linear motion to open and close valves. They typically have a higher torque output than rotary actuators and are better suited for larger valves.

Rotary actuators use a rotating motion to open and close valves. They typically have a lower torque output than linear actuators and are better suited for smaller valves.

Scotch yoke actuators use a reciprocating motion to open and close valves. They typically have a higher torque output than both linear and rotary actuators and can be used for both large and small valves.

How to choose the right electric valve actuator for your application

Electric valve actuators come in a variety of shapes and sizes, each with its own advantages and disadvantages. Choosing the right one for your application depends on a number of factors, including the type and size of valve you are using, the operating environment, and the level of control you need.

The first step is to determine the type of actuator you need. There are three main types: linear, rotary, and scotch yoke. Linear actuators open and close valves using a linear motion. They produce more torque than rotary actuators and are better suited for larger valves. Rotary actuators open and close valves by rotating them. They produce less torque than linear actuators and are better suited for smaller valves. To open and close valves, Scotch yoke actuators use a reciprocating motion. They typically produce more torque than both linear and rotary actuators and can be used for both large and small valves.

The next step is to determine the size of actuator you need. Actuator size is typically expressed in terms of stroke length (the distance the actuator can move) or torque output (the amount of force the actuator can generate). The stroke length will be determined by the size of the valve you are using; for example, a butterfly valve will require a shorter stroke length than a globe valve. The torque output will be determined by the operating environment; for example, an actuated valve in a high-pressure system will require more torque to overcome the fluid pressure than one in a low-pressure system.

Finally, you need to consider the level of control you need from your actuator. Electric valve actuators can be controlled manually, automatically, or remotely. Manual control means that someone has to physically operate the actuator every time the valve needs to be opened or closed; this is typically only used for small valves or in applications where there is no power available. Automatic control means that an external controller (such as a PLC) is used to operate the actuator; this allows for remote operation and gives you more flexibility in terms of when and how often the valve is opened or closed. Remote control means that you can operate the actuator from any location with an internet connection; this is ideal for applications where you need to monitor or adjust the flow of fluid remotely.

When choosing an electric valve actuator, it is important to consider all of these factors in order to select one that is well suited for your particular application.

conclusion

In conclusion, Electric valve actuators are devices that control the movement of a valve using electromechanical or electrohydraulic means. Electric valve actuators are classified into three types: linear, rotary, and scotch yoke.

Linear actuators open and close valves using a linear motion. They produce more torque than rotary actuators and are better suited for larger valves.

Rotary actuators open and close valves by rotating them. They produce less torque than linear actuators and are better suited for smaller valves.

To open and close valves, Scotch yoke actuators use a reciprocating motion. They typically produce more torque than both linear and rotary actuators and can be used for both large and small valves.

Electric valve actuators are available in a variety of shapes and sizes, each with its own set of benefits and drawbacks. The right one for your application is determined by a variety of factors, including the type and size of the valve used, the operating environment, and the level of control required.

Cair Euromatic Automation is a leading manufacturer and supplier of electric valve actuators in India.We offer a vast range of electrical actuators for rotational and linear motion.

3 notes

·

View notes

Text

An excellent example of an audio product from Switzerland at the height of precision mechanics engineering.

Later, electronics played an increasingly large and important role in the devices, and the triumphant advance of Japanese manufacturers began.

This later left only niches, such as particularly small, portable devices, where the electromechanical components still required were of particular importance in terms of freedom from interference and robustness in the face of difficult environmental conditions. Contrast this with today's media players, which no longer have any “moving parts” at all.

(Translated from German with DeepL.)

Stellavox Fi-Cord 101S // portable tape recorder (Switzerland, 1962)

via

533 notes

·

View notes

Text

Exploring the Roots of Computing: From Ancient Machines to Modern Innovation

The history of computing is a fascinating journey that spans millennia, showcasing humanity's ingenuity in creating machines to solve problems, automate tasks, and process information. Let’s take a chronological dive into some of the world's earliest computing devices, each a milestone in the evolution of what we now call "the computer."

