Don't wanna be here? Send us removal request.

Text

How To Choose The Perfect Retail Store Fixtures For Your Business

Setting up a retail store involves various crucial considerations, one of which is the selection of modern retail store fixtures. These fixtures not only add to the overall look and feel of the store, but they also help with organizing and displaying products. But how do you choose the perfect retail store fixtures for your business? Keep reading, as we delve into the key factors to consider. Get ready to elevate your store's appeal and functionality!

Understanding Your Store Layout And Design

The layout and design of your store are crucial elements that can make or break your business. Before you start shopping for fixtures, it's essential to analyze the available space, study the traffic flow, and consider product placement. By understanding these aspects, you can identify the quantity and type of fixtures needed to optimize your store's layout. A well-designed store layout not only enhances the aesthetic appeal of your business but also helps to improve customer flow and experience. Additionally, a well-organized store layout can make it easier for customers to find what they're looking for, which can lead to increased sales and customer satisfaction.

Considering Your Target Audience

When it comes to designing your store fixtures, it's important to keep your target audience in mind. By understanding their preferences and shopping habits, you can tailor your fixtures to better meet their needs. This can help to create a more engaging and personalized shopping experience that can ultimately lead to increased sales.

For example, if your target audience consists of tech-savvy millennials, you may want to consider incorporating interactive digital displays or charging stations into your store design. This can not only cater to their preferences but also make it more convenient for them to shop in your store.

Taking the time to consider your target audience and their needs can go a long way in creating a successful store design that resonates with your customers.

Assessing Your Product Range

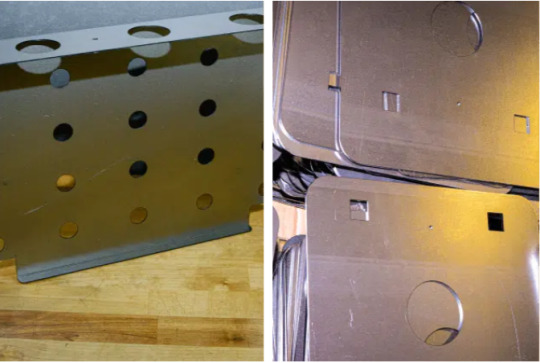

The size, shape, and quantity of your products should also be evaluated to determine the ideal fixtures. Depending on the items sold, such as apparel or smaller items like jewelry, the fixtures required may vary. The elite metal fabricators at Midland Metal Products can help you design unique fixtures that can significantly enhance product display and organization.

Focusing On Versatility And Flexibility

One way to keep your store fresh and engaging is to opt for versatile fixtures that allow easy adaptation to changing merchandise. Metal fixtures designed for adjustability, modularity, or easy reconfiguration can enable varied layouts and bring flexibility to your retail space.

Prioritizing Quality And Durability

When it comes to designing a store, prioritizing quality and durability is key. Opting for durable materials like metal fixtures not only enhances the aesthetics of your store but also ensures longevity and resilience against daily wear and tear. Investing in high-quality fixtures can go a long way in complementing your store's design while also ensuring that they can withstand the test of time.

Budget Considerations

It's crucial to balance quality and budget. Our team at Midland Metal Products designs and creates fixtures that are cost-effective, and made with high-quality metal that promises long-term benefits while suiting budgetary requirements.

Consult With A Retail Store Fixture Manufacturer And Metal Fabricator To Enhance Your Retail Space

Empower your retail space with our elegant metal fixtures designed to elevate your business. Connect with our experts today for a personalized consultation tailored to meet your unique store layout and vision. From ideation to implementation, our team at Midland Metal Products is committed to sculpting a retail environment that stands out.

Let's shape your retail future together!

Midland Metal Products Co

1401 E 165th St, Hammond, IN 46320, United States

+1 7739275700

0 notes

Text

Discover The Beauty Of Custom Light Fixtures For Your Space

Are you tired of the same old boring light fixtures that do not add any character or charm to your space? It's time to discover the beauty of custom light fixtures! These unique and personalized lighting options can transform any room into a stunning and inviting space.

