Text

A Bellow Mechanical Seal may be a ring-type seal

Aspects of a Bellow Mechanical Closure

A Bellow Mechanical Seal may be a ring-type seal which is used to prevent leaks within a mechanical pump. This China Rubber Bellows Mechanical Seal Factory type of seal has a group of advantages, including its easy installation and adjustment. It is designed with regard to medium-to-high viscosity fluids and is suitable for plenty of operating conditions, including higher and low-temperature contents.

Ashish Seals is a ISO-certified manufacturing company throughout Mumbai, India that offers a bunch of Bellow Mechanical Seals. They are designed to deliver rugged durability and are suitable for a large number of applications, including chemical process pumps, sewage pumps, as well as water pumps. Ashish Seals producers these seals using SS 304 plus SS 316 materials. On the other hand, they can also end up being manufactured using materials rather than these materials as each customer requirements.

These mechanical seals can be easily installed, and normally require no measurements and also set screws. They furthermore don't damage sleeve or maybe shaft components, as there is no relative movement between the actual seal's rubber boot along with shaft. As a result, they're mostly used within waste water treatment crops.

Another type of Bellow Mechanical Seal can be a metal Bellow Seal. These seals are ideal for corrosive and high-temperature applications. Their metal lugs give positive mechanical drive in addition to protect elastomer bellows. They're also popular in pulp in addition to paper mills, oil pumps, dewatering pumps, and sewage penis pumps.

The Rubber Bellow Mechanical Seal is usually an extremely versatile unit. Designed to contain fluid in the glass-lined vessel, this type of close up can protect top entry drives when it comes to a pump or machine. Its unique design makes it possible for it to compensate intended for abnormal shaft run-out along with protect against fretting. Additionally it is comfortable to use and carries a large variety of software.

Unlike a mechanical bellow, which will requires two o-rings, a metal bellow mechanical seal requires one. It's not dynamic, so it may not be suited for high pressure applications. However, a PTFE o-ring can even be used. A PTFE encapsulated o-ring comes into play most sizes.

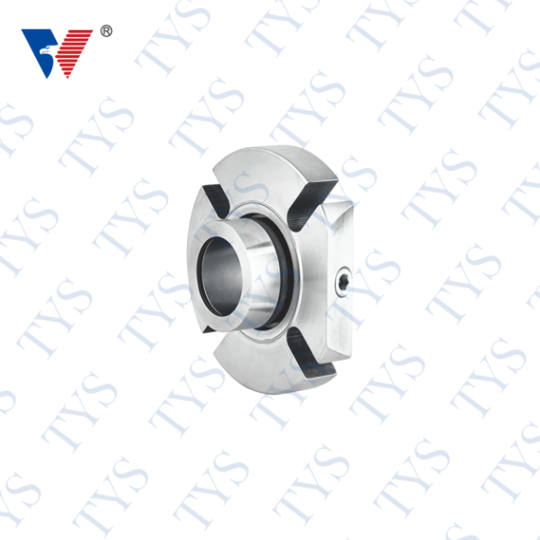

The BSIV(tm) series single cartridge Bellows are intended to provide excellent affordable sealing solutions. A bellow mechanical closure TYS T01 Cartridge Mechanical Seal double sealing depac 365 cartridge mechanical seal for agitator water pump is lightweight and includes a lower friction drag than the usual pusher seal. It also features superior face tracking as well as face loading. Furthermore, metal bellows mechanical seals reduce the chance of frictional heat.

0 notes

Text

Another type of Bellow Mechanical Seal is really a metal Bellow Seal

Benefits of a Bellow Mechanical Seal

A Bellow Mechanical Seal may be a ring-type seal utilized to prevent leaks in the mechanical pump. This type of seal has a number advantages, China Pump Mechanical Seal Factory including its quick installation and adjustment. It is designed for medium-to-high viscosity fluids it is suitable for a lot of operating conditions, including high and low-temperature contents.

Ashish Seals is really a ISO-certified manufacturing company throughout Mumbai, India that offers a range of Bellow Mechanical Seals. They are designed to deliver rugged durability and are suitable for a good number of applications, including chemical progression pumps, sewage pumps, in addition to water pumps. Ashish Seals brands these seals using SS 304 plus SS 316 materials. On the other hand, they can also possibly be manufactured using materials aside from these materials as every customer requirements.