Antikythera Mechanism: The Ancient Astronomical Computer

Dating back to around 100 BCE, the Antikythera Mechanism is often considered the world’s first analog computer. Discovered in a shipwreck near the Greek island of Antikythera, this intricate device used bronze gears to predict astronomical events, such as eclipses, and to track the cycles of the Olympic Games. Its complexity and precision were unparalleled for its time, revealing a deep understanding of mechanical engineering in ancient Greece.

youtube

The Jacquard Loom: The Dawn of Programmable Machines

Invented by Joseph Marie Jacquard in 1804, the Jacquard Loom revolutionized textile manufacturing by introducing punched cards to control the patterns woven into fabric. This innovation not only automated the weaving process but also laid the groundwork for programmable machines. The concept of punched cards would later influence early computing devices, including those developed by Herman Hollerith and IBM.

youtube

Charles Babbage and the Difference Engine

Charles Babbage, often referred to as the "Father of the Computer," designed the Difference Engine in the 1820s. This mechanical device was intended to automate the production of mathematical tables by performing polynomial calculations. While Babbage never completed a fully functioning Difference Engine in his lifetime, his vision of a programmable, mechanical computer paved the way for future innovations.

Babbage later conceptualized the Analytical Engine, a general-purpose computing device that included features like a memory unit and a processing unit. Though it was never built during his era, the Analytical Engine’s design is recognized as a precursor to modern computers.

youtube

youtube

The Enigma Machine: Cryptography in the Digital Age

Fast forward to the 20th century, the Enigma Machine was a cipher device used by Nazi Germany during World War II to encrypt military communications. Designed by German engineer Arthur Scherbius, the Enigma used rotating wheels to scramble messages into complex codes that were nearly impossible to crack without the correct settings. Its influence extended beyond cryptography, shaping the need for computational devices capable of rapid decryption.

youtube

Alan Turing, the Bombe, and Codebreaking

Alan Turing, a British mathematician and computer scientist, played a pivotal role in cracking the Enigma code. During World War II, Turing and his team at Bletchley Park developed the Bombe, an electromechanical device designed to systematically test Enigma settings and decipher German communications. Turing’s work not only helped shorten the war but also laid the foundations of theoretical computer science through concepts like the Turing Machine, an abstract model of computation.

youtube

youtube

ENIAC: The First General-Purpose Electronic Computer

In 1945, the Electronic Numerical Integrator and Computer (ENIAC) became the first general-purpose electronic computer. Designed by John Presper Eckert and John Mauchly, ENIAC was a behemoth, occupying a room and containing 17,468 vacuum tubes. It could perform complex calculations at unprecedented speeds, making it a groundbreaking tool for scientific research and military applications.

youtube

Conclusion: From Analog to Digital

The evolution of computers—from the Antikythera Mechanism's intricate gears to ENIAC's vacuum tubes—illustrates humanity's relentless pursuit of automation and problem-solving. Figures like Charles Babbage, Joseph Jacquard, and Alan Turing, alongside innovations like the Difference Engine, the Jacquard Loom, and the Bombe, collectively laid the foundation for the digital age.

Today, the smartphones and laptops we use owe their existence to these pioneering inventions and individuals. By looking back at this journey, we can better appreciate how far we've come—and the limitless possibilities that lie ahead in the realm of computing.

1 note

·

View note

Text

Revolutionizing Industrial Processes with Automation Components

Automation components are at the heart of modern industrial systems, enabling seamless, efficient, and reliable operations. Industries worldwide depend on these essential components to enhance productivity, optimize workflows, and achieve precision in their processes. At Ram Automations, we provide a comprehensive range of high-quality automation components from globally recognized brands, tailored to meet your industrial needs.

What Are Automation Components?

Automation components refer to the various parts and systems used to automate industrial processes. These components work together to improve operational efficiency, reduce downtime, and minimize human intervention in repetitive tasks. Key automation components include:

1. Sensors

Sensors detect environmental changes like temperature, pressure, or motion and send signals to other components for necessary adjustments.

Examples: Smart temperature sensors, pressure sensors, motion detectors.

2. Actuators

Actuators convert electrical signals into mechanical movements, enabling tasks like opening valves or moving robotic arms.

Examples: Pneumatic actuators, hydraulic actuators, and electric actuators.