At Midland Metal Products, our dedication lies in curating exceptional metal-crafted light fixtures. We understand the allure of customized designs, shaping stunning fixtures that echo your individuality. Just like picking the perfect piece of jewelry to complement your style, custom light fixtures can illuminate and accentuate your space like no other.

As professionals in metal fabrication, we're well-versed in industrial decorative lighting, custom lighting, and metal lighting fixtures. Our team takes pride in transforming your imaginative designs into reality, offering custom solutions that redefine lighting aesthetics for your space. Let us explore the many benefits of custom light fixtures.

Adding Personality To Your Space

One of the greatest advantages of custom light fixtures is the ability to add personality to your space. Unlike mass-produced lighting options, custom fixtures are designed specifically for you and your space. Whether you prefer a modern and sleek design or a vintage-inspired look, a custom light fixture can be tailored to your exact preferences. By choosing a custom option, you are creating a unique and personalized space that reflects your individual style.

Enhancing The Aesthetics With Custom Light Fixtures

Custom light fixtures are a fantastic way to enhance the aesthetics of your space. These fixtures are crafted with attention to detail, using high-quality materials and finishes. From hand-blown glass to intricate metalwork, custom fixtures are made to stand out and become a focal point in any room. By investing in a custom light fixture, you are not only adding beauty but also elevating the overall ambiance of your space.

Perfectly Fitting Your Space

Another significant advantage of custom light fixtures is the ability to perfectly fit your space. Whether you have low ceilings, limited wall space, or unusual room dimensions, a custom fixture can be designed to meet your specific requirements. By working with a professional custom light fixture fabrication company, you can create a fixture that seamlessly integrates into your space, ensuring a cohesive and harmonious look.

Tailoring The Lighting Experience

Custom light fixtures not only provide beautiful aesthetics but also allow you to tailor the lighting experience in your space. Lighting designers can customize the brightness, color temperature, and even the direction of light to suit your needs. Whether you desire soft and warm lighting for a cozy atmosphere or bright and cool lighting for a vibrant ambiance, a custom light fixture can be designed to achieve your desired effect.

Advantages Of Custom Metal Light Fixtures

Custom metal light fixtures offer a plethora of advantages, including their ability to adapt to any space, their long-lasting durability, and their versatile design options. These fixtures can be tailored to meet specific needs and preferences, making them an ideal choice for those seeking unique and personalized lighting solutions.

High-Quality Lighting Fixture Fabrication In Hammond, IN

If you're looking to elevate the ambiance of your space, consider investing in custom metal light fixtures. Our team consists of knowledgeable and skillful technicians who can help you bring your unique vision to life with tailor-made lighting solutions that reflect your distinct taste and style.

Whether you're in need of statement pieces for a commercial space or want to add a touch of luxury to your home, our team will work with you every step of the way to ensure your lighting journey is seamless and stress-free. Let's transform your space into a work of art with our exclusive metal light fixtures.

Midland Metal Products Co

1401 E 165th St, Hammond, IN 46320, United States

+1 7739275700

0 notes

Text

How CNC Panel Bending Machines Are Transforming Sheet Metal Manufacturing

The Emergence of CNC Panel Bending

In the constantly evolving manufacturing landscape, innovation is the key driver of efficiency and precision. One such innovation that is revolutionizing the sheet metal industry is the CNC Panel Bender. Whether you're involved in metal fabrication or simply interested in the future of sheet metal manufacturing, this article will provide insights into how and why CNC Panel Bending machines are transforming the industry.

The Mechanics: How CNC Panel Bending Works

CNC Panel Bending Machines use a digital blueprint to create precise sheet metal components. The machine calculates where to bend the metal, and robotic arms do the work. Sensors and cameras ensure quality control for flawless results. When considering whether CNC Panel Bending is the right choice for your metal fabrication needs, important factors to consider include complex geometries, high-volume production, short lead times, and cost-effectiveness.

When To Opt For CNC Panel Bending?

Here are some important factors to consider when determining whether CNC Panel Bending is the right choice for your metal fabrication needs

• Complex Geometries:

When working with intricate shapes and bends, CNC Panel Bending is a great option. Traditional methods may struggle to achieve the precision and consistency that CNC machines can offer.