These mechanical seals can be easily installed, and often require no measurements or set screws. They likewise don't damage sleeve or perhaps shaft components, as there's no relative movement between that seal's rubber boot along with shaft. As a effect, they're mostly used inside waste water treatment crops.

Another type of Bellow Mechanical Seal is really a metal Bellow Seal. These seals are perfect for corrosive and high-temperature software. Their metal lugs present positive mechanical drive and protect elastomer bellows. They're also popular in pulp in addition to paper mills, oil knocks out, dewatering pumps, and sewage penis pumps.

The Rubber Bellow Mechanical Seal is surely an extremely versatile device. Designed to contain fluid within a glass-lined vessel, this type of seal can protect top entry drives in the matter of a pump or mixing machine. Its unique design permits it to compensate pertaining to abnormal shaft run-out plus protect against fretting. It is additionally comfortable to use and has a large variety of purposes.

Unlike a mechanical bellow, which usually requires two o-rings, a metal bellow mechanical seal requires just one. It's not dynamic, so it's actually not suited for high strain applications. However, a PTFE o-ring is usually used. A PTFE encapsulated o-ring will come in most sizes.

0 notes

Text

One of the important things when picking a Vertical Pump Seal

Silicon Carbide Mechanical Seal Suppliers

A few Important Considerations When Buying a Vertical Pump Closure

If you're looking for a replacement top to bottom pump seal, you've come to the right location. Here are three important considerations when investing in a Vertical Pump Close up:

The seal have to be precise. The gap between the 2 seal faces need to be large enough for any liquid to stream through but small enough to prevent the entrant associated with any contaminants. The gap can be as small as one micron, which is about 75 times smaller than a human hair. So that they can prevent contamination, the seal should prevent excessive leakage and permit the lubricating liquid to get rinsed through some sort of cooler or orifice dish. This mechanical seal cooling can be essential for lessening the fluid heat and minimizing coking.

Another consideration will be the size of this seal blade. A mechanical seal is far more flexible than the equivalent hydraulic close up, but the former can often be more durable. ANY mechanical seal, by way of example, can withstand big shaft movements along with particles without sacrificing suction. This signifies that a hydraulic pump can continue to function effectively despite if excessive wear. The size from the seal blade relies on the flow rate in the fluid, but some sort of mechanical seal will probably resist even increased vapor tensions, plus it will handle loss resistance quickly and completely.

The pump's BEP flow is going 8, 750 m3/h. The rated point flow is about 95 percent with BEP flow. The pump's efficiency on the rated point is approximately 85 percent. The head rise to shutoff is going 26 percent, that makes it suitable for this kind of service. These specifications are just a number of the benefits of with a Vertical Pump Close up. If you're in search of a replacement Directory Pump Seal, consider these benefits:

One of the important things when picking a Vertical Pump Seal is a material. Water that is certainly low in abrasiveness can still work with a ceramic face. As soon as water temperature variations dramatically, the face in the seal will erode or swell on account of heat. If that seal is impregnated along with salts, the seal will degrade sooner rather when compared with later. A carbon/graphite face is superior to nothing, but it is expensive and could possibly be harder to substitute.

A mechanical seal is a good option whenever you prevent leakage throughout high temperatures. In the vertical turbine pump, the two looks are connected by way of shaft that is actually rotating. Typically, the rotating face is definitely protected by bendable "boots. " These boots are made of elastomer, but may be made of metallic bellows or Teflon. Nonetheless, a Teflon seal is hard to install, so if you're purchasing a new vertical pump motor, make sure to do your research 1st.

A vertical generator pump is difficult to spot, specifically because it's listed below the floor. Even so, a Silicon Carbide Mechanical Seal Suppliers damaged base or wear happens to be can significantly lessen the pump's performance. If you're interested in the cost, look at rebowling. If that shaft has essential wear, it's effortless to replace the rebowling. A rebowling may restore performance along with lower operating expenses. You'll love the new performance and lessened operating costs.

1 note

·

View note