3. Programmable Logic Controllers (PLCs)

PLCs act as the brain of automation systems, managing complex tasks and ensuring seamless operations.

Popular models: Allen-Bradley MicroLogix PLCs, Siemens SIMATIC PLCs.

4. Relays and Switches

These components regulate electrical currents, ensuring safe and controlled power distribution across devices.

Examples: Electromechanical relays, solid-state relays.

5. Communication Devices

Facilitate smooth interaction between various automation components. They ensure that systems work in harmony.

Examples: Industrial Ethernet, wireless communication modules.

Top Brands in Automation Components

At Ram Automations, we collaborate with globally renowned brands to bring you reliable automation solutions.

1. Allen-Bradley

Known for innovative automation systems.

Popular Products:

Programmable Logic Controllers (PLCs).

Human-Machine Interfaces (HMIs).

2. Siemens

Specializes in cutting-edge technology for industries like energy and manufacturing.

Popular Products:

SIMATIC PLCs, Drive Systems, Smart Sensors.

3. Schneider Electric

A leader in sustainable automation solutions.

Popular Products:

Modicon PLCs, Variable Frequency Drives (VFDs), Smart Sensors.

4. Honeywell

Recognized for its automation and control innovations.

Popular Products:

Flame Detectors, Pressure Transmitters, Control Systems.

5. Danfoss

Focused on energy-efficient and sustainable automation solutions.

Popular Products:

Pressure Transmitters, Pressure Controls.

Why Choose Automation Components?

Automation components are indispensable for industries looking to:

Enhance Productivity: Streamline operations and reduce downtime.

Improve Safety: Minimize manual interventions in hazardous processes.

Optimize Energy Usage: Achieve greater efficiency with smart technologies.

Ensure Accuracy: Eliminate human errors in repetitive tasks.

Your Partner in Automation – Ram Automations

Looking for reliable automation solutions? At Ram Automations, we pride ourselves on offering top-quality components and unmatched customer support. Whether you need PLCs, sensors, or any other industrial automation equipment, we have the expertise to guide you.

Why Choose Us?

Access to globally trusted brands.

Competitive pricing and swift delivery.

Expert support for installation and integration.

For more information, explore our wide range of automation components on Ram Automations today!

Final Thoughts

Investing in high-quality automation components can transform your industrial processes, enhancing efficiency and productivity. Choose Ram Automations for a seamless experience and solutions that fit your business needs. Contact us now to take your operations to the next level!

By incorporating automation components, your business can stay ahead of the curve and thrive in a competitive market. Make the smart choice with Ram Automations – your trusted partner in industrial automation!

0 notes

Text

Electromechanical Switch market Analysis, Size, Share, Growth, Trends, and Forecasts by 2031

The electromechanical switch market report showcases an important role in the broader landscape of electrical control and automation. These switches have managed to hold their ground as indispensable components of various applications, demonstrating an enduring legacy rooted in their simplicity and reliability. At the core of electromechanical switches is a mechanical masterpiece.

𝐆𝐞𝐭 𝐚 𝐅𝐫𝐞𝐞 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭:https://www.metastatinsight.com/request-sample/2428

Top Companies

APEM Components, Inc.

C&K Components

Carling Technologies

Electroswitch Power Switches and Relays

Elma Electronic Inc.

E-Switch, Inc.

Grayhill, Inc.

Honeywell International Inc.

ITW Switches

Nidec Corporation

NKK Switches

Omron Corporation

OTTO Controls

Panasonic

TE Connectivity

A simple yet ingenious design allows them to bridge the gap between the electrical and mechanical worlds. The switch comprises a movable actuator, often manipulated by human interaction, that drives a set of electrical contacts to connect or disconnect. This mechanical simplicity has proved to be their enduring strength, allowing them to function with reliability and durability even in the most demanding conditions.