• High-Volume Production:

If you require large quantities of the same part, CNC Panel Bending can efficiently produce identical components. This can reduce lead times and costs.

• Short Lead Times:

For time-sensitive projects, CNC Panel Bending's automation and precision enable quick turnaround times.

• Cost-Effectiveness:

While the initial setup costs may be higher compared to traditional methods, CNC Panel Bending can save on long-term costs by reducing material waste and labor expenses through precise bending that minimizes the need for rework.

Why CNC Panel Bending: Advantages and Benefits

The advantages of adopting CNC Panel Bending technology go beyond precision and efficiency.

• Unmatched Precision:

CNC Panel Bending offers a level of precision that is difficult to achieve with manual methods. This precision ensures consistently high-quality products.

• Versatility:

These machines can work with a wide range of materials, including aluminum, stainless steel, and copper, making them suitable for various industries.

• Reduced Material Waste:

Precise bending minimizes material waste, which is not only cost-effective but also environmentally friendly.

• Enhanced Design Possibilities:

CNC technology allows for intricate and creative designs that were once considered too challenging or costly.

• Competitive Edge:

By embracing CNC Panel Bending, you gain a competitive edge in delivering superior products quickly, attracting more clients and opportunities for your business.

The Future Prospects of CNC Panel Bending Machines

When it comes to CNC panel bending machines, there are many future prospects and industry applications to consider. These machines are highly versatile and can be used in a variety of industries, including aerospace, automotive, construction, and more. With the ability to quickly and accurately bend a wide range of materials, CNC panel bending machines are a valuable tool for any production process. Plus, as technology continues to advance, these machines are only going to become more efficient and effective in the years to come.

Midland Metal Products Co

1401 E 165th St, Hammond, IN 46320, United States

+17739275700

0 notes

Text

The Role of Custom Metal Fabrication in Modern Architecture and Design

As metal fabrication plays a larger role in modern architectural design, it becomes increasingly important for architects and fabricators alike to understand the potential of custom-fabricated structures. Custom fabrication creates opportunities for architects to develop sophisticated solutions that bring form, function, and beauty to their projects. It offers almost limitless possibilities when it comes to using modern materials like aluminum or stainless steel in innovative ways. From efficient fabrication solutions and innovative designs to superior workmanship with attention to detail, custom metal fabrication is setting new standards for architects and designers seeking an aesthetically pleasing yet practical option for their projects.

The Role of Custom Metal Fabrication in Modern Architecture and Design

In the realm of modern architecture and design, the bond of creativity and functionality is the cornerstone of every visionary project. As architects and designers push the boundaries of what's possible, custom metal fabrication emerges as a pivotal force that transforms concepts into tangible works of art. Let us delve into the profound impact of custom metal fabrication on modern architectural marvels, redefining the possibilities of form, function, and aesthetic allure.

Fusion of Form and Function: Custom Metal's Artistry

The synergy between architectural aesthetics and structural integrity is where custom metal fabrication shines. From the sleek curvature of contemporary facades to the intricate lattice of grand entrances, custom metal pieces blend seamlessly with design visions. Unlike off-the-shelf solutions, custom fabrication allows architects to envision and materialize bespoke elements that not only elevate the structure's appearance but also serve specific purposes.

Unique Statements in Every Detail: Custom Metal's Versatility

Custom metal fabrication bestows architects with a versatile palette, enabling them to craft signature design elements that stand as singular expressions. Whether it's an ornate metal screen that plays with light and shadow or a robust metal framework supporting large expanses of glass, the uniqueness of each detail transforms spaces into experiences. Architects harness custom fabrication to compose personalized stories within the architecture itself.

Engineering Aesthetics: Custom Metal's Influence

The interplay between engineering and aesthetics is an intricate dance that defines modern architecture. Custom metal fabrication fuses these realms harmoniously, allowing architects to push design boundaries while maintaining structural integrity. From intricately designed staircases that seem to defy gravity to bold exterior sculptures that capture attention, custom fabrication weaves art into the very bones of the building.

Functional Innovation: Custom Metal's Practicality

Custom metal fabrication isn't just about appearance; it's about innovation. Architects integrate functional elements seamlessly into their designs, from kinetic facades that adapt to changing weather to retractable roofs that transform spaces. Custom fabrication breathes life into these concepts, transforming them from blueprints into functional realities that elevate the user experience.

Collaborative Artistry: Architects and Fabricators

The symbiotic relationship between architects and custom metal fabricators is a testament to collaborative artistry. Architects envision the impossible, while fabricators use their expertise to bring those visions to life. This collaboration blurs the lines between design and fabrication, resulting in structures that push the boundaries of imagination. Every curve, angle, and joint reflects the shared dedication to pushing the envelope.

Conclusion: Shaping Modern Landscapes

Custom metal fabrication isn't a mere tool; it's a catalyst for redefining modern landscapes. It transforms architectural sketches into monumental realities that captivate, inspire, and endure. The intricate balance of functionality and aesthetics that custom fabrication introduces has become a hallmark of contemporary design. As modern architecture evolves, custom metal fabrication stands as a testament to the human spirit's capacity to blend innovation, beauty, and purpose seamlessly.

As we stand on the threshold of a new era in architectural design, custom metal fabrication is poised to play an even more pivotal role in shaping the skylines of tomorrow. Through the hands of architects and the expertise of fabricators, the fusion of metal and vision continues to redefine what's achievable in modern architecture and design.

Midland Metal Products Co

1401 E 165th St, Hammond, IN 46320, United States

+1 773-927-5700

0 notes

Text

Crafting Tailored Solutions for Every Project with Custom Welding

In the intricate realm of metal fabrication, where each project holds distinct requirements and challenges, the art of custom welding emerges as a transformative force. Custom welding is not just about fusing metals; it's about crafting tailored solutions that align with the unique demands of every project, across diverse industries including retail, agriculture, construction, and automotive. This article delves into the essence of custom welding and how it revolutionizes the way industries bring their visions to life.

Bridging Precision and Purpose: The Role of Custom Welding

At the heart of custom welding lies the convergence of precision and purpose. Unlike standard welding, which adheres to predefined techniques, custom welding adapts to the intricacies of each project. Whether it's designing custom fixtures for retail spaces, reinforcing structural elements in construction, fabricating specialized agricultural equipment, or enhancing automotive components, custom welding ensures that every joint, seam, and connection serves its intended function flawlessly.

Discover the Versatility of Custom Welding: Every Project is One-of-a-Kind

In the realm of metal fabrication, one size certainly does not fit all. This is where the prowess of custom welding shines. From the delicate intricacies of retail displays to the robust demands of construction frameworks, custom welding adapts its techniques and materials to suit the project's individuality. For instance, in the agricultural sector, where equipment durability is paramount, custom welding ensures the fabrication of rugged machinery that stands up to the rigors of the field.

Revolutionizing Industries: Tailored Welding Services for Every Sector

The impact of custom welding resonates across diverse sectors, reflecting the breadth of its application. In retail, it transforms raw metal into captivating store displays that seamlessly merge aesthetics and functionality. In construction, custom welding strengthens structures, elevating safety and durability. For the automotive sector, it fine-tunes components to enhance performance and resilience. Agriculture witnesses the metamorphosis of metal into reliable equipment that underpins food production. The common thread? Custom welding's ability to bring visions to life, no matter the sector.

A Symphony of Skill and Innovation: The Welding Process

Crafting tailored solutions through custom welding is a multi-dimensional process that blends skill with innovation. Techniques like MIG welding harness electrical arcs to create strong, clean joints suitable for various projects. TIG welding, on the other hand, offers precision for intricate designs, making it ideal for creating sleek automotive parts. Each welding method is a note in the symphony of fabrication, orchestrated to harmonize with the project's demands.

Beyond the Torch: The Vision of Custom Welding

Custom welding isn't solely about welding torches and sparks; it's about visionary collaboration. When a project's challenges seem insurmountable, custom welders step in as problem-solvers. They translate concepts into tangible structures, breathing life into blueprints. Whether it's fashioning a unique display for a retail brand or creating custom metal parts that fit seamlessly into an automotive assembly line, custom welding adds value by turning ideas into reality.