𝐄𝐱𝐩𝐥𝐨𝐫𝐞 𝐭𝐡𝐞 𝐅𝐮𝐥𝐥 𝐑𝐞𝐩𝐨𝐫𝐭:@https://www.metastatinsight.com/report/electromechanical-switch-market

The market for electromechanical switches is undergoing significant changes due to various factors. Notably, the demand for automation in numerous industries is on the rise. This increased demand is primarily driven by the need for more efficient and streamlined processes. Electromechanical switches play a crucial role in automation systems, enabling control and regulation in industrial settings. As industries aim to improve productivity and reduce human intervention, the use of these switches becomes integral.

Another influential factor in the electromechanical switch market is the rising adoption of Internet of Things (IoT) devices and the growth of smart homes. With the proliferation of IoT technology, there is an increasing need for reliable and versatile switches that can handle the complex network of interconnected devices. Electromechanical switches have proven to be dependable in this regard, as they offer the durability and performance required to manage the diverse demands of IoT systems and smart homes.

The electromechanical switch market is a bustling arena with a multitude of players, each offering a diverse range of switches catering to different applications. The competition is fierce, and innovation is the name of the game. As technology evolves, so does the demand for better, more reliable switches, driving companies to develop novel designs and manufacturing processes to stay ahead.

Global Electromechanical Switch market is estimated to reach $5,852.6 Million by 2030; growing at a CAGR of 4.0% from 2023 to 2030.

Contact Us:

+1 214 613 5758

0 notes

Text

Héroux-Devtek Inc. engages in the design, development, manufacture, assembling, and repair and overhaul of aircraft landing gears, hydraulic and electromechanical flight control actuators, custom ball screws, and fracture-critical components.

0 notes

Text

Infinitely variable speed cylinders

1. Supporting foot type: The angle between the axis and the horizontal plane can be adjusted to adapt to the wind blowing. When adjusting, loosen the adjusting nuts at both ends of the barrel, press the whole machine to reach the ideal working angle, and then tighten the nuts.

2. Rotary type: The height of the whole machine can be adjusted according to the needs, and each of them can be adjusted by rotating parallel to the horizontal plane. When adjusting, loosen the top tightening screw, and then turn the big bolt to adjust the height. Rotate the whole machine to adjust the rotation. , and tighten the bolts.

0 notes

Text

T-3630L DIGITAL INSULATION RESISTANCE TESTER

T-3630L Digital insulation resistance meter also known as megohmmeter, high voltage insulation resistance tester, etc., for the insulation resistance test. The instrument has a large LCD screen gray backlight display, data storage, data access, alarm, automatic shutdown and other functions. At the same time, it also has the function of measuring AC voltage absorption ratio and polarization index of DC voltage. The machine is beautiful and upscale, has a wide range, high resolution, convenient operation, easy to carry, accurate, reliable, stable performance, strong anti-interference ability. Moreover, it has a shockproof, dust-proof, moisture-proof structure and is a commonly used and indispensable instrument for telecommunications, electricity, meteorology, computer rooms, oil fields, electromechanical installation and maintenance, and industrial enterprises that use electricity as industrial power or energy. T-3630L insulation resistance meter is suitable for measuring the resistance value of various insulating materials and the insulation resistance of transformers, motors, cables and electrical equipment. T-3630L Digital insulation resistance meter consists of medium and large scale integrated circuits. The output power of T-3630L is large, and its output voltage level is 5 voltage levels. Rated insulation test voltage range 100-2500V, insulation resistance measurement range 0.01MΩ - 200GΩ. DC voltage measurement range 0-1000V, AC voltage measurement range 0-750V.

FUNCTION & FEATURES ■ 0-200GΩ; ■ Accuracy 3%; ■ DC Voltage test; ■ AC Voltage test; ■ AC voltage 0-750V; ■ With gray backlight; ■ DC voltage 0-1000V; ■ Recorder 500 sets data; ■ With replacement battery; ■ 100V, 250V, 500V, 1KV, 2.5KV; ■ Digital insulation resistance test; ■ User friendly menu guided operation;

APPLICATION ■ Universities; ■ Power plant; ■ Oil gas company; ■ Research institutes; ■ Electrical laboratory; ■ Electrical testing center; ■ Communication company; ■ Railway electrical department; ■ Electrical equipment manufacturers; ■ Electricity power bureau & power company; ■ Power engineering commissioning company; ■ Electrical department of industrial and mining enterprises;

0 notes