Conclusion: The Necessity of Adapting

In the world of metal fabrication, the phrase "one size fits all" has no place. Custom welding embodies adaptability, innovation, and expertise, enabling industries across retail, agriculture, construction, and automotive to overcome challenges and achieve their goals. It's a testament to the transformative power of combining creativity with craftsmanship, resulting in projects that not only meet requirements but exceed expectations. From the sparks of the welding torch to the intricate weld joints, custom welding is the artistry of adaptation that fuels industries' growth and success.

Midland Metal Products Co

1401 E 165th St, Hammond, IN 46320, United States

+17739275700

0 notes

Text

Bringing Flexibility To Store Designs With Modern Retail Display Fixtures

In the ever-evolving world of retail, businesses must adapt to evolving consumer preferences to achieve success. One crucial aspect of this adaptation lies in the design and arrangement of retail stores. Increasingly, retailers are turning to modern retail display fixtures to achieve dynamic and visually appealing store layouts. These fixtures bring flexibility to store designs, empowering retailers to create captivating shopping experiences.

The Evolution Of Retail Display Fixtures: A Paradigm Shift In Store Designs

Traditional, static store displays are now a thing of the past. The introduction of modern retail display fixtures has brought about a paradigm shift in store designs. Designed with versatility in mind, these fixtures offer numerous benefits for retailers. With adjustable shelves, modular components, and customizable configurations, retailers can easily adapt their store layouts to reflect changing product assortments, seasonal campaigns, and emerging trends. This newfound flexibility allows for seamless store transformations that captivate shoppers with fresh and engaging displays.

The Imperative of Flexibility in Store Designs

In today's retail landscape, the contemporary shopper demands variety, novelty, and personalization. To meet these expectations, retailers must embrace flexible store designs. Additionally, the rise of eCommerce has significantly influenced physical retail stores. Online stores frequently update their layouts, provide personalized suggestions, and offer comprehensive product information. To remain competitive, brick-and-mortar stores must emulate this level of flexibility and adaptability.

Adapting To Changing Trends: Tailoring Displays to Brand Identity

Retailers strive to differentiate themselves through their brand identity and unique value propositions. Modern retail display fixtures provide a canvas for retailers to express their creativity and reinforce their brand messaging. With a wide range of fixture options, from sleek and minimalist designs to rustic or avant-garde aesthetics, retailers can align their store designs with their brand personality. This alignment creates a cohesive shopping environment that strengthens brand recognition and fosters a deeper connection with customers.

Maximizing Space and Visual Appeal

Flexibility in space utilization is an integral aspect of effective retail design. Modern retail display fixtures offer the ideal solution by maximizing both functionality and visual appeal. With their optimized vertical space utilization and clever designs, these fixtures enable retailers to make the most of their store's footprint. By incorporating these fixtures, retailers can create a flexible and well-organized arrangement that not only showcases a wider range of products but also avoids overcrowding. This approach invites clients to explore and interact with the products, ensuring an aesthetically pleasing and engaging shopping experience.

Applying Flexibility to Your Store Design

So, how can you introduce this flexibility into your store design? The first step is selecting the right retail display fixtures. Choose modular fixtures that can be easily rearranged or adapted for different uses. By crafting custom solutions, embracing versatility, maximizing space efficiency, and elevating brand identity, you can transform your store layout to showcase new products, highlight seasonal promotions, and create captivating displays that resonate with your target audience. This flexibility not only enhances the overall shopping experience but also allows for seamless adaptations as trends and customer preferences evolve.

Midland Metal Products Co

1401 E 165th St, Hammond, IN 46320, United States

+17739275700

https://goo.gl/maps/9z25D7EZo13tBgFR8

0 notes

Text

Coil Processing & Metal Stamping Services In Hammond, IN

If you’re searching for complex metal stamping services, Midland Metals has you covered for virtually any use case you have. Midland Metal Products offers a wide range of metal stamping and fabrication services. Are coil steel processing and midland stamping essential to your manufacturing process? Do you need components made to the highest quality standards and your exact specifications? If so, you’re in the right place. At Midland Metal Products, we support today’s captains of industry as we have for the last hundred years. We create quality components that give your products a competitive advantage. To learn more visit here Coil Processing & Metal Stamping Services

Midland Metal Products Co

1401 E 165th St, Hammond, IN 46320

+17739275700

https://goo.gl/maps/gXfUgXXioqVhfZ8j7

0 notes

Text

Metal Grinding & Polishing Services In Hammond, IN

Mechanical grinding and polishing involve removing material from components with a fine-grit grinding compound or paper. Midland Metal Products offers a wide range of grinding, polishing, and fabrication services. Midlands Metal Products offers highly efficient metal polishing solutions to help you improve your bottom line without compromising quality. By partnering with us, you can free up time and space in your facility while scaling operations. We perform a mechanical grinding and polishing service using paper or a fine-grit metal grinding compound to bring out the sparkle in your components. The result is a highly attractive mirror finish. To learn more visit here Metal Grinding & Polishing Services

Midland Metal Products Co

1401 E 165th St, Hammond, IN 46320

+17739275700

https://goo.gl/maps/gXfUgXXioqVhfZ8j7

0 notes

Text

Assembly, Packaging, and Warehouse Services In Hammond, IN

Many businesses and manufacturers need specific packaging and warehousing services, from kitting to component assembly to palletizing. At Midland Metals, we’re proud to offer these services to our clients. Midland Metal Products offers a wide range of assembly packaging, warehousing, and fabrication services. Midland Metal Products offers highly efficient assembly, packing, and warehousing solutions. Since our establishment in 1923, we’ve provided services and products to help businesses like yours boost ROI, save space, and effectively manage inventory. Our team takes your ready-to-assemble components, puts them together, packages them, and stores them on your behalf. When a client orders from you, you send our kitting and fulfillment services the details, and we handle the rest. To learn more visit here Assembly, Packaging, and Warehouse Services

Midland Metal Products Co

1401 E 165th St, Hammond, IN 46320

+17739275700

https://goo.gl/maps/gXfUgXXioqVhfZ8j7

0 notes

Text

Innovations in Custom Wire Forming Manufacturers: Trends to Watch in 2023

Are you curious about the latest trends in metal manufacturing? Manufacturers have been making big waves in recent years with several technological and procedural advancements that have improved the quality and speed of metal wire production.

As these technologies and procedures enter the market, we expect big changes in wire-forming services as we continue into 2023. So the team at Midland Metal Products is here to discuss some of these trends to watch out for in the coming year. Read more here Innovations in Custom Wire Forming Manufacturers: Trends to Watch in 2023

Midland Metal Products Co

1401 E 165th St, Hammond, IN 46320

+17739275700

https://goo.gl/maps/DkxcEnrJ3VEN7M656

0 notes

Text

The Beauty of Custom Metal Fabrication Furniture: Why It’s Worth the Investment

Whether you are looking for tables for your commercial kitchen or furniture for your outdoor patio, custom metal fabrication furniture is a good idea. Metal-fabricated furniture gives you custom, durable pieces that will serve you well and stand the test of time. So today, the team at Midland Metal Products is present to speak about why custom metal fabrication furniture is a good business investment.

Give us a call today to discuss our custom metal fabrication furniture!

Read more here The Beauty of Custom Metal Fabrication Furniture: Why It’s Worth the Investment

Midland Metal Products Co

1401 E 165th St, Hammond, IN 46320

+17739275700

https://goo.gl/maps/n6zs3162FDf3n3Bi6

0 notes

Text

Metal Fabrication for Architects: Enhancing The Design of Your Project

Several types of metal may be used as the core of a building’s structure. For example, using steel beams provides strength and durability, and their recyclability makes them an optimal choice for sustainable construction. But steel and other common types of metal can also enhance architecture with their aesthetic value. Whether sculpted into visually pleasing decorative components or adding texture and interest to the interior and exterior of a building, metal brings your entire project together from the inside out.

At Midland Metal Products, we’re experts at metal fabrication design. We provide custom architectural metal fabrication for both residential and commercial projects. No matter how simple or intricate the design, our in-house team of metal fabricators delivers the highest quality product completed precisely to your qualifications. Read more here Metal Fabrication for Architects: Enhancing The Design of Your Project

Midland Metal Products Co

1401 E 165th St, Hammond, IN 46320

+17739275700

https://goo.gl/maps/MA4VLWFpnpuUsbT49

0 notes

Text

What Are the Benefits of Automation in Metal Fabrication?

Do you remember the cartoon “The Jetsons,” where robots and machines cared for almost everything while humans did little more than press buttons and oversee the process? It seemed like the possibility of completely automated manufacturing might happen in the far-off future — and given how many times the machines went haywire, that might not be the best idea.

Well, that future is here. The benefits of automation in metal fabrication might include something other than the ability for supervisors like George Jetson to spend the day with their feet up on the desk. Still, they include some big advantages for companies like Midland Metal Products, our employees, and our customers. Read more here What Are the Benefits of Automation in Metal Fabrication?

Midland Metal Products Co

1401 E 165th St, Hammond, IN 46320

+17739275700

https://goo.gl/maps/MA4VLWFpnpuUsbT49

0 notes

Text

What Will the Effects of Labor Shortages Be on Metal Fabrication in 2023?

Business owners are desperate to fill open jobs, and most say the labor shortage is the biggest challenge they face right now. Even after the mass layoffs of the early days of the pandemic, most businesses have open positions and simply cannot find enough qualified people to fill them. Signs like “help wanted” and “closed for staffing” are everywhere.

And it’s not just small businesses looking for staff, either. Every industry is struggling. For proof of that, look no further than the impact of the labor shortage on metal fabrication.

American Welding Society data shows that the metal fabrication industry faces a shortage of up to 40,000 workers by 2024. The reasons range from older workers leaving the workforce in droves to pandemic-driven changes in worker expectations. Still, the effect is the same: the entire manufacturing industry feels the pinch in unexpected and far-reaching ways.

Come along as we explore how the ongoing lack of skilled workers influences the metal fabrication industry and how companies respond. Read more here What Will the Effects of Labor Shortages Be on Metal Fabrication in 2023?

Midland Metal Products Co

1401 E 165th St, Hammond, IN 46320

+17739275700

https://goo.gl/maps/pkcVyW2474jx6JSG6

0 notes

Text

How Metal Fabrication Company is Setting the Standard for Managing a Business During a Pandemic

Metal fabrication companies have faced numerous challenges during the COVID-19 pandemic. However, some have managed to navigate the crisis successfully by prioritizing the safety of their employees, being transparent about their financial situation, and being flexible in adapting to changing circumstances. By doing so, these companies have set the standard for how businesses can manage during a pandemic. One such company is Midland Metal Products, a family-owned business that has gone above and beyond to ensure the safety of its employees during the pandemic.

Midland Metal Products has provided its employees with all types of PPE, facilitated COVID testing, and offered flexible sick time related to COVID. Its strong financial management has also ensured job security for its employees. Midland Metal Products' success during the pandemic can serve as an example for other metal fabrication companies and businesses in general, showing that by prioritizing the safety and well-being of employees and being transparent and flexible in their approach, businesses can not only survive but thrive during difficult times.

Prioritizing Employee Safety

Prioritizing employee safety has been a crucial aspect of managing a business during the COVID-19 pandemic. With the virus spreading rapidly and causing serious illness or even death, companies must take every possible measure to protect their employees. This includes providing personal protective equipment (PPE), facilitating COVID-19 testing, and implementing social distancing and hygiene protocols. Metal fabrication companies like Midland Metal Products have made employee safety a top priority during the pandemic. They have taken a proactive approach to minimize the risk of exposure to the virus by providing employees with appropriate PPE such as masks, gloves, and face shields. They have also implemented strict hygiene protocols, such as regular cleaning and disinfecting of workspaces and common areas.

Offering Flexible Sick Time Related to COVID

Offering flexible sick time related to COVID-19 is another important way that metal fabrication companies can prioritize employee safety and well-being during the pandemic. By allowing employees to take time off if they experience symptoms of COVID-19 or need to care for a family member who is sick, companies can help prevent the spread of the virus and reduce the risk of exposure for other employees. Midland Metal Products have implemented flexible sick time policies related to COVID-19, allowing employees to take time off as needed without fear of losing their jobs or facing disciplinary action. This approach not only helps to protect employees from the virus but also ensures that the company can maintain productivity and continuity in its operations by reducing the risk of widespread illness among its workforce. By offering support and understanding, metal fabrication companies can create a positive work environment and foster a sense of loyalty and commitment among their employees.

Maintaining Job Security Through Strong Financial Management

With the economic uncertainty caused by the pandemic, many businesses have struggled to stay afloat and have been forced to lay off employees or cut back on hours. By implementing sound financial management practices, such as reducing expenses, managing cash flow, and accessing financial relief programs, the companies have been able to weather the economic storm caused by the pandemic and avoid layoffs or other drastic measures. In addition to providing job security for employees, strong financial management can also help companies maintain their reputation and credibility in the industry. By demonstrating financial stability and resilience, metal fabrication companies can instill confidence and trust among their clients and stakeholders, which can help to ensure continued business and success in the long term.

Transparency in Communications with Employees

Transparency in communications with employees is another important aspect of managing a metal fabrication company during the COVID-19 pandemic. With so much uncertainty and fear surrounding the virus, employees need clear and honest communication from their employers in order to feel informed and supported. Metal fabrication companies like Midland Metal Products have prioritized transparency in their communications with employees during the pandemic. They have provided regular updates on the company's response to the virus, including safety protocols, changes in operations, and financial updates. They have also encouraged employees to ask questions and share their concerns, and have provided resources such as employee assistance programs to support their mental health and well-being.

Adapting to Changes and Remaining Flexible

With the situation constantly evolving and new challenges arising, companies need to be able to pivot quickly and adjust their operations as needed in order to remain competitive and viable. Midland metal products have implemented new safety protocols and procedures to protect its employees and customers, and have adjusted its production schedules and processes to meet changing demand and supply chain disruptions. By remaining flexible, metal fabrication companies can also explore new opportunities and markets that have emerged as a result of the pandemic. For example, some companies have shifted their focus to producing products that are in high demand during the pandemic, such as medical equipment or components for home office furniture.

Midland Metal Products Co

1401 E 165th St, Hammond, IN 46320

+17739275700

https://goo.gl/maps/c43BtZ4wvquYn1ib6

0 notes

Text

The Advantages of Laser Cutting to the Design for Manufacturing Process

Laser cutting is a highly versatile manufacturing process. It produces clean, precise cuts in various materials, including wood, plastic, and metal. It is also highly cost-effective and applicable to a range of industry applications.

So what are the advantages of laser cutting for the manufacturing industry? This article explains these advantages and gives examples of how you can use laser cutting efficiently.

What Is Laser Cutting? Laser cutting is a method of cutting through materials using a high-powered beam of light. The laser beam melts the material, cooling and hardening around the cut line. Metal fabricators repeat this process until they obtain the desired shape.

You can use this process for different applications, such as cutting holes in metal or plastic sheets, engraving designs onto objects, or creating artwork on wood or fabric. The process works best with hard materials, such as metals like copper or aluminum, that can withstand high temperatures without melting completely. Read more here The Advantages of Laser Cutting to the Design for Manufacturing Process.

Midland Metal Products Co

1401 E 165th St, Hammond, IN 46320

+17739275700

https://goo.gl/maps/L3CRK2Fqw95p7UB77

0 notes

Text

Top Reasons Why You Should Work With a Local Metal Fabricator

When you think of metal fabrication, what comes to mind? Maybe it’s the images of massive machines working autonomously? Or an experienced individual doing all the work?

While there are some big players in the industry, choosing local product fabricators has many advantages. So, why choose a local fabricator when looking for metal fabrication services?

If you’re planning on working with a metal fabrication firm and would rather deal with a small and local company, you won’t regret reading through this post! Read more here Top Reasons Why You Should Work With a Local Metal Fabricator

Midland Metal Products Co

1401 E 165th St, Hammond, IN 46320

+17739275700

https://goo.gl/maps/L3CRK2Fqw95p7UB77

0 